Instrumentation requirements and design of a facility for turbulent natural... by David Allyn Pracht

advertisement

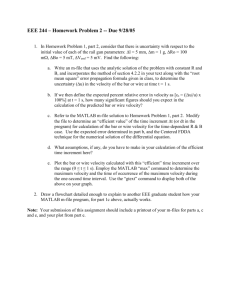

Instrumentation requirements and design of a facility for turbulent natural convection studies by David Allyn Pracht A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science in Mechanical Engineering Montana State University © Copyright by David Allyn Pracht (1983) Abstract: A facility was designed and constructed which is to be used for turbulent natural convection boundary layer studies in air adjacent to a heated vertical thin wire. The apparatus was shown experimentally, by the use of anemometer bridge voltage output fluctuations, to be of a suitable size to achieve fully developed turbulent flow. From these fluctuations transition to turbulence has occurred by Rax. = 1.2x10^10 and by Rax = 7.8x10^11 the flow has become fully turbulent. Measurements of the mean velocity and temperature profiles were made and the qualitative results obtained compare very favorably with experimental data of other research efforts. As the distance along the wire is increased the mean velocity profiles indicate a decrease in maximum velocity and a widening of the velocity boundary layer. The temperature profiles tend to retain the same basic shape over the entire length of the wire. A slight increase in the thermal boundary layer thickness was observed as measurements were made further up the heated vertical wire. INSTRUMENTATION REQUIREMENTS AND DESIGN OF A FACILITY FOR TURBULENT NATURAL CONVECTION STUDIES By David A l Iyn Pracht A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science " in Mechanical Engineering MONTANA STATE UNIVERSITY Bozeman, Montana March 1983 main UB Pg'gs ii dop. £ APPROVAL of a thesis submitted by David A l Iyn Pracht This thesis has been read by each m e m b e r of the thesis committee and has been found to be satisfactory regarding content, E n g l i s h usage, format, citations, b i b l i o g r a p h i c style, and consistency, and is ready for submission to the College of Graduate Studies. Committee Date Approved for the Major Department Date H e a d , Major Department Approved for the College Date of Graduate Graduate Dean Studies iii STATEMENT OF PERMISSION TO USE In. p r e s e n t i n g the requirements University, I this for thesis in partial a master's agree th a t the degree fulfillment at M o n t a n a Library shall quotations permission, from this thesis are allowable State make a v a il ab le to b o r r o w e r s und er rules of the Library. without of it Brief special provided that accurate acknowledgment of source is m a d e . Permission reproduction professor, when, this or in his in the material of for is opinion for extensive thesis absence, may quotation be g r a nt ed by by the Director of either, the p r o p o s e d scholarly purposes. from my or major of Libraries use Any copying of or use the of the m a t e r i a l in this thesis for fi n a n c i a l gain shall not be allowed without my written permission. Date V ACKNOWLEDGEMENTS The pr es en t appreciation this au th or w i s h e s to the following to express his for their thanks contribution and to investigation. His support advisor. throughout Bill this Bob Warrington, Martindale for his gu id an ce and investigation. Ron Mussulman and Anthony Demetriades, for serving as committee members and reviewing this thesis. Gordon Williamson, their helpful maintenance And State this the Pat V o w e l l assistance in of the experimental Mechanical University, investigation. for the construction for an d apparatus. Engineering financial and L u t h e r Hartz Department assistance and of Montana funding of vi TABLE OF CONTENTS CHAPTER PAGE LIST OF T A B L E S . . . .......... ..... .................. ..... vii LIST OF F I G U R E S ....... .............. ..... .............. viii N O M E N CL AT UR E ... .......... ABSTRACT.................. 1. 2. 4. I STATEMENT OF THE PR O B L E M .......................... 2 LITERATURE R E V I E W ... ........................... 3 4 5 10 EXPERIMENTAL APPARATUS AND P R O C E D U R E .............. 16 HEATED VERTICAL WIRE AND S H R O U D .................. HOT-WIRE AN EM OM ET R Y. .......... ............... ..... CALIBRATION FA C I L I T Y .............. EXPERIMENTAL PRO CE D UR E ....... ..................... 16 20 21 25 EXPERIMENTAL RESULTS AND DISCUSSION............ .. 29 MEAN TEMPERATURE RE S U L T S ............ ........... . . MEAN VELOCITY RESU LTS .. .-----------------------ANEMOMETER OUTPUT FL U CT UA TI ON S.... .............. 5. xii INTRODUCTION AND ST ATE ME NT OF THE P R O B L E M ...... NATURAL CONVECTION - TR A N S I T I O N .................. NATURAL CONVECTION - T U R B U L E N C E .................. VELOCITY MEASUREMENT T E C HN IQ UE S............... . . . 3. ix CONCLUSION AND RECOMMENDATIONS FOR FURTHER W O R K . . 29 32 38 ' 42 RECOMMENDATIONS FOR FURTHER WORK. ................ 43 REFERENCES CI TE D. ................ 46 APP EN DI X .. .. . .......... . ................................ 49 MEAN VELOCITY AND TEMPERATURE D A T A ............... 50 vii LIST OF TABLES Table Description I. Velocity Boundary Layer Thicknesses for Distances Along the Heated Vertical W i r e ..... 35 Dimensionless Numbers Used in the Experiment.. 40 2. Page viii LIST OF FIGURES Pa^e Figure 1. Tower with Supporting S t ru ct ur e.... . 17 2. Schematic of the Test Facility with Supporting Instrumentation. ......... 18 3. Pexiglass with Aluminum Connecting Straps..... 23 4. Calibration Equipment and Instrumentation.... 23 5. Experimental Equipment and Hot-wire Anemometer Ins trumentation...................... 27 Orientation of the Hot-wire Probe to the Heated Vertical W i r e ............... 27 Mean Temperature Profiles for the Air Adjacent to the Heated Vertical W i r e . . . . . ............... 30 Mean Temperature Profiles for the Air Adjacent to the Heated Vertical W i r e . . . . .... . 31 Mean Velocity Profiles for the Air Adjacent to the Heated Vertical Wi r e . . . . . . . ............ 33 Mean Velocity Profiles for the Air Adjacent to the Heated Vertical Wi re .. .. .. .. .. .. ...... 34 Maximum Anemometer Output Fluctuations for the Air Adjacent to the Heated Vertical Wire...... 39 6. 7. 8. 9. 10. 11. ix NOMENCLATURE Symbol Descript ion C S p e ci fi c heat at co nstant pressure, ( JZ k g 0C ). CF Correction factor used to correct bridge voltage output for variations in fluid temperature. e Local kinetic energy flux, e = G '(v^Z g,x^ )^ Eb Anemom eter bridge fluid temperature, output EC Anemometer bridge voltage output overheat resistance, volts. g Gravitational acceleration, (9.81 mZsec ). G* 5(Grx *Z5)1 / 5 . Gr x Grashof number, •*,* Modified Gra^shof number for surface, Grx = gflxq'Zkv • h Heat t r a n s f e r ( WZ m2oC ). k Thermal Nux Nusselt number Nux = hxZk. Pr Prandtl q' Uniform heat flux, BTUZhr ft2 ( WZm^ r d i st a nc e ( cm ) . R Change in overheat resistance to simulate fluid temperature variations, ohms. Rh Overheat probe voltage volts. fr om with . variable with variable 32.17 ftZsec 2 3 2 Grx = gpx ATw Zv c o ef fi ci en t, conductivity, number, B T U Z l b 0F uniform heat flux B T U Z h r f t P t 2 P t 0F BTUZhr ft°F ( W Z m 0C ). Pr = pcZk. the h e a t e d v e r t i c a l resistance, ohms. ). wire, in. X Symbol Description Rax Rayleigh number, a*:* Modified Rayleigh number for uniform heat flux surface, Rax = Grx Pr. T Mean temperature Tc Calibration temperature 0F (0C). T o Reference Rax = GrxP r . of the fluid, 0F (0C). of the hot-wire sensor, temperature, 0F (0C). Ts Hot-wire sensor temperature, 0F (0C). TW Temperature Tro Ambient AT Local (0C) . AT W Surface (0O . U M e a n v e l o c i t y i n t h e x d i r e c t i o n , ft / sec (m/sec). X Distance from the leading edge of the plate/ w i r e , ft (m). y Horizontal (cm). a Thermal P Coefficient 8V Velocity boundary layer thickness, n Inner length scale for constant temperature surface, n = [a ZgP(Tw -T00)] ' . X Resistance coefficient of temperature wire sensor, I /0F (IZ0C ) . p- viscosity, V K i n e m a t i c v i s c a s i t y e v a l u a t e d at the m e a n temperature, ft Zsec (m /sec). of the heated surface, temperature, temperature temperature di st a n c e 0F (0C). 0F (0C). di fference, AT = T- T00, 0F difference AT from = T -Tco, 0F the flat plate, in. diffusivity a = k/pc. of thermal IbZsec ft expansion, I/ 0F (I /.0 C ) . in. (cm). for hot­ (kg/sec m). Symbol Descr it)t ion vw Kinematic visco|ity evaluated at the surface temperature, ft /sec (m /sec). V 00 Kinematic viscosity evaluated at the ambient temperature, ft^/sec (mi /sec). P Density, IbZft^ (kg/m^). xii ABSTRACT A facility was designed and constructed which is to be used for t u r b u l e n t natural c o n v e c t i o n b o u n d a r y layer studies in air a d j ac en t to a h e a t e d v e r t i c a l thin wire. The a p p a r a t u s wa s s h o w n e x p e r i m e n t a l l y , by the use of anemometer bridge voltage output fluctuations, to be of a sui tab le size to ac hi eve fully d e v e l o p e d t u r b u l e n t flow. From these f l u c t u a t i o n s t r a n s i t i o n to t u r b u l e n c e has o c c u r r e d by R a 5. = 1.2x10 and by R a 3, = 7.8x10 the flow has b e c o m e full y turbulent. M e a s u r e m e n t s of the m e a n v e l o c i t y and t e m p e r a t u r e p r o f i l e s were m a d e and the q u a l i t a t i v e resu lts o b t a i n e d c o m p a r e very f a v o r a b l y wi t h e x p e r i m e n t a l data of other r e s e a r c h efforts. As the dis ta nc e along the wi re is i n c r e a s e d the m e a n v e l o c i t y p r o f i l e s ind ic at e a dec r e a s e in m a x i m u m v e l o c i t y and a widening of the velocity boundary layer. The temperature p r o f i l e s tend to re t a i n the same basic shape over the entire le ngt h of the wire. A slight increase in the thermal boundary layer thickness was observed as measurements were made further up the heated vertical wire. I CHAPTER I . INTRODUCTION AND STATEMENT OF THE PROBLEM A thorough transition understanding and t u r b u l e n c e development and relationships profiles in the and of free general t u r bu l e n t in na tur e initial free to convective fo r c e d stages turbulence accurate co n v e c t i v e mathematical mechanics of the is transition both elusive stage within Generally turbulence. ho we v e r , an velocity considered the similar Beyond the the m e c h a n i c s fairly unclear, models and layer, a t m o s ph er e. turbulence still reactor, m a n y studies of temperature boundary of transit io n, are continued nuclear To date, of turbulence have provided Nusselt e n c l o s u r e s and in an inf inite onset mechanics to the of aerospace, and t u r b o m a c h i n e r y technology. number the is e s s e n t i a l advancement forced and free convective of with simple goal. are The even less of and actual well defined. In th i s ve l o c i t i e s , fluctuations further process. st ud y, mean the distributions temperatures, have be e n definition Measurements and investigated of the were of the turbulent in order turbulent free mean velocity to provide convection taken at four locations in the 2 IA range of field I9 10 around < R a x < 10 a 24.0 ft. in the buoyancy driven (7.32 m) long heated vertical flow wire. Air was used as the fluid m e d i u m . STATEMENT OF THE PROBLEM The objectives of the investigation may be summarized as : (1) To give show that turbulent (2) To the facility.is of suitable size to flow. show that the instrumentation used is adequate to make temperature and velocity measurements. (3) To experimentally velocity and mean range of values (4) To determine temperature profiles in the boundary of mean layer over a of the Rayleigh number. estimate the boundary layer size at v a r io us locati ons . It was en co un t er ed , realized, after that a t t a i n m e n t several problems of the second o b j e c t i v e was not p o s s i b l e w i t h the time and r e s o u r c e s available. will be discussed further were in Chapters 4. and 5. Th i s 3 CHAPTER 2. LITERATURE REVIEW The problem of turbulent natural layer flow, next to a h e a t e d v e r t i c a l subject of numerous efforts to date dynamics of the studies have temperature depended surface has be e n the Almost on all profiles flow boundary and theoretical analogies layer. fluctuations, and with the Experimental included heat transfer relations, typic al cu rve d have forced of the mechanisms with investigations. convection boundary velocity and investigations involved in the transition to turbulence, geometries be in g the flat plate as well as surfaces. The b u o y a n c y induc ed fl o w of a fluid al on g a surface can be d i v i d e d into three regions: tu rb ul enc e, and analyzed by many discussed turbulent. The investigators further. The laminar, laminar region in the past remainder of t r a n s i t i o n to has be e n and will not be th i s chapter is intended to provide a useful background for this particular investigation and convection research. is not The a complete following surve y of discussion will natural include the t r a n s i t i o n to tur bu l e n t and turbu le nt studies done in the past. A discussion of velocity measurement techniques 4 used by previous transfer investigators is also of natural convection heat included. NATURAL CONVECTION - TRANSITION The mos t ex t e n s i v e work in the field of natural c o n v e c t i o n t r a n s i t i o n has b e e n c a r ri ed out by B. Gebhart and his c o l l e a g u e s Gebhart [13] correlated have [4], [13], [14], and [15]. postulated that J a l ur ia and transition events by the ratio of the modified Grashof the characteristic length, can be number to x, raised to an empirical power, n: G / x 11: wh e r e x is the d i s t a n c e from the l o w e r edge of a vertical flat plate and n is of the order 1/2. At the first t r a n s i t i o n e v e n t , from l a m i n a r to t r a n s i t i o n flow, the ratio is p r o p o r t i o n a l to a p a r a m e t e r local k i n e t i c en e r g y flux, with water separately wh er e the va lue s the at velocity e = Prand tl and and number 15.2, is the . In studies transitions r e s p e ct iv el y. on the order of coincide. A value of In 0.7, e occur air, these the development of fully turbulent flow was not identified. In of the nearly thermal ) as for te rm s should 13.6 e = G (v/gx defined R a y l e i g h n u m b e r m o d i f i e d for * con st an t heat flux on the wa l l surface, Ra^ , Q u r es hi and Gebhart of 1.2 [4] x conventional have I O 13 identified transition points < Rax* < 4 x transition and 5 x 10 ^ 3 < R a x turbulence. These values agree I O 13 as the in the range beginning of < 1 0 ^ ^ for fu ll y d e v e l o p e d fairly well with the ranges 5 o b t a i n e d by Vlie t and Li u point [6] define wh er e decrease. and Li n the the as measured fluctuations the in earl ie r initial Cheesewright turbulence [6] transition surface [10] point has where studies. event temperature defined Vliet the as the begins to beginning of significant temperature in the b o u n d a r y layer be g i n to occur. Both studies d e f i n e d the end of t r a n s i t i o n as that point wh e r e the respective temperature fluctuations decreased. NATURAL CONVICTION - TURBULENCE The earliest attempt convection boundary Eckert on the and Jackson assumed convection. This to analyze the turbulent natural layer [7] on vertical whose empirical similarity analysis provided for the rate of heat transfer, co n s i s t e n t profile [10]. with and - J a c k s o n was due to approach was based forced and free reasonable predictions but has not been found to be experimental obtained by Warner Ec ke rt between surfaces data for the m e a n v e l o c i t y and Arpaci [1] or Cheesewright [7] found the heat transfer- Rayleigh number relation to be: N u x = ( .021)Rax2 / 5 . More s u c c es s fu l (2.1) r e c e n t l y there have b e e n a n u m b e r attempts to ap p l y turbulence of p a r t i a l l y computational models to the calculation of buoyant flows next surfaces. assuming Kato e t a I [12] an eddy a p p l i e d the diffusivity in tegral to vertical m e t h o d by relationship and a 6 distribution of the heat so derived flux across the profiles than assuming the boundary layer and of velocity and temperature rather t h e m . They then found a local Nusselt number relation to be: Nu x = .149[(V/a)^175--SS](Grx ) *3 6 . The Eckert re su lts and are Jackson integrated the not [7]. continuity, numerically. In very their different Cebeci and momentum, study (2.2) from Khattab and energy they consider those [8] of have equations the eddy viscosity formulation developed for forced convection flows and ap pl y it to free convection transfer rates, velocity profiles, on v e r t i c a l number flat plates. ve rs us experimental of the coefficients. empirical constants they were able with number Eckert av a i l a b l e heat curves the ir Nuss el t agree [1] with the but disagree and Jackson. [9] used a modification of a program Patankar-Spalding transfer predict and temperature profiles data of W a r n e r and A rp ac i and Seban to Th e y re port that Rayleigh with the predictions of Mason flows type After adjusted to a numerically substantial to fit the predict heat exploration experimental of data, to ob ta in r e s u l t s that a g r e e d f a i r l y well measured data. Their report also used ' turbulence parameters which successfully predicted forced c o n v e c t i o n fl o w s m o d i f i e d for free c o n v e c t i o n flows from vertical surfaces. 7 A more Capp [2] recent ana ly s i s has been done by George and in which classical scaling arguments were used to pr e d i c t the ex i s t e n c e of a two layer turbulent natural c o n v e c t i o n b o u n d a r y layer for f l o w s ad ja ce nt to ve rt i c a l heated surfaces. The two layers include: an outer region c o n s i s t i n g of mo st of the b o u n d a r y layer in w h i c h v i s co us and conduction terms which the layer is mean are negligible, convection identified as of several negligible. heat compared well The flux with layer. inner The experimental authors. Many different temperature are a co ns t a n t results of their analysis data terms and an inner region in and measurements velocity of the heat profiles have transfer and been tu r b u l e n t na tu ral c o n v e c t i o n past a vert i c a l made for surface. The mo s t c o m m o n g e o m e t r y used has b e e n the flat plate. One of the e a r li es t conducted mos t recognized Cheesewfight wo rk s was p r o f i l e s next to a con sta nt t e m p e r a t u r e wall in air. Both distance were the plate experiments numbers layer we r e and wall reported temperature as For Grx > 2x10"*"® the boundary being e n c o u n t e r e d was due to the side turbulent. screens causing a lack of two-dimensionality, that the plate was varied. ca r ri ed out over a range of Grashof from IO^ to 1.5 xlO^^. is who these temperature along [10], of measured The by and sufficiently wide On e problem of the ap pa r a t u s but Cheesewright felt so that measurements 8 down the c e n t e r — line were not significantly affected. Temperature profiles are plotted as ATZATw versus so that Capp the b u o y a n t [2], collapsed appea rs to subrange, as p r e d i c t e d by George as a straight a single curve, line. but appear, as wel l as the The also defined inverse cube root region where would — (y/n) data not exhibited the buoyant linear r eg io n 1/3 ' and only a well sublayer next to the wall. The data are shown to be in reasonable agreement with the empirical results of Eckert and Jackson [71 also. More recently Cheesewright and Doan [21] have measured spacial correlations normal and l o n g i t u d i n a l fluctuations to a heated vertical flat plate space-time in the t u r b u l e n t regions. correlations transition and turbulence structure was noted the dissipation length by and Another undertaken slow Warner and su bl a y e r was the temperature flat plate Arpaci in air, most [1], dimensional dis ta nc e from the of geometry usi ng a was single constant of the t e m p e r a t u r e profile data could be c o l l a p s e d w h e n p l o t t e d as the of scales aluminum flat plate. They showed that for a single wall sublayer variation length Also to the wall. investigation of the by outside correlation turbulence with distance normal developed from that outside. a fairly uniform as fully The flow in the viscous shown to be relatively independent found, of t e m p e r a t u r e the wall. A T /A T w v er su s y, An e x p e r i m e n t a l 9 study done by Fu ji i ethyleneglycol relationships boundary [11] provides ba s e d with the following on t e m p e r a t u r e Comparison [1] ag re em en t . used 4.34, of at This are useful in his because Nusselt in number distributions in the Rax < 8.5 xlOy .49(Ra )1/4 (2.3) Nux = .87(Rax ) 1/4 Fujii cylinder layer: Nu, Ar pa ci a vertical these results similar seem s to in dicate It curvature of Warner that sh ow s the number a length apparatus range, effect. There poor have were of (Pr=SS), / diameter may and re l a t i o n s sh ould be no t e d h o w e v e r dimensions, cylindrical those numbers only in the Prandtl of physical significant with Rayleigh e x p e ri me n t. Fujii's 8 . SxlO9 < Rax <8xl010 that ratio = produced a no velocity profiles measured for this geometry. Fu j ii e t a I [3] experiments usi ng temperature. entirely conducted vertical Since g o v e r n e d by the the an extensive cylinders at heat transfer wall layer, co ns ta nt at greater as long as the than the wall layer radius measured onto over a wi de a single curve range is expected same as that They found is much that for the temperature profiles of w a l l over most of wall wall of curvature thickness. a narrow range of Prandtl numbers, the it can be that the heat tr a n s f e r r e l a t i o n will be the for flat plates series conditions of the b o u n d a r y collapsed layer. The 10 profiles for different oil, substantially as expected. and Mobil therm different The ir Prandtl resu lt s numbers for w a te r, were spindle oil could be shown to correlate as: (Mux )(VwZv00)-21= .13 (Rax ) 1/3 (2.4) 1010< Rax These results are in excellent agreement with George and Capp [2], It wa s also d e t e r m i n e d by m i r a g e method based on the principle the fluid rise, that in the boundary layer that turbulence oil. Again, method, the refractive decreases with be g a n at R a x = 2 x I 0 there were no velocity profiles II a index of temperature for spindle given. VELOCITY MEASUREMENT TECHNIQUES Although the main turbulent flo w make measurements some region, calibration purposes. measuring tu r b u l e n t latter, of flows. it was none the be flow, in the in te n d e d particularly as both For me a n v e l o c i t y w as desirable such velocities work the less therefore should mean of in laminar It was technique measurement in te re st to in to for that the permit the laminar an d m e a s u r e m e n t s in the the output of any suitable measuring instrument had to be capab le of be i n g a v e r a g e d over a p e r i o d of one m in ut e or longer, be c a u s e of the e x p e c t e d low f r e q u e n c i e s of the turbulence.velocities below, Many techniques have been along with developed a for the measurement and discussion several of are three of fluid described calibration 11 procedures [16], that have Cheesewright been used by Hollasch and Gebh ar t [10] and Aydin and Leutheusser [22]. One of the most commonly used techniques for measuring flow v e l o c i t i e s difference is that i n v o l v i n g the m e a s u r e m e n t between the local static pressure stagnation pressure at a point in the fluid, static tube and some form of manometer. ob vi ous that this present problem tec hn i q u e because cou ld the much accuracy, period too small and the local using a pitot- It was immediately not maximum be us e d pressure involved would be of the order of 9x10 * in. water, of the in the difference (2x10 ^ cm) of to be m e a s u r e d w i t h any degree of p a r t i c u l a r l y in v i e w of the need for long time averaging. A straight forward tracer p ar ti cle s, mo s t optical technique often h e l i u m of photographing filled bubbles, and measuring track lengths has been used with limited success. This method would require a large the an a l y s i s would not of be fluctuation accuracy ba s e d to measurements near due to the make of the in turbulent velocity the random he a t e d of work type flow. and needed movement vertical involving of wire It velocity in the where this air good is essential. Another is p'h o t o g r a p h s s u f fi c ie nt in ve s t i g a t i o n , especially the amount on commonly used technique, the relationship hot-wire between the anemometry, rate of heat 12 tr a n s f e r fro m a h e a t e d w i r e and the v e l o c i t y of the fluid flowing past it. eventually used Since to make this w as velocity the method measurements, that was its use in p r e v i o u s natu ral c o n v e c t i o n heat tr an sf er i n v e s t i g a t i o n s an d the respective calibration procedures, discussed in the remainder of this Although gr e a t e r simple hot-wire than task determine 10.0 using (3.0 is far more can accurately comparable determine which an anemometer output problem signal ma k e s is relatively a calibration at One reason is due to the pitot-static low velocities can be matched. convection flow s calibration facility experimental apparatus. that sensor combined with the are to be me a s u r e d . is the same as that in the Since the anemometer output bridge voltage be in g wi t h Another it n e c e s s a r y that the d i r e c t i o n of the fl o w by the to encountered is due to the importance of the natural convection cooling of the hot-wire fo rc ed velocites, and thermocouple complicated. to the lack of an instrument that tube high a known velocity and temperature, low velocities tube at m/sec), a pitot-static be chapter. , calibration ft/sec will temperature me as ur ed , temperature correction as well as calibration encountered in the v e l o c i t y must the be flow factor becomes necessary. made or a This in the actual is governed of the fluid at the exact temperature 13 Hollasch calibrating variations and a Ge bh ar t presented constant-temperatnre in fluid temperature. varying the fluid temperature wire analytically ove rh ea t [16] overheat rel at in g re s i s t a n c e calibration relation anemometer was (E^). order c o r r e c t i o n term to account probe of for consisted of at a constant then output w i t h (Ef,) to a n e m o m e t e r temperature variations method hot-wire Their method during A a derived a va ri ab le output w i t h fluid Their relation, with a first- for p r o p e r t y v a r i a t i o n s is : (2.5) An experimental and G eb ha rt error study to v e r i f y in velocity was the then presented analysis. measurements by Hollasch The m a x i m u m without using percent the property correction term was approximately 9.0%. variable The error is not significantly improved using the correction term, fact, the natural error is greater convection in the caused low velocity range where by the temperature is equally as important the of the wire. cooling correction term Three were longitudinal use hot-wire by and sensors, Bill and no r m a l sensor as forced convection in of the variable is not recommended by the authors hot-wire used The in calibrated Gebhart components in [14] of property [16], this manner, to measure velocity in the 14 transition layer flo w re g i m e adjacent surface. to These a of the b u o y a n c y con s t a n t measurements characteristics and beat were pr o f i l e s flux used of induced boundary vertical to determine velocity flat growth fluctuation levels. Cheesewright distributions layer, as a used of m e a n the calibration laminar boundary Grashof number ambient wa s given at different In each calculated were layer, distribution and by test fr o m selected of theoretical the theoretical as to layer velocity Three positions in the local local the (plate) plate cold and the power at a n u m b e r so the the the boundary theory. R e a d i n g s -of then made determine boundary that that made layer. convection the hot. wire resistance, the hot wi re r e ad in gs was to a turbulent assuming temperatures. resistance, boundary were in natural medium, therein tests attempting velocity laminar calibration distribution [17], a velocities. velocities, wire input to of point s gi v e and in the reasonable From values these of the N u s s e l t and R e y n o l d s n u m b e r s for the h o t - w i r e probe were calculated and these results were then graphed. It was c o n c l u d e d by the a u t ho rs that the c a l i b r a t i o n curves o b t a i n e d in this m a n n e r m a y have be e n in error by up to 15% for the h i g h e s t R e y n o l d s divided into two parts. One due numbers. This error was to the assumption that the 15 velocity was that given by theory and the errors in measurements. may be made anemometry velocities by An estimate considering measurements with of the first a comparison of other was due to laminar of these of other hot-wire natu ra l convection the th eo ry and wa s r e p o r t e d to be of the order of 10%. Aydin and Leutheusser consisting of a square its b o t t o m surface. inside base distance. 10.0 used to switches wi t h at the (3.0 m/sec), experimentally which was slot in two end points carried out and in excellent timed over a digi ta l the calibrated determine agreement tim er of the in the range of d i s t r i b u t i o n in l a m i n a r plane Coue tt e flow. obtained were facility tube with a narrow distance Calibration was ft/sec a towing The probe to be c a l i b r a t e d was m o v e d m e a s u r e d base actuated by magnetic were aluminum used the tube by a towing carriage, a precisely 0 to [22] the probes velocity The results with the analyticalIy predicted linear velocity distribution. 16 CHAPTER 3. EXPERIMENTAL EQUIPMENT AND PROCEDURE HEATED VERTICAL WIRE AND SHROUD A 0.035 was in. (0.89 cm) d i a m e t e r supported cylindrical lb. (2.04 fr o m a beam a cr os s cylindrical weight, surface for the exp eri m en t . te n s i o n on copper the ce nter the wi r e and provided of a to keep the To each of the two ends lead wire was v o l t a g e to the wir e attached The later to be of wire' st raight and these leads were W i t h this v a r i a c the the t e m p e r a t u r e of the l e n g t h of the h e a t e d wi r e after applying voltage was 24.0 ft. demonstrated he ated of this h e a t e d wire a a nd and t h e r e f o r e could be controlled. the The w e i g h t was used to keep c o n n e c t e d to a va r i a c p o w e r supply. wire top which shroud and w e i g h t e d at the b o t t o m w i t h a 4.5 kg) vertical. tin alloy wire, (7.32 m), which will sufficient length be to obtai n fu ll y t u r b u l e n t flow. The he a t e d investigation, illustrated by a 5.0 in Figures was to minimize to not ve r t i c a l interfere ft. was (1.52 I. and 2. ambient with wire m ) diameter The purpose influences the natural surrounded and yet be in this shroud of the shroud large enough convective flow from the 17 Figure I. Tower with Supporting Structure 18 Figure 2. Schematic of the Test Facility with Supporting Instrumentation 19 heated vertical 4.0 ft. (1.22 (0.32 cm) a wire. m) It w as c o n s t r u c t e d by p l a c i n g two by 8.0 ft. plexiglass end to end cylinderical section (2.44 by m) sheets of 0.125 and then forming placing the two them fr e e in. into ends together. P l e x i g l a s s was used b e c a u s e / v i s i b i l i t y through the shroud was and for essential determining for flow visualization an initial radial techniques distance from the wire. An a l u m i n u m pla te 2.5 in. (6.35 cm) wide by 0.375.in. (0.95 cm) entire th ic k 4.0 ft. with a groove (1.22 m ) l e n g t h was the ends of these plexiglass of this 0.375 plate along a slot in. (0.95 cm) was wide w h i c h in t e r i o r of the shroud. 46.0 edge used to h o l d sheets* cut either of its to ge t h e r Along the center-line in. (116.8 cm) long s e rv ed as an access by to the T h r o u g h these slots the hot wire probe and support was placed and the measurements were made radially outward from the heated vertical wire. Five stacked on of top these of c o n s t r u c t e d of 0.125 d e s c r i b e d above was masonite through was the used cylindrical one and a pl ac ed on the b o t t o m reduce section was costs not were sixth in. (0.32 cm) m a s o n i t e to help bottom an o t h e r sections then section in the m a n n e r as a base. The since v i s i b i l i t y required for the expe rim ent . The plexiglass and together with an aluminum masonite connecting sections strap, we r e 0.375 f it te d in. (0.95 20 cm) th ic k by 0.75 and b o t t o m in. (1.91 of a d j ac en t cm) wide, se ct io ns by p l a c i n g the top into a 0.25 in. (0.64 cm) deep groove that had be e n cut along either edge. A detail of the c o n n e c t i n g ea r l i e r is section s straps shown gave a in Fi gu re total b o t t o m of the to w e r and the 3. height g r o ov ed plate described on These of page 24.7 23. ft. (7.53 six m). The rest ed on a p a r t i c l e b o a r d pl at fo rm , while a masonite top was used for complete enclosure. HOT-WIRE ANEMOMETRY Constant temperature hot-wire anemometry equipment was utilized for all investigation, equipment only and since measurements the description further details to — [20]. Basically, concerning hot-wire in the theory of hot-wire operation has become a br ie f [18] velocity well will the be known anemometry anemometry in recent years, presented following present here. For discussion refer is concerned with the determination of the convective heat transfer from a heated wire as fluid composition depends only moves remains past constant, the the wire. If the convective heat on the fluid velocity, temperature fluid transfer difference, b e t w e e n the wir e and the fluid, and the fluid t e m p e r a t u r e and t h e r m o d y n a m i c propert ie s. hot-wire anemometer, con st an t temperature, In a co nstant t e m p e r a t u r e the h e a t e d sensoris m a i n t a i n e d at a so that in an i s o t h e r m a l flow the 21 heat transfer Maintenance depends of the wi re obtained by connecting br id ge circuit. changes, required As a change circuitry The a the wire the means td the current mean converted before past the wire t h r o u g h the wi r e loop. output and this The bridge is is anemometer voltage is through the hot-wire. to the m e a n flow dir ection, However, is leg of a Wheatstone temperature, the velocity. temperature velocity a feedback velocity conveniently measured by placing be as one fluid so that fluid co ns t a n t constant of longitudinal voltage. the in current p a s s i n g is arranged proportional upon at the to maintain accomplished by only the hot-wire can be probe normal and read in g the output bridge the to velocities, component output bridge it was voltages necessary to could determine the relationship between the two by means of a calibration. CALIBRATION FACILITY The calibration of the hot-wire probe was accomplished using a blower and duct work to determine once flow the flo w rate Meter. To necessary rate was to a have c o n s i s t e d of a bell duct work. the The e nt ra n ce th ro ug h the duct w o r k w as found. found find a known velocity by using velocity a a TSI from con st an t model this area test se c ti on w as and at a point w h e r e flow test shaped n o z z l e at the 4100 The Airflow rate it section was which en tr a n c e to the 18.0 in, (45.7 cm) from the d i a m e t e r b e c a m e a 22 con st an t used, 4.86 the support in. (12.34 cm). electronic with eq u i p m e n t , and 4. shows the the nozzle hot-wire probe the traverse. Br id ge v o l t a g e s this test F i gu re were r e c o r d e d at the c e n t e r - l i n e of section, and assuming a constant velocity profile with the mean velocity equal to the center-line velocity, a velocity was matched to each bridge voltage. Traverses of across the test one half the diameter se ct ion to d e t e r m i n e the v e l o c i t y p r o f i l e at each fl o w p r o f i l e s an ite ra t iv e were then made the actual rate used. shape of F r o m these p r o c e d u r e was used to correct the con sta nt v e l o c i t y p r o f i l e a s s u m p t i o n to d e t e r m i n e actual velocities at the center-line Once each constant the in the same Because it could experimental as of the heated vertical temperature. bridge varied It was voltages test calibrated temperature temperatures the was temperature, velocities at probe of the be in this used apparatus the wire greatly section. manner to determine if the fluid was calibration facility. in the experiment, from the the calibration therefore necessary to correct for temperature this at a each of difference. The mos t a c cu ra te a p p r o a c h is to c a l i b r a t e the probe over the range of temperatures experiment. voltages Measurement that of in the e x p e r i m e n t will be encountered in the temperature along with bridge would then be m a d e and these 23 Figure 4. Calibration Equipment and Instrumentation 24 bridge voltages recorded would be matched to a velocity for the temperature measured. H o w e v e r b e ca u se facility, one that w o u l d al lo w t e m p e r a t u r e s encountered used. of a lack of a suitable in the Therefore ex p e r i m e n t , the this method readings were calibration in the range could not be corrected by multiplying by the factor: CF = (3.1) as suggested in [20]. reported [2 Q ] temperature to The use of this correction factor is be satisfactory of a high speed flow, those encountered in the present the magnitude of the flow over fo rc ed h ig he r investigation. The should be g o ve r ns that natural convection the amount an in the of heat temperature difference in. (0.13 cm) fr o m temperature temperature was the wire between values and approximately difference, the than reason important convection cooling of the and the a m b i e n t transferred natural convection from a constant temperature The a is justified using an sensor wi r e at near zero v e l o c i t y flows, temperature with considerably velocity c o n s i d e r a t i o n is due to the fact dominates flows d i f f e r e n c e up to I O O 0F (56° C ) , a l t h o u g h this upper limit of temperature difference example in by sensor wire. measured at 0.05 calibration facility I O O 0F (56° C). This high along with the low velocity flows. 25 ra ise d c o n s i d e r a b l e questions as to the v a l i d i t y of this temperature correction multiplying factor. correction factor also neglects the The temperature effects that variable thermodynamic properties have on the fluid. A l t h o u g h there were the use several p r o b l e m s e n c o u n t e r e d in of this correction correction ma de for reduce the errors factor, temperature involved in using it remains variat io ns . the To only help this correction, to a high sensor temperature was used and the calibration temperature was increased to the highest the available equipment. obtainable By increasing these Equation 3.1 was made as near A Thermal anemometer, we r e utilized with 10% r h o d i u m (1.27 mm). able to (270 C) with temperatures. to one as possible. Inc. DC voltmeter, throughout t h e m s e l v e s we r e remounted Systems, digital (Si0F) the constant probe temperature and probe i nv es ti ga ti on . The probes a T S I m o d e l 1210 st an d a r d st ra ig ht probe a 0.0003 in. (0.007 6 mm) diameter platinum- sensor wi r e w i t h an active l e n g t h of 0.05 in. A probe locate the support probe traversing mechanism to w i t h i n 0.005 in. which was (0.127 a l l o w e d pr e c i s e p o s i t i o n i n g of the h o t - w i r e probe boundary support mm) in the layer. EXPERIMENTAL PROCEDURE The p o w e r applied to heat su pp ly was ac ti vated, and 45.0 volts were the vertical wire. This resulted in a power 26 consumption of of 700 watts, approximately sufficient 720°F warm-up temperatures and produced over period, the normally and v e l o c i t i e s a wire temperature entire length. A allowed the 48 hours, to stabilize in the b o u n d a r y layer. Data was then co l l e c t e d at 5.0, 10.0, 15.0, and 20.0 ft. (1.52, the wir e 3.05, 4.57, in the and 6.10 m) from f o l l o w i n g manner. connected to the probe traversing unit. Figure supp or t the b o t t o m end of A h o t - w i r e probe which 5. illustrates w as the held in the probe i n w a r d until the h e a t e d wi r e wa s obtained, from the linear u s u a l l y 0.05 in. (0.13 cm), to the probe heated support sensor wa s was was A strip voltage was turned t im e constants to on the and on the traverse. and support shown in F i g u r e to make heated the with wire. respect 6. certain The that the Next correct The the operating set. of r e co r d e r the 300 of the bridge the changes from one level to another. The DC con st an t was or graph was made anemometer in velocity fluctuations v o l t m e t e r time is then r o t a t e d chart output probe wire perpendicular anemometer resistance vertical from the heated wire was scale orientation of the hot-wire By a c e r t a i n d i s t a n c e from the location of the zero distance recorded the traversing unit, the h o t - w i r e a n e m o m e t e r and other r e l at ed eq ui pment. extending was to determine set at 100 seconds seconds was allowed and three to elapse 27 28 be for e the br i d g e v o lt a g e ou tput was di gi tal reado ut of the DC v o l t m e t e r . moved the recorded from The probe was the then to a ne w l o c a t i o n f u r th er from the h e a t e d wire and above procedure was repeated, until re a c h e d 24.0 in. (61.0 cm) from the wire. at each probe of the sta tio ns was the probe had The t e m p e r a t u r e found by using the h o t - w i r e as a r e s i s t a n c e t h e r m o m e t e r and r e c o r d i n g the cold resistance. Using these r e s i s t a n c e s the t e m p e r a t u r e was determined, f r o m a graph of r e s i s t a n c e versus t e m p e r a t u r e which had previously been made using known temperatures and recording resistances. Th e c o r r e c t e d for v a r i a t i o n s calibration correction factor, a velocity curve nine facility, was Eqn. using 3.1. versus velocity data points po int s points. we r e tak en The data bottom can be at 1.0 and end of the wir e to From bridge turbulence the the probe 2.0 to was then that of the mentioned corrected and twenty-five found from previously voltage at each level made transition the using Strip chart re c o r d i n g s were voltage in t e m p e r a t u r e determined of velocity bridge values calibration output. Twenty- temperature for a total of 216 data data in the Appendix. of the v e l o c i t y f l u c t u a t i o n s ft. (0.30 determine occurred and 0.61m) wh e r e and to make the flow was laminar in the lower regions. the from onset the of certain that CHAPTER 4. EXPERIMENTAL RESULTS AND DISCUSSION This chapter will present and discuss the experimental resul ts that were will be divided temperature into (3) fluctuations. temperatures anemometer form with three sections: measurements, measurements, boundary ob t a i n e d d ur in g the i nv es ti ga ti on . layer be of of mean and thicknesses output anemometer the shown, a will fluctuations Results of mean R e s u l t s of m e a n v e l o c i t y Results Profiles will (2) (I) It will output velocities discussion be be and of presented. given in the The graphical a d i s c u s s i o n th e re of and a c o m p a r i s o n to other investigators results will be included. MEAN TEMPERATURE RESULTS The distributions in Fi g u r e s local the that vertical the con sta nt basi c wire. The resu lt s fluid temperature versus heated graphs 7. and 8. of the mean temperatures are plotted wire. It temperature shape with The p r i m a r y effect extension of the thermal r, are in t e r m s the radial can be seen profiles seem increasing of T, distance from to distance the from these r e ta in along a the of i n c r e a s e d d i s t a n c e x is the layer deeper into the ambient. 200 Symbo I 10.0 15.0 20.0 +* 100 Radial distance Figure 7. from the w i r e , r (in.) Mean Temperature Profiles for the Air Adj a cent to the Heated Vertical Wire 1.22 9.73 32.8 77.8 200 SymboI O § X 5.0 10.0 15.0 20.0 C a O • 3 150 0 « 43 -W O W W 0 *» 100 SI M 4> P. B e *» (ft) Rax xlO -10 1.22 9.73 32.8 77 .8 I 8 8 § O 8 I I i 1.0 1.5 2.0 (3 03 0) ae 0.5 Radial Figure 8 distance from the w i r e , (in.) Mean Temperature Profiles for the Air Adjacent to the Heated Vertical Wire 2.5 32 Warner and Arpa c i similar resu lts 7.9x10* < RaT r e s p e c ti ve l y. increased velocity for < 7.9x10 10 wil l and Cheesewright a vertical This x [I ] of shown layer b e h a v i o r plate 7 .2x10* and widening be flat to the in the < Ra' air with < 6.O x l O 10 layer co n s i s t e n t following investigations reported temperature give in thermal he [10] with with section. the Both results by plotting the d i m e n s i o n l e s s t e m p e r a t u r e A T /A T ^ , v e r s u s y , the di st an ce fr om the v e r t i c a l flat plate. temperatures obtainable for the entire in the p r es e nt were comparisons not will length and provided be of the w i r e i n v e s t i g a t i o n due sufficient instrumentation, temperatures Exa ct h e a t e d v e r t i c a l wire made since by of temperatures measured with those not to a lack of dimensional these the were fluid investigators, magnitude of no the of [1] and [10]. M EAN VELOCITY RESULTS Figures pr o f i l e s 9. that and we r e 10. show obtained the from dimensional the velocity experimental data using the p r o c e d u r e and e q u i p m e n t d i s c u s s e d in Chapter 3. They are plotted direction, vertical versus wire. four levels as U, shows adj ace nt outer edge of the plexiglass a detailed mean velocity r, the radial di st an ce Figure 9. from the the from the x the h ea te d entire profiles to the h e a t e d w i r e shroud, in of the to near the while figure 10. shows graph of the profiles near the wire. 2.0 Mean velocity of the fl u i d , U (ft/sec) Symbol O D O • O O I .5 X (ft) Rax xlO -10 5.0 10.0 15.0 20.0 1.22 9.73 32.8 77.8 fa I .0 S r* • g o O •8 o o o 0.5 I 6 6 ° O O 0 O O o _6_ 8 0.0 J_____________________________________________ 5 10 Radial distance Figure 9 . 15 from the wire, r (in.) Mean Velocity Profiles for the Air Adjacent to the Heated Vertical Wire 8 n 8 2.0 I I i I *o O * I .5 _ O 5.0 10.0 15.0 20.0 Rax xlO~1C 1.22 9.73 32.8 77.8 O O O O O •o •O eo • OO I 1.0 QO n O O °o* ° #0 e fluid, O 8 O • 8 • C « O - Mean 0.5 C C • of the (ft) O O a O O O velocity % O a O • U (ft/sec) SymboI 8 I 0.5 Radial Figure 10. i I 1.5 O i 0.0 distance from the wire, I 2.0 r (in.) Mean Velocity Profiles for the Air Adjacent to the Heated Vertical Wire 2. u> 35 M e a s u r e d local v e l o c i t y b o u n d a r y layer thicknesses, Sy , were estimated from Figure 9. However, the c o n v e n t i o n a l d e f i n i t i o n of the edge of the b o u n d a r y layer as the l o c a t i o n wh e r e the v e l o c i t y has d r o p p e d to 1% of its pea k val ue was portion the b o u n d a r y of velocities too not practical. small. region The profile is too Therefore, flat in the and outer the peak the edge of the boundary layer was tak en as the p o s i t i o n at w h i c h the v e l o c i t y had dropped to 10% of its m a x i m u m va l u e . Sy was Using this definition evaluated and these values are given in Table I. Table I. distance Velocity Boundary Layer Thicknesses for Distances Along The Heated Vertical Wire from the beginning of the wire, feet x velocity boundary layer thickness, meters in cm 5.0 1.52 13.7 34.9 10.0 3.05 13.4 33.9 15.0 4.57 15.5 39.4 20.0 6.10 15.9 40.4 &y 36 The b o u n d a r y layer thickness, 5.0 ft (1.52 m) level is c o n s i s t e n t with S v i n c r e a s e d from to the 20.0 ft (6.10 m) level. the resu lt s the This of G o d a u x and G e b h a r t [5] who have found that the velocity and thermal boundary layer thicknesses vertical increase with length from the leading edge of a flat plate in water until the flow becomes fully t u rb ul en t at w h i c h point bo t h b o u n d a r y layer t h i c k n e s s e s st op ped growing. It can be no te d that there is a s i g n i f i c a n t increase in Sy f r o m 10.0 ft (3.05 m) to 15.0 ft (4.57 m ) w i t h only a slight inc rease shown later th i c k n e s s th a t inc rease m ) is in the the 20.0 at the 20.0 ft (6.10 m) level. region of large boundary layer (10.0 f t < x <15.0 ft) (3.05 m< x < 4.57 t r a n s i t i o n to t u r b u l e n t (6.10 m ) level flow at increase in boundary F i g u r e s 9. and 10. also seem to indicate a small but therefore layer thickness significant small would be expected. d e c re as e along the wire, a very was The to be fully and however region. found turbulent ft the It will be x. in m a x i m u m velocity with This could possibly be explained if the recirculation of the air within the shroud were Since the t o w e r was closed at b o t h ends for the u p w a r d f l o w i n g it wa s considered. necessary air to reverse d i r e c t i o n near the top of the t o w e r and r e c i r c u l a t e botto m. distance itself b a c k d o w n to the W i t h the air rising along the c e n t e r - l i n e of the 37 wire the recirculated air outsi de of the shroud. the shroud mor e w as required to go down the As the fl o w a p p r o a c h e d the top of air was evidently reversing direction. The re fo r e, as the dis tan ce along the wire increased, m o r e flow may have decreasing satisfy A its diverted maximum from velocity the fr o m boundary-layer, that required to continuity. dec re as e consistent [12], be e n with [15], in m a x i m u m v e l o c i t y along the wire is experimental results of other researchers however water was used as the working fluid in both cases and recirculation effects were present. Results of an experiment in air with no recirculation were provided [10] no and show measurements plate, In decrease in m a x i m u m v e l o c i t y as x p r o g r e s s e d u p w a r d along the v e r t i c a l flat rather a slight the absence theoretical of r e su l ts composition as comparisons of profiles measurements. similar used in experimental geometry th i s data In addition, obtained questionable value. fluid investigation, than actual magnitudes of the the validity of the use of the factor discussed in Chapter is u n c e r t a i n in this p a r t i c u l a r i n v e s t i g a t i o n , the and or of the general trends o b s e r v e d in rather correction reported. comparable a those we r e ma de the velocity temperature increase was for the velocity 3., CF, t h er ef or e profiles is of 38 ANEMOMETER OUTPUT FLUCTUATIONS As reported beginning of temperature occur. earlier Cheesewright turbulence as fluctuations the [10] has point where in the b o u n d a r y significant layer be g i n to Since the a n e m o m e t e r b ri dg e volt ag e constant temperature sensor defined the output for a is governed by fluctuations the t e m p e r a t u r e as well as the v e l o c i t y of the fluid, variations experiment the in fr om to it is present. wa s voltage felt and method that of used G eb ha rt and other r e s e a r c h e r s in the this flow begins fu ll y developed is slightly different determining sufficient i n f o r m a t i o n on the d e v e l o p m e n t output when Although this o b t a i n e d f r o m these fl uc t ua ti on s. the a n e m o m e t e r were the point at which the tu r b u l e n c e C h e e s e wri ght's events, br id ge to determine transition turbulence output in transition resu lt s could be To o bt ai n q u a l i t a t i v e of the t r a n s i t i o n region, [5] and [13]-[153 to d e t e r m i n e v e l o c i t y also used disturbance levels. Figure 11. demonstrates the present investigation, the bridge the variations showing the max im um determined in amplitude of output voltages for each of the four levels used to ob t a i n v e l o c i t y and t e m p e r a t u r e data as w e l l as values o b t a i n e d at the I ft, (0.30 m ) and 2 ft. (0.61 m ) levels. It can c l ea r ly be lo we st levels are seen fr o m in the this Figure laminar that the two r eg io n b e c a u s e of the 15 I I Symbo I I (ft) Rax x I 0 10 -M P Qi -M A P O a O • O Q> CO OS M vM # O .00973 .0778 I .22 9 .73 32.8 77.8 _ O > O oo fO •H to N 4> M 0) E O a e> fl 1.0 2.0 5.0 10.0 15.0 20.0 A O • O O O LU VO e • O O A A O O J___ i __ 0.1 Radial Figure 11. • O • O 8 o O 8 O O O O O □ O • O o O I 0.2 distance I 0.3 from the wire, I 0.4 T (in. ) Maximum Anemometer Output Fluctuations for the Air Adjacent to the Heated Vertical Wire • f O 0.5 40 small amplitude of the fl uc t u a t i o n s . it can observing increased amplitude seen that transition turbulence as defined by Cheesewright [10], has the 5.0 ft. (1.52 m ) level. to the Gr a s h o f properties are T m = (Tw +Tco)/ 2. the b e g i n n i n g numbers ev a l u a t e d listed in at mean by the [10] transition This value w o u l d rei nf o rc e occurring the 5.0 ft. has Table 2., fluid taken according where (ft) all temperature, R a x = I.4x10^ to his as criterion. the o b s e r v a t i o n of t r a n s i t i o n (1.52 m ) level Dimensionless Numbers Used Cl M M X to started by in the present investigation. Table 2. the These points w o u l d c o r r e s p o n d Cheesewright of be By in the Experiment Rax I .0 I .1 6 x l 0 8 7 .91x10? 2.0 9.29x10* 6.33x10* 5.0 1 .4 5 x l 0 10 9.88xl09 10.0 I . I b x l O 11 7 . 9 1 x l 0 10 15.0 3 . 9 2 X 1 0 11 2 . 6 7 X 1 0 11 20.0 9 . 2 9 X 1 0 11 6 .S S x l O 11 P 41 Figure 11. also show s that the fluctuation amplitudes con ti nu e to inc rea se th ro ug h the 15 ft. (4.57 m) level and then the a m p l i t u d e s dec re as e at the 20 ft. (6.10 m ) level. This can be d e s c r i b e d as the poi nt b e c o m e full y turbulent. the w o r k s reported temperature end of R a x = I .4x10 [10] and Vliet transition fluctuations Cheesewright's [1 0] in the as to point wh e r e boundary layer decreased. turbulence reported fully developed turbulent in all tests showed that with the reported values heat the had that resul ts of parameter transition Jularia occurred decreased, at an with Th e y the Vliet found are that G being the and Liu [6] Gebhart number, the [13] simply number. dependent They upon the and the surface transition events when the derived from w a t e r along a v e r t i c a l flat plate. data to air along a vertical and Rayleigh events increasing results and en d e d is not correlated * q '. at investigation. of G , the modified Grashof flux, that c o n d u c t e d w h i c h agrees f a v o r a b l y the end of transition single noted the flow was present by Rax with the results obtained for this H o w e v'e r , [6] w ho that flow was reported to be fully turbulent. = 1.3x10 H and L i u investigation transition the flow has These resu lt s are c o m p a r e d w i t h of C h e e s e w r i g h t the at w h i c h heat flux experiments was in C o r r e l a t i o n s of their thin wire were not suggested. 42 CHAPTER 5. CONCLUSION AND RECOMMENDATIONS FOR FURTHER WORK The design, I main objective con struct, of this investigation and e x p e r i m e n t a l l y v e r i f y was to a fa ci l i t y that can be used for t u r bu l e n t b o u n d a r y layer an al ys is in n at ur al convection heat transfer studies. sh o w n by a n e m o m e t e r bridg e v o l t a g e that the facility necessary turbulent is of flow. a It output suitable has be e n fl uc t u a t i o n s , size to o bt ai n the The approximate locations of the beginning and end of the transition to turbulence have been found be to < 7.8x10*^ 7 .8x 1 0 8 < R a x < 1 . 2 x l 0 10 respectively. These over temperature a range of 3 .3 x I 0 11 < R a x values have been shown to be consistent with results of other Mean and investigators. and velocity profiles Rayleigh numbers in the were measured boundary layer ( s u r r o u n d i n g the h e a t e d ve r t i c a l wire. trends observed investigators in the findings, of the m a g n i t u d e s there the h o t - w i r e could achieve the i n ve st ig a ti on . the probe s desired A agreed is some doubt of the profiles. ca l i b r a t e not profiles While the general with other in the validity The f a c i l i t y used to for v e l o c i t y m e a s u r e m e n t s temperatures temperature encountered correction factor in of 43 l i m i t e d a p p l i c a b i l i t y was used to adjust br id ge flui d voltage output surrounding the adequate calibration at temperatures high adjusted with the for chan ge s to with the wire. compare same correction factor, using this method of correction The in t e m p e r a t u r e he a t e d v e r t i c a l facility the a n e m o m e t e r Without known an velocities temperature the error of the flows involved in is unknown. temperatures recorded for the boundary also be s u b s t a n t i a l l y in error due to the m e t h o d used to determine them. the temperature of the the increased probe and fluctuations of exact cold resistance support was difficult to and again the magnitude of the error involved was obtainable. problems of adjacent to the wire, hot-wire determine not Because layer may wi ll Possible be solutions discussed in to the the above mentioned following section. V e l o c i t y b o u n d a r y layer size was e s t i m a t e d from v e l o c i t y p r o f i l e s m e a s u r e d in the i n v e s t i g a t i o n and the thickness of the boundary layer was noticed to increase the distance along the heated vertical wire was the as increased. R E COMMENDATIONS FOR FURTHER WORK A calibration facility for the h o t - w i r e anemometer probes that could be op e r a t e d at t e m p e r a t u r e s up to 2 0 0 0 F (93*0 with velocities in the range of O to 2.0 ft/sec (0.61 m/sec) w o u l d al lo w v e l o c i t y prof i l e s to be o b t a i n e d with a minimal amount of error from the actual velocities. 44 This would exact allow calibration temperatures correction A factor mo re obtained. method al s o could thermocouple (0.0127 mm) of fl o w and achieved [21]. probes, in digi tal fluid at the make a temperature improve by the using Temperatures form. results the method were measured chromel-alumel, d i a m e t e r butt jointed, was r e c o r d e d the mean greatly be utilized by Che es e wr ight with in probe unnecessary. would This the hot-wire encountered s u i ta bl e measurement of 0.0005 and the ou tput A sampling in. signal rate of 100 Hz Vfas used t h r o u g h o u t , w i t h a s t a n d a r d l e ng th of record of six minutes. A method of observing p h o t o g r a p h i n g tracer p a r t i c l e s and very small size, resu lts mo r e while flow visually by of a s u b s t a n t i a l q u a n t i t y would improve the dependability of the describing meaningful the the manner. direction Particles to of the be flow in a investigated include h e l i u m fi ll ed bu b b l e s w i t h a b u o y a n c y s i m il ar to air. This bubble re q u i r e s the purchase or construction of a generator. Improved results could also be a La s e r D o p p l e r A n e m o m e t e r velocity independent layer flow. to be m a d e The the use of (LDA) to make m e a s u r e m e n t s of of temperature. velocity measurements boundary obtained by This would without disadvantage allow the disturbing the of the use of an LDA 45 sy st em not is that an easy encountered it req ui re s task in in natural Investigation conditions mesh reduce infinite the such as those alternative convection experimental in ac hi e v i n g results. The opened at both the top and the bottom sc ree n p l a c e d over the openings from disturbing the flow. a wi re effects of larg er cylinder s u p p l i e d to the wir e area. natural recirculation vertical the heat flows and These better to keep openings simulate an atmosphere. Also heated several turbulent external currents would speed w h i c h is convection. of shroud used could be a fine low m a y also prove to be b e n e f i c i a l significant and s e e di ng of the flow, flux held could velocities or con stant cylinder which velocities found are be or a sm a l l investigated. diameter The power or c y l i n d e r could be i n c r e a s e d w i t h This would increase wire diameter due to the increased surface the amount of heat transfer from and theoretically easier in the present to measure give than investigation. higher the low REFERENCES CITED 47 REFERENCES CITED 1. 2. Warn er, C . Y. and Arpaci, V., An E x p e r i m e n t a l I n v e s t i ­ ga ti on of T u r b u l e n t N a t u r a l C o n v e c t i o n in Air at Low Pressure Along a Vertical Heated Flat Plate, I a M r n a t i o n a l Journal of Eeat and Ma..s.s Tr an_s f_e r , Vo 1 . 11, pp 397-406, 1968. e George, W . K. and Capp, S. P., A T h e o r y For Natu ra l C o n v e c t i o n T u r b u l e n t B o u n d a r y L ay er s Next To H e a t e d V e r t i c a l Surfaces, I n t e r n a l i o n a l J o u r n a l of Heat and Mm T r a n s.li r , V o l . 22, pp 8^13-826 , 197 9 . 3. Fuj ii, T., Takeuchi, M., Fujii,. M., Uehara, H., E x p e r i m e n t s On N a t ur al Transfer From The O u t e r Surface C y l i n d e r to Liq uids, I n t e r n a t i o n a l and Mjisjs Transfer, Vol. 13, pp 753-7 4. Qureshi, Z. H., an d G e b h a r t , B., T r a n s i t i o n a nd T r a n s p o r t in a B u o y a n c y D r i v e n F l o w in W a t e r Ad ja c e n t to a V e r t i c a l U n i f o r m Flux Surface, Jslernallena.! J o u r n a l o f I e s l and M a n J r a n e f e r , Vol. 21, pp 1467-1479, 1978. 5. Godaux, F . and Gebhart, B., An E x p e r i m e n t a l Study of the Transition of Natural Convection Flow Adjacent to a V e r t i c a l Surface, J s l e i n a!J o n al J o u r n a l of Heal and M m J i e s s J n * Vol. 1 7 , pp 93-107, 1974. 6. Vliet, G . C. and Liu, C. K., An E x p e r i m e n t a l Study of Turbulent Natural Convection Boundary Layers, Journal of HeeJ J i e s s J n > Vol. 9 i , pp 5 1 7 - 5 3 1 , 1969. 7. Eckert, E. R. G. and Jackson, T. W., A n a l y s i s of T u r b u l e n t Free C o n v e c t i o n B o u n d a r y L a y e r on a Flat Plate, NACA TN 1015, 1950. 8. Cebeci, T. and Khatab, A., Prediction of Turbulent Free C o n v e c t i o n Heat T r a n s f e r F r o m a V e r t i c a l Flat Plate, JourseJ of HeeJ Jiess J n * Vol. 97, pp 46 9— 4 7 1, 1975. 9; Mason, H. and Seban, R., Numerical P r e d i c t i o n s For T u r b u l e n t Free C o n v e c t i o n F r o m V e r t i c a l Surfaces, J s J e r n e J J o s e I J o u r n e J of I e e J e s A M a e s J i e s s J n , Vol. 17, P P 1329-1336, 1974. 10. Suzaki, K., and C o n v e c t i o n Heat of a V e r t i c a l J o u r n a l of Heal 87, 1970. Cheesewright, R., Turbulent Natural Convection From a V e r t i c a l Plane Surface, J o u r n e J e J S s s J Jl'eSSJn* Vol. 90, pp 1-8, 1968. 48 11. Fujii, T., E x p e r i m e n t a l Stud ie s of Free C o n v e c t i o n H e a t T r a n s f e r , B u Jl I.e.Jfcj,n .of. J S M E , Vo I. 2, No. 8, PP 555-558, 1959. 12. Kato, H., Nishiwaki, N., Hirata, M., On The Turbulent Heat T r a n s f e r by Free C o n v e c t i o n F r o m a V e r t i c a l Plane, International Journal of Heat and Mass. Tra n sf er . Vo I. 11, pp 1117-1125, 1968. 13. Jaluria, Y., and Gebh art, B., On Transition Mechanisms in V e r t i c a l N a tu r al C o n v e c t i o n Flow, J o u r n a l of E-IsjLd. Mjec: h.anl_c_s , Vo I. 66, p t . 2, pp 3 0 9-337 , 1974. 14. Bill, R. G., Jr., and. G e b h a r t , B., The D e v e l o p m e n t of Turbulent Transport in a Vertical Convection Boundary Layer, I n t e r n a t i o n a l J o u r n a l of H e a t an d M a s s . T rans fer . Vol. 22, pp 267-277, 1979. 15. Gebhart, B., Ins tab i l i t y , T r a n s i t i o n , and T u r b u l e n c e in Buoyancy Induced Flows, Annuzil Re.vi.ew of Fluid Me ch anic s . Vol. 5, pp 213-246,. 1973. 16. Ho l l a s ch, K., Gebhart, B., C a l i b r a t i o n of C o n s t a n t T e m p e r a t u r e H o t - W i r e A n e m o m e t e r s at L o w V e l o c i t i e s in Water with Variable Fluid Temperature, Journal of Heat T ra.ns^e._r, Vol. 94, pp 17-22, 1972. 17. Che e s e w r i g h t , R., Na t ur al C o n v e c t i o n F r o m a V e r t i c a l Plane Surface, PhD thesis in Mechanical Engineering, University of London, Oct. 1966. 18. Hot Wire and Hot Film Measurements and Applications, Thermal Systems Inc., Technical Bulletin No. 4. 19. Fingerson, L., Freymuth, P., Thermal Anemometers, Thermal Systems Incorporated, 1979. 20. Heat Flux System Model 1010A Instruction M a n u a l , Thermal Systems Inc or porated. 21. 22 C h e e s e w r ight, R., Doan, K., S p a c e - T i m e C o r r e l a t i o n M e a s u r e m e n t s in a T u r b u l e n t N a t u r a l C o n v e c t i o n B o u n d a r y Layer, I n t e r n a t i o n a l J o u r n a l of Heal and M as s Transfer, Vol. 21, pp 911-921, 1978. A y din, M .> and L e u t h e u s ser, B., Very L o w V e l o c i t y Calibration and Application of Hot-Wire Probes, DISA Information Report, No. 25, F e b . 1980. 49 APPENDIX APPENDIX VELOCITY AND TEMPERATURE DATA 51 The following temperature conditions profile is a list in g data taken in of all this the velocity and investigation. The for the measurements are as follows: T s = SOO0F T c = 810F Rh = 10.98 ohms Mean Velocity Data Distance from the beginning of the heated vertical wire, feet 5.0 , inches 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 1.00 I .50 2.00 2.50 3.00 3.50 4.00 5.00 6.00 7.00 8.00 10.0 12.0 14.0 16.0 18.0 20.0 22.0 24.0 10.0 15.0 Mean velocity , U , I .16 I .51 I .63 1.62 1.61 1.64 I .57 1.51 I .54 1.35 I .23 1.14 1.06 0.92 0.85 0.67 0.45 0.31 0.24 0.17 0.18 0.19 0.16 0.16 0.16 0.14 0.10 0.11 0.54 0.90 1.06 I .13 1.14 I .24 1.23 1.26 1.24 1.25 1.20 I .08 1.02 0.91 0.84 0.78 0.75 0.63 0.49 0.46 0.35 0.25 0.16 0.11 0.06 0.04 0.00 0.01 0.01 20.0 ft/sec 0.11 0.92 0.97 1.01 1.08 I .09 1.03 0.99 0.98 0.95 0.87 0.84 0.81 0.79 0.72 0.71 0.67 0.61 0.52 0.47 0.47 0.33 0.21 0.17 0.09 0.03 0.06 0.07 0.10 0.10 0.71 0.96 0.96 1.02 0.91 0.88 0.93 0.92 0.92 0.83 0.79 0.79 0.75 0.71 0.65 0.66 0.57 0.50 0.44 0.39 0.23 0.17 0.14 0.10 0.08 0.14 0.14 0.15 52 Me^an ^ em£e.ra t.ur^ d a_t Distance from the beginning of the heated vertical wire, feet 5.0 Mean temperature, , inches 0.05 0.10 0.20 0.30 0.40 0.50 1 .00 I .50 2.00 2.50 3.00 3 .50 4.00 5.00 6.00 7.00 8.00 10.0 12.0 14.0 16.0 18.0 20.0 22.0 10.0 181 147 119 116 106 101 95 93 91 91 91 89 89 89 88 88 88 86 86 86 85 85 84 84 195 150 125 116 109 106 100 96 95 93 93 93 92 92 91 91 89 89 89 89 89 88 88 88 15.0 T, 184 148 120 116 107 104 98 96 95 93 93 92 92 91 91 91 91 91 91 89 89 89 89 89 20.0 0F 184 154 126 119 113 108 100 98 98 96 95 93 93 93 93 93 92 92 92 92 91 91 91 91 MONT A N A STATE UNIVERSITY ITRRARTFt 762 10056640 3 VAIN LIB. N378 P882 Pracht, D. A. cop.2 Instrumentation requirements and design of a facility for turbulent natural ... I S SUED T O DATE «Li2-S APT? - AJ31% P&Z-' Q^<L-/p 2 < — ^ *