The effect of reduced pressure on the efficiency of a... by Daniel O Popovac

advertisement

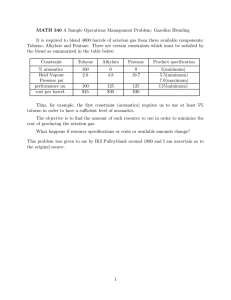

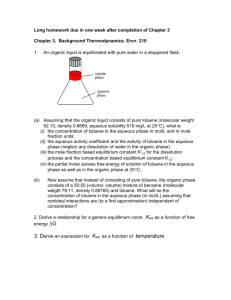

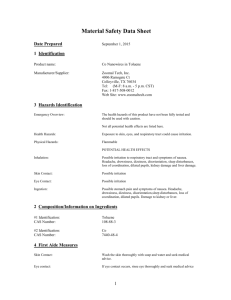

The effect of reduced pressure on the efficiency of a packed rectification column by Daniel O Popovac A THESIS Submitted to the Graduate Committee in partial fulfillment of the requirements for the degree of Master of Science in Chemical Engineering Montana State University © Copyright by Daniel O Popovac (1948) Abstract: A study is presented of the effect of reduced pressure on the efficiency of a packed rectification column. A rectification column two feat long, one inch diameter and packed with 1/8 inch stainless steel Fenske helices Wss employed* A test mixture of n-octane - toluene was used. Vapor-liquid equilibrium was determined for this system at pressures of 20, 50, 100, 200, 300, 400, 640.3 and, 760 mm. Hg. absolute. The column was then tested with the mixture at the same pressures, operating at just "below the flooding point* Calibration was made at total reflux and at reflux ratios of 3041 and 20*1, in each case it was found that the number, of theoretical • plates as determined' from the corresponding vapor-liquid equilibrium diagram via the IeCabe-Ihiele method was between 11 and 14* Ihe same column calibrated 14 plates at 760 mi* Hg^ with the standard test mixture n-heptane * toluene/ IheSe results indicate that column efficiency is independent of pressure * Design calculations may be based on vapor-liquid equilibrium data determined at the same pressure as that at which the colum is to operate, the H.E.T.P. of a given packing re-maining constant^ t ' I ' ■„ !BESBt 3###%' Q# BamWW 2 W M B # ,; - ' by • ^WiEBb -$& '#&|M3dg3W& - sS AW $ # Snbmibted to th e CJtaanate' Sbamittee-. % U aytial fu lfillm e n t o f the requirements ■ fo r the degree Of Master o f Sqience in Chemical Engineering \ .. - .*# Montana State College ipproyedg Sozemang Montana Angus#* 0P'A 'p g l * ' 2 IA i- Ii CF COATFWIS Page I SUinzaary XI Introduction* . 3 . . . . . . 4 . III Experimental M aterials, Equipment and Procedure . . . . . . . . . . • • • • IV R esults . . . . . . . . . . . . . . . 11 V Conclusions . . . . . . . . . . . . . 19 VI References. . . . . . . . . . . 16 V II Appendix. . . . . . . . . . . 18 . (Tables and Figures) V 87103 8 3 , -& s t * # i s ,p#ese#ted pf the. !Bdrgfeetr e f yWiicGa jpyw@%m . W the .#& a;2&d&ed %e^#ic&t&6& gel##,* .& SfdMdbj,* f&o&tla& GolWa two f g # Iomg,. .one I n # &K#ietey &&a gashed With i / 0 Iiaei-I g ta in le s g s t e e l Fenske h e lic e s Wes employe<i« i t e s t s l » t w g o f 'a^oetase * to ia e n e was n sei^ agallfkriam was dateymlaed f or th is #0^ fapoy*M<|UiS. a t pressures o f 106,5 200% 3609 400$ #40$ and. /#6 MM4. I g * ahsolnth* Ihe eoliinm was then tested, with the mixture a t th e same' pressurest Operatj1Ug'. a t ju st halew ■the flooding p oin t.^. S alih ration TRas #&#$ a t t o t a l z a flu # ahd.8t..r#f%%%, ratl&a o f 30&I a&d$o$t<. i& eadh a&ee. i t was p la te s sis # a t . tW wWW; a# tW @ r& tl#al...' from the 4yqaf3*ews%iqd3dti&ig; ##1» lihrium diagram v ia the IeSahe^f-Mele method ms he tween 11 and 14* Ihe same column calibrated 14 p la t e s ,a t # 0 mi® %# w ith the staM ar# t e s t mlBtura W%g#Wa 4 teiue&a^ fh # e ' r e s u lts in d ica te th a t column e ffic ie n c y i s independent: of pres* sure* Design ca lcu la tio n s may he based on w p or*liq n id e q u ili* brlum data determined a t t h e .same pressure as that .at which the nelw w i s t e #p@#ate% the &*#*#*#*'of e given packing re* m&iWag eon stah tt . X .,y v ^ y ,,s . .. .. 4 $6 ■$M d * e i# o f ' eolmms ■# e -# # i^aWIng $$ p la te # # -:@apa$a%lW'" 4esire'4 and ■t&e operating eonditlana^ ■'IIany metfeads '■tax.'&$,&*> enlating' tW nmMy .'^ eo y etieal .'piates: 03? -,soew* Saary -fo? a given aeparatian. have %aen yapeg### T hiele grapMeal method and the ^enske eqnatlon are -t# ll - ■■ known* ilQ-f-'B%- -fanthra InfineneAng Oolwnn e f^ ieaghey-'tonstth erefore ..play an Important, role 'In design caleulatioB * ' ■ '- ^ ffleM noy i s not. a- funet-ion o f '.any 'single- p rep erly '# ' "r ren d ition and -hs:S been 'in vestigated with, nany n eeu ltin g -eer# re la tio n s# • Many stu d ie s have been reported in the" litera tu re' on th e o f f e e t - o f the p h y sical p rop erties of the m aterial being fraotl-onated* • SrihkSw y and B ridfetd Showed th a t fo r PheS^7 • merelai' hydroearhon fraetionatSng eolW ps and ahserhers,#7.the* p la te e ffie ie n e y increased with th e .'deereasihg' v isc o sity # # ') .Ji- Thls- C orrelation was made:on commercial equipment -Wt i s ih lt * a b le only fo r hydrocarhon. separations with low r e la tiv e v#a#t l l i t y -of- th e key components and'the average: molal liq u id ' v is c o s it y o f the column' feed.$ hoth’'at th e average tower temp**-erature and pressure*, ( I D Brown and Soekhart- -studied the -effect o f vapor lead on p la te e f fic ie n c y in fra ctio n a tin g columns* (3) They report th a t except for Very low v e lo c itie s ^ the. overall column e ffi* clency is re la tiv e ly independent o f mean tap er velocity^ ' . \ - :/ ^ ' . , -' ■BeSlmWa ■•efflusteacy being 'obtained a t the 'Basiatiam ailbwable' v elo city Xrom ;the |ondezs:.- Brpwn Oqnatipn, (13)» ' -SBoSsp and Blackburn Investigated and correlated th e e ffe c t of re la tiv e amounts of the components in the s is tn r e and th e rate, OX'' dig* t il la t io n ,upon efficiency#" .(16) ' ■' • • : 1. • _ *: • , ■^ressnre has,- appeared in- t h e ' t ©chnical". lite ra ttire ' to date#Binary mixtures fo r evaluating" low' pressure d is tilla tio n col* umns have been reported*- ‘W illiams suggested mixtures' o f M ty l phythalate and dl^n^butyi, amolate fo r th is purpose for pressures o f .about I mm, (17) ■Wldmak^ '%leS and -SrOhih : ■ .-V*1 studied binary m istures fo r evaluating r e c tif ic a tio n columns‘ a t pressures from 20 mm, Sg, to IGO mm, Hg* (7) ■lhey presented -data on■two t e s t m ixtures; Ca) n*dodeeane and' cyclohexyl cyclopentane and (b$ nitride-cane' and d icycioh exyl, *in, t h is ’ - ,rep o rt a- p lo t' of average re la tiv e v e la ti l l t y ■■versus the pres* su re: shewed th a t for. the mixture n itrid e cane ' dicyclqheXylg y the r e la tiv e v o l a t i l i t y approaches' a minimum a t ■about 1 # mm* then r i s e s again*' For Wdodecane * ,cyolohexyl cyclopentane the 'relative" v o l a t i l i t y :fol'l,ows' a t 20 smooth' curve"' from a'.--Mgh to a: low" a t #% mm* fhe- vapor liq u id equilibrium - diagram for the: n^dodeeane cyclohexyl' cyclopentane'' system approaches the 4 5 -degree diagonal -from -above' as the pressure increases' from 20 to 400 .mm* fh e diagram for n-tridecane ^ C icyclohexyl moves from below the 4-5 degree diagonal through Ineldehoe w ith to .above fo r InereasiB g (pressure from SD mm to' '375: mm* '-Srissoid^ 'ihd^es hhd #& $i#.^ow ed ■■! ■high' ^fessW es 'oh' th e "Vapor, liq u id equilibrium = hehsehe to lu w e ^ (5^ ! 'f h e ir p lo ts ' showed t h a t th e vapor ’ .••- l i q u id w rv e 'Bppro^ehed .the ';;0 degree d la g ^ h a l from "Bhove'".as ■ the" p re ssu re IB oreased from Btmespherie to' 5©0 p s i f ': •,s fh e purpose' o f th lh 'sofk i s ' t o ' determlBe t h e -Offeet Wf re* duced pressure on columh OffIciehef*' ■’ifowhere In' th e lite r a tu r e i s there information conoerning' the spe'eifio e f f e o t on Veeti*- • f lo a t ion Offioieney of-changes IB operating pressure-,i - th e • widely diverse views enterjtaihe^ by- d f s tf lia tlo h O # 0 rt# Wh' t h i s subIeet in d ica te a nood fo r a .berreiatloB' o f those v a fi* a b le s -9 ! ,t e s t mixture . was sought, which- approached id e a lit y ? ■ which was easy to analyse accurately, and would'.operate oyer ■a wide range' o f pressures.,. ■f he 'system m*0#tame v toluene -prow ed to f u l f i l l these 'requirements most readily* th e Vaporliq u id equilibrium rela tio n sh ip s were determined a t a number of d iffe re n t pressures between -SD mm# and 760 mm.#. Sg.» absolute* A sta n d a rd ise d packed column was th e n c a lib ra te d a t t o t a l r e f lu x a t 30 i l r e f lux- r a ti o and a t '#$*1 re flu x ratio- -with th e -# s t mix* tu re a t the 'same pressures at-which the vapor liq u id 1e q u ilib ria had' been determined-, the number -of th e o re tic a l p la te s of the was determined from the vapor l l q a i i e q u ilib ria by th e McOabe^fhleid method* ' #'inee vapor a # .liquid o u tp u t , ' - F. ' Map w e ll W a -faeiatriMtlngS etem inatlbns ■ i' in .eeltimn' e f f le i e ii # g ' a l l . made with the column operating a t ju st below the llooaing- pd in t? and th e ,ra te of liq u id ,take: c-ff . determined fo r ’t he ru n s, other’ than t o t a l ■> . • ■ mmBBiA&G* A# m G ##® normal heptane (.Waatyaao -Ghemiea l was su ffic ie n tly pure, for use without fa rth e r processing* . ' • ‘ • ■ - ■ - . . ■ ■ ■ ' - normal octane ' (Connecticut SarG Suther Go.) and toluene (Baker’s Analyzed) were- subjected to r e c tific a tio n in a laboratory column haying approximately th ir ty th e o re tic a l p la te s $ and h eart c u ts .boll* i n | net more than ± 0*2%/ f r ^ the-normal b oiling pointer were' separated* :- i Vapor liq u id equilibrium determinations were made in a glass Othmer s t i l l ? (12) which.was, .connected to th e vacuum eySbeto4* -fhe. 'vaonnm system, consisted of two fiv e gallon surge tanks.g one of which was connected to a Wegavac vacuum pump* A B etro it lu b ricato r GO## So# 683*3# solenoid valve was placed in the lin e between the surge tanks and the valve was activated fey a mercury contact vacuum regulator through ;a Fisher-SerfasS electro n ic re la y , (SMUSte*'- Bi dlS* connecting the vacuum pump, p ressu risin g one surge tan k with nitrogen and reversing th e relay# th e system could be made- to operate a t super atmospheric pressure* operating pressure was read from a mercury manometer connected to the system.# ■ The r e c tif ic a tio n column employed was made of pyrek-glass two fe e t long#: one inch in., diameter# packed 23 inches high w ith 1/8 inch ^ensM sta in le ss s te e l helicea ahd equipped w ith a gored constant r e f i t s rubles d is ti lli n g head* The head and fGHasMs* %We##L v&aw#& syeWet sws t W t fe&e&vwe t@ %W *##&& W '#WWw%& a t %&& o$)@r# daitdLagg: pewmwe*. M # » .-ata#- <0 =GwaiaKt %w tk » a%Wm w e # # d W ##& # 8 8 th e W#% j&#gB4aN%'i8d%3Bo8B9bsM5t' swat # & t # e W W & 'Ope$&t0 8 a t $& # TaetBbGMe th e fl#@# IPTggMKB Bkdbg&aj&dt : WWM&WAWwa www <AW W 6 by th e A ?3&3&&* 8#8#&& 4 # (M aetm e; '#3% ahe *y 3#&#$R#&&8 o f th e m Wo s#QN& ga&B&gaw* t # th e #%&&* ;%#e e t& # #a# @WW a # ##& TS^mAy ywo### t # #& dw #*#' ###@#%&*. $W M e t TRWtsa t* $$#a a r a t e * f @W# w e # # pey e@W8&* # 8 m W a##» .w e - al&ooe# W bwt t # &#p@ Iwot &tte3& ItaisWBt IBRbB W a t %8s tayoed o f f ae# th e TgSbGaaaxa; 8&Wy ^WWywWA* IRagBGBf #8# MggaM W W W . W » SkedGaBR «hd ##& y ,d e W m # # Tw W&# && & %3aet&#e #% e # # e W W ^ m o W , -WWWW t& SSkdGW SSSSL*, W& #yev&@Wy W w obte&Bea 0 # em%gW mWa#na# o f W e &&#%&# e e W e t th e o##WLt&0B Of # 0 M y W # *##%# Sb** read fy#*'* A $ e g |# # R W lh@#i * tm # 0 8 ltf0 8 oozmie* W OW wW w TBw&gLiteea t o o # W % # o Wo TpggGHBf te#pg#&t#r@ && # e #1%%* . <»3? "% » 'W W 0 TPgte Ooae At SdBws ewW y e$ w w e# f o r %&&#; e#l!U ^& % 8 a e t* #%ee o h te f m a t A oW fge ^ %* ootaBO * 1h9#88W wee M doa t o th o <edKdL&3%%H98& m d TR&#o%#B $&# m e f l o o d # to R esw e & tW fim ghiy we# # # $ % # W & 'W WarB liipmt /aagmstei sa tfiat Ifee p w ti# # jfesl slS.gfela.3r fealow'.#o0##m# &M- 'rfefes were oo&tjWeW'W 'C ' ' '" ' ' ' ' fi' . t o t a l r e f i l l fa r afeont. fiv e .fe6mra@.:. 4 vacnm receiver wap used to obtain samples to fee analysed Wfeile Ifee eolmma re*. imW&d a t # e p^aemre*' were taken'PdM I the analrsis .was eofestamt# # Ifee re S lw r a tio s of BOsl and 20sl$ tfee bead was properly adjusted and' the rah eontifeued fo r a h a lf hour before, samples were taken*. BurMg th i s time th e r a te of take o ff was determined., ffeeu several samples were taken a t 15 minute Mterrals*. ■All ,e#ly*. Sis Was done on the refractom eter and eompositioh determined by the re fra c tiv e index'I- composition curve. .Samples---Were■' taken in th is manner u n til d i s t i l l a t e and bottoms composition _ became a constant number- o f th eo retical, p lates apart,*: .... . ' - . -* .. e<mia W #5%# si -#$9 $;@%gB'. aa# .#&$# 0e#faet* I YB iMiBea' WB3?B IiffBYent' e:fioug-$i to permit accurate atiaiyslSte - The f i r s t mixture ehosem was. eth^ibeB&B&e •■» n-octane, ' Ehese liq u id s s a tis fie d the requirements .above hut the data obtained on the system was .uusuita&&9* 4 ameetb equilibrium m m # ew &' da& t W abtaiae# ' a t ' Im d' r .pm ssw #.^ %&&a &a&e #&&*#& e a lib ra tio h with t h i s mixture impractieai^. # e system to # e a e * , metby&uyelo&e$&ae was the# te ste d but was found to h a # to p lcmr $ b illin g p o in t a t 20, ami* and was therefore unsuitable fo r th i s study* : *. ' #*#etene * -toluene,prove# sa tisfa e to ry an# f u l f l l l s d a l l th e requirements^ ■ the- boiling p oints of th e pure- components determined" Sn the" equilibrium s t i l l compared favorably w ith the vapor pres* SUre data found in the literatu re . (59 14, IS) Ihese were plotted' on at #ox CkBuairt and IdadLs;. MrW need to calculate- agtib*-' v ity soeffieie& te* u n reliab le temperature measurements a t ' 20 mm. #&» made ca lib ra tio n s of vapor pressures an# a&tivl&y co e ffic ie n ts impossible a t th is pressure, the experimental equilibrium date and th e calculated data ,are shown In E eb les I to V lIlf inclusive^ An example o f th e equilibrium-diagram , # t 480 mm* % * In 'ilia e tra te d 'In % # ra& I* B and '3# E&a&e 13 were p lo tted on graph paper.20 " . % 20 " .to give s u ffic ie n t ,. aecwaey»'- : The eonsistance of the data is shown' to he satis^ faeto rv w m laspehfIon of th e a c tiv ity .coefficient .-dwves, -of Mgnres- 4- and 5 ah suggested by Oaaisen and Ooibnrn* (4) Their •study shows th a t deviations- in these curves' indicate ■ inaccuracies in 'th e data* Siepes o f the lin es must always of oppdaite s&gh'.'ht /given v&lne o f &; i f th e _'8l$p& one of the curves. Is equal to aero.)^fhe. other must .have a herd slope a t the seme value e f.h # c e p t a t theytermlhhl peihts% " u " '" ' • • I' * . - X» , . -N , ry* The approach to the value of 1#0 with a horizontal, tangent In* d ic ates tabwali Baeult^s law applies to the opponent whose.mei fra c tio n approaches 1 # -and Eehryt-S law demands th a t the -other end of each curve reach a f in i te value with a f i n i t e slope* fig u res 6 to 9:$ Inclusive^ -are p lo ts of the re la tiv e v o la tility sis Awam the data* ' .& p la t -of-average re la tiv e t i l i t y versus pressure is ' shown, in Figure 10 * TM average' re la tiv e v o la tility of th is system -Ms a maximum a t abdut- 4©0 ■ mm. Eg^ a s shown i n figure. 10*. o t# ie r reported th a t the mixture aeetohe*water forms, eh azeotrope a t high pressures a n d :# # de* creasing-, p re s s u re -th e 're la tiv e .M l d i i l i t y 'ihcreased* J '|B | ■ • • Ber&* Harrison and MOhtgomery showed th a t the azeotrope cm# p o sitio n of lsebuianol ^ethylbenzene decreases with increased pressure* (I) This, illu s tr a te s decreasing re la tiv e v o la tility w ith decreasing pwegmte^ o f these reported M ta with, th a t o f this, pgpe.^ ••.isd io ste ^ ,.-that "the e f te s t o f 'p^esstm OA.th e r e i & t & v e " w i t h tia#*'. . •’ '!Tahis- l i :hOhtsihs the; % ta..Shtmihea- ^som the eaiiM atiO h •• rm s* ; toes© data: '.used- tsv-meke. hMsbe.^ihieie diagrams a t •the various ptessw es* ■(figures.. I 3. 2 and 3) . From these dla# grams the. number: of th e o re tic a l p la tes in the. column w a s , , VRA' hpm the - 2$- 44^ 0» @# packing In t w ho&mw*' $he 4 # a , are ahaW in / ’fa h ie S# She -Bumher' o f th e o re tic a l p la tw obtained at.'the various pressures-- were h cn sisten tiy between I i and 14*. - -r •.i s lig h t % -higher w lt-es obtained # t the lower pressures.; might b e ,gusti^iad'- 'bf: the Fadt th a t operation .closer- to Flooding, was e a sie r to obtain at- .these- pressure's'giving a higher .eFfioieney^.. Ihe F aet that, the number of th e p re tic a l p la te s are eons.istentlf between the •lim its o f 11 and 14 shews th a t the o f fie le n e f mains, re la tiv e ly the same with changes in operating pres sure b I t is in te re stin g to note that, the re s u lts do n et get ste a d ily lm rer e r higher b a t th a t th e .^ # t'# a e re p a h a ie 'S .in .tw .)W b .e r o f p la te s obtained are scattered ,enough to in d icate ":-ne .-define- ■ i t e trend#. ■ . In order to W r iff the r e s u lts obtained with the system n>octane »• toluene> th e column-was c a lib ra te d . a t -th e th ree • . WFlm'" r a tio s with .ano#em t e s t W i# ta n e , *We3#e&e*. ^W se W w lt s 'were -p lo tte d * 6 # g . t h e . e^uiMbrium, dh#- -o f - =Brotiiilef and Quiggle0 (2) Ihe number o f th e o r e tic a l p la te s ■oMa'ined' mas' # which' Compares , , .. System ^dctaiije' 1% #&&'.%* _ with # 1# ' ' , t W ' ",\ I .: tolnehe'i=. '"9-hase .kata a & *"im#3^d 6d- ’3m -SalbleS' ' . '" ' '/ ' - ' '•, . . . . The fo,ITowlhg conclusions' may'he .drawn from t h i s study? ' ■!(*.. Packed column eTTicioney' i s re la tiv e ly independent, of changes in operating pressure and/factors normally ass©*- ' elated with pressure change # 2% The increase or decrease ■in the. degree of separation •of a mixture- in a given column accompanying pressure, change is due prim arily to change in the average re la tiv e v o la tility w ith pressure.#. ■ 3* ‘Design calculations fo r re c tific a tio n should he based upon the vapor liq u id equilibrium re la tio n a t the oper­ ating, pressure# ' // V, W%5 W Berg. &k, : Wr W%4. . 4 * ' % * » . ' & * 3%d* Bag, #hem*j%a* # # % # # ) M Bpamiiey* is* #* ea# @a&gg%e*. #** 2&a* Bog* 3.136 (1933) a) Bewn# 0* S.9 aiaS loekbaet*. F» (# Berieea* &*, 8* eB&'gol&o&B* &-* ?&* ia6*;B#g*. #e%**3&* (g) B o s s , # 4 P * * & b y3l@ & l'8@ n ateB tB q f t% e P r & o c ip a l H y d ro * ( 6) B r le k a A e * * 5 » 8 * a o d B * e d f@ e a , j * B * , i r a o s * & * !* # * $ % (7) 63 (1943) '" lr e a e * ^ « $ * ^ 1 * » 981 (1942) earMns^ 4tB Ed* ike f e?ras.Sb*-) 1943 a&* 33# ( w a } . . F e ia a e o * # 4 a Blsclei;* H* * BOG. O r c k lB a J * , P a p e r p r e s e o t e d kef ore the Petroleum Division of the American Ohemzeal Societyi5 April*., 1948 (8) EeBshe5 M., E* % Ind# EBg» BlieMe5 p4q. 482 (1932) ( 9) Griswold. AtB^GhaM (10) (11) Bicdake5 #* ':$,* end T h iele5 S* W*9 TraBa, A*I*dh#45 M 605 ( 1 9 2 5 ) . . . . . . . . .................. , Q^Qonnell5 H*, Bs.$,'IraBS» .A*l#Qh*^* * /41 (194o) ( 12 ) Othmer5 #4 3 ,* TBd^, Eag* .dhe#. .Aoal# $4* jk ' ^ 0 (1932) ( 13 ) Othmer5 D5 E,,. and C orley, .E, H*5. Paper presented kef ore the 108th meeting o f the ,AMerican Ohemicai SOciety5 September 5 1944 .. (14) Perry. 36k». 2Bd ( 15) Souders5 S5. J r^ 5 and Brown5 0» G. 5 Xnd5 Eng6 Ihem55 98 (1934) . . . ABdpeB9 D,, and klAlo* B, A*? ipaaB*. 223 (1943) handbook, f O r , EBgl neer8% % c W ^ # ill Boeh # * * # w Tork (1941) ( 16 ) Ehodes9 E5 H* and BlackkurB5 P* O55 Ind* EB%_0 hem* 5 51 (1937) ^ W * B&e, # .# * , : MljlZaas:,, K ■ • 779; <-1947),,. f 18). sHantbo^k of abem lstfy a^a. $by&&e&% ' W 6: '' '2#h- ga# f ' $h&m$.t3&l' Bubbai1'•Bubll , %&$$#;■ ;-f194243,); 18 Page it Fquillbriim Data, for, n-Oetaue ^ Toluene a t 20 iBBie. % -# B' #- % »' f <s- o ^ -ff- ■80 Table I I . Squilibritm Data for S fstem n^Oetane !a b le III* Squlllbrium Data for, Syete# n*#otena * . ' , Teluene a t 100 mm^ #. .? $ > * *■ ■•» % ■»= » ■#. TB $ab le VIf Bquilibriim Data .for System n^Oetane •* . Toluene a t 200, mm. , *,* * ». ^ »;»' », » »■. a. . 23, Toluene a t mm* . .v » •« *. * $ * # a f » T li $abie Equilibrium Data, fo r System n^Oetane 4 . Ioluene a t 300 Bm^ #- •*■ » ^ •> -» *■ » @* 24 Table VI* Equilibrium Data' fo r System n^Oetane. 4. Table VII* Equilibrium Bata fo r System nroqtane * 'Toluene a t 640 mm» ^ .*. .* >* 4 ■* * t 4 4 .»• 86 Teiusne a t . 48# mm* . + .*;&..* * » *,%,* 2# T able V I llf Equilibrium Data for. System n^Octane $ Toluene a t 760 mm* s # % . * 4. # -#• ■« »• # & 2T T a b le.% Column C alibration Bata far System Table %* Column O a lib fltie n i Bata- for System n-Oetane % Toluene » * * 4 » 4 *■ #. » *. * .29 Figure I . Equilibrium Curya and T heoretical P la tes UeOotaue * Toluene .# 4 # * * ^ * 4 ? a #- 28 a t T otal Reflux a t 400 mm# Hg:# ‘ » .# <? » * 3© fig u re a# Equilibrium Surye -and T heoretical P lates - a t 39#& &efTu& B stlo a t %G mm&Bg* 4.* # . 31 Figure 3» Equilibrium Curye and Theoretical P lates a t 2011 Reflux Ratio at, 400 mm, Hg, . » » 32 Figure 4 b A ctiv ity C o efficien ts at Various Figure A c tiv ity O o effloieu ts a t Various . Pres-Sure-S # .« -$- # .-# #. 4 ». « .$ $ # 4 -4 4 -.34 Pressures#, 4 * •* * .*•,# -# # ’* #. # * # # # 3.3 Rage. IFSgWe 1 BeSeMw IhoIfatSSftieTgr. s ir # " Wk- em# § 0 SBQjt 'Bg-W * -P *: 'S' 'S :.*. -S-■.^. •«. -p A # 8 # # 35 . S1Igure fir " B e M t S v e s*: SOO sm* aW 2d0.' B#*- BgA" # #' '» #' «• % * > * •*. # # # A'' 36 SiSgtoe 8 sf R elative V o la t ilit ie s a t 300. may and : ' 400 iffi% Bg'W-' w % # %' # # # ■&•: j#. * ¥ * # S ig to e 9< 37'. "R elative ■f o l a t i l i t l e .s -a t 640 mu. and 4 * * * St" 3# 76O mm# Rg4.' '# 4 * 4 SSgure :10t "Average- R elative V el& tW ty vereue S reeeto e Sn. min* %.* # *. « #• » w •» -* * X t 39 TABLE I E quilibrium Data fo r n-Octane - Toluene at 20 nsn. Weight % in Liquid R e la tiv e V o la tility Weight # in Vapor n-Octane Toluene IOO 9 8 .1 9 4 .4 9 1 .3 8 7 .7 8 3 .0 8 2 .6 7 9 .5 7 2 .5 6 4 .5 5 6 .0 4 7 .7 3 8 .9 3 1 .8 2 6 .3 2 0 .7 1 6 .0 1 1 .3 8 .0 0 O 1 .9 5 .6 8 .7 1 2 .3 1 7 .0 1 7 .4 2 0 .5 2 7 .5 3 3 .5 4 4 .0 5 2 ,3 6 1 .1 6 8 .2 7 3 .8 7 9 .3 8 4 .0 8 8 .8 9 2 .0 1 0 0 .0 n-Octane 100 9 5 .8 8 8 .0 8 2 ,3 7 7 .1 6 9 .8 6 9 .4 6 5 .4 5 7 .3 4 7 .5 4 0 .8 3 4 .4 2 7 .6 2 2 .0 1 8 .4 1 4 .9 1 1 .9 8 .7 6 .4 0 Toluene 0 4 .2 1 2 ,0 1 7 .7 2 2 .9 3 0 .2 3 0 .6 3 4 .6 4 2 .7 5 2 .5 5 9 .2 6 3 .6 7 2 .4 7 8 .0 8 1 .6 8 5 .1 8 8 .1 9 1 .3 9 3 .6 1 0 0 .0 2 .2 6 5 2 .3 0 2 .2 6 2 .1 2 2 .1 1 2 .1 0 1 .9 9 1 .9 6 3 2 .0 1 .8 5 1 .7 4 1 .6 7 1 .6 5 1 .5 7 1 .4 9 1 .4 1 1 .3 2 1 .2 7 TABLE I I E q u ilib r iu a D ata f o r S y stem n - O ctane - T olu en e a t $0 mm. Weight % in Liquid Temp. 0C. n -Octane 50.7 50 U9.8 lt8.8 1(8.3 1(7.5 1(6.7 L5.8 1(5.0 ltlt.2 1(5J( 1 0 0 .0 9 9 .9 1(2.8 1(1.7 1(1.2 1(0.5 1(0.2 59.3 38.9 38.5 38.2 37.9 37.6 37Jt 37.0 36.9 Toluene 0 .0 0 .1 0 .9 99.1 96.9 9L.5 92.7 88.5 85.7 3.1 lt.5 7.3 11.5 Ht.2 8 2 .8 1 7 .2 77Jt 71.9 68.7 61.0 60.0 52.0 ltlt.2 37.6 29.7 23.3 18.5 15.0 11.3 8.0 5.7 0 .0 22.6 28.1 31.3 39.0 1(0.0 1(8.0 55.8 62Jt 70.3 76.7 81.5 85.0 88.7 92.0 9U.3 100.0 Weight # in Vapor n -Octane 1 0 0 .0 98.9 95.5 90.0 87.0 82.1 75.5 70.7 65.5 58.2 52.8 50.0 43.2 42.5 35Jt 29.2 2b.5 20.0 16.5 13Jt 11.2 8.5 6.2 4.3 0 .0 Toluene 0 .0 l.l 4.5 1 0 .0 13.0 17.9 24.5 29.3 34.5 4i.8 47.2 50.0 56.8 57.5 64.6 70.7 75.5 80.0 83.7 86.6 08.8 91.5 93.8 95.7 100.0 Vapor Pressure mm. Hg. n -Octane 50.0 49.8 49.2 46.3 45.5 43.7 42.0 4o.5 38.5 37.0 36.0 35.0 33.2 33.0 31.2 30.6 29Jt 28.8 28.2 27.7 27Jt 26.7 26.5 26.0 Toluene 92.5 90.0 86.0 85.0 83.0 78.0 7 6 .0 73.0 70.5 68.0 67.0 64.0 62.0 60.5 59.6 57.0 55.8 54.8 54.0 53.2 52.5 51.8 51.0 50.0 A c tiv ity C o e ffic ie n t n -Octane Toluene R e la tiv e V o la t i l i t y 0.981 1.003 1.012 1.012 1.016 1.019 1.028 1.013 1.021 i.o4o 1.072 1.068 1.091 1.078 1.108 1.170 1.240 1.305 1.365 I JtCB lJt6c 1.450 2.780 1.880 1.700 lJt80 1.370 1.360 1.370 1.310 1.240 1.190 1.140 1.160 1.110 1.060 1.060 1.020 0.996 0.984 0.981 0.963 0.982 0.995 5.2 3Jt7 3.17 2.77 2Jt9 2.50 2.53 2Jt6 2.28 2.19 2.06 2.03 1.98 1.91 1.86 1.69 1.56 lJt7 1.40 1.37 1.31 1.34 TABLE I I I E q u ilib r iu m B ata f o r S ystem n - O otane - T olu en e a t 100 mm. Weight % in Liquid Temp. °C* 65.5 6^.6 6U.2 63 6U.o 62.5 61.2 59.6 58Ji 57.0 55.6 55.2 5UJi 53.8 53.3 53.0 52.6 52.2 52.0 n-Octane 100.0 99.9 97.8 97.6 91.9 96.9 99.0 65.5 78.6 70.8 62.8 5U.2 12.3 32.1 25.6 17.5 13.3 9.0 6.9 0.0 Toluene 0.0 0.1 2.2 2J| 8.1 3.1 i i .0 H1.5 21Ji 29.2 37.2 Ii5.8 57.7 67.9 7l|Ji 82.5 86.7 91.0 93.1 100.0 Weight < in Vapor Vapor Pressure mm. Hg. n -Octane Toluene n -Octane 100.0 98.9 9(|.0 93.5 8IJ1 90.7 76.2 70.2 60.5 50.2 ii3.1 37Ji 28.5 22.2 18.2 13.1 10.5 7.0 5.5 0.0 0.0 1.1 6.0 6.5 18.6 9.3 23.8 29.8 39.5 ii9.8 56.9 62.6 71.5 77.8 81.8 86.9 89.5 93.0 9ti.5 100.0 100.0 96Ji 91.8 91.5 98.5 90.5 85.5 8I.5 76.0 71.0 67.5 63.O 62.0 60.0 58.0 57.0 56.5 55.0 51.5 Toluene 168 165 162 157 161 152 Hi5 137 130 123 116 IlIi HO 107 105 103 102 100.5 100 A c tiv ity C o e ffic ie n t n -Octane Toluene 1.030 1.052 1.042 1.000 6.55 1.65 1*67 lJ|6 1.86 1J|2 I J|2 1.35 1.31 1.25 I . 0l|0 1.002 1.008 1.013 1.000 1.018 1.095 1.088 1.150 1.225 1.310 I JlOO I JllO IJ46C 1.18 1.09 I .Oil 1.025 1.003 1.002 1.002 1.010 R e la tiv e V o la t il it y Uel 2.78 2.79 2.59 3.21 2.53 2.50 2J|0 2.k) 2.23 1.9ll 1.ali 1.66 1.55 IeUl 1.31 1.31 1.27 TABLE IV E q u ilib r iu m D ata f o r S ystem n - O ctane - T olu en e a t 200 mm* Weight % in Liquid Weight % in Vapor Vapor Pressure ran. Hg. Temp. °C. n-Octane Toluene n -Octane Toluene n-Octane 83 J+ 8 2 .0 8 1 .0 79 7 8 .0 7 6 .2 TM 7 3 .8 7 2 .8 7 1 .0 7 0 .0 6 9 .7 69*6 6 9 .5 69 Jt 100.0 9 9 .0 9 5 .0 9 0 .7 8lt.6 7 6 .0 67.3 5 7 .0 lt9.5 3 7 .3 2 7 .8 2 0 .3 1 3 .6 0 .0 1 .0 5 .0 9 .3 15 Jt 2Lt.0 3 2 .7 1+3-0 5 0 .5 6 2 .7 7 2 .2 7 9 .7 86 J ; 9 2 .8 100.0 100.0 9 3 .0 8 7 .1 7 8 .8 6 8 .7 5 7 .9 ItS .3 3 9 .7 33-5 2k Jt 1 8 .9 lit .9 0 .0 7 .0 12 .9 2 1 .2 31 .3 1+2 .1 5 1 .7 6 0 .3 6 6 .5 7 5 .6 8 1 .1 8 5 .1 9 0 .0 9k .6 100.0 200 190 183 173 162 152 lk3 138 132 123 119 117 116.2 116 7.2 0 .0 IO rO 5Jt 0 .0 Toluene "306 298 285 268 252 239 230 223 210 20k 202 201 200.2 200 A c tiv ity C o e ffic ie n t n-Octane 0.990 1.002 1.003 1.005 1.003 1 . 00k 1.010 1.025 1.063 1 . 11+2 1.255 1.263 1.293 Toluene k .560 1.730 1.600 1.515 1.390 1.320 1.220 1.180 1.155 1.110 1.060 I . oko 1.022 R ela tiv e V o la t il it y 7.53 2.81 2 .5 9 2 .5 0 2 .3 0 2 .2 0 2 .01 1.89 1 . 8k 1.6 6 lJ+5 l J +2 1 .3 6 TABLE V E q u ilib r iu m D ate f o r S ystem n - Ootane - T o lu en e a t 30 0 mm* Weight % in Liquid Temp. °C. n -Octane 9U4 93.1 92*3 91.it 90.7 88*8 87.3 85.7 83.1 82.0 81.3 80.8 80.6 80Jt 80.2 80.1 100.0 Toluene 96.7 92.3 88.6 82.5 73.8 6U.7 52.0 2*3.7 3W 29.0 18.9 0.0 1.6 3.3 7.7 IlJt 17.5 26.2 35.3 2*8.0 56.3 65.2 71.0 81.1 11.8 8 8 .2 0 .0 100.0 98 J j 8.2 91.8 Weight % in Vapor n -Octane 100.0 93.6 68.3 83.0 76.7 66.1 56.2 2*6J* 36.8 30J* 23.8 19.7 13.2 8.5 6.5 0.0 Toluene 0.0 6Jt 11.7 17.0 23.3 33.9 2*3.8 53.6 63.2 69.6 76.2 80.3 8 6 .8 91.5 93.5 1 00.0 Vapor Pressure mm. Hg* n -Octane 500 280 273 265 236 239 230 215 198 190 185 182 179 178 177 A c tiv ity C o e ffic ie n t Toluene n -Octane 2*2*2 2*32* 1*20 2*12 390 368 350 321 310 307 302* 302 301 300.2 300.0 1.020 1.005 1.020 1.015 1.005 1.008 1.002 1.072 1.100 1.110 1.115 1.165 1.215 1.32*5 Toluene 2.720 2J*50 1.580 1J*85 1J*90 1.365 1.300 1.230 1.200 1.150 1.120 1.067 1.01*0 1.020 R e la tiv e V o la t il it y i*.20 3.89 2j*6 2.36 2J*2 2.20 2.12 1.86 1.78 1.71 1.67 1.53 I J*2* 1.29 TABLE VI E q u ilib r iu m D ata f o r P ystw a n - Octane - T olu en e a t JiOO am . Weight % in Liquid Temp. 0C. n -Octane 103.0 101.6 100.0 98.5 97.0 95J+ 94.5 93.5 94J: 93.7 92.5 92.0 91.5 91.2 90.7 90.3 89.6 89.2 88.9 88.8 88.7 100.0 98.5 95.5 91.9 86.0 BO.9 73.5 56.9 71.9 64.0 53.8 50.5 46.3 36.6 27.7 22.7 18Jj 13Ji 8.5 4.2 0.0 Toluene 0.0 1 .5 4.5 8.1 14.0 19.1 26.5 43.1 28.1 36.0 46.2 49.5 53.7 63Ji 72.3 77.3 81.6 86.6 91.5 95.8 100.0 Weight % in Vapor Vapor Pressure am. Hg. n -Optane Toluene n -Octane 100.0 94.3 87.7 78.3 67.5 61.0 53.5 4i.o 52.1 46.1 36Ji 34.3 32.0 24.9 19.8 16.1 12.8 9.7 6.5 5.7 0.0 0.0 5.7 12.3 21.7 32.5 39.0 46.5 59.0 47.9 53.9 63.6 65.7 68.0 75.1 80.2 83.9 87.2 90.3 93.5 96.3 100.0 400 370 350 334 314 302 290 281 288 282 270 268 264 261 258 255 248 246 240 239 Toluene 575 560 530 512 480 470 450 467 454 437 432 424 420 415 4n 4o4 402 4oi 400.5 4oo A c tiv ity C o e ffic ie n t n -Optane 1.035 1.050 1.020 1.000 1.010 1.005 1.025 1.005 1.020 1.005 1.015 1.045 1.040 1.110 1.115 1.125 1.185 1.275 lJi75 Toluene 2.650 1.950 2.030 1.840 1.700 lJi90 1.220 IJ4.6O 1.320 1.265 1.240 1.200 1.130 1.075 1.058 1.0$2 1.042 1.020 1.010 P e la tiv e V o la t i l i t y 3.97 2.97 3.14 2.96 2.71 2Jil 1.90 2.35 2.08 2.04 1.95 1.83 1.74 1.55 1.53 1.53 1Jt4 1.34 1.14 TABLE V II E q u ilib r iu m D ate f o r S ystem n -O c te n e - T o lu en e a t 6 J4.O mm* Weight % in Liquid Temp* n -Octane Toluene w eigh t % in Vepor n~Octane Toluene n -Octane 100.0 95.5 91.8 89.0 8?fO 76.9 70.6 63.2 5lt.0 50.0 a .3 39.1 3l*.8 30.8 26.8 22.2 19.8 17.1 0.0 lt.5 8.2 11.0 16.0 23.1 29Jt 36.8 lt6.0 50.C 55.7 60.9 65.2 69.2 73.2 77.8 80.2 82.9 85Jt 87.3 89.2 91.2 93.7 100.0 6lt0 °c. 118J t 116.6 115.8 115.3 l l i t .8 lllt.O 112.8 111*5 109Jt 108.8 107.8 107.2 106.5 105.8 105.6 105.0 ICit.6 lC it.2 IQLfO 10%.8 103.6 1(9 Jt 103.3 103.2 100.0 99.0 97.6 96Jt 93.8 90Jt 86.1 79.3 72.5 68.7 62.3 56.7 lt9.9 a .7 38.1 32.7 26.3 23.8 20.0 17.1 IltJt I lJ t 8.1 0.0 0 .0 1.0 2Jt 3.6 6.2 9.6 13.9 20.7 27.5 31.3 37.7 W.3 50.1 55.3 61.9 67.3 71.7 76.2 80.0 82.9 85.6 88.6 91.9 100.0 Vapor Pressure mm. Hg* llt .6 12.7 10.8 8.8 6.3 0.0 595 580 568 557 5lt0 520 510 1*75 1*61* Ut8 Wt2 1*35 i»2lt lt20 ItlO lt07 'tOlt lt03 1x02 ltd ItOO ItOO Toluene 920 875 870 865 8lt5 820 780 7h0 720 705 697 677 668 660 655 6ft9 646 6U, 6Lt3 61*2 61tl 61*0 titO A c tiv ity C o e ffic ie n t n -Octane I . OttO I . OttO I . OttO 1.030 1.010 1.010 1.000 1.005 1.005 1.015 1.000 1.025 I . OttO 1.070 1.060 1.100 1.HtO 1.160 1.190 1.230 1.21x0 1.260 Toluene 3.130 2Jt90 2.21*0 1.910 1.820 1.650 lJ*6o Ut50 I Jt20 1.31*0 1.29c 1.230 1.200 1.150 1.130 1.10$ 1.082 1.065 1.050 I . OttO 1.030 1.022 R e la tiv e V o la t i l i t y lt.66 3.6t* 3.27 2.88 2.85 2.58 2 .2 3 2.25 2.19 2.08 2.d* 1.87 1.81 1.68 1.70 1.60 1.51 IJ46 1 J tP I.39 1.5U 1.31 TABLE VIII E q u ilib r iu m D ata f o r System n - O ctane - T o lu en e a t 760 mm* W eight % i n L iq u id W eight % in Vapor Temp. 0C n -Octane Toluene n -Octane Toluene 125.2 12U.0 125.0 122.2 120.7 119.0 117 116.2 115.0 115.8 115.0 112.5 111.6 100.0 9 9 .3 9 7 .7 9L .9 9 0 .7 8 5 .6 0 .0 0 .7 2 .3 5 .1 9 .3 16 J i 2 2 .6 3 0 .2 3 5 .5 ii5 .5 5 3 .8 6 3 .8 7 3 .2 8 0 .8 8 9 .5 9U-8 100.0 100.0 9 7 .1 9 3 .5 8 7 .7 80 Ji 6 9 .3 6 1 .8 5 5 .6 1(6.9 3 8 .1 3 2 .7 2 5 .2 19.3 111.2 8 .2 it.l 0 .0 0 .0 2 .9 6 .5 12.3 IS .6 3 0 .7 3 8 .2 111.0 110.5 110.2 110.1 rrJx 6 9 .8 6U.5 5h.5 U&,2 3b .2 2 6 .8 19.2 10.5 5 .2 0 .0 UhJx 5 3 .1 6 1 .9 6 7 .3 7*1.6 8 0 .7 8 5 .8 9 1 .8 9 5 .9 100.0 Vapor P ressu re nun. Hg. n -Octane 760 720 700 660 660 6L5 598 579 558 527 522 518 511 1*98 I186 ii78 Toluene 1200 1150 1060 1050 975 930 900 866 titiO 822 810 790 775 766 762 760 A c t iv it y C o e f f ic ie n t n~Ge tane 1.035 l.d iO 1.035 1.020 0 .9 9 0 1.015 I . 0L5 0.990 1.010 1.025 1.020 1.075 1.130 1.220 1.250 Toluene 2.630 1.870 1.700 1.560 1J*60 1.580 1.21*0 1.310 1.230 1.160 1.100 1.060 l.OtlO 1.020 I . UlO R e la tiv e V o la tility h»2h 2 .9 5 2^1 2.3 8 2 .2 6 2 .1 2 I .85 2 .0 6 1.95 1.7 7 1.61* I .53 1.1*3 1.32 1.28 28 TABLK IX Column C a lib r a tio n Data f o r System n-Ootane - Toluene ■Veiyht $ Toluene In S t i l l p o t P re ssu re h e ig h t % Toluene in D i s t i l l a t e Kim. Hg. T o ta l R eflu x 3 0 :1 R e flu x R a tio 2 0 :1 R e flu x R a tio T o ta l R eflu x 30 :1 R eflu x R a tio 2 0 :1 R e flu x R a tio Through­ put m l./ia in . 20 1 7 .6 1 1 .0 8 .1 9 6 .6 9 6 .5 9 6 .2 1 .8 0 50 5 .5 7 .3 1 6 .0 9 6 .9 9 6 .9 9 6 .2 9 .3 100 4 .4 7 .3 8 .4 9 6 .7 9 6 .2 9 6 .5 1 2 .7 200 3 .9 8 .0 1 0 .5 9 6 .7 9 6 .5 9 6 .5 1 8 .7 300 9 .9 1 2 .0 9 .9 9 7 .0 9 6 .6 9 6 .1 2 0 .8 400 1 0 .6 1 3 .0 1 5 .8 9 6 .4 9 6 .1 9 5 .9 2 5 .8 640 8 .1 1 4 .0 1 7 .4 9 6 .0 9 5 .5 9 4 .4 2 6 .9 760 7 .6 1 2 .8 1 8 .1 9 5 .4 9 5 .6 9 5 .3 ' .-■/♦ Column S ta n d a r d iz a tio n w ith System n-Heptana - Toluene 2 8 .6 2 0 .5 1 8 .0 2 8 .0 9 2 .5 760 8 8 .9 9 0 .0 2 8 .0 29 TABLS X C olu m C a lib r a t Ioh Data f o r System n-O ctane - T oluene Nuidber o f T h e o r e t ic a l P la t e s •ea sure i* Hg. T o ta l H eflu x 30 s i R e flu x R a tio H .S .T .P . 20 Si R eflu x R a tio T o ta l R eflu x 30 s i R eflu x R a tio 2 0 :1 R eflu x R a tio 20 13 14 15 1 .7 7 1 .6 4 1 .5 3 50 13 14 12 1 .7 7 1 .6 4 1 .9 2 100 1 3 .5 1 3 .5 1 3 .7 5 1 .7 0 1 .7 0 1 .6 7 200 1 2 .5 1 2 .5 1 2 .5 1 .8 4 1 .8 4 1 .8 4 300 1 1 .5 1 1 .7 5 1 1 .5 2 .0 1 .9 6 2 .0 400 11 11 11 2 .0 9 2 .0 9 2 .0 9 640 1 1 .5 1 1 .5 1 1 .5 2 .0 2 .0 2 .0 760 1 1 .7 5 12 1 1 .7 5 1 .9 6 1 .9 2 1 .9 6 1 .6 4 1 .6 4 Column S ta n d a r d iz a tio n w ith System n-IIeptane - T oluene 760 14 14 ' 14 1 .6 4 WEIGHT PER CENT TOLUENE IN VAPOR 30 20 WEIGHT 40 PER CENT 60 TOLUENE 80 IN LIQUID Figure I Equilibrium Curve and Theoretical Plates at Total Reflux at 400 mm. Hg. 31 20 WEIGHT 40 PER CENT 60 TOLUENE 80 IN LIQUID Figure 2 Equilibrium Curve and Theoretical Plates at 30:1 Reflux Ratio at 400 mm. Hg. 32 WEIGHT PER CENT TOLUENE IN LIQUID Figure 3 Equilibrium Curve and Theoretical Plates at 20:1 Reflux Ratio at 400 mm. Hg. 33 O TOLUENE • N-OCTANE 50 MM ACTIVITY COEFFICIENT * • #-+- *o IOO MM 200 MM WEIGHT PER CENT TOLUENE IN LIQ.UID Figure 4 A ctiv ity C o efficien ts at Various Pressures v~ o 34 O • MM 400 MM A CTIV ITY COEFFICI 300 TOLUENE N O C T A NE 20 W EIGHT PER 640 MM 760 MM 40 CENT 60 TOLUENE IN 80 LIQUID Figure 5 A ctiv ity C o efficien ts at Various Pressures MM RELATIVE 50 ) 20 WEIGHT 30 PER 40 50 CENT TOLUENE Figure 6 60 IN 70 LI OkUI D RELATIVE VOLATILITY 36 WEIGHT PER CENT Figure TOLUENE IN L KXUID 7 R elative V o la t ilit ie s at 100 mm. and 200 mm. Hg t 37 3 .0 - MM RELATIVE VOLATILITY 400 W EIGHT PER CENT TOLUENE IN LIClUID Figure 8 R elative V o la t ilit ie s at 300 mm. and 400 mm. Eg 38 W EIGHT PER 760 MM 640 MM CENT TOLUENE IN Lt CXUI D R elative V o la t ilit ie s at 640 mm. and 760 mm. Hg. " 2.1 v K O (3 3 5 C) d'a > W > P 3'« U OC UI O W S 200 ABSOLUTE 300 400 PRESSURE 500 IN 600 700 *00 MM. Figure 10 Average R elative V o la tility versus Pressure in mm. Hg. MONTANA STATE UNIVERSITY LIBRARIES 762 100 5208 9 N3 7 S I uuJ l g y io a _______ nnp. g__________________ _ Popovac, D. 0. ----Ihe—e ffe c t—o f reduced pressure on the e ffic ie n c y of a packed recti f i r a t i o n r»r>1nmn —------------— nUTF K3?8 I ISSUED TD 87108 cap. 2 Z