Document 13515999

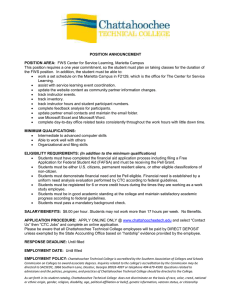

advertisement