Acid and enzymatic hydrolysis of autohydrolyzed lignocellulosic substrates

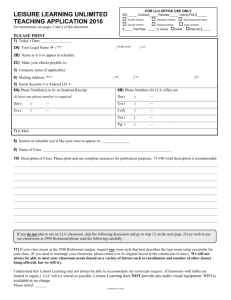

advertisement