Evaluation of a model for simulating biofilm processes in porous... by Warren Thomas Sharp

advertisement

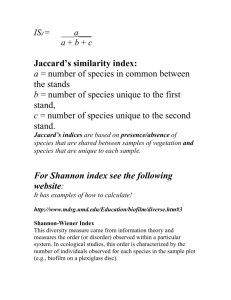

Evaluation of a model for simulating biofilm processes in porous media reactors

by Warren Thomas Sharp

A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science in

Chemical Engineering

Montana State University

© Copyright by Warren Thomas Sharp (1996)

Abstract:

Biofilms are ubiquitously present in many natural and manmade porous media systems. Natural and

engineered biofilm systems are important to bioremediation and biofiltration and include both

one-fluid-phase flow and two-fluid-phase flow systems. Complex interactions exist between net

biomass accumulation, porous media characteristics, and the rates of biofilm/biological processes. This

complexity requires a systematic approach to analyzing experimental results. The dynamic behavior of

biofilms in porous media is encapsulated in the rates of the biofilm/biological processes contributing to

net biomass accumulation. The key to understanding and predicting biofilm/biological processes in

porous media is modeling. The goal of this research is to evaluate a biofilm process model in porous

media systems for the prediction of experimental results.

Most porous media biofilm models in the literature pertaining to both one-fluid-phase and

two-fluid-phase flow porous media systems utilize insufficient biofilm models. The mixed-culture

biofilm model (MCB) overcomes many limitations of the former. Combining the MCB model with the

appropriate reactor transport models give a porous media biofilm reactor model that has the capability

to simulating many types of porous media biofilm systems. Experimental data from four separate

systems, including two one-fluid-phase and two two-fluid-phase, were analyzed in order to evaluate the

MCB model coupled with the appropriate reactor transport model.

Predicted results from the model for which experimental data exists give a good fit. However, the

model can predict more than what is available experimentally; therefore, a full evaluation of model

capabilities is not possible at this time. A simulation-experimentation framework which can elucidate

necessary experimental data for further model evaluation is provided. EVALUATION OF A MODEL FOR SIMULATING

BIOFILM PROCESSES IN POROUS MEDIA REACTORS

by

Warren Thomas Sharp

A thesis submitted in partial fulfillment

of the requirements for the degree

of

Master of Science

in

Chemical Engineering

MONTANA STATE UNIVERSITY - BOZEMAN

Bozeman, Montana

May 1996

ii

APPROVAL

of a thesis submitted by

Warren Thomas Sharp

This thesis has been read by each member of the thesis committee and has been

found to be satisfactory regarding content, English usage, format, citations, bibliographic

style, and consistency, and is ready for submission to the College of Graduate Studies.

/ 2 / 9U

Dr. John Sears

D atej/

Dr. Al Cunningham

Approved for the Department of Chemical Engineering

Dr. John Sears

Approved for the College of Graduate Studies

Robert L. Brown

(Signature)

Date

iii

STATEMENT OF PERMISSION TO USE

In presenting this thesis in partial fulfillment of the requirements for a master’s

degree at Montana State University - Bozeman, I agree that the Library shall make it

available to borrowers under rules of the Library.

If I have indicated my intention to copyright this thesis by including a copyright

notice page, copying is allowable only for scholarly purposes, consistent with “fair use”

as prescribed in the U.S. Copyright Law. Requests for permission for extended quotation

from or reproduction of this thesis in whole or parts may be granted only by the copyright

holder.

Signature

Date

iv

TABLE OF CONTENTS '

Page

INTRODUCTION................................................................................................................ I

Relevance of Biofilms in Porous Media........................................................................ I

Complexity of Biofilms and Biofilm Processes in Porous Media................................. I

Relevance of Modeling Biofilm/Biological Processes in Porous M edia......................3

Porous Media Biofilm Reactor Models.........................................................................4

Porous Media Groundwater Biofilm Models............................................

4

Biofilter Models....................................................................................................... 5

The Extended Mixed-Culture Biofilm Model.....................

5

Research Goal................................................................................................................6

MODELING........................................................................................................................8

One-fluid-phase Flow Porous Media Reactor................................................................9

Two-fluid-phase Flow Porous Media Reactor............................................................. 10

Biofilm......................................................................................................................... 11

Biological Reactions.........................

14

Biological Process Stoichiometry Matrices........................................................... 15

EXPERIMENTAL SYSTEMS......................................................................................—17

One-fluid-phase Flow Porous Media Reactor Experiments........................................ 17

Case I - Microbial transport experiment............................................................... 17

Case 2 - Biofilm detachment experiment............................................................... 18

Two-fluid-phase Flow Porous Media Reactor Experiments....................................... 18

Case 3 - Flat plate VPBR experiment.................................................................... 18

Case 4 - Bench-scale VPBR experiment................

20

SIMULATION.... ..............................................

21

Aquasim........ ......................................:.......................................................................21

One-fluid-phase Flow Porous Media Reactor Simulations Case I and Case 2 .....................................................................................................21

Two-fluid-phase Flow Porous Media Reactor Simulations Case 3 and Case 4 .....................................................................................................24

RESULTS..........................................................................................................................28

Case 1...........................................................................................................................28

V

TABLE OF CONTENTS - continued

Page

Case 2 ...........................................................................................................................29

Case 3 ...............................................................................................................

30

Case 4 ................................................................................................................

30

DISCUSSION....................................................................................................................52

Case 1...........................................................................................................................52

Case 2 ........................................................................................................................... 53

Case 3 ........................................................................................................................... 54

Case 4 ........................................................................................................................... 55

Overall.......................................................................................................................... 56

Simulation-Experimentation Integration......................................................................56

CONCLUSIONS................................................................................................................59

Case I .......................................................................................................................... -59

Case 2 ........................................................................................................................... 59

Case 3........................................................................................................................... 60

Case 4 ...........................................................................................................................60

Overall..........................................................................................................................60

Simulation-Experimentation Integration......................................................................61

RECOMMENDATIONS...................................................................................................62

REFERENCES CITED......................................................................................................63

APPENDICES...................................................................................................................65

Appendix A - Materials and methods for Case 2 - MSU biofilm detachment

experiment............................................................................................66

Appendix B - Tables of Results...................................................................................70

BT - Case 1............................................................................................................71

B.2 - Case 2 ............................................................................................................78

B.3 - Case 3............................................................................................................86

B. 4 - Case 4 .........................................................................................................89

Appendix C - Aquasim data files................................................................................. 96

CT - Case I ..................................................................................

97

C. 2 - Case 2 .......................................................................................................108

C.3 - Case 3.......................................................................................................... 118

C.4 - Case 4.......................................................................................................... 135

LIST OF TABLES

Table

Page

1. Biological process stoichiometry matrix for general

growth processes............................................................................................... 15

2. Biological stiochiometry matrix for Cases I and 2........................ .................22

3. Summary of parameters for Case I ........... ...................................................... 23

4. Summary of parameters for Case 2..................................................................23

5. Biological process stoichiometry matrix for Cases

3 and 4.............................................................................................................-26

6. Summary of parameters for Cases 3 and 4 ............................. ........................27

7. Time series aje values for Case I ...... .....................................:........................29

8. Time series ade values for Case 2 ...... :...............

30

9. Predicted and experimental vapor phase toluene

concentration results for Case 3...................................................................... 31

vii

LIST OF FIGURES

Figure

Page

1. Complexity of biofilms in porous media.............................................................2

2. Conceptual model of integrated biofilm and reactor

models.......................................................................................................... -......8

3. Diagram of experimental setup for the flat plate VPBR.................................... 19

4. Diagram of experimental setup for the bench scape

VPBR.......... .........................................

20

5. Case I - Predicted and experimental acetate

concentration profiles...............................

32

6. Case I - Predicted and experimental nitrate

concentration profiles........................................................

32

I. Case I - Predicted and experimental biomass

concentration profiles........................................................................................33

8. Case I - Predicted and experimental biofilm thickness

profiles...................................................................................................

33

9. Case I - Predicted detachment velocity profiles................................................34

10. Case I - Predicted attachment velocity profiles.................................................34

II. Case I - Predicted temporal biofilm thickness profiles,....................................35

12. Case 2, Run I - Experimental flow rate................................................

36

13. Case 2, Run I - Predicted and experimental glucose

concentration profiles.....................................................

36

14. Case 2, Run I - Predicted and experimental effluent biomass concentration

profiles...............................................................................................................37

viii

LIST OF FIGURES - continued

Figure

Page

15. Case 2, Run I - Predicted and experimental effluent TOC

profiles...............................................................................................................37

16. Case 2, Run I - Predicted biofilm thickness at steady

state....................................................................................................................38

17. Case 2, Run I - Predicted detachment velocity profiles:..................................38

18. Case 2, Run 2 - Experimental flow rate............................................................39

19. Case 2, Run 2 - Predicted and experimental effluent

glucose concentration profiles...........................................................................39

20. Case 2, Run 2 - Predicted and experimental effluent

biomass concentration profiles..........................................................................40

21. Case 2, Run 2 - Predicted and experimental effluent

TOC profiles......................................................................................................40

22. Case 2, Run 2 - Predicted biofilm thickness at steady

state...............................................................................................

41

23. Case 2, Run 2 - Predicted detachment velocity profiles....................................41

24. Case 3, Run I - Concentration profiles of toluene,

oxygen and intermediates in the biofilm over ports 2, 5

and 8..............................................................

42

25. Case 3, Run I - Volume fraction profiles of X++, X+'

and X" phenotypes in the biofilm over ports 2, 5 and 8 .................................,...43

26. Case 3, Run 2 - Concentration profiles of toluene,

oxygen and intermediates in the biofilm over ports 2, 5

and 8.......................

44

27. Case 3, Run 2 - Volume fraction profiles OfX4+, X+"

and X" phenotypes in the biofilm over ports 2, 5 and 8 .................................... 45

28. Case 4, Run I - Predicted and experimental vapor phase

toluene concentration profiles.......................

46

LIST OF FIGURES - continued

Figure

Page

29. Case 4, Run I - Predicted and experimental toluene degradation rate.............46

30. Case 4, Run I - Concentration profiles of toluene,

oxygen and intermediates in the biofilm at day 50................................. •'.........47

31. Case 4, Run I - Volume fraction profiles O f X 4+, X+"

and X" phenotypes in the biofilm at day 5 0 .............................................. ........48

32. Case 4, Run 2 - Predicted and experimental vapor

phase toluene concentration profiles............................................

49

33. Case 4, Run 2 - Predicted and experimental toluene

degradation rate..................................................................................................49

34. Case 4, Run 2 - Concentration profiles of toluene,

oxygen and intermediates in the biofilm at day 50........................................... 50

35. Case 4, Run 2 - Volume fraction profiles of X4+, X+"

and X" phenotypes in the biofilm at day 5 0 ...................................................... 51

36. Simulation-experimentation framework outline................................................57

ABSTRACT

Rinfilms are ubiquitously present in many natural and manmade porous media

systems. Natural and engineered biofilm systems are important to bioremediation and

biofiltration and include both one-fluid-phase flow and two-fluid-phase flow systems.

Complex interactions exist between net biomass accumulation, porous media

charactersistics, and the rates of biofilm/biological processes. This complexity requires a

systematic approach to analyzing experimental results. The dynamic behavior of biofilms

in porous media is encapsulated in the rates of the biofilm/biological processes

contributing to net biomass accumulation. The key to understanding and predicting

biofilm/biological processes in porous media is modeling. The goal of this research is to

evaluate a biofilm process model in porous media systems for the prediction of

experimental results.

Most porous media biofilm models in the literature pertaining to both one-fluidphase and two-fluid-phase flow porous media systems utilize insufficient biofilm models.

The mixed-culture biofilm model (MCB) overcomes many limitations of the former.

Combining the MCB model with the appropriate reactor transport models give a porous

media biofilm reactor model that has the capability to simulating many types of porous

media biofilm systems. Experimental data from four separate systems, including two

one-fluid-phase and two two-fluid-phase, were analyzed in order to evaluate the MCB

model coupled with the appropriate reactor transport model.

Predicted results from the model for which experimental data exists give a good

fit. However, the model can predict more than what is available experimentally;

therefore, a full evaluation of model capabilities is not possible at this time. A

simulation-experimentation framework which can elucidate necessary experimental data

for further model evaluation is provided.

I

INTRODUCTION

Relevance of Riofilms in Porous Media

Biofilms are ubiquitously present in many natural and manmade porous media

systems. Rittmann maintains that “[biofilms] play crucial roles in the biodegradation of

contaminants and the clogging of porous media ...” [8] Many natural and engineered biofilm

systems utilize porous media as a support for biofilm formation. Natural biofilms in

subsurface porous media formations can be used in the field of bioremediation in order to

degrade contaminants. Engineered biofilm systems can be used in industrial processes such

as biofiltration and drinking water treatment. Together, these examples constitute two types

of porous media systems: one-fluid-phase and two-fluid-phase. The two primary

measureable activities of importance in porous media biofilm systems are biomass

accumulation and biotransformation.

Complexity of Biofilms and Biofilm/Biological Processes in Porous Media

The complexity of biofilms and biofilm processes in porous media stems from the

relationship between net biomass accumulation, changes in porous media characteristics, and

rates of biofilm/biological processes. Figure I summarizes the complexity of biofilms in

porous media systems.

2

Net biomass

accumulation

©

Porous media

characteristics

Biofilm/biological

process rates

Figure I. Complexity of biofilms in porous media.

One level of complexity of biofilms in porous media, shown as relationship I in

Figure I, is the effect of biomass accumulation on the characteristic properties of a porous

medium, such as porosity, permeability, and dispersivity. These effects have been quantified

by Taylor, Milly, and Jaffe: increasing biomass accumulation in a porous medium will

decrease the porosity and permeability, and increase the dispersivity. [12] Conversely, a

second level of complexity, shown as relationship 2 in Figure I, relates the changes in porous

medium characteristics to the transport of substrates to the biofilm. Again, this has been

quantified and understood to some extent through computational fluid dynamics. The third

level of complexity, shown by relationship 3, explains how the rates of biofilm/biological

processes, which depend on the transport of substrates and biomass, contribute to net biomass

accumulation. The complexity of this relationship depends on the large variety of potential

biological reactions. Rittmann says that the net accumulation of biomass is controlled by 4

biofilm/biological processes: growth and decay (biological), and deposition and detachment

(biofilm). [8] The issue of biofilm/biological process complexity becomes very important

3

when multispecies biofilms are considered. Biological processes of growth alone need to be

considered for m bacterial species utilizing n substrates, the totality of which contributes to

net biomass accumulation. One final consideration is that the effect of net biomass

accumulation on transport depends on the ratio of overall biofilm thickness to pore volumes.

For email ratios that are usually seen for packed beds, the effect on transport will be minimal.

However, for sand packed systems, the effect may be significant.

Relevance of Modeling Biofilm/Biological Processes in Porous Media

The dynamic behavior of biofilms in porous media is encapsulated in the rates of all

pertinent biofilm/biological processes contributing to net biomass accumulation. Little work .

has been done with respect to modeling biofilm processes complexity other than the work

done by Wanner, Guyer and Reichert [9,10,11,15]. Applications of complex biofilm models

to porous media biofilm systems has been sparse. Therefore, the key to quantifying and

understanding biofilms in porous media systems to effectively utilize biofilms is modeling

the biofilm/biological processes. The potential complexity of the problem requires a

systematic approach to analyzing experimental data. The modeling process gives a

framework in which educated decisions can be made about both the experimental design and

results and the accuracy of the simulations. As a result, the capability to predict

biotransformation and biomass accumulation in a porous media will allow for better

understanding, control, and design of porous media biofilm systems.

Additionally, regulatory acceptance of a biofilm process used to degrade or transform

contaminants is hindered by a lack of understanding On the part of the regulators. Successful

4

modeling and simulation of biofilms and biofilm processes in porous media may speed

acceptance of biofilm processes in industrial applications.

Porous Media Biofilm Reactor Models

In the literature there is a definite distinction between one-fluid-phase and two-fluidphase models for porous media biofilm systems. Generally, one-fluid-phase models are

found in the porous media groundwater modeling literature while two-fluid-phase models are

located in the biofilter modeling literature.

Porous Media Groundwater Biofilm Models

Much work was done by Taylor, Milly, and Jaffe [12] to measure and quantify the

effect of biofilm growth on the physical properties of a porous medium, which include

porosity, permeability, and dispersivity. The strong effort of their biofilm porous media

model was to describe transport of biomass and substrates. [13] The biofilm in their model

was described by a single Monod growth expression. However, they do acknowledge that

more complex kinetics could be incorporated into their model. Baveye and Valocchi [2]

provide an evaluation of three different representations of spatial distributions of biomass

within a porous medium. Their biofilm is described by a single Monod growth expression.

While both of these papers discuss methods to model changes in porous media characteristics

due to biomass accumulation, neither provides an evaluation of the importance of the rates at

which the processes of biofilm growth and substrate utilization take place. These processes

define the dynamic behavior of porous media biofilm systems.

<

5

Biofilter Models

Recently, Deshusses, Hamer, and Dunn [3] offered a biofilter model for waste air

treatment. Their description of a biofilter included gas and biofilm phases as well as a

sorption volume. The biofilm was modeled as a homogeneous, monoculture system. Monod

kinetics are used to describe growth and degradation kinetics, but the biofilm is assumed to

be at steady state and the degraders are assumed to be evenly distributed throughout the

biofilm. Diks and Ottengraf [4] created a model to describe the degradation of

dichloromethane in a trickling filter. Their assumptions included steady state thickness, zero

order kinetics, and constant volume fraction of the degraders in the biofilm. Baltzis and

Shareefdeen [1] give a model for a packed-bed biofilter. The biofilm is modeled as an

effective biolayer. More complex kinetics, such as substrate competition, are considered, but

only one bacterial species is considered. The drawback to each of these biofilm models is the

usage of oversimplified biofilm models, especially when there may be more biological

processes than degradation/growth that can affect biofilter degradation performance. Biofilm

thickness, volume fraction of cells, and kinetics are not always constant. These models lack

the flexibility to describe more complex biofilm processes.

The Extended Mixed-Culture Biofilm Model

Most current groundwater porous media models are of the advection-dispersionreaction or advection-reaction type. Some models consider the biofilm to be a “sink” for

given substrates while others estimate fluxes into the biofilm using Monod expressions and

biofilm thicknesses. Biofilter models utilize more complex biofilm models than do the

groundwater models, but most still lack the flexibility to consider many important

biological/biofilm processes. The potential complexity of biofilm processes, including

detachment, multiculture and multisubstrate biofilms requires a flexible, dynamic biofilm

model. The important issue is not only the relationship between biofilm thickness, porous

media characteristics, and transport, but also how the rates of biofilm/biological processes are

dynamically integrated into the behavior of biofilms in porous media systems.

The most recent biofilm model capable of modeling multiculture, multisubstrate

biofilms is the mathematical mixed-culture one-dimensional biofilm (MCB) model discussed

by Wanner and Reichert [15]: .

Basically, the MCB model consists of a set of one-dimensional mass balance

equations by which the progression of the biofilm thickness and the spatial

distribution and development in time of various dissolved components (nutrients,

electron donors, and electron acceptors) and particulate components (microbial cells,

extracellular polymeric substances, organic and inorganic particles) in a biofilm can

be modeled as a function of transport and transformation processes. These mass

balance equations are generally valid and can be applied to almost any microbial

system if the appropriate stoichiometry and kinetics are provided.

Coupled with the appropriate reactor transport models, the resulting porous media biofilm

reactor model has the capability to simulate a large variety of experimental geometries and

biofilm/biological processes.

Research Goal

The goal of this research is to evaluate the capability of the extended mixed-culture

biofilm process model for modeling porous media biofilm processes in porous media systems

for prediction of experimental results. The objectives required to reach this goal are:

O Evaluate the mixed-culture biofilm (MCB) model with the appropriate reactor

transport model as a complete porous media biofilm process model with

I

experimental data from both one-fluid-phase flow and two-fluid-phase flow

porous media reactors.

o Determine the limit of behavioral complexity of biofilm/biological processes in

porous media reactors that can be modeled with the extended mixed-culture

biofilm process model.

8

MODELING

There are three parts to the porous media biofilm reactor model to be analyzed

herein: reactor, biofilm and biological processes. The reactor part of the model is either

a one-fluid-phase or two-fluid-phase reactor. The biofilm is represented by the mixedculture biofilm (MCB) model which can consider an arbitrary number of bacterial and

substrate species. Figure 2 shows the conceptual model for the integration of the MCB

and reactor models for both one-fluid-phase and two-fluid-phase porous media biofilm

reactors. Biological processes can occur in the biofilm, bulk liquid, and bulk gas phases,

and area described via appropriate kinetics and stoichiometry.

Bulk liquid-biofilm

Interface

Bulk gas-bulk liquid

Interface

L

tA

/

/

/

/

/

/

/

/

/

/

/

/

C ctDi

C itDi

CptDi

CptPi

;

c LPi

—

A LF

Vf

PPi

Epi

Lf

y

B u lk G as

FL, B ulk L iq u id

Biofilm

—

;

-- > J g

A GL /

>

A ........K1' ..........

Vg

i

Ql

Qg

CcOtDi

:

ClOtDi

C u tPi

Bulk Liquid

Boundary Layer

Bulk Gas

Boundary Layer

&

&

Figure 2. Conceptual model of integrated biofilm and reactor models.

9

One-fluid-phase Flow Porous Media Reactor

Mass transport is described by a one-dimensional advection-diffusion equation.

The reactor is divided into axial segments, and bulk liquid and biofilm sections are

distinguished. The bulk liquid phase is well mixed. The mass balance equation for

dissolved and particulate components in the bulk phase, respectively, are

3

b

"o

Il

'i i p

LO1Di

L {c LO1Pi

- Q

dt

C

~

l iDi

) + j ^ L F J LF 1Di + ^ L r Di

C L 1P i )

+ A

lf

J L F 1Pi + ^ L r Pi

(I)

(2)

where Clo is the segment influent concentration (ML'3), Cl is the bulk liquid

concentration (ML3) J l is the mass flux per unit interfacial area across the biofilm-bulk

liquid interface (ML2Lx), r is the net production rate (ML3Lx) , Vl is the bulk liquid

volume (I?), Ql is the liquid volumetric flow rate (L3Lx), Alf is the biofilm surface area

(L2) of the segment, and t is time. The interfacial mass flux of dissolved and particulate

components per unit biofilm surface area is given by

— cD L tD i i p FL,Di ~ ^ L ,D i)

J

l iPi ^

L

—

c^ L 1P i i p F L 1Pi ~ ^ L 1P i )

^

^

where Xl is the mass transfer resistance coefficient (L), <Dl is the effective diffusivity

(L1Lx) of the dissolved or particulate species in the liquid phase, and Cfl is the

concentration (ML3) at the biofilm-bulk liquid interface. The bulk fluid volume, Vl is

related to the total segment volume and total biofilm volume by

10

(5)

where Vc is the total volume of the segment, and P> is the biofilm volume.

Two-fluid phase Flow Porous Media Reactor

Mass transport is described by one-dimensional advection-diffiision equation.

The reactor is divided into axial segments. Bulk gas, bulk liquid and biofilm sections are

distinguished. The bulk gas and bulk liquid phases are well mixed. The mass balance

equation for dissolved and particulate components, respectively, in the bulk liquid is

= Ql ( c L0 Di —CLDi j + ALFj LDi - A glJ g Dj + VLrDi

(6)

where Clo is the segment influent liquid phase concentrations (ML'3), Cl is the bulk liquid

concentrations (MU3) J l is the mass flux per unit interfacial area across the biofilm-bulk

liquid interface (MU2f x), r is the net production rate (ML"3/'1), Vl is the bulk liquid

volume (£3), Ql is the liquid volumetric flow rate (I? fx), A lf is the biofilm surface area

(I?) of the segment, A ql is the bulk gas-bulk liquid interfacial area (I?), and t is time.

The mass balance equation for dissolved components in the bulk gas is

A

- Qa (Cmjll - Ca a ) + AaJ a a

( 8)

where Cgo is the segement influent gas phase concentration (MU3), Co is the bulk gas

concentration (MU3), Vq is the bulk gas volume (Ju ) J g is the mass flux per unit

interfacial area across the bulk gas-bulk liquid interface (MU2Q), Qg is the gas

11

volumetric flow rate (XY1). The biofilm-bulk liquid interfacial mass flux of dissolved

and particulate components, respectively, is

(9)

J ltDl^L ~ ®L3Di \pFL,Di ^L,Di

( 10)

JL,Pi^L ~ cDL,Pi{pFLyPi ~ ^LyPij

where Zl is the mass transfer resistance coefficient (L) across the biofilm-bulk liquid

interface, (Dl is the effective diffusivity ( lY 1) of the dissolved or particulate species in the

liquid phase, and Cfl is the concentration (ML'3) at the biofilm-bulk liquid interface. The

bulk gas-bulk liquid interfacial mass flux of dissolved components is

J LyDi^O

'GyDi

Y,

c GyDi

/Zn, /

(H)

where Zq is the mass transfer resistance coefficient (L) across the bulk gas-bulk liquid

interface, ®Gis the gas phase molecular diffusivity (Z2Z1)5and H is the dimensionless

Henry’s Law coefficient. The bulk liquid volume is given by

where Vc is the total volume allowable for biofilm growth in the segment, and Vf is the

biofilm volume. The bulk gas volume, Vq, is constant,

Biofilm

Equations (13)-(26) constitute the MCB model [15] with the one exception that

the presented formulation assumes that the volume fraction of water in the biofilm does

not change in time or space.

The porous media provides support for biofilm growth. The formation of biofilm on the

surface of the porous media is described by a one-dimensional mass balance equation for

biomass

F 1Pi

' F 1Pi

dt

dy

+ r Pi

(13)

where Cp1Pi is the concentration (ML"3) of particulate i in the biofilm, z is the distance (L)

perpendicular to the solid surface, and JpiPi is mass flux (MU3T1) of particulate i in the

biofilm in they direction. Biofilm mass flux results from biofilm growth in the biofilm

interior and is given as

J p iPi

u F ^ F 1Pi

-

where uFis the advective velocity (Lf1) of the biofilm matrix due to growth. This

velocity is calculated as

where si is the volume fraction of the liquid phase in the biofilm and ppt is the specific

density (MU3) of particulate i. The relationship between density and concentration is

given by

C p iPi

=

P p i e Pi

where Spi is the volume fraction of particulate i in the biofilm. The boundary conditions

are

JF, P

i^

= 0

at the biofilm-substratum interface and

( 1 ? )

13

( 18)

JptPi \y=LF = JLtPi

at the biofilm-bulk liquid interface, where J f and J l are the interfacial mass fluxes

(ML'2/'1) of particulate i in the biofilm and bulk liquid phases, respectively, and Lp is the

biofilm thickness. The mass flux_/> is given by

uJeCptPj UatCPLtPi

JptPi y-LF

(19)

where Uje is the velocity (L f i) at which biomass is detaching from the biofilm and into

the bulk liquid and ual is the velocity (Lf1) at which biomass is attaching to the biofilm

from the bulk liquid. Progression of the biofilm thickness is modeled by

dLp

(20)

UF\y=LF- Ude + Ual

Dissolved components in the biofilm are modeled by the one-dimensional mass balance

equation

d ( siCF Di)

d j FtDi

rDi

(21)

The mass flux is given by

JFtDi ~ Up(J

<9CFtDi

£l)CptDi f 1DLtDi '

(22)

w here/is the ratio of diffusivity in the biofilm versus diffusivity in the bulk liquid. The

boundary conditions are

J FtDi\y=0 = 0

C p tDi IiV=Ly?

~~ C

JptDi ~ J LtDi

(23)

F i >D,

(24)

(25)

14

with the interfacial mass flux of dissolved component i at the biofilm side of the biofilmbulk liquid interface given as

F jDi

J p jDi

—

UF

(l

s I ^ F jDi

(26)

L jDi

y=LF

Biological Reactions

The bacteria utilize an electron donor and an electron acceptor to produce

biomass. Biomass is considered as cellular mass and extra polymeric substance (eps).

The rate of production of biomass is modeled by either double Monod kinetics or

Haldane kinetics which includes inhibition of the overall rate due to electron donor

concentration:

Cr

Cj

(27)

rX

Cj

-X

Cl K j +C j

where

is the rate of production

JUmax

(28)

is the maxim specific growth rate ( t !),

Cd and Ca are the concentrations (ML'3) of the electron donor and electron acceptor,

respectively, K d and Ka and the half-saturation constants (ML'3) for the electron donor

and electron acceptor, respectively, X is the concentration (ML'3) of biomass, and Ki is the

inhibition constant (ML'3) with respect to the electron donor. The utilization rates of the

electron donor and electron acceptor are given by

15

~ rx

(29)

^XlD

and

~ rx

(30)

^XlA

where rx is the production (growth) of biomass (MZ/V1), r# and

are the utilization rates

(MU3Tx) of the electron donor and the electron acceptor, Yx/d and Yx/a are the observed

yield coefficients for biomass with respect to the electron donor and electron acceptor,

respectively.

Biological Process Stoichiometry Matrices

Since biological reactions can be more involved than the growth of one species

utilizing an electron acceptor and electron donor, a more concise method of describing

processes is by a process matrix. The biological process stoichiometry matrix can

describe the generation (+) or consumption (-) for all species. The rate of generation or

consumption for a given species by a specific processes is determined by multiplying the

coefficient for that species/process combination inside the matrix by the rate expression

Table I . Biological process stoichiometry matrix for general growth

processes.________ ____________________________ ___

PROCESSES

Haldane Kinetics

Double Monod Growth

SPECIES

+ 1

X

+ 1

D

-I/Yx/d

-1 /Y

x /d

A

-1 /Y x /A

-1 /Y

x /a

R a te

e x p re ssio n

A ""

Co

c,

JC0 + C d K a + C 1

.

C*

,

^

%

16

for that process given at the bottom of the matrix. Table I shows the biological process

stoichiometry matrix representing equations (27)-(30).

17

EXPERIMENTAL SYSTEMS

Experimental data from four separate cases, two one-fluid-phase and two two-fluidphase, were used to evaluate the previously described porous media biofilm model. The

experimental systems for Case I and Case 2 were designed in order to determine attachment

and detachment rate functionalities in one-fluid-phase porous media reactors. The

experimental systems of Case 3 and Case 4 were designed to determine the peformance of

toluene degradation in a vapor phase bioreactor (a two-fluid-phase reactor). Following are

synopses of the experiments.

One-fluid-phase Flow Porous Media Reactor Experiments

Case I - Microbial transport experiment

Case I was a porous media microbial transport study done at Washington State

University by David Jennings. [5] Experiments were performed to determine the

detachment and attachment rate of an unspecified denitrifying bacteria isolated from Hanford.

The experimental reactor was a 50 cm by 2.1 cm column packed with sand particles having

an average diameter of 190 pm. Data were obtained for three growth rate levels, denoted as

low, middle, and high, of the acetate and nitrate substrates. Only the middle growth rate level

was analyzed. Measured quantities include pressure drop, and influent and effluent

concentration of substrates and biomass. An attempt was made to determine the spatial

distribution of biomass within the column at the end of the experiment.

18

Case 2 - Biofilm detachment experiment

Case 2 was a porous media biofilm detachment experiment performed at Montana

State University by Al Cunningham, Paul Stoodley, and Shanon Bakich. The goal of this

experiment was to determine the detachment rate of Pseudomonas aeruginosa in a small

sand-packed rectangular column (1.0 cm by 1.2 cm by 4.5 cm). The substrates were glucose

and oxygen. The average particle diameter was 190 pm. An assumption was made that

attachment could be neglected because of the short length of the column. Data were obtained

for two glucose concentration levels, 6.7 and 13.5 mg glucose/L, denoted as Run I and Run

2. Measured quantities include influent and effluent glucose, biomass, TOC, and flow rate.

Confocal microscopy was used to noninvasively image biofilm accumulation in the porous

media. This experiment is explained in greater detail in Appendix A.

Two-fluid-phase Flow Porous Media Reactor Experiments

Case 3 - Flat plate VPBR experiment

The experimental system for Case 3 was a flat plate vapor phase bioreactor (VPBR).

The goal of the experiment was to predict vapor phase toluene concentration and toluene

degradation rate. A flat plate reactor allows for the system to be modeled with a known

geometry: a surface area of 50 cm x 4 cm or 200 cm2, and a volume of 50 cm x 4 cm x 4 cm

or 800 cm3. The unique aspect of this experiment was the utilization of phenotypic

transformation rates of P. putida 54G. There are three phenotypes present: wild type,

reversibly injured, and irreversibly injured. The wild type cells degrade toluene. The

irreversibly injured cells are injured by toluene and can no longer grow on any substrate. The

19

reversibly injured cells can no longer utilize toluene, but have the capability to utilize

intermediates from the partial degradation of toluene and from lysis products generated via

death and endogenous decay. The characterization of phenotypes and phenotypic

transformation rates was done by Mirpuri [6]. Figure 3 is a schematic of the experimental

system. Sampling ports are numbered from I at the gas influent to 9 at the gas effluent.

Measured parameters include vapor phase toluene concentration at the influent and effluent

as well as at ports 2, 5 and 8. Two experimental runs with influent toluene concentrations of

150 and 770 ppm were performed, denoted as Run I and Run 2, respectively. Experimental

methods and data are in Mirpuri, 1995 [6]

Flow

controller

G as In

M icrosensor

Sample Ports

G as Out

n n n n n n n n n

Humidifier

0.2 pm

filter

Flow

controller

-3

Effluent

sam pling

well

G lass plate

to enable

viewing with

Toluene

Figure 3. Diagram of experimental setup for the flate plate VPBR. [6]

Liquid

20

Case 4 - Bench-scale VPBR experiment

Case 4 is identical to Case 3 except the biofilm was grown in a packed column with

0.25 in. ceramic ring packing material. Vapor phase toluene concentration profiles were

obtained for two experimental runs with influent toluene concentrations of 150 and 750 ppm,

denoted as Run I and Run 2. Figure 3 shows a diagram of the experimental system.

Experimental methods and data are in Mirpuri, 1995 [6]

Effluent G as

Sam pling Port

H ouse

Air

Effluent

-----I r hI

G as to

n

^

Flow Meter

fi)

Liquid Media

Influent

O a s Z

Sam pling

Ports x

Control

Valve

Toluene

» M

-1/4" Ceram ic

R asch ig R ings

,

Control

Valve

Influent G as

Sam pling Port

0 H

Humidifier

®—^

Liquid

Sam pling

Port

G as Mixer

Figure 4. Diagram of experimental setup for the bench scale VPBR. [6]

Liquid

Effluent

to W aste

21

SIMULATION

Aquasim

Simulations were performed with Aquasim, a software package for the simulation

of aquatic systems [9,10,11] which contains an implementation of the extended mixedculture biofilm (MCB) model. Aquasim is capable of simulating a wide variety of

aquatic systems. The basis for modeling reactors and reactor systems in Aquasim are

mixed fluid compartments and mixed biofilm compartments. A reactor or reactor system

can be defined by a combination of any number of either type of compartment connected

via advective or diffusive links. With respect to the porous media biofilm reactor

conceptual model, mixed fluid compartments represent the bulk gas phase and mixed

biofilm reactors represent the bulk liquid and biofilm phases. Biological processes are

user defined dynamic processes and affect the concentrations of dissolved and particulate

species. The Aquasim data files for each case are in Appendix C.

One-fluid-phase Flow Porous Media Reactor Simulations - Case I and Case 2

For Case I, the porous media column was defined by a configuration of ten

equally sized mixed biofilm compartments. In Case 2, the porous media column was

modeled as a series of I mixed biofilm reactors: the first 5 sections were 0.5 cm in length

and the remaining 2 sections, were 1.0 cm in length. Each case had one bacterial species

present and an electron acceptor and electron donor. Case I consisted of an unspecified

22

denitrifyer, acetate, and nitrate, respectively. Likewise, for Case 2, the combination was

Pseudomonas aeruginosa, glucose and oxygen. For the purposes of simulation, the

surface area available for biofilm growth was estimated from the following relationship,

Aw

,0.152£>J

where/f w is the specific surface area per unit volume (m2 m"3) and Dp is the porous media

particle diameter (m). The appropriate biological process stoichiometry matrix for these

experiments is shown in Table 2. X, D and A represent biomass, electron donor and

electron acceptor, respectively. Likewise, Ksd, Ksa,Yx/d and Yx/a are the Monod half­

saturation constants and yield coefficients for both the electron donor and electron

acceptor, respectively. Tables 3 and 4 give the parameters values for each case. All

parameters are from the experimental data or literature unless otherwise noted.

Table 2. Process matrix for cases I and 2.

PROCESS

Growth

SPECIES

X

D

A

Rate

expression

+1

f

zw I

-1 /Y

x/d

-1 /Y

xza

D Y

tty

^

Ir

23

Table 3. Summary of parameters for Case I .

Physical Parameters

Description

Value

Units

7.61E -05

0.00288

5.9965

5E-06

1.071E-04

1.469E-04

1.0E-4

0.8

4.068

0.2558

3.54E + 05

m3

m 3d 1

m2

m

m2 d 1

m2 d 1

m2d 1

gC m3

gN m 3

KCm3

Description

Value

Units

M axim um specific grow th rate (Pmax) [7]

A verage density o f biom ass (p x)

M ass yield o f biom ass per unit nitrate (electron acceptor) (Y xw)

1.8

4 0,000

0.353

d'

gC m

g C -biom ass

/ g N -nitrate

g C -acetate

/ g N -nitrate

d '1

R eactor bulk fluid volum e (V c)

Flow rate (Q )

T otal biofilm surface area (A uf)

L iquid boundary layer thickness (X)

D iffusivity o f acetate in w ater (D a)

D iffusivity o f nitrate in w ater (D n)

D iffusivity o f biom ass in w ater (D x)

D iffiisivity o f biofilm / diffiisivity in w ater (f)

H alf-saturation constant for acetate (electron donor) (K sa ) [7]

H alf-saturation constant for nitrate (electron acceptor) (K sn) [7]

D ensity o f biom ass

Kinetic Parameters

[7]

Stoichiom etric utilization o f nitrate to acetate (electron donor)

1.585

(Y xza) [7]

A ttachm ent coefficient (K a)

80

Table 4. Summary of parameters for Case 2.

Physical Parameters

Description

R eactor bulk fluid volum e (Vc)

Flow rate (Q)

Biofilm surface area (A l f )

M ass transfer resistance coefficient (X)

G lucose diffiisivity (D g|u)

D issolved oxygen diffiisivity (D qz)

B iom ass diffiisivity in w ater (D x)

D iffiisivity in biofilm / diffiisivity in pure w ater

V olum e fraction o f biom ass (es )

B iom ass density (p x)

(f)

Value

Units

5.4E-06

Figs. 1 2 ,1 8

0.189

5E-06

5.18E-05

1.56E-04

0.0001

0.1

2.5E+04

m3

m3d"1

m2

m

m2 d '1

m2 d 1

m2d 1

gC m "3

Value

Units

9.0

0.80

0.20

0.66

1.1

d '1

gCm 3

g 0 2m 3

g C x / g Cgiu

K C 02 / g C c|„

0.8

Kinetic Parameters

Description

M axim um specific grow th rate (p max)

G lucose half-saturation constant (K s)

O xygen half-saturation constant (K 0)

B iom ass yield on glucose (Y xzo)

S toichiom etric factor for oxygen yield (k)

Detachment is considered to be only growth related; therefore, the detachment

velocity is modeled as a fraction of the growth velocity. The parameter Ctje represents the

fraction of the growth velocity of the biofilm that is detached. The product of biofilm

growth velocity and

gives the detachment velocity, «<&,. This allows modeling of

biomass detachment without having to know the explicit functionality of detachment on

other parameters, such as pressure drop, growth rate, and biofilm thickness. When Cije is

1.0 , all biofilm growth is detached and a steady state biofilm thickness is forced only if

there is not attachment.

The approach to evaluating the model was to fit the measured time series of

effluent electron acceptor, electron donor, and biomass concentrations and a profile for

biofilm thickness at the end of the experiment by only changing the time-series values of

CldeTwo-fluid-phase Flow Porous Media Reactor Simulations - Case 3 and Case 4

The flate plate vapor phase bioreactor (VPBR) was modeled as a series of 9

equally-sized mixed biofilm reactors representing the biofilm and bulk liquid phases

diffusively linked to 9 equally-sized mixed reactors representing the bulk gas phase. The

bench-scale VPBR was modeled as a series of 4 equally sized mixed biofilm reactors

diffusively linked to 4 equally-sized mixed reactors. The bulk liquid and bulk gas phases

flow countercurrently. The specific surface area of the packing for Case 4 was estimated

at 500 m2 m'3. The three bacterial phenotypes (wild type, reversibly injured and

irreversibly injured) o f Pseudomonas putida 54G and three substrates (toluene, oxygen,

and intermediate products) were considered. Table 5 shows the biological process

matrix used for the biofilter systems. The three phenotypes are represented by X h", Xf',

and X", respectively. Table 6 contains the model parameter values for Case 3 and Case 4.

All model parameters except those in bold were determined or estimated independently.

An arbitrary detachment rate equal to 10% of the growth velocity was introduced to

promote calculation of steady state biofilm thicknesses.

The approach to evaluating these cases was to apply the experimental influents

(flow rates and concentrations) to the model and compare the predicted and experimental

toluene vapor phase concentration profiles. A qualitative analysis of the bacterial

phenotypic profiles was also made.

Table 5. Biological process stoichometry matrix for Cases 3 and 4.

PROCESSES

SPECIES

Growth of X h"

Injury

Variant

Formation

+X ^

-X ~

-X ^

Growth of X

Endogenous

Decay

Death

-X++

-X++

-X+

+X

-X

-X

-X/Yo

-XArI

-(X+++X)/Yob

+^u,(X+++X)

+fcells(X+++

+X ^

X+-

+X ^

X"

T

O

I

-X hTYt

-X++/Yo

+L,(X^/YT)

X+'+X)

Rate

expression

f

T

Y

O '

^ K K s j +T +T2I k X ksO+0J

Kinj

Kgl

, f

Mman^

i Y

o )

z + / J i 1Ks0 + Oj

6 f

^ I

x \K s0 + o)

dx

27

Table 6. Summary of parameters for Case 3 and Case 4. Physical parameters vary for the

experimental setup. Kinetic parameters vary for influent toluene concentration.

Parameters in bold represent coefficients adjusted to obtain the best fit to total toluene

degradation.

Physical parameters

Units

Case 4

Case 3

Description

Total gas volum e (V 0)

L iquid flow rate (Q l )

G as flow rate (Q g)

Total liquid volum e (V u)

Total reactor volum e (V)

Total surface area (A )

T otal gas-liquid interfacial area (A g l)

T otal gas-liquid interface thickness (Xg )

Liquid-biofilm interface thickness (Xl )

L iquid phase diffusivity o f toluene

L iquid phase diffusivity o f oxygen

G as phase diffusivity o f toluene

G as phase diffusivity o f oxygen

H enry’s law constant for toluene (H t )

H enry’s law constant for oxygen (H 0)

D iffusivity in biofilm / diffusivity in w ater (f)

V olum e fraction o f biom ass (e)

7.20E-04

0.00144

0.072

8.00E-05

8.00E-04

0.02

0.02

Kinetic parameters

150 ppm

M axim um specific grow th rate (P max)

T oluene half-saturation constant (K st )

O xygen half-saturation constant (K s0)

Inhibition constant (K,)

Y ield o f biom ass on toluene (Y t )

Y ield o f biom ass on oxygen (Y 0)

E ndogenous yield on oxygen (Y ob)

Injury rate (K inj)

Irreversible injury rate (Kg l )

M axim um specific grow th rate for X" cells

750 ppm

Units

10.08

3.98

0.025

42.78

day"1

gm3

g m "3

gm3

0.86

g /g

g /g

g /g

day 1

day 1

day 1

0.55

0.55

0.06783

0 .00655

0.42696

0.06551

5.0

(P 1max)

Interm ediates half-saturation constant (K s1)

Y ield o f biom ass on interm ediates (Y 1)

Fraction o f toluene incom pletely degraded (flol)

Fraction o f biom ass converted to interm ediates

via deathZdecay (fccll!i)

Endogenous decay rate (bx)

Death raWdy)

m3

m3 d"1

m 3 d"1

m3

m3

m2

m2

m

m

m2 d 1

m2 d 1

m2 d 1

m2 d 1

g m 3Zg m 3

g m 3Zg m 3

gm3

1.00E-05

2.50E-05

6.89E-05

2.16E -04

0.72

1.54

0.19

43.0

0.8

0.08

5.00E+04

Density of biomass(px)

Description

1.90E-03

0.00288

1.44

1.04E-03

5.00E-03

2.6

2.6

gm 3

2.0

0.5

0.2

0.2

0.65

0.10

g /g

1.5

0.5

day 1

28

RESULTS

Case I

Simulation results were obtained for the middle substrate loading case. Several

iterations were required to obtain meaningful results. Only the results from the final iteration

are given.

Figures 5 ,6 ,7 and 8 show the predicted versus experimental values for the three time

series and one spatial series of interest. The experimental and calculated effluent substrate

profiles were in good .agreement. The calculated effluent biomass profile is relatively close

to the experimental values, considering the low value of measured effluent biomass.

However, the calculated biofilm thickness profile in the column at the end of the experiment

does not agree with the experimental values.

Figures 9,10,11 and 12 show additional model output used to evaluate the

detachment rate of the biomass. Figure 9 shows the detachment velocity of the biofilm in

each compartment with time. The detachment velocity is directly proportional to the amount

of biomass detaching from the biofilm. Note how the detachment velocity increases and then

decreases over the length of the simulation. At the end of the simulation, the only

compartment detaching biomass is the first compartment of the column. Figure 10 is a plot of

the attachment velocity of biomass in each compartment. The attachment velocity is directly

proportional to the amount of biomass being attached. Note how the attachment rate

decreased down the length of the column. Figure 11 shows the calculated biofilm thickness of

29

each biofilm compartment with time. Note

how it seems that none of the biofilm

thickness profiles has reached a steady-state

Table 7. Time series Oge values for Case I.

time fd

3de

0.3

4

1.0

10

1.0

21

value by the end of the simulation. Table 7

shows the time series values used for aje, the fraction of the growth velocity that is detached.

Note that the value of Bde is 1.0 past day ten, meaning that all new growth is detached from

the biofilm.

Case 2

Figures 12-17 show the experimental and calculated time series of glucose, TOC,

effluent biomass and biofilm thickness for Run I . Figures 18-23 show that same information

for Run 2. Figures 12 and 18 show the recorded flow rate for each experiment. Figures 13

and 19 show the experimental influent and the experimental and calculated effluent glucose

concentrations. Linearly interpolated values were used for both flow rate and influent

glucose concentration as input to the simulation. Figures 14 and 20 show the experimental

effluent biomass compared to the calculated effluent biomass. The experimental biomass

concentration was obtained by subtracting the experimental effluent glucose from the

experimental TOC. Figures 15 and 21 show the experimental and calculated concentration of

TOC. The calculated TOC is the sum of the carbon from both glucose and biomass. Figures

16 and 22 show the calculated biofilm thickness profile in the columns. Figures 17 and 23

show the resulting detachment velocity profile along the column.

Table 7 shows the time

series values of Ude used for each run to obtain simultaneous fits to the experimental data.

30

Table 8. Time series a^e values for Case 2.

Run I

time [d

time [d

a<ie

1.0

0.3

0.0

4.3

1.0

1.0

10

1.0

18

Run 2

<*de

0.4

1.0

1.0

Case 3

Table 9 shows a comparison of toluene degradation profiles experimentally

determined in the fiat plate VPBR and calculated results for both 150 ppm and 770 ppm

influent toluene concentrations. The simulation results match the experimental values of

toluene concentration at different points along the length of the reactor as well as total

toluene degradation rate. Figures 24 and 25 show the substrate and phenotype profiles in the

biofilm at ports 2, 5 and 8 for low influent toluene concentration. Figures 26 and 27 show the

same information for high influent toluene concentration. For both low and high influent

toluene cases, the volume fraction of X++, the toluene degraders, is highest near the biofilm

surface and decreases toward the substratum. The volume fraction X+' and X cells increase

towards the substratum.

Case 4

Figures 28 and 32 show a comparison between experimentally obtained vapor phase

toluene concentrations and predicted profiles for low and high influent toluene

concentrations, respectively. The predicted toluene concentration profiles compare favorably

to the experimental measurements. Figures 29 and 33 show the resulting degradation profiles

with time. The deviation from the experimentally calculated profile is less than 10% for low

influent toluene concentration and less than 20% for high influent toluene concentration.

31

Figures 30 and 34 show the spatial concentration profiles of toluene, oxygen, and

intermediates in the biofilm at day 50 for both low and high influent toluene concentration.

Figures 31 and 35 show the spatial profiles of the volume fraction of the various phenotypes

in the biofilm.

Table 9. Predicted and experimental vapor phase toluene concentration results for

Case 3.

Units

Toluene concentration

Experiment

Run I (150 ppm)

Influent

Port 2

Port 5

Port 8

Effluent

Toluene degradation rate

Run 2 (770 ppm)

Influent

Port 2

Port 5

Port 8

Effluent

Toluene degradation rate

Experimental

Predicted

152.00 ±5.6

123.00 ±5.2

94.00 ± 4.7

74.00 ± 3.9

59.00 ± 4.2

0.0212

152.0

127.3

96.8

72.6

60.8

0.0208

ppm

ppm

ppm

ppm

ppm

g day"1

767.00 ± 32.2

642.00 ± 39.3

475.00 ± 29.5

425.00 ±38.2

363.00 ± 29.2

0.0920

767.0

681.1

561.2

449.7

381.8

0.0876

ppm

ppm

ppm

ppm

ppm

g day'1

32

“

15 --

time [d]

----- Predicted effluent

p

Experimental effluent

x Experimental influent

Figure 5. Case I - Predicted and experimental acetate concentration profiles.

_

i o --

time [d]

----- Predicted effluent

x

Experimental influent

■ Experimental effluent

Figure 6. Case I - Predicted and experimental nitrate concentration profiles.

33

1.4 --

1.2

- -

1.0

- -

0.8

- -

0.6

0.4 --

0.2

- -

time [d]

------Predicted effluent

■ Experimental effluent

Figure 7. Case I - Predicted and experimental biomass concentration profiles.

1.0E-06

9.0E-07 -□ Predicted

8.0E-07 --

■ Experimental

7.0E-07 -6.0E-07 - 5.0E-07 -4.0E-07 -3.0E-07 -2.0E-07 -1.0E-07

to

5

to

10

to

15

to

20

to

25

to

30

to

35

to

40

to

45

to

50

Position in Column [cm]

Figure 8. Case I - Predicted and experimental biofilm thickness profiles.

'g

Detachment velocity [m <T ]

34

re 9. Case I - Predicted detachment velocity profiles along the

length of the column.

Attachment velocity [m d ]

8E-08

7E-08 --

10 cm

6E-08 --

15 cm

5E-08 --

20 cm

25 cm

4E-08 --

30 cm

3E-08 -2E-08 --

50 cm

0E+00

time [d]

Figure 10. Case I - Predicted attachment velocity profiles along the

length of the column.

35

1.0E-06

film thickness [m]

9.0E-07 --

20 cm

7.0E-07 --

15 cm

6.0E-07 ■■

5.0E-07 -4.0E-07 --

30 cm

10 cm

40 cm

50 cm

1.0E-07 -0.0E+00

time [d]

Figure 11. Case I - Predicted temporal biofilm thickness profiles along the

length of the column.

Flow rate [mL min

36

cS

time [d]

re 12. Case 2, Run I - Experimental flow rate.

Iucose [g C m '3]

2.5

2.0

1.5

0.5

tim e [d]

■ Experimental effluent

-----Predicted effluent

x Experimental influent

Figure 13. Case 2, Run I - Predicted and experimental glucose concentration

profiles.

37

5.0 --

4.0

3.0

2.0

1.0

time [d]

Figure 14. Case 2, Run I - Predicted and experimental effluent biomass

concentration profiles.

5.0

4.0 -

3.0 --

1.0

time [d]

Figure 15. Case 2, Run I - Predicted and experimental effluent TOC profiles.

38

7.0E-06

6.0E-06

£,

5.0E-06

M

S

5

O

!E

»5

E

5

.2

CD

4.0E-06

3.0E-06

2.0E-06

1.0E-06

O.OE+OO

Position in colum n [cm]

Figure 16. Case 2, Run I - Predicted biofilm thickness at steady state.

2.5E-06

0.5 cm

2.0E-06 -1.0 cm

1.5E-06 -1.5 cm

1.0E-06 -2.0 cm

5.0E-07

2.5 cm

3.5 cm

4.5 cm

8

10

time [d]

Figure 17. Case 2, Run I - Predicted detachment velocity profiles along the

length of the column.

39

^

5.0

-J 4.0

u- 2.0

time [d]

Figure 18. Case 2, Run 2 - Experimental flow rate.

6.0

-■

5.0

O 4.0

O 3.0

2.0

- -

1.0

--

time [d]

Figure 19. Case 2, Run 2 - Predicted and experimental effluent glucose

concentration profiles.

40

3.5

3.0

E

2.5

2.0

1.5

1.0

-

0.5

time [d]

Figure 20. Case 2, Run 2 - Predicted and experimental effluent biomass

concentration profiles.

6.0

5.0 --

O 3.0

2.0

-

1.0

--

time [d]

Figure 21. Case 2, Run 2 - Predicted and experimental effluent TOC profiles.

41

8.0E-06

7.0E-06

O.OE+OO

Position in colum n [cm]

Figure 22. Case 2, Run 2 - Predicted biofilm thickness at steady state.

3.0E-06

2.5E-06 --

0.5 cm

2.0E-06 --

1.5E-06 --

1.0E-06 --

5.0E-07 --

1.0 cm

1.5 cm

time [d]

Figure 23. Case 2, Run 2 - Predicted detachment velocity profiles along the

length of the column.

Concen

42

N orm alized d is ta n c e from s u b s tratu m

— T o lu e n e ------- O x y g e n .............Interm ediates

Concentration [g m"3]

P o rt 5

N orm alized d is ta n c e from s u b s tra tu m

T o lu e n e ------- O x y g e n ............ Interm ediates

P o rt 8

N orm alized d is ta n c e from s u b s tra tu m

T o lu e n e ------- O x y g e n .............Inte rm e diates

Figure 24. Case 3, Run I - Predicted concentration profiles o f toluene, oxygen

and intermediates in the biofilm over ports 2, 5 and 8.

43

Port 2

0.08

c

.2

Volume fr:

i

0.07

0.06

0.05

0.04

0.03

0.02

0.01

0

0

0.2

0.4

0.6

0.8

1

N orm alized d is ta n c e from s u b s tra tu m

-------- X + + -------- X + - ............X-

P o rt 5

Volume fraction

0.08

0.07

0.06

0.05

0.04

0.03

0.02

0.01

0

0

0.2

0 .4

0.6

0.8

N orm alized d is ta n c e from s u b s tr a tu m

-------- x + + -------- x + - ............ X-

Volume fraction

P o rt 8

0.0 7

- -

0.06

0.05

- -

0.04

- -

0.0 3

- -

0.02

- -

0.01

- -

\

\

N orm alized d is ta n c e from s u b s tra tu m

-------- x + + -------- X + - ............X-

Figure 25. Case 3, Run I - Predicted volume fraction profiles OfX4+, X+"

and X phenotypes in the biofilm over ports 2, 5 and 8.

1

44

P ort 2

18

16

14

- -

12

- -

1 0

- -

- -

N orm alized d is ta n c e from s u b s tra tu m

— T o lu e n e --------O x y g e n ............ Interm e diates

P o rt 5

10

- -

N orm alized d is ta n c e from s u b s tr a tu m

T o lu e n e ------- O x y g e n .............Interm ed iates

P o rt 8

N orm alized d is ta n c e from s u b s tr a tu m

------Toluene — j - O x y g e n ........... Interm ed iates

Figure 26. Case 3, Run 2 - Predicted concentration profiles o f toluene, oxygen,

and intermediates in the biofilm over ports 2, 5 and 8.

45

P o rt 2

I

N orm alized d is ta n c e from s u b s tra tu m

^ _ _ x + + E - - x + - - — X-J

Volume fraction

P o rt 5

0.08

0.07

0.06

0.05

0.04

0.03

0.02

0.01

0

0

0.2

0.4

0.6

0.8

N orm alized d is ta n c e from s u b s tra tu m

-------- X + + -------- X + - ............X-

Volume fraction

P o rt 8

0.07 -0.06

0.05

0.04 -0.03 -0.02 - -

N orm alized d is ta n c e from s u b s tra tu m

-------- X + + -------- X+- * ..........X-

Figure 27. Case 3, Run 2 - Predicted volume fraction profiles o f X4"1", X+'

and X phenotypes in the biofilm over ports 2, 5 and 8.

1

46

c

O

C

0)

O

C

O

O

0)

C

0)

3

£

x

Predicted effluent

Experimental middle

Experimental influent

----- Predicted effluent

Predicted middle

Figure 28. Case 4, Run I - Predicted and experimental vapor phase toluene concentration

profiles.

r e

2

0.6

- -

0.5 --

> 0.4 -a? 0.3 -c 0.2 -0.1

- -

30

time [d]

•

Experimental ----- Predicted

Figure 29. Case 4, Run I - Predicted and experimental toluene degradation rate.

Section 3

Section 1

0.35

-■

Toluene I Ii

[g m"3]

0

0.6

- -

0.30

Oxygen

0.8

0.40

1 j p 0.25

0.5 - ■

0.4 --

o E 0.20

® 2

O

0.2 - ■

0.1 - r

0.15

0.10

0.05

0.00

0

Normalized distance from substratum

0.8

1

Section 4

0.40

0.40 ■■

0

0.35

I 6

0.30

5

1 j p 0.25

4

o E 0.20

3

--

0.15 -

§ 2

0.15

0.10

O

0.10

2

0.05

I

--

0.05 • ■

Oxygen

Toluene I Inter.

[g m 3]

0.6

Normalized distance from substratum

Section 2

0.20

0.4

1------ Toluene..........Intermediates-------Oxygen

---- Toluene.......... Intermediates-------Oxygen |

0.30 -0.25 --

0.2

0.00

0

Normalized distance from substratum

Toluene......... Intermediates-------Oxygen

0.2

0.4

0.6

0.8

I

Normalized distance from substratum

-------Toluene..........Intennediates-------Oxygen |

Figure 30. Case 4, Run I - Predicted concentration profiles of toluene, oxygen, and intermediates in the biofilm at day 50.

Section 3

Section 2

Section 4

Volume fraction

Volume fraction

Section 1

0.07 --

0.07 --

0.06 - -

0.06 - '

0.05 • -

0.05 - -

0.04 - -

0.04 --

0.03 --

0.03 --

0.02

0.02

--

.p

OO

--

0.01 - i _ .

Normalized distance from substratum

X ++------ X + -..........X-

Normalized distance from substratum

-----x++-----x+......... x-

Figure 31. Case 4, Run I - Predicted volume fraction profiles of X h", X+*and X' phenotypes in the biofilm at day 50.

49

O O) 400

0

10

x

20

30

time [d]

Experimental influent

m

40

50

60

Experimental effluent

--------Predicted effluent

.........Predicted middle

Figure 32. Case 4, Run 2 - Predicted and experimental vapor phase toluene concentration

profiles.

2.5 -2.0

- -

1.5 --

0.5 -

30

time [d]

•

Experimental----- Predicted

Figure 33. Case 4, Run 2 - Predicted and experimental toluene degradation rate.

Toluene / Oxygen

[g m"3]

Section 1

Section 3

14 «

10 "O •.

3 " Z-ZTIT"

0.2

Normalized distance from substratum

Toluene / Oxygen

[g m"3]

T 18

' 16

14

12

" 10

8 I 2

6

4

2

k

I

4o

0.6

0.8

Normalized distance from substratum

-T oluene------ Oxygen

•Intermediates

0.8

• Intermediates

-T oluene------ Oxygen

Section 2

0.4

0.6

Normalized distance from substratum

------ Toluene------- Oxygen........... Intermediates

0.2

0.4

1

c

O

Section 4

7 -c

6 --

Ln

O

1 - 4

i l = '

Ii-

21 .."

0 -0.2

0.4

0.6

0.8

Normalized distance from substratum

-Toluene------ Oxygen

• Intermediates

Figure 34. Case 4, Run 2 - Predicted concentration profiles of toluene, oxygen, and intermediates in the biofilm at day 50 .

Volume fraction

Section 1

0.06

0.05

0.04

0.03

0.02

0.01

Section 3

0.08

0.07 -t____________________________________________________

o 0.06--

--•-

2 0.05--

0 0 04"

1 0.03-O 0.02 --

---

>

Normalized distance from substratum

0.01

-

............ .....L . „ „ . . . . . . .

0 - t-------------- 1----------------1--------------------------------1----------—

0

0.2

0.4

0.6

0.8

1

Normalized distance from substratum

-X++ — —X + -........ X-

' l l — x + + ------ x+.............X-!

Volume fraction

Section 2

0.07

0.06

0.05

0.04

0.03

0.02

0.01

---->

--

Section 4

0.07

0.06

0.05

0.04

-----

0.03 -0.02 - 0.01 - -

---

Normalized distance from substratum

X++------ X+-..........X-

Normalized distance from substratum

X++------ X+-......... X-

Figure 35. Case 4, Run 2 - Predicted volume fraction profiles of Xh", X+' and X' phenotypes in the biofilm at day 50.

52

DISCUSSION

Case I

The initial goal of this experiment was to determine the net bacterial detachment rate

from the provided experimental data, assuming that the only significant processes occurring