Document 13504283

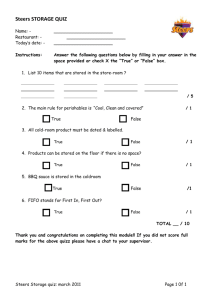

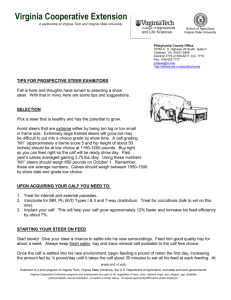

advertisement