Coagulation of organic color with ferric chloride

advertisement

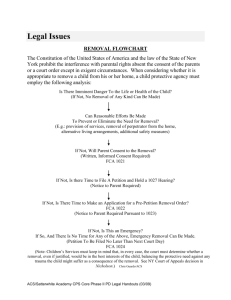

Coagulation of organic color with ferric chloride by C Hunter Nolen, jr A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science in Environmental Health Engineering Montana State University © Copyright by C Hunter Nolen, jr (1984) Abstract: This study investigates the conditions of pH and ferric chloride dosage required for the removal of organic color from water. The results of this laboratory study were obtained with the use of a jar testing apparatus. Extensive data were collected and it was found that ferric chloride can be a very effective coagulant for color removal. The data presented in this thesis should provide a useful tool for the operation and design of water treatment facilities when coagulation with ferric chloride is considered. COAGULATION OF ORGANIC COLOR WITH FERRIC CHLORIDE ■ by C. Hunter Nolen, Jr. A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science in Environmental Health Engineering MONTANA STATE UNIVERSITY Bozeman, Montana August 1984 APPROVAL of a thesis submitted by C. Hunter Nolen, Jr. This thesis has been read by each member of the thesis committee and has been found to be satisfactory regarding content, English usage, format, citation, bibliographic style, and consistency, and is ready for submission to the College of Graduate Studies. ________ 3 J y Date Z+ , _______ QitAMuiAZj y Chairperson, Graduate Committee Approved for the Major Department Approved for the College of Graduate Studies Date Graduate Dean STATEMENT OF PERMISSION TO USE In presenting this thesis in partial fulfillment of the requirements for a master’s degree at Montana State University, I agree that the Library shall make it available to borrowers under rules of the Library. Brief quotations from this thesis are allowable without special permission, provided that accurate acknowledgment of source is made. Permission for extensive quotation from or reproduction of this thesis may be granted by my major professor, or in his absence, by the Dean of Libraries when, in the opinion of either, the proposed use of the material is for scholarly purposes. Any copying or use of the material in this thesis for financial gain shall not be allowed without my permission. Signature Date 7 - ^ iv ACKNOWLEDGMENTS My sincere thanks to all. the persons and institutions for the support they have given me during this program. Special thanks to the Department of Civil Engineering and Engineering Mechanics and the Engineering Experiment Station at Montana State University for support for this study; and to Dr. A. Amirtharajah for his advice and assistance. To my parents and to my sisters, for their moral support. V TABLE OF CONTENTS Page APPROVAL........................................................................................................................ ii STATEMENT OF PERMISSION TO USE........................................................................ iii ACKNOWLEDGMENTS.................................................................................................... iv TABLE OF CONTENTS.................................................................................................... v LIST OF TABLES............................................................................................................... vi. LIST OF FIGURES............................................................................................................. vii ABSTRACT........................................................................................................................ ix INTRODUCTION............................................................................................................... I NATURE OF ORGANIC COLOR..................................................................................... 2 THEORY OF COAGULATION....................................................................................... 3 Coagulation of Color.................................................................................................. 4 AQUEOUS CHEMISTRY OF F e (III)....................................................................... 5 MATERIALS AND METHODS......................................................................................... 9 RESULTS AND DISCUSSION......................................................................................... 14 Color R em oval........................................................................................................... Effect of Turbidity.................................................................................................... Removal Mechanisms................................................................................................ Apparent Color Removal........................................................................................... Turbidity Rem oval.................................................................................................... 14 16 24 36 44 CONCLUSIONS........................................................................ 48 REFERENCES 49 vi LIST OF TABLES Table I. Page Color Solutions.................................................................................................... 9 vii LIST OF FIGURES Figures Page 1. Fe(III) Log Concentration Diagram......................................... ; ....................... 7 2. Iron (III) Coagulation Diagram.......................................................................... 8 3. Color Removal Domain—Initial Color = 100 CU, Turbidity = 27-30 T U ......................................................................................... 11 Data Points and Corresponding Percent Color Removal Values Initial Color - 100 CU, Turbidity = 27-30 TU.................................................. 13 Data Points and Corresponding Percent Color Removal Values Initial Color = 100 CU, Turbidity = 0 ............................................................... 15 Data Points and Corresponding Percent Color Removal Values Initial Color = 500 CU, Turbidity = 0 .................................................... .. . . . 17 Data Points and Corresponding Percent Color Removal Values Initial Color = 1000 CU, Turbidity = 0 ............................................................. 18 Common Color Removal Domain - Initial Color. 100-1000 CU, Turbidity = 0......................................................................................................... 19 Data Points and Corresponding Percent Color Removal Values Initial Color = 225 CU, Turbidity = 27-30 TU.................................................. 20 Data Points and Corresponding Percent Color Removal Values Initial Color = 500 CU, Turbidity = 27-30 TU.................................................. 21 Data Points and Corresponding Percent Color Removal Values Initial Color = 700 CU, Turbidity = 27-30 TU.................................................. 22 Data Points and Corresponding Percent Color Removal Values Initial Color = 1000 CU, Turbidity = 27-30 TU................................................ 23 Common Color Removal Domain - Initial Color 100-1000 CU, Turbidity 27-30 TU...................................'.......................................................... 25 14. Color Removal Domain - Initial Color = 100 CU, Turbidity = 0 ................... 26 15. Color Removal Domain - Initial Color = 500 CU, Turbidity = 0 .................... 27 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. viii Figures 16. Page Color Removal Domain - Initial Color = 1000 CU, Turbidity = 0.......................................................................................................................... 28 Color Removal Domain - Initial Color = 100 CU, Turbidity = 27-30 T U ........................................................................................................... 29 18. . Color Removal Domain - Initial Color = 225 CU, Turbidity = 27-30 T U ........................................................................................................... 30 17. 19. Color Removal Domain - Initial Color = 500 CU, Turbidity = 27-30 T U ........................................................................................................... 31 Color Removal Domain - Initial Color = 700 CU, Turbidity = 27-30 T U ........................................................................................................... 32 Color Removal Domain - Initial Color = 1000 CU, Turbidity = 27-30 T U ........................................................................................................... 33 22. Stoichiometry for the Color Removal Domains pH - 4 . 5 ............................... 34 23. Stoichiometry for the Color Removal Domains pH - 5.5, pH - 6 . 3 ........................................................................................... 35 Particle Charge and EM Values - Initial Color =100 CU, Turbidity = 27-30 T U ........................................................................................................... 37 25. Particle Charge - Initial Color =100 CU, Turbidity = 27-30 T U .................... 38 26. Particle Charge - Initial Color = 500 CU, Turbidity = 27-30 T U .................... 39 27. Particle Charge - Initial Color =1000 CU, Turbidity = 27-30 T U .................... 40 28. Apparent Color Removal Domain - Initial Color =100 CU, Turbidity = 27-30 T U ........................................................................ 41 Apparent Color Removal Domain - Initial Color = 500 CU, Turbidity = 27-30 T U ......................................................................................... 42 Apparent Color Removal Domain - Initial Color = 1000 CU, Turbidity = 27-30 T U ......................................................................................... 43 Turbidity Removal Domain - Initial Color = 100 CU, Turbidity ' = 27-30 T U ........................................................................................................... 45 Turbidity Removal Domain - Initial Color = 500 CU, Turbidity = 27-30 T U ........................................................................................................... 46 Turbidity Removal Domain - Initial Color = 1000 CU, Turbidity = 27-30 T U ........................................................................................................... 47 20. 21. 24. 29. 30. 3 1. 32. 33. ABSTRACT This study investigates the conditions of pH and ferric chloride dosage required for the removal of organic color from water. The results of this laboratory study were obtained with the use of a jar testing appa­ ratus. Extensive data were collected and it was found that ferric chloride can be a very effective coagulant for color removal. The data presented in this thesis should provide a useful tool for the operation and design of water treatment facilities when coagulation with ferric chloride is considered. I INTRODUCTION Organic color, in natural water supplies, is due primarily to the presence of humic substances, i.e., humic acid, fulvic acid, and humins. Humic substances are undesirable in a potential water supply for a number of reasons including aesthetics, the formation of trihalomethanes and other chlorinated organic substances, utilization of adsorption capacity of activated carbon beds, extension of chlorine demand, and possible transport of organic and inorganic pollutants through water treatment facilities and into the water supply [1]. Coagulation with ferric and aluminum salts is standard treatment for the removal of suspended colloids from water supplies. It has been shown that aluminum sulfate, the most commonly used coagulant for turbidity removal is also effective in color removal [1-6]. The coagulant ferric chloride, in contrast, has been the focus of very few color removal studies. Tlie objective of this research is to determine the effectiveness of ferric chloride in the removal of organic color from water. This paper deals with the delineation of optimum color removal areas with respect to the operational diagram for ferric chloride coagulation [7]. The independent variables con­ sidered are: humic acid (color) concentration, coagulant dosage, and pH. Results for true color removal, apparent color removal, turbidity removal, and electrophoretic mobility are presented. 2 NATURE OF ORGANIC COLOR Humic substances are of natural origin, derived from organic material in soil or pro­ duced within surface waters and sediments by biological and chemical processes [ I ]. Schnitzer and Khan [8] characterized them as “amorphous, brown or black hydrophilic, acidic, polydisperse substances of molecular weight ranging from several hundred to tens of thousands.” The primary definition of humic substances, however, is operational. They are classified into the three main groups based on their solubilities: (I) humic acid, which is soluble in base, but insoluble in acid; (2) fulvic acid, which is soluble in both base and acid; and (3) humins, which are insoluble in both [9]. Operational definitions are not abso­ lute, however, and humic substances from any single source have a continuous range of solubility, absorptivity, molecular size, and chemical reactivity [ I ]. The individual molecules of humic substances are complex as well. The molecules appear to be part aromatic and part aliphatic [10]. There are acidic hydrophilic sites on the molecules which are reactive with cations such as trace metals and the hydrolysis species of aluminum and iron. Also, there are hydrophobic sites which may be responsible for the association between humic substances and certain nonionic, organic compounds [ I ] . Humic substances contain the following functional groups which affect their stability in water; carboxyl, phenolic, alcoholic, ketonic, quinoniod, and methoxyl. Both the charge density and configuration of the humic macromolecules in solution are affected by pH. Under the pH conditions of most natural waters, humic materials are negatively charged macromolecules (anionic polymers). As the pH is increased„increasing stability results due to dissociation of the functional groups and a resulting increase in the magnitude of the negative charge on the color molecules [3]. 3 THEORY OF COAGULATION Colloidal particles range in size from about I to 100 nanometers and are characterized by large surface area and very slow settling rates [11]. The surface of a colloidal particle tends to acquire an electrostatic charge due to the ionization of surface groups and the adsorption of ions from the aqueous phase. Most colloids in water develop a negative pri­ mary charge but a colloidal dispersion does not have a net charge. Charges on the particles are counterbalanced by charges in the solution phase. This need for electroneutrality results in an electrical double layer which consists of the charges on the particle and an equivalent excess of counter ions which accumulate in the water near the surface of the particle. Forces of diffusion and electrostatic attraction spread the charge in the water around each particle in a diffuse layer [12]. The stability of colloids in water is due primarily to their electrostatic characteristics. When two colloidal particles with similar charge approach each other, their diffuse layers interact and produce a repulsive force. The repulsive force is counterbalanced to some degree by an attractive van der Waals force, and the resulting potential of both the repul­ sive and attractive forces often forms an energy barrier which prevents aggregation [13]. The process of overcoming the energy barrier and allowing aggregation to occur is called coagulation. 0 1Melia [12] presents four distinct mechanisms of coagulation. These are: (I) com­ pression of the diffuse layer (DLVO theory); (2) adsorption to produce charge neutraliza­ tion (adsorption-destabilization); (3) enmeshment in a precipitate (sweep coagulation); and (4) adsorption to permit interparticle bridging. In water treatment, coagulation of colloids 4 is probably accomplished by adsorption-destabilization, sweep coagulation, or both simul­ taneously. In the adsorption-destabilization process, metal cations such as Fe(III) and Al(III) are hydrated in water and are present as aquocomplexes. Hydroxo-metal complexes are formed and are readily adsorbed at interfaces. Because of the adsorption of oppositely charged species, the colloids become destabilized or neutralized, allowing aggregation to occur. Stoichiometry between the colloidal surface area and coagulant dosage exists, and overdosing results in charge reversal, i.e., restabilization [12]. In sweep coagulation, the dosage of the aluminum or iron salt is large enough that a sufficient degree of oversaturation occurs to produce a rapid precipitation of the metal hydroxide. As the precipitate settles, it enmeshes the colloidal particles and sweeps them from the solution. Coagulation of Color The mechanisms that are responsible for the removal of humic substances when salts of aluminum or ferric iron are used as coagulants are often uncertain but may include direct precipitation of humic substances by dissolved iron species (sometimes described as a ferric or iron humate precipitate), adsorption of humic substances on solid ferric hydroxide [Fe(OH)3 ^ ] , or a combination of the two. In this paper, “precipitation” describes the formation of Fe(OH)3 ^ as well as the formation of a solid phase that is composed of previously soluble species of iron and humic acid. “Adsorption” is used to describe the reaction between solid phase ferric hydroxide and the soluble humic acid molecules [I ]. 5 AQUEOUS CHEMISTRY OF Fe(III) To understand the ability of ferric chloride to destabilize colloidal particles, it is necessary to consider the chemistry of Fe(III). 0 1Melia [12] stated that all metal cations are hydrated in water and that simple species such as Fe3+ do not exist. Rather, Fe(III) is present as part of aquocomplexes such as Fe(H2O)6 3+. Ions or molecules, such as water molecules, which are bonded to a central metal atom are termed ligands. The addition of an Fe(III) salt to water in concentrations less than the solubility limit of the metal hydroxide leads to the formation of soluble monomeric, dimeric, and small polymeric hydroxo-metal complexes, in addition to the free aquo-metal ion. The hydroly­ sis of Fe(III) can be described as a stepwise consecutive replacement of H2O molecules in the hydration shell by OH" ions. For example: Fe(H2O)6 3t -+ Fe(H2O)6OH++ -> Fe(H2O)4 (OH)+ -+ Fe(H2O)3 (OH)3 -> Fe(H2O)2 (OH)4 The OH" ions are also ligands. When writing the hydrolysis reactions of a metal ion, it is common to omit the H2O ligands for brevity. For example, the monomeric hydroxo-metal complex Fe(H2O)6 (OH)2+ is written as Fe(OH)2+. For Fe3+ in pure water, Snoeyink and Jenkins [9] present the fol­ lowing equilibria: Fe3+ + H2O - Fe OH2+ + H+ ; IogK Fe3++ 2H20 * Fe(OH)+ + 2H+ ; log K - : -6:74 Fe(OH)3 - F e3+ + 30H" F e3+ + 4H20 * Fe(OH)4 + 4H+ ; IogK Fe2(OH)S+ + 2H+ ; log K - -2.85 2Fe3+ + 2H20 = -2.16 ; i°gK ,o= = -23 6 The effect of these hydroxo-complexes on solubility is dramatic and is most con­ veniently illustrated by using a log concentration diagram or pC-pH diagram (Figure I). Figure I is the most commonly encountered stability diagram when ferric salts are used in coagulation and is developed from purely thermodynamic equilibria. The interior por­ tion of the diagram indicates the area in which precipitation of Fe(OH)3 ^ may theoreti­ cally occur. Figure 2 is a superposition of the areas of sweep coagulation, adsorptiondestabilization, and restabilization, with charge reversed, on the operational diagram. The locations of these zones have been developed in previous work on coagulation of turbidity with ferric chloride [7]. The boundaries and locations of color removal areas are slightly different as will be shown later in this paper. FeCI -GH O - m g /I LOG [ F e ] -moles/lite r -2 pH FIGURE I : Fe(III) Log Concentration Diagram ESTAE5/LIZA V A \ ; y y% Sw e e p zCOagulaJION ///'////// • ' * / / / (/'Z// Z/// /z" / / // //Z/ S' ' ZZ ZZ Z Z > Z ZZZz Z^/ / 's / * 270 IOO ZVZ/^ Z/^ 27 IO LOG [Fe] - mole5/ I iter M -BESJABIL ZATlONX t e ZONE(CHANGE S I _W| TH COLLOID/5 FACE ARE A) X^FeOl H2 + ~7 / Fe(OH)" 4 FefC / _ 4 6 8 IQ 12 RH FIGURE 2 : IRON (III) COAGULATION DIAGRAM 2.7 1.0 .27 | / 6 uj - oCH9' ID3J ADS - 4 - Z O \ -------------- H- Q 2 ________ CL I— O. o: ,------------ ©1 F = \ 9 MATERIALS AND METHODS —. The most critical factors influencing the efficiency of coagulation for color removal are pH, coagulant dosage, and concentration of color [14]. The pH controls both the speciation of the inorganic coagulant and the charge on the organic color molecule. Synthetic waters were prepared containing the desired concentrations of humic acid, turbidity, and alkalinity. Five solutions of different color concentrations plus turbidity and three varied color solutions without turbidity were used in the color removal tests. Tech Grade humic acid* was used for color, and turbidity, in the range of 27-30 turbidity units (TH), was obtained through the addition of the colloid, Min-U-Sil-30.** Alkalinity was added to the distilled water in the form OfNaHCO3. Table I shows the constituents of the raw water solutions. Table I. Color Solutions. Color Designation Low Med. Low ' Medium Med. High High Humic Acid Concentration True-Color (CU) 4 mg/1 8.2 mg/1 20 mg/1 28.8 mg/1 37.5 mg/1 100 225 500 700 1000 Min-U-Sil I I I I I NaHCO3 .2N g/1 g/1 g/1 g/1 g/1 5 ml/1 5 ml/1 5 ml/1 5 ml/1 5 ml/1 Standard color solutions without turbidity are similar to those for Low, Medium, and High concentrations, without Min-U-Sil. Extensive jar testing was conducted so that areas of optimum color removal could be defined. A Phipps-Bird jar testing apparatus with a six unit mixer was used for the tests. Ferric chloride was added during a rapid mix period of one minute at 100 rpm. This was *Aldrich Chemical Company, Inc., Milwaukee, WI 53233. ^Pennsylvania Glass Sand Corporation, 3 Tenn Center, Pittsburgh, PA 15235. 10 followed by a slow mix, flocculation stage of 20 minutes at 24 rpm. Sedimentation was then allowed to occur over a 2 hour period. True color, apparent color, pH, and turbidity values were obtained for all samples. pH values were taken during the slow mix period. True color, apparent color, and turbidity readings were taken after the slow mix and at the end of the 2 hour settling period. Color readings were made with an Hitachi-Perkin Elmer, Colemen 139, Spectrophotometer. The wave length used was 422.2 nm with a slit size of 2.36 mm. Percent transmittance was con­ verted to color units with the use of a standardization curve. Turbidity readings were made with a HACH model 2100 turbidimeter. In disagreement with the procedure for color measurement presented in Standard Methods [15], the pH of the sample was not adjusted to a common value prior to spectrophotometric analysis. In coagulation experimentation, it is impossible to adjust the pH for color measurement without possibly inducing further coagulation thus interfering with the accuracy of the results. After turbidity readings and apparent color readings were taken, the samples were centrifuged for 5 minutes at 7500 rpm to remove excess turbidity which could interfere with true color readings. A decrease in color of 90% of the original measurement within the 2 hour settling period was considered to indicate effective color removal. The electro­ phoretic mobility (EM), which is proportional to the zeta potential or particle charge, was determined with the use of a “Zeta-Meter.” Electrophoretic mobility is a measure of the velocity at which particles traverse a measured path in a DC current at a specific voltage. Because of the variation in initial color concentrations of the different waters tested, removal areas on the operational diagram are defined by percent removal, not the magni­ tude of the residual color. For each o f the raw waters tested, approximately 50-80 jars were run. This adds up to a total of approximately 500 jars in a series of 83 jar tests. Figure 3 shows the operational FeCI • G H O - m g /I LOG [ F e ] - m o l e s / n t e r Removal PH FIGURE 3 : Color Removal Domain — Initial Color = 100 CU, Turbidity = 27-30 TU. 12 diagram for ferric chloride with the 90% color removal area for a water containing a color concentration of 100 color units (CU) and turbidity in the range of 27-30 TU. Figure 4 is an expanded form of part of the operational diagram. Shown are percent removal values used to delineate the optimum color removal area. This gives an example of the number of points used to define the color removal domains. Similar data were obtained for all of the suspensions tested. Because the boundaries and the extent of the color removal areas can be better seen on the expanded diagram, it will be used in the following presentation of results. The delineation of color removal areas are restricted to pH values not less than 4 and ferric chloride dosages not greater than 100 mg/1. Data outside of these ranges would be of little use in practice. 13 FeCI3- 6 H2O - mg/I F I G U R E 4: D a t a P o i n t s a n d C o r r e s p o n d i n g Percent Color Removal Val ue s - initial Color = 100 CU, T u r b i d i t y = 2 7 - 3 0 TU 14 RESULTS AND DISCUSSION Color Removal In this research, ferric chloride was found to be very effective in the removal of color from water. In cases where the dosage of the coagulant was either too low or too high for color removal, however, the color of the water was actually increased as a result of the addition of Fe(III). It is therefore important that correct dosages of ferric chloride be used in order to achieve color removal and to prevent an actual increase in the color of the water. The area of 90% color removal on the operational diagram varies significantly depend­ ing on the initial concentration of color. First, samples which contained color but no tur­ bidity are considered. Three different color concentrations were used, and the optimum removal, areas for each were delineated. Numerous studies [1,2,3] have shown that when alum is used in coagulation, opti­ mum color removal occurs in the range of pH 5 to 6.5. Ferric chloride, on the other hand, can be effective over a wider pH range [16]. Figure 5 shows the color removal domain for a solution containing a color concentration of 100 CU. Ninety percent color removal occurred over a range from pH 4 to pH 8.8. The area of highest color removal occurred in the range of pH 6.1 to 8.8 with ferric chloride dosages greater than approximately 10 mg/1. The dominant removal, mechanism here is probably the adsorption of color molecules on ferric hydroxide floe. The presence of an upper boundary for color removal probably results from particle restabilization, i.e., charge reversal. This can be viewed as an excess of positively charged ferric hydroxide interacting with the negatively charged color molecules. The lower boundary for coagulation is probably a function of the magnitude of.charge on 15 IQ) 100 loo IOO 0 O O IOO IOO 8 9 2 .: IOO IOCKO Removal 9 3 . 0 9 6.1/0 KO IOO O O pH FIGURE 5: Da t a Po i n t s and C o r r e s p o n d i n g Percent Color Removal V a l u e s - Initial C o l o r= 100 CU, T u r b l d I t y = O FeCI3 1GH2O - mg/l O SG.4 16 the color molecules. As the pH is increased, the dosage of ferric chloride required for removal also increases. This results from the fact that, with increasing pH, color molecules become more stable due to dissociation of functional groups, thus increasing the magni­ tude of the negative charge [2]. Color removal in the pH range of 4.0 to 6.1 at ferric chloride dosages of 2-100 mg/1 is slightly lower than in the area where adsorption of color molecules to ferric hydroxide floe seems dominant. This is believed to be a function of the concentration of humic acid mole­ cules present in solution. With low concentration, the chances of collisions following destabilization, and ensuing floe growth, are reduced. In general, the 90% removal areas follow a trend toward lower pH levels and higher ferric chloride dosages as the color concentration increases. With an initial color concen­ tration of 500 CU, the area o f 90% color removal occurred in the range of pH 4 to 6.7 with ferric chloride dosages of 10 mg/1 and greater (Figure 6). Color removal, for the water con­ taining a color concentration of 1000 CU, occurred in the pH range of 4 to 6.3 with ferric chloride dosages not less than 18 mg/1 (Figure 7). Tire only common color removal area for all three color concentrations occurred from pH 5.8 to pH 6.3 at ferric chloride dosages from 50 to 100 mg/1 (Figure 8). Effect of Turbidity The presence of turbidity in the range of 27-30 TU has little effect on the removal of color. Studies on coagulation with alum [2,4] have also shown this to be the case. Figures 4 and 9-12 show the optimum color removal areas obtained for the suspensions which con­ tained color concentrations of 100, 225, 500, 700, and 1000 CU with turbidity. The color removal domains show nearly identical ranges for pH and coagulant dosages as for those waters containing no turbidity. This probably results from the fact that the addition of negative charge due to the presence of turbidity, in the range of 27-30 TU, is negligible in 17 0 /9 8 .4 0 9 9 .5 /0 9 8.4 9 0 % Removal D o o 7 PH FIGURE 6 : Dat a Poi nt s a n d C o r r e s p o n d i n g Percent Color Removal Va l u e s - Initial C o l o r = 5 0 0 CU, T u r b I d I t y = O FeCI3 • 6 H2O - m g /| 9 2 .3 7 /6 18 0*0 98.7 ! 5 .3 /0 0 0 0 E 9.3 9 9 .6 9 9.7 9 6 .3 9 0 % Removal PH FIGURE 7 : Dat a Poi nt s and C o r r e s p o n d i n g Percent Color Removal Va l u e s - Initial C o l o r = IOOO C U , T u r b I d I t y = O Fe CI 3 • 6 H2O - m g / | 9 4 . 5 / 3 0 .0 19 • 6 HgO - m g / I FI GURE 8 : Common - Initial Color Color Turbidity = 0 Removal 1 00 - Domai n 1000 CU, |/ 6 i u - O 2H S - I D S - ! 20 FI GURE 9 : D a t a P o i n t s a n d C o r r e s p o n d i n g Percent Col or R e mo v a l V a l u e s - Initial C o l o r = 2 2 5 CU, T u r b i d i t y = 2 7 - 3 0 TU 21 0 0 9 9.7 100 100 0 0 IOO .5 10 0 9X 7 9 9 .3 0 0 0 9Sr8 IOO 38.2 6 .7 IOC I 0 0 50 100 9 6 .0 30 97.3 20 99.4 99.1! 9 0 % Removal vt o 10 5 3 I PH F I GURE 10: D a t a P o i n t s a n d C o r r e s p o n d i n g P e r c e n t Col or Re mo v a l Va l u e s - I ni t i al C o l o r = 5 0 0 CU, T u r b i d i t y = 2 7 - 3 0 TU •6 H O - mg/1 9 8 .5 heCI 100 9 5 .8 22 9 9 .2 9Z I 9 9 .4 9 9 .4 O O PH F I G U R E 11 : D a t a P o i n t s a n d C o r r e s p o n d i n g Percent Color Removal V a l u e s - Initial C o l o r = 7 0 0 C U , T u r b i d i t y = 2 7 - 3 0 TU ^ e CI3 ' 6 HgO - m g / 1 9 0 % Removal 23 O 98.6 99.3 99.7 99.4 9 9.7 IOO 9 8 .4 9 9 .8 100 9 8 .7 7.0 9 9.5 9 9 .4 9 9 .3 /0 0 100 99.1 / , 2 . 2 0 i.5 0 10 0 9 0 % Removal PH F I G U R E 12: D a t a P o i n t s a n d C o r r e s p o n d i n g Percent Color Removal V a l u e s - Initial C o l o r =s 1 0 0 0 C U , T u r b i d i t y = 2 7 - 3 0 TU f'CCIg • 6 H O - m g / | 0 0 0 24 comparison to the magnitude of negative charge due to the presence of color in the range of concentration tested. A composition of the areas for color removal again defines a common region of color removal for color concentrations in the range of 100 to 1000 CU (Figure 13). The pH and ferric chloride dosage ranges are near those defined in the composite diagram (Figure 7) for waters containing no turbidity. The color removal domains for all the solutions tested are shown in Figures 14-21. This data should provide a useful tool in the design and operation of water treatment facil­ ities. Removal Mechanisms Color removal may be accomplished by charge neutralization resulting from specific chemical interactions between positively charged ferric species and the negatively charged groups on the humic colloids. The fixation of multivalent cations onto ionized groups on hydrophilic colloids may be due to electrostatic or chemical interactions causing a reduc­ tion in the charge on the particle [16]. Precipitation by this mechanism probably occurs at all the pH values tested but seems to be dominant at pH values ranging from less than pH 6.1 to values less than about 5.0 (Figures 4 and 9-12) depending on the concentration of humic acid in the water. Figure 22 illustrates that color removal and charge restabilization are dependent on the color concentration. In Figure 22, the upper and lower boundaries of the removal areas shown in Figures 4 and 9-12 are graphed as a function of coagulant dosage versus color concentration. Results at pH 4.5 show a straight line or stoichiometric relationship. Similar stoichiometric relationships are observed at pH values of 5.5 and 6.3 as well (Figure 23). The range of ferric chloride concentration within which coagulation is observed widens considerably with increasing concentration of surface. This is probably due to improved 25 HeCI3 • 6 H2O - mg/I FIGURE 13 Common Initial Color Color Turbidity 27 Removal 100 - 30 - Domai n 1000 TU CU, 26 I p p * ' ' m W ■ ^ ^ 9 0 % M FeCI • 6 H O - mg/1 W Rem oval * — ■ I f lliSISIl HFr — 4 5 6 7 8 pH F I G U R E 14: -Initial Color C o l o r = 100 Removal CU, Domain Turbidity = 0 9 27 Mm m p - I OO r ■ P 90 % Removal — -- — ------ --------- ----I PH F I G U R E 15: -Initial Color Color= Removal 500 CU, Domain TurbIdity = O FeCI 3 • 6 H O - mg/1 i 28 IOO r ™ ! ■ k J jP ^ 30 "^90 % Rem oval — — PH F I G U R E 16 : C o l o r Initial Removal Domain C o l o r = 1000 C U, T u r b i d i t y = O 20 FeCI3 ' 6 H O - mg/1 — 29 Wf* 18 F 50 30 10 — 5 3 — 1 5 6 F I G U R E 17: Initial Color Color = 7 8 Removal Domain pH 100 C U , T u r b i d l t y = 2 7 - 3 0 9 TU f-eCI • 6 H2O - mg/1 — 20 9 0 % Removal / ill W IOO 30 ■11 FeCI • 6 FLO - mg/1 f — ^ 9 0 % Removal UP — — 5 6 7 Q 9 pH F I G U R E 18: Initial Color Removal C o l o r = 2 2 5 CU, Domain T u r b I d I t y = Z 7 - 3 0 TU 31 /■ i ^ ^ 9 0 % 30 — 20 Removal — ---------------------- pH F I G U R E 19: Initial Color Removal Domain C o l o r = 5 0 0 C U , T u r b i d i t y = 2 7 - 3 0 TU FeCI • 6 H2O - mg/1 / W f p IOO 32 W III W 0 k PeOI ' 6 H O - mg/1 — a ^^9 0 % Removal — — 4 5 6 7 8 R e m o v a l Domain 9 pH F I G U R E 20: Initial C olo r C o l o r = 7 0 0 C U , T u r b I d 11 y= 2 7 - 3 0 T U 33 F j a m I p i ^ ^ 9 0 % Removal — ----------- --------- - pH F I G U R E 21 : C o l o r Initial Removal Domain C o l o r = IOOO C U , T u r b I d 11 y = 2 7 - 3 0 TU FeCI 3 • 6 H O - m g / | — f/ ioo90H - upper boundary Jov/er boundary COLOR CONCENTRATION- CU FIGURE 2 2 : Stoichiometry for the Color Removal Domains pH - 4.5 ioo- on COLOR CONCENTRATION- CU FIGURE 2 3 - ‘ Stoichiometry for the Color Removal Domains • p H - 5.5 , © pH- 6.3 36 ■coagulation kinetics (improved contact opportunities) with increasing color concentration [17]. Electrophoretic mobility data further substantiates the mechanisms of charge neutral­ ization and restabilization. Figure 24 shows partial charge and EM values (microns/second per volt/centimeter) for a water containing a color concentration of 100 CUwith turbidity. Figures 25, 26, and 27 show particle charge results for waters containing color concentra­ tions of 100, 500, and 1000 CU with turbidity. All restabilized dispersions were found to be positively charged. The production of zero charge on the color particles occurred infrequently. In agreement with Black and Singley’s [18] data, highest color removal occurred at slightly negative mobilities. Highest color removal for the various solutions tested occurred at pH values ranging from greater than approximately 5.0 to greater than 6.1 (Figures 4 and 9-12). Particle charge tended to be slightly negative and the dominant removal mechanism was probably adsorption of color molecules to ferric hydroxide floes. At these higher pH values within the color removal domains, the OH” formation function ([OH"] bound per [Fe(III)]) increases, thus, the net positive charge on the hydrolysis species decreases. As a result, complete charge neutralization and restabilization become retarded or eliminated [16]. Apparent Color Removal Apparent color is true color plus the interference in color measurement due to the presence of turbidity. The removal of apparent color is a measure of a simultaneous removal of both color and turbidity. Figures 28, 29 and 30 show areas of apparent color removal for waters containing color concentrations of 100, 500, and 1000 CU with turbidity in the range of 27-30 TU. The boundaries for true color removal (dashed lines) are also depicted on these figures. The removal areas for apparent color correspond closely to those for true color. For the , 37 - + 1.4, - + 1.9 + 1.7 + I/. 7 + 2 .3 0.6 - -0.5 - 3 .2 0.6 - 0 .7 • 2.6 -U - 1.8 2.0 - 3 .4 ^3.1 -3. i -3.5 -3.7 -1 .6 -3.1-3. L + 2 .3 Rem oval 2.1 + 2 .3 /+ 0 .8 - 3 .2 -3 .1 + 0.6 3.3 -3 .5 - 3 .2 - 3 .6 PH F I GURE 2 4 : - Particle Initial C h a r g e and EM Values Color Turbidity = 27 = -30 I OO TU CU I FeCI5 • 6 H O - m g /| + 2 .4 38 FeCI5 -G H2O - m g /| pH FIGURE 25 : P a r t i c l e - Initial Charge Color Turbidity = 27 = -30 I OO TU CU 39 pH figure 26: - Particle Initial Char ge Color Turbidity = 27 = 500 -30 TU CU, FeCI3 -G H2O - mg/1 Removal 40 FeCI 3 • 6 H2O - m g /| FIGURE 27: - Particle Initial Charge Color Turbidity= 27 = I OOO -30 TU CU, 41 IOO 50 30 I 10 pH FI GURE 28 ■ A p p a r o n t - Initial Color Col or Turbidity = R6 m o v a I Domai n = 100 2 7 - 3 0 TU CU, FeCI 3 • 6 H2O - mg/J 20 42 ■ ' / % W r / ^ ^ 9 0 % Rem oval E — 4 5 6 7 8 pH FI GURE 29: Apparent - Initial Color Col or Turbidity = Removal = 500 2 7 - 3 0 TU Domai n CU, FeCI •6 H O - m g /| ■ij — 43 Tr- F I — x ^ ^ 90% Rem oval -------------------------- I 5 — 4 5 6 Q------------------- — 7 2 Il pH FI GURE 30 • Apparont - Initial Color Color Turbidity= = Romoval IOOO 2 7 - 3 O TU Domai n CU, FeCI 3 •6 H2O - m g /| — 2 44 water containing a color concentration of 100 CU, however, the apparent color removal domain corresponds only to the upper portion of the true color removal domain. The lower boundary, which occurs at a higher ferric chloride dose than that for true color removal, is probably a function of the amount of coagulant involution and related coagu­ lation kinetics. Precipitation does not occur in the time allowed for settling. Centrifuga­ tion for true color analysis, however, resulted in the removal of these small slowly settling particles. Turbidity Removal Although the presence of turbidity in the range of 27-30 TU has little effect on the removal of color, the presence of color has a dramatic effect on the removal of turbidity. Figures 31, 32, and 33 show areas to 50% turbidity removal for waters containing color concentrations of 100, 500, and 1000 CU. The boundaries to true color removal (dashed lines) are superimposed on these figures as well. Effective turbidity removal occurred in the ranges of color removal. This is probably due to the fact that the magnitude of the negative charge resulting from the presence of color far exceeds the magnitude of negative charge due to the presence of turbidity. Hall and Packham [4] achieved similar results. 45 Z ______ Jfk \ ^ W Z L p 5 — % Removal 0 — / / CT — pH F I GU R E 3 1 : T u r b i d i t y - initial Removal Color Turbidity = = 27 Do ma i n I OO - 30 CU, TU FeCI3 • 6 H2O - mg/1 m /IW Yk W ___________________________ 46 FrCCI3 ' 6 H2O - mg/1 50 % Removal FIGURE 32: Turbidity - initial Removal Color Turbidity = = 2 7 - Domain 500 30 C U, TU 47 ■ F — ^ ^ 5 0 % Removal — 4 s ----------------- - I C PH F I GU R E 3 3 : Turbi di ty - initial Removal Color Turbidity = 27 = Domai n IOOO - 30 CU, TU FeCI3 • 6 H O - m g / | JP 48 CONCLUSIONS When the variables involved are properly controlled, ferric chloride is a very effective coagulant for the removal of organic color. For each colored water there is a specific range of pH values and ferric chloride dosages within which effective color removal is achieved. The two variables that must be controlled are pH and ferric chloride dose, both of which, as a result of the data presented, can be predicted with considerable accuracy from the raw water color alone. Color removal areas follow a trend toward lower pH levels and higher ferric chloride dosages as the color concentration is increased. The presence of turbidity in the range of 27-30 TU has little effect on the removal of color. Removal areas for both waters with and without turbidity occurred in the same ranges of pH and coagulant dosage. The areas of turbidity removal on the operational diagram were dependent on the con­ centration of humic acid in the water. Effective color removal and charge restabilization are dependent on the color concen­ tration. The range of ferric chloride dosage within which removal occurred widened with increasing color concentration. Highest color removal tended to occur at higher pH values where the formation of solid phase ferric hydroxide was probably prevalent. The results of this paper represent an extensive delineation of optimum color removal areas with the use of ferric chloride as the coagulant. The diagrams should provide a useful tool in the design and operation of water treatment facilities. REFERENCES 50 REFERENCES 1. Dempsey, B. A., Ganho, R. H., and O’Melia, C. R. The Coagulation of Humic Sub­ stances Using Aluminum Szits. Joum alof American Water Works Association, Vol. 76, No. 4, 141, April 1984. 2. Edwards, G. A., Color Removal Domains on the Alum Coagulation Diagram. Unpub­ lished professional paper submitted in partial fulfillment of the requirements for the Master of Science degree, Department of Civil Engineering and Engineering Mechanics, Montana State University, 1982. 3. Edzwald, J. K., Coagulation of Humic Substances, AIChE Symposium Series No. 190, W ater-1979, Vol. 75, SY, 1979. 4. Hall, E. S. and Packlram, R. F., Coagulation of Organic Color with Hydrolyzing Coag­ ulants, Journal o f American Water Works Association, Vol. 57, 1149, 1965. 5. Semmens, M. I. and Field, T. K., Coagulation: Experiences in Organic Removal, Jour­ nal o f American Water Works Association, Vol. 72, 476, 1980. 6. Mangravite, F. J., Buzzell, T. D., Cassell, E. A., Matijevic, E., and Saxton, G. B., Removal of Humic Acid by Coagulation and Microflotation, Journal o f American Water Works Association, Vol. 67, 88, 1975. 7. Johnson, P. N. and Amirtharajah, A., Ferric Chloride and Alum as Single and Dual Coagulants, Journal o f American Water Works Association, May, 1983. 8. Schnitzer, M. and Khan, S. V., Humic Substances in the Environment, Dekken, New York, N.Y., 1972. 9. Snoeyink, V. L. and Jenkins, D., Water Chemistry, John Wiley and Sons, New York, N.Y. 1980. 10. Siao, W., Christman, R. F., Johnson, J. D., Millington, D. S., and Hass, J. R., Struc­ tural Characterization of Aquatic Humic Material, Environmental Science and Tech­ nology, Vol. 16, No. 7, 403, 1982. 11. Sawyer, C. N. and McCarty, P. L., Chemistry For Environmental Engineering, Third Ed., McGraw-Hill, New York, 1978. 12. O’Melia, C. R., Coagulation and Flocculation, Physicochemical Processes for Water Quality Control (W. J. Weber, Jr., ed.), Wiley Interscience, New York, N.Y., 1972. 51 13. Galarragara, E. P., Influence of pH on Dosage Requirements of Ferric Chloride. Unpublished thesis submitted in partial fulfillment of the requirements for the Master of Science degree, Department of Civil Engineering, North Carolina State University, 1980. 14. Kavanaugh, M. C., Modified Coagulation for Improved Removal of Trihalomethane Precursors, Journal o f American Water Works Association, Vol. 70, 613, 1978. 15. Standard M ethodsfor the Examination o f Water and Wastewater, fifteenth ed., Amer­ ican Public Health Association, Washington, D.C., 1981. 16. Hyde, C. H., Practical Aspects of Coagulation with Ferric Chloride, Journal o f Ameri­ can Water Works Association, Vol. 27, No. 5, 631, 1935. 17. O’Melia, C. R. and Stumm, W., Aggregation of Silica Dispersions by Iron (III), Journal o f Colloid and Interface Science, Vol. 23, 437, 1967. 18. Black, A. P., Singley, J. E., Whittle, G. P., and Maulding, J. S., Stoichiometry of the Color-Causing Organic Compounds with Ferric Sulfate, Journal o f American Water Works Association, Vol. 55, 1347, 1963. MONTANA STATE UNIVERSITY LIBRARIES K378 N T lT N o le n , v . n . c o p .2 Coagulation c o lo r w ith fe date MAIN LIB. N378 NTlT cop. 2