Heat transfer characteristics of small configuration hot-wires in low Reynolds... supersonic air flows

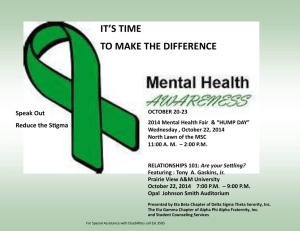

advertisement

Heat transfer characteristics of small configuration hot-wires in low Reynolds number subsonic and

supersonic air flows

by Peter Sean Hertel

A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science in

Mechanical Engineering

Montana State University

© Copyright by Peter Sean Hertel (1985)

Abstract:

Heat loss measurements from 20 gin. and 50 gin. hot-wires with aspect ratios between 95 and 420 were

obtained in air flows in the range 0<3.0 and 0.1 < 10. Measurements in compressible flows were

obtained in the throat region and test section of the Montana State University Supersonic Wind Tunnel.

An alternative theory suggested by Demetriades is used for determination of the Nusselt number and

recovery temperature of the hot-wire. The heat loss measurements were corrected for conductive end

losses to the hot-wire supports and compared to the correlations of Dewey and Collis and Williams.

The results indicate that flow conditions in the vicinity of lower aspect ratio wires are altered so that

heat loss from the wire may not be correctly determined from theory. High aspect ratio hot-wires

converge toward Dewey's correlation for M>2; however, similar hot-wires may behave differently and

individual flow calibration for each wire is necessary for quantitative flow measurements. Nusseit

number measurements in low velocity flow fall below the correlation of Collis and Williams by 5 to 20

percent. Recovery temperature measurements in M=3 flows vary considerably (30 %) for probes under

similar flow conditions and show no distinct dependence on either SI/d or Kn. Recovery temperatures

of the hot-wires in low velocity flows indicated the stagnation temperature w ithin 2 .5 %. HEAT TRANSFER CHARACTERISTICS OF SMALL CONFIGURATION HOT-WIRES

IN LOW REYNOLDS NUMBER SUBSONIC AND SUPERSONIC AIR FLOWS

by

Peter Se an Hertel

A thesis submitted in partial fulfillment

of the requirements for the degree

of

Master of Science

in

Mechanical Engineering

MONTANA STATE UNIVERSITY

Bozeman, Montana

March 1985

APPROVAL

of a thesis submitted by

Peter Sean Hertel

This t h e s i s has b e e n read by each m e m b e r of the thesis c o m m i t t e e

and has been found to be satisfactory regarding content, English usage,

format, citations, b i b l i o g r a p h i c style, and consistency, and is ready

for submission to the College of Graduate Studies.

Chairperson, Graduate Committee

Date

Approved for the Major Department

2 - 2 7 - (Pd'

Da te

Head, Major Department

Approved for the College of Graduate Studies

Date

Graduate Dean

STATEMENT OF PERMISSION TO USE

In

presenting

requirements for

this

thesis

in

partial

fulfillment

a master's degree at Montana State University,

of

the

I agree

that the Library shall make it available to borrowers under rules of the

Library.

Br i e f

quotations

special permission,

from

this

thesis

are

allowable

provided that accurate acknowledgement

without

of source is

made.

P e r m i s s i o n for ex t e n s i v e q u o t a t i o n f r o m or r e p r o d u c t i o n of this

thesis m a y be g r a n t e d by my m a j or professor, or in his absence, by the

Director

of Libraries when,

in the opinion of either,

of the m a t e r i a l is for s c h o l a r l y purposes.

material

the proposed use

A ny copying or use of the

in this thesis for financial gain shall not be allowed without

my written permission.

/5J

Date

O

V

O

ACKNOWLEDGEMENT

O

The author is indebted to the following for

their contributions to

this investigation.

His

advisor.

Dr.

Anthony

D e m e t r i ade s,

for

his

able

guidance

O

throughout the investigation.

G l e n n M c C u l l o u g h and J o h n R o m p e l

for their technical assistance

with the laboratory equipment. ■

Pat V o w e l l

O

and G o r d o n W i l l i a m s o n of the m a c h i n e

shop for their

assistance with fabrication of equipment used in this investigation.

Drs.

Ron Mussulman and Harry Townes for their support as committe

O

members.

The

Department

of

Mechanical

Engineering

and

the

Engineering

Experimental Station for financial assistance.

Special

thanks

to

family

and

friends

O

for

their

support

and

encouragement throughout the course of this graduate program.

O

O

O

TABLE OF CONTENTS

page

LIST OF F I G U R E S ..................................................... viii

NOMENCLATURE ............................................................

A B S T R A C T ............................... ...................... ..

%

xiii

1.

I N T R O D U C T I O N ..............................................

2.

THEORETICAL R E V I E W ...............................................

Incompressible Flows

.............................................

Compressible F l o w s ......................

Free— Molecule Theory

............................................

End loss c o r r e c t i o n ........................... ■.................. 17

Recovery temperature

.............................................

7

7

10

H

14

21

3.

EXPERIMENTAL APPARATUS AND P R O C E D U R E ...............................22

Hot-Wire Probes ...................................................

22

Supersonic Wind Tunnel ...........................................

24

Low Velocity T u n n e l ............

27

Flow Measurement Apparatus

......................................

28

Calibration O v e n ..............................

30

Data A c q u i s i t i o n .................................................... 32

Experimental Procedure ..............

34

4.

R E S U L T S ............................................................... 40

G e n e r a l ......................................

40

Nusselt N u m b e r

.................................................

40

End Loss C o r r e c t i o n ..................................................52

Recovery Temperature

.............................................

52

5.

C O N C L U S I O N .......................................................... 64

A P P E N D I C E S .......................................................... 66

APPENDIX A - OVEN CALIBRATION DATA REDUCTION C O D E ................ 67

APPENDIX B - FLOT CALIBRATION DATA REDUCTION CODE:

INCOMPRESSIBLE F L O W .................................. 70

APPENDIX C - FLOW CALIBRATION DATA REDUCTIOSf CODE:

COMPRESSIBLE F L O W S ..................................... 73

APPENDIX D - HOT-WIRE R E S ISTANCE-TEMPERATURE COEFFICIENTS .

77

O

vii

O

TABLE OF CONTENTS— Continued

APPENDIX E - FLOW CALIBRATION RESULTS

79

REFERENCES CITED ....................

96

O

O

O

O

O

O

O

O

O-

viii

O

L IST O F FIGURES

Page

O

1.

2.

Correlation of end loss corrected hot-wire characteristics

( r e p r o d u c e d f r o m { 3 } ) ......................

3

End loss corrected heat transfer data, MSU/SWT catalog data

(M>3.0) .............................................................

5

O

3.

Hot-wire characteristic data,

from {15] )

incompressible flow (reproduced

12

4.

Hot-wire characteristics,

supersonic flow ......................

13

5.

Hot-wire characteristics,

subsonic flow (reproduced from {15}).

15

6.

Normalized recovery factor data

7.

Hot-wire probe c o n f i g u r a t i o n ......... '.......................... 23

8.

Photographs of hot-wire element .................................

9.

Major components of M S U / SWT (reproduced from {25} ) ................. 25

10.

Test area of M S U / SWT (reproduced from { 2 5 } ) .......................25

11.

Variation of M with axial location in MSU/SWt n o z z l e ............ 26

12.

Low velocity tunnel ( L V T ) ........................................... 27

13.

Probe configuration, M S U /SWT (M=3).

14.

Probe configuration,

M S U /SWT ( .18<M<2.2)........................... 29

15.

Probe configuration,

LVT (M=O)...................................... 30

16.

Oven calibration equipment........... ' ........................... 31

17.

Data acquisition equipment diagram

18.

Oven calibration overheat traverse data ........................

19.

Resistance-temperature correlation obtained from intercept

data (R(W=O)) of figure 1 8 ........................................ 36

20.

Typical

(reproduced from {3})

.........

.............................

.............................

O

21

23

O

O

28

33

O

O

35

O

flow calibration overheat traverse data ...........

38

O

O

ix

LIST OF FIGURES— Continued

21.

End loss corrected

22.

End loss corrected heat transfer data; MSU/SWT catalog

data; M= 3, d=20 g i n .................... .......................... 43

Q.

heat transfer data; M= 3', d=20 jiin.............. 42

O

23.

End loss corrected

heat transfer data; Jfc=3, d=50 (iin.............. 44

24.

Support prong proximity effect on Nusselt number

(normalized with Dewey's correlation) ..........................

47

25.

End loss corrected

heat transfer data; .2<M<1, d=20 pin . . . .

48

26.

End loss corrected

heat transfer data; Probe 2 9/8 . ............

49

27.

End loss corrected

heat transfer data*;. M=O, d=20 pin...............50

28.

End loss corrected heat transfer data; Jfc=O, d=50 pin........... 51

29.

Summary of heat transfer d a t a ................................... 53

30.

Theoretical

end loss correction correlation ....................

31.

Typical end

loss

correction data; M = 3 ,

d=20 p i n ................... 55

32.

Typical -end loss

correction data; Jf=3,

d=50pin . . . . . . . .

33.

Typical end

loss

correction data; M =O,

d=20 p i n ................... 57

34.

Typical end

loss

correction data; Jfc=O,

d=50.p i n ................... 58

35.

Recovery temperature

data; M = 3 , d=20

pi n ..............

36.

Recovery temperature

data; Jfc=3 > d=50

p in........................... 61

37.

Recovery temperature

data; Jfc=O, d=50 p i n ........................... 62

38.

Recovery temperature

data; Jfc=O, d=20 pin. ................

O

O

54

O

56

O

60

O

63

O

O

O

O

X

O

NOMENCLATURE

SvmboI

Description

CD

Drag coefficient

d, D

Wire diameter

f (S 1 ), g(s-i )

Functions of molecular speed ratio S 1

CD

O

Gr

■■ Grashoff Number

h

Heat transfer coefficient

i

Current

k

Thermal conductivity

(amps)

Q

kb

Boltzmann constant,

5.66 X 10 ^

ft-IbsZ0F per molecule

Kn

Knudsen number

I,L

Wire length

LVT

Low velocity tunnel

M

Mach number

MSU

Montana State University

Nu

Nusselt number

Num

Measured Nusselt number (not corrected for end loss)

P

Static pressure

Pd

Dynamic pressure

Pe'

Peclet' number

Po

Stagnation pressure

P o2

Pitot pressure

Pr

Prandlt number

Ic

Convective heat transfer

O

O

O

(yPM^/2)

O

O

O

O

xi

NOMENCLATURE— Continued

SvmboI

Descrintion

R

Wire resistance

Re

Reynolds number

sI

Molecular speed ratio

S

Dimensionless end loss parameter

SWT

Supersonic wind tunnel

T

Temperature

W

Power

^

„

O

Uy H

M)

^

(Watts)

O

a

Thermal accomodation coefficient

ar ■

Temperature-resistance coefficient

Y

Ratio of specific heats

O

Te

Euler's constant

n

Recovery factor

(.577) '

(Ta^ ZT0 )

Experimental continuum recovery factor

O

Rf

Theoretical free-molecule recovery factor

X

Measured wire recovery factor

R

Nondimensional recovery factor

O

crYP

Yield stress of hot-wire material

r

Dimensionless overheat temperature

%

Nusselt number end loss correction factor

( >a

air property

< >aw

evaluated at equilibrium temperature- (i= 0)

( )m

measured value

( >x

evaluated at arbitrary reference

(T-Taw)/Taw

Q

!

O

temperature

O

O

xii

O

NOMENGLATO RE— Continued

Symbol

Description

( )o

evaluated at stagnation conditions

O

evaluated at conditions behind a normal

( )

free stream property

( )

pertaining .to the hot-wire supports

shock

O

O

O

O

O

O

O

O

I

ABSTRACT

Heat loss m e a s u r e m e n t s f r o m 20 jiin. and 50 gin. h o t - w i r e s w i t h

aspect ratios between 95 and 420 were obtained in air flows in the range

0<M <3.0 and 0.1 <Re< 10. Measurements in compressible flows were obtained

in the throat r e g i o n and test s e c t i o n of the M o n t a n a State U n i v e r s i t y

Supersonic W i n d Tunnel.

An alternative theory suggested by Demetriades

is used for determination of the Nusselt number and recovery temperature

of the ho t - w i r e .

The h e a t loss m e a s u r e m e n t s w e r e c o r r e c t e d for

c o n ductive e n d l o s s e s to the h o t - w i r e s u p p o r t s and c o m p a r e d to the

c o r r e l a t i o n s of D e w e y and C o l l i s and W i l l i a m s .

The re s u l t s indicate

that flow c o n d i t i o n s in the v i c i n i t y of l o w e r aspect ratio w i r e s are

altered so that heat loss from the wire may not be correctly determined

f r o m theory.

H i g h aspe c t ratio h o t - w i r e s converge t o w a r d Dewey's

correlation for M>2; however, similar hot-wires may behave differently

and i n d i v i d u a l flow c a l i b r a t i o n for e a c h w i r e is n e c e s s a r y for

quantitative flow measurements.

N u s s e l t n u m b e r m e a s u r e m e n t s in low

velocity flow fall below the correlation of Collis and Williams by 5 to

20 percent.

R e c o v e r y t e m p e r a t u r e m e a s u r e m e n t s in M= 3 fl o w s vary

considerably (30 %) for probes under similar flow conditions and show no

distinct dependence on either H d or Kn.

Recovery temperatures of the

hot-wires in low velocity f l o w s i n d i c a t e d the s t a g n a t i o n t e m p e r a t u r e

w ithin 2 .5 %.

O

I

O

CHAPTER I

INTRODUCTION

O

Hot-wire

anemometers have

determination

of

flow

measuring turbulence.

h e a t-loss

from

the

become

properties

an

and

important

are

especially

This a pplication u t i l i z e s

hot-wire

and

the

mean

instrument

for

the

suitable

for

the r e l a t i o n b e t w e e n

properties

of

flow

O

and

therefore requires the measurement of the Nusselt number, Nu.

In general,

in a

transverse

the Nusselt number dependence

flow

may

be

expressed

for an infinite cylinder

in

terms

of

O

dimensionless

parameters as

Nu=NuCRe, M, Pr, Gr, t w )

(I)

w h e r e Re, M, Pr, and Gr are the R e y n o l d s n u m b e r ,

number,

and G r a s h o f f n u m b e r and T w = ( T w - T a w ) / T aw

loading.

has prevented

the establishment

loading.

of a universal

special a p p l i c a t i o n s (I) m a y be simplified.

the

P randlt

is the t e m p e r a t u r e

Equation (I) neglects radiation effects which have been

to be negligible up to high temperature

flows

M a c h number,

dependence

(Pr=Constant).

overheat (Tw=O),

Further,

of

Nu

on

Prandlt

shown

O

The complexity of (I)

relation,

however,

for

For m e a s u r e m e n t s in air

number

may

be

O

eliminated

if we consider only forced convection for zero

O

equation (I) may be expressed as

N u = N u (Re, M)

In actual a p p l i c a t i o n s ,

O

(2)

the l e n g t h of the h o t - w i r e m u s t be r e s t r i c t e d

for greater resolution and

to prevent

wire breakage.

the infinite wire solution is no longer valid.

For

these

wires,

For a finite hot-wire,

O

a

O

O

2

percentage

of heat, is lost by

axial

conduction to the supports and the

Nusselt number is dependent on an additional parameter,

O

S, such that

(3)

N u ffl= N u (Re, M, S)

O

where

The s t a ndard p r a c t i c e is to e v a l u a t e the N u s s e l t n u m b e r a s s u m i n g all

heat

transfer

from

the

hot-wire

to

be

conv e c t i v e

and

applying

a

O

correction factor,

a

measured

i|^(S),

to account for the losses by conduction:

Thus

Nusselt number is evaluated from

(4)

^nkaNumAT=I2Rw

O

and N u m (Re, M, S) is then c o r r e c t e d to o b t a i n the actual N u s s e l t n u m b e r

Nu(Re, M, S=ro) from

N u (Re, M, S=m )= I^(S)Num (Re7M jS)

(5)

O

The

ea r l y

work

of

Betchov

Kovasznay and T o r mark (2), Dew ey

{I }

and

more

{3}, and Behrens

recently

studies

by

(4) addressed the heat

transfer f r o m fin i t e w i r e s u s i n g the above procedure.

The heat loss

O

correlation presented by Dewey for the special case

N u 0=N u q (Re 0,M, S=°=,r=0)

(6)

where the subscript " o'.1, refers to the evaluation of the air properties |i

O

and k at the s t a g n a t i o n t e m p e r a t u r e , w a s d e t e r m i n e d u t i l i z i n g (4) and

(5) and remains

the

state-of-the-art

for low Reynolds number air flows.

Dewey's correlation,

s h o w n in f i g u r e I, is b a s e d on his m e a s u r e m e n t s

from 100 pin.

mm) hot-wires

O

and M c C l e l l a n

(.00254

{5},

C y b ulski

and

on supplemental

and B a l d w i n

others,

and the theory of Stalder,

Roshko

{§}.

Goodwin,

[6],

data of Laufer

Vrebalovich

and Creager

{7),

and

{8} and Cole and

O

An

outstanding

feature

of

Dewey's

correlation

is

an

O

IO

Z

__

—

—

Z

'

Z

o

D

2

Z

ZZ Z

0

/

z z

OJ

I/

/

x

Z

/

/ Z

/

'

Z

Z ------

/

Z

Zzz

Z

—

4r

a

nr.?j q .

rn i r

P HQM Uf n

FREE M O L E C U L E S O L U T IO N

S T A L O E R ,G O O D W IN , 3 C R E A G E R

_

/

//Z

.01

100

01.

Figure I.

A

'

/

Z

/

/

/

/%

ZZ

"

/

Z

Z

Zz

ZZ

V

Correlation of end loss corrected ho t - w i r e c haracteristics

(reproduced from {3} ).

O

4

independence of N u 0 on M for M>2.0.

For actual applications,

O

it is desireable to utilize the above heat

transfer correlation to predict properties

known,

the f l o w R e y n o l d s N u m b e r m a y t h e n be p r e d i c t e d using Dewey's

correlation.

required for

(note

that additional measurements

hot-wires

of relatively

associated with

limited

to

O

of flow properties are

the determination of the mean velocity.)

Figure I is in some ways restrictive

control

If (5) and (6) are

of flow.

larger

large diameter

smaller

aspect

in that (I) the data are from

O

alleviating problems of quality

configuration probes, . (2) the data are

r a tios

where

the

correction

^(S)

was

O

r e l a t i v e l y small, and (3) there is i n s u f f i c i e n t data to guarantee the

correlation over

the

entire range

of R c q and M.

Therefore,

additional

data are n e e d e d for s m a l l e r d i a m e t e r w i r e s of a w i d e range of aspect

O

ratios in low Reynolds number flows in the range M < 3 .

Finite hot-wire data (Nuffl(Re 0,M>3 .0, S)) o b t a i n e d f r o m a n u m b e r

sources

and

c o m p i l e d by D e m e t r i a d e s

M S U / SWT Catalog data) were

corrected using

Dewey's c o r r e l a t i o n for M > 2.0.

from

the

data

of

measurements were

Dewey's

not

{10}

(hereafter r e f e r r e d to as

(5) in an attempt

correlation

the focus

and aspect ratio.

of

in

that

(I)

conclusion that

(5)

additional

as

the

proper

heat

loss

that

O

of

Figure 2 shows that a fit of these

for Re 0<1.5

such

the

and (2 ) the h o t - w i r e s w e r e

correlation is non-existant

overlooked

to verify

i n v e s t i g a t i o n and the data w e r e

data to Dewey's

is invalid or

O

These data, s h o w n in figure 2, differ

o b t a i n e d u n d e r m o r e severe conditions,

smaller diameter

of

some

measurement

of

leading

to

O

the

factor has been

N u q (Re 0,M, S ) or

the

O

aerodynamics of the miniature probe configurations of the hot-wires used

O

Figure 2.

End loss corrected heat transfer data; MSU/SWT catalog data (M>3)

Q

6

O

in {10}.

C o n s i d e r i n g the p r e c e d i n g discussion,

fluid properties

from

of finite h o t - w i r e s

the heat

of the

transfer

the p r o b l e m of p r e d i c t i n g

Nu 0 CRe0,M,S),

characteristics,

u s e d in {10 } is r el event for actual

type

O

a p p l i c a t i o n s in steady and u n s t e a d y flows but has not yet b e e n fully

examined.

This -investigation,

conducted at the Montana State University

Supersonic Wind Tunnel Laboratory,

was undertaken to provide additional

heat loss data for

smaller diameter hot-wires over a wide

for

numbers

low

Reynolds

alternative

technique

for

in

the

the actual

range

0<M<3

and

to

O

range of &/d

p r esent

an

measurement of the Nusselt number

O

and recovery temperature.

O

O

O

O

O

O

O

7

O

CHAPTER 2

THEORETICAL REVIEW

O

Thi s

investigation

is

concerned

characteristics of fine wires and,

the Nusselt

number

with

therefore,

and recovery temperature

th:e

heat

transfer

requires the evaluation of

of the hot wire.

Assuming

O

n e g l i g i b l e h e a t loss by r a d i a t i o n and na t u r a l convection, the Nu s s e l t

number may be expressed as

Nu=NuCRe, M, S,-c)

(7)

Flow measurement based on the characteristics of an unheated wire

further

simplifies

the

correlation

as

does

theoretically eliminates the dependence on S.

figure I in actual

applications,

the

Thus,

use

of

(5)

O

(t = 0)

which

in order to utilize

O

the c o r r e c t i o n factor 1I^(S) must be

accurately predicted.

Consider the

lumped

evaluation of the heat loss from the hot-wire

O

(8 )

I2Rw = TrLlcaNu0AT - jrd2kv.7dT '

x=L/ 2

where

AT=Tw- T aw-

Equation

(8) m a y

be

simplified

using

a

rough

O

approximation of dT/dx=-(Tw - T a w )/(&/2) where

assumed

equal

to

the

equilibrium

the support temperature

tem p e r a t u r e .

This

is

a

is

valid

assumption considering the relative size of the supports with respect to

O

the hot-wire.

Equation (8) then reduces

to '

I2R=L 7IkaNum AT

(9)

Num= Nu 0 (1+1/S2 )

where

O

Although

the

above

analy s i s

provides

only

a poor

estimate

of

the

O

O

8

magnitude

of

conductive

losses,

justification for

equation (4) (i.e.

conduction losses

using

the p a r a m e t e r

it

is

useful

measurement

a single convective

S on w h i c h .the

correction

in that

of both

it prov i d e s

O

convection and

type relation) and presents

factor

is

dependent.

O

Axial conduct ion and the end loss c o r r e c t i o n factor are a d d r e s s e d in

more detail later in this chapter.

The mechanisms of energy transfer between the hot-wire and the gas

v a r y dep e n d i n g o n the p h y s i c al

characteristics

generally separated according to the continuum,

O

of the fluid and are

slip,

and free-molecule

flow regions.

O

In c o n t i n u u m

flow

the heat

transfer

is,

for

the most part,

a

f u n c t i o n of the R e y n o l d s n u m b e r ( i n d i c a t i n g v i s c o u s effects) and the

M a c h n u m b e r ( i n d i c a t i n g e f f e c t s due to compr e s s i b i l i t y ) .

transfer of e n e r g y is r e l a t e d to the drag on the w i r e

viscosity and the conversion of kinetic energy

Thus,

the

surface due to

into thermal

energy.

At

l o w v e l o c i t i e s ( i n c o m p r e s s i b l e flow) the e n e r g y a s s o c i a t e d w i t h the

velocity

is

compressible

less

influential.

effects b e c o m e m o r e

dependence is evident.

the flow fie l d

Depending

At M= I, a bow

in the v i c i n i t y

on the

strength

incompressible

the

velocity

increases,

d o m i n a n t and a large

shock,

again becomes

we

expect

the

and

the h o t - w i r e

to

the

r e c overy

the

of

the

cylinder

O

attain a temperature equal

to the static t e m p e r a t u r e of the fluid w h i l e at h i g h v e l o c i t i e s

temperature

O

subsonic.

A n u n h e a t e d cylinder p l a c e d in a l o w

continuum flow will

O

Mach number

shock forms ahead of the wire,

of the w i r e

of this

beh a v e as in the s u b s o n i c case.

velocity

As

O

will

approach

or

equal

O

stagnation temperature of the flow.

O

O

9

For- smaller diameter wires

and low density (rarefied)

flow field in the vicinity of the wire no longer behaves

and the

thermal

behavior

structure of the fluid.

by the Knudsen number;

of the hot-wire

O

as a continuum

The approach to free-molecule flow is indicated

O

the ratio of the m e a n free molecular path of the

(Kn=X/d).

molecule

et al. to exist

flow has been shown by

Stalder

Fully developed free

energy transferred between the hot-wire and the fluid is

cylinder.

the

is dependent on the molecular

fluid molecules to the cylinder diameter

molecular

gasses,

at Kn=2.0.

The

O

in the form of

energy i n c ident to and r e - e m i t t e d f r o m the surface of the

In f r e e - m o l e c u l e flow,

the

Reynolds

number

dependency

O

reflects density effects rather than viscosity effects of continuum flow

while the Mach number reflects effects due to free steam velocity rather

than c o m p r e s s i b i l i t y effects.

E x p e r i m e n t a l evidence and theory have

O

shown that the recovery temperature of an unheated wire in free-molecule

flow will

exceed the stagnation temperature of the wire.

h o t - w i r e b e h a v i o r in f r e e - m o l e c u l e f l o w

The theory of

is a d d r e s s e d later in this

O

chapter.

Most

supersonic

the slip f l o w region,

molecule flow.

and compressible

In this region,

at the surface of the hot-wire.

behavior.

so

that a non-zero velocity occurs

In slip flow,

transfer behavior

the fluid retains some of

the m a g n i t u d e

O

also e x h i b i t i n g f r e e - m o l e c u l a r

of

the hot-wire in the slip flow

region will therefore show dependencies both on Mach number and Reynolds

number,

Q

the boundary layer associated with fully

characteristics while

The heat

data falls in

that is, the r e g i o n b e t w e e n c o n t i n u u m and free-

developed continuum flow is altered

its c o n t i n u u m

subsonic hot-wire

O

of w h i c h are d e p e n d e n t on the m a g n i t u d e of the

O

O

10

O

Knudsen number.

E v a l u a t i o n of (4) is n o n - r e s t r i c t i v e as to the type of flow (i.e.

continuum,

slip,

free-molecule,

as long as

the heat

transfer

compressible,

coefficient

is the c o n v e c t i v e h e a t transfer.

or incompressible

flows)

is defined by qc=hAT where q c

O

The v a l u e of h, h o w e v e r , is h e a v i l y

dependent on the flow parameters Re, M, and Kn.

O

Incompressible Flows

The

heat

transfer

from

cylinders

in low

velocity

air flow is w e l l r e p r e s e n t e d at. h i g h Re (see M c A d a m s

incompressible

{11}),

however,

O

hot-wire

data

at

low

Re

(Re <10)

h as

been

obtained

only

by

few

investigations.

There is some disagreement among researchers as to what conditions

O

the R e y n o l d s n u m b e r and N u s s e l t n u m b e r should be evaluated.

The m o s t

common

thermal

practice

conductivity

at

is

the

to

evaluate

free

stream

the

air

viscosity

temperature

or

the

and

mean

(film)

O

temperature b e t ween the

wire,

free stream

and the hat-wire.

For an unheated

the film temperature is equal to the free stream temperature.

One

of

the

first

and

most

widely

applied

relations

used

in

O

incompressible hot-wire

anemometry was

developed by King

{12}.

King's

law,

Nu=O.318 + 0.690(Re)1/2

(9)

O

was

determined

theoretically

assuming

two-dimensional

inviscid

i n c o m p r e s s i b l e f l o w and c o n s t a n t heat flux over the boundary.

King's

relation has been used by many in slightly modified forms retaining

the

O

square-root

dependence

on Reynolds number with empirically determined

O

O

11

constants.

O

Cole and Roshko obtained the relation

2 / Nu= Jln(SZPef)- Y e

bas e d on the O s e e n v i s c o u s

(Ye = E u l e r fS

flow

c o n s t a n t = 0.577).

P e 1= R e 'Pr

(10)

theo r y v a l i d for the

Hilpert

{13}

limit

investigated

as Re-O

the

heat

O

transfer from fine wires in the Reynolds number range from 2.6 to 3x10^.

Hilpert's data

in the

range

of Reynolds numbers between 2.6 and 4.0 may

O

be expressed as

Nu=.891 [Re (Tw Z T 00)174]'330

where

the

conductivity

temperature.

and

viscosity

are

(U)

evaluated

Measurements in low Reynolds number

by Collis and Williams

Nu=

at

the

film

incompressible flows

O

{14} were best expressed by the relation:

T w + T4

-17 [ .2 4 +. 5 6 R e ,4 5 ]

.1<Re <44

(12)

O

Again,

the f l u i d p r o p e r t i e s w e r e e v a l u a t e d at the f i l m temperature.

Baldwin, S a n d b o r n, and L a u r e n c e

and R o s h k o , H i l pert,

{15} have s u m m a r i z e d the data of Cole

Collis and W i l l i a m s ,

and others in the R e y n o l d s

O

n u m b e r range b e t w e e n .01 and IxlO^.

Dewey's correlation for M=O

This

summary

is c o m p a r e d w i t h

in figure 3.

Compressible FlOw

O

A considerable volume

of r e s e a r c h in the 1950's and 196 0's w a s

directed toward hot-wire behavior in compressible flows.

in supe r s o n i c

f l o w s at h i g h e r R e y n o l d s n u m b e r s

{16}, Laufer and McClellan,

of

Investigations

(Re>20) by K o v a s z n a y

and Spahgenberg {17} have shown a dependence

the Nusselt number on the square-root of the Reynolds

number

as was

seen in the incompressible flows.

Kovasznay's data in the range of Mach

numbers

showed

from

1.15

to 2.05

O

also

that

for

small

O

temperature

O

12

-!Ifc^n I

S s ld S t i A i r *

I C T E t if

i

D

%

IfflH

5

IO

Reynolds number, Re

Figure 3.

Heat loss characteristics;

(reproduced from {15}.

differences

between

the

incompressible air flow

hot-wire

i n d e p e n d e n t l y of the M a c h number.

and

air,

the

hot-wire

b ehaves

This M a c h n u m b e r ind e p e n d e n c e for

supersonic flows has been varified many times and is generally accepted

for

Mach

numbers

s u p ersonic

data

Lowell {19},

g r e ater

than

of K o v a s z n a y

2.

Baldwin

and T o r m ark,

Sandborn and Domitz

{20},

et

a I.

Winovich

summarized

and Stine

Laufer and McClellan,

the

{18},

Stalder et

al., W e l t m a n n and Kuhns {21}, and W o n g {22} for air f l o w s in the range

of Mach numbers from 1.155 to 6.083.

shown in figure 4.

agreement

A portion of the data for Re<10 is

Data obtained by Dewey in air at M= 5 .8 was in close

to the data

of L a u f e r

and M c C l e l l a n and is also

shown

in

figure 4.

As w i t h the i n c o m p r e s s i b l e case,

of

the

flow

researchers.

properties

in

the choices for the e v a l u a t i o n

compressible

flow

vary

widely

amo n g

In addition to evaluation of properties at the free stream

13

c o n d i t i o n s or f i l m

t e m p e r a t ure,

p and k m a y also be e v a l u a t e d at the

stagnation temperature or, in the case of supersonic flow, at conditions

behind

the

shock.

As w i t h

the m o r e

recent

investigations,

in this

study, p and k were evaluated at the stagnation conditions.

The

MSU/ SWT

discussion.

Catalog

The

consequence

the

shown

in

figure

These data were collected under

distinguishing them

1.

data

data

of

data w e r e

from

were

merit

the f o l l o w i n g

further

cond i t i o n s

the data presented above.

not

turbulence,

obtained

2

the

focus

boundary

under

of

layer,

conditions

investigation

and wake

more

but

studies.

severe

were

As

a

such,

than n o r m a l l y

encountered in hot-wire heat transfer studies.

2.

20

pin.

M o s t of the data w e r e f r o m h o t - w i r e s of 10 pin. (.000254 mm),

(.000508

mm),

and

50 pin.

ratios m u c h lower than encountered in

Figure 4.

Hot-wire characteristics;

(.0 012 7 mm)

diameter

previous hot-wire

supersonic flow.

with

aspect

investigations

O

14

(£/d

as

I ow

as

120).

Some

sc a t t e r

is

expected

for

these

sm a l l e r

O

configuration probes because of f a b r i c a t i o n d i f f i c u l t i e s r e s u l t i n g in

poor quality control.

data for

included in his

is evident

(Re 0 >1 .5)

larger hot-wires

Dewey's correlation.

with

This scatter

show

in figure 2 in which the

less

scatter

and a p p r o a c h

Data collected by Dewey for 50 pin. hot-wires

correlation)

were

also

(not

scattered and in poor agreement

O

the 100 pin. hot-wire data shown in figure I.

3.

losses

The s m a l l

than

for

wires

asp ect

ratios result

of previous

in greater

investigations,

thus

con d u c t i v e heat

resulting

in

O

larger errors associated w i t h (5).

Subsonic compressible

Baldwin, Baldwin

and L a u r e n c e

{23},

flows have been investigated by Cybulski and

Spangenberg, and Vrebalovich.

(figure I) however

similar

the values

to

the

low

Re

relations

Sandborn,

The data of

O

presented by Dewey

of N u q in figure 5 are considerably lower

than the data by V r e b a l o v i c h (Dewey's

figure I.

Baldwin,

s h o w n in figure 5.

s u g g e s t e d the r e l a t i o n s

figure 5 is qualitatively

O

c o r r e l a t i o n for M< I) s h o w n in

O

This discrepancy and the limited amount of available data in

compressible

research in this area.

subsonic

flows

suggests

the

need

for

further

Measurements in subsonic compressible flows were

O

made in this investigation and will be discussed in chapter 4.

Free-Molecule Theory

O

Stalder et al. have t h e o r e t i c a l l y d e t e r m i n e d the N u s s e l t n u m b e r

and recovery temperature

flow.

relationships

for a hot-wire

in free-molecule

The infinite wire Nusselt number may be expressed as

O

Nun _

( y — I ) U R e n Pr

2(n)3/%

g ( s -, )

si

(13)

O

Cv

Rer

Figure 5.

Hot-wire characteristics;

subsonic flow

(reproduced from {5}).

and the. recovery factor as

=

where

a

is

the

thermal

speed ratio (s^=

(14)

f (s I )

sTip

^aJiC =

O

accomodation

coefficient,

s^

is the molecular

M) and f(s^) and gts^) are functions dependent only

on s^ and the n u m b e r

of e x c i t e d d egrees

of f r e e d o m

of the

gas.

The

thermal accomodation coefficient is an indication of the efficiency with

which energy is exchanged between

impinging

above

air

stream

relation

radiation.

molecules

applies

Equations

to

the

solid hot-wire

surface

and

and is determined experimentalIy.

infinite

(13) and

unheated

(14) were

wires

and

f o r m u l a t e d by

the

The

excludes

equating the

jo u l e h e a t i n g (i^R) to the m o l e c u l a r e n e r g y (both t r a n s l a t i o n a l

and

r o t ational

the

surface

for

a diatomic

of the

gas)

inci d e n t

on and re— e m i t t e d f r o m

cylinder using a simpli f i e d kinetic

classical M a x w e l l i a n v e l o c i t y d i s tribution.

theory a s s u m i n g

A d e t a i l e d anal y s i s and

t a b u l a t e d v a l u e s of s^, f(sq) and g(s]_) m a y be f o u n d in r e f e r e n c e

Equation (13)

is shown in figure I.

As was

wire

indicated earlier,

immersed

temperature.

magnitudes

{ 8}.

in

a free-molecule

Stalder

of

the recovery

flow

temperature of a unheated

exceeds

the

stagnation

et al. explained this phenomenon by comparing the

incident

and

re-emitted

molecular

energies.

The

translational component of the incident molecular energy is the total of

the free

stream

translational

kinetic

molecular

energy

superimposed

kinetic

energy.

on

The

the r a n d o m

incident

thermal

energy

per

molecule has a value ranging from 2k^T to 5/2k^T (depending on the speed

and

orientation

of

the

flow)

as

opposed

to

a value

of

3/2k^T

per

O

17

molecule

for

continuum

flow.

Similarly,

the energy

of the re-emitted

O

stream is Zk^Taw for free-molecule flow and 5/Zk^Taw for continuum flow.

Thus, under steady state conditions,

energy incident in each case,

if the re-emitted energy equals the

the temperature of the body,

T a w , must be

O

higher in the case of free-molecule flow.

As in the c o n t i n u u m f l o w case,

ratio are nearly

independent

the N u s s e l t n u m b e r and r e c o v e r y

of Mach number for M>Z.O.

This effect can

O

be seen in f i g u r e I.

End Loss Correction

O

If the t e r m for axial

c o n d u c t i o n is included,

the steady state

heat equation for the hot-wire is:

+

H k aN u 0 A T

4

dxz

(15)

i2-|»

&

O

The average w i r e r e s i s t a n c e is d e t e r m i n e d by c a l i b r a t i o n and m a y be

expressed as a linear function of temperature as

Rw= R r [l+ar (Tw- T r )]

where Rr is

the resistance

(usually O 0C).

The

at

solution to

some

(16)

arbitrary reference

(15),

temperature

Tr

expressed in terms of the average

wire temperature is:

O

rm=c+frc_c^t a n h ■ p

b

b

p

where

In a similar manner,

O

b= Nu0 -JLJLnfLr

P=ZbTa

C=

. i ^r

[!+ U r

(17)

O

(Taw-Tr)]

equation (4) can be nondimensionaliz ed to obtain:

Num (Tw~T aw)=c+ZTw

(18)

O

where

Z I^RrUx.

K-Jika

O

O

Substituting

(18)

into (5),

the Nusselt number correction factor becomes:

=Nti0 (Trw-1E aw)

^

The

n o n d i m e n s ional

substituting

recovery

(19)

temperature,

T a w , may

be

obtained

by

i=0 into (17) to obtain:

-CgtanhS

(20 )

Then equation (19) b e c o m e s :

C

F o r the

limiting

case

(t 0- c ) t a nh P - t _ t anh

b

3

t

“c + ' ( T 0 - c ) t a nh P

b

b

P

_

c +

„b

Nu0

+

of

Z

i-^0 ,

equation

(21 ) m a y

be

S

(21)

simplified

and

linearized in iz to obtain:

(22 )

tanh S

IfJN=1The above a n a l y s i s w a s fir s t p r e s e n t e d by Dewey.

Nusselt Number Measurements

Consider now the actual measurement of Num

in (4). Using (16),

the

temperature difference in (4) m ay be expressed as:

Tww >Ta0w

(23)

Rw~R aw

Jirar

The heat loss equation for the infinite wire becomes:

I Nu

The

usual

linearizing

technique

used

in

=

many

(24) in the limit as i-*0.

earlier

investigations

involves

Then:

j CarR 1) Iim _i^

R„

_________

i-0

(24)

( Rr1^r \

„

Q r-RrR

nw

—Etr

R rR nw

( K m - R aw) " ( d R w / d i Z ) i =0

(25)

Q

O

19

Substituting,

we

O

then obtain:

Nu.

hawRr

(26)

(dRwZdi2)i=O

'm

In order to determine the Nusselt number in this manner,

measurements of

Q

R w are n e c e s s a r y at v e r y low v a l u e s of i.

A c c u r a t e m e a s u r e m e n t s of i

and R w at small, i are difficult and invite error.

Demetriades

{24) suggests an alternative procedure that eliminates

O

the need to r e s t r i c t m e a s u r e m e n t s

of N u m at l ow v a l u e s

of current.

Equation (24) may be writ t e n as:

R -R 1 + J L

"

i2b

, I 2h=JLiaSlaL

”

-,R 1

V=I2IL

1

(27)

O

.

A linear fit of R vs. W m a y t h e r e f o r e be u s e d to obta i n R aw and N u m if

kNu is assumed

constant.

This method

that (27) is ex a c t and the range

temperature of the wire.

the actual

offers

an advantage

over (26)

in

of i is l i m i t e d only by the m e l t i n g

O

Since k is a function of temperature, however,

r e l a t i o n b e t w e e n R and W

shou l d not be linear.

However,

Demetriades points out that the dependence of kNu on temperature must be

O

weak for the following reasons.

(a) Conduction, k, is

not a strong

function of T.

O

(b) The temperature controlling k is only partially

d u e to

the w i r e t e m p e r a t u r e (e.g. f i l m

temperature=(Tw+ T aw)/2.)

(c) I t i s k n o w n f r o m e arlier w o r k s that Nu is

affected by Tw in a way balancing changes in k.

O

B a s e d on the abo v e o b servations,

written as:

j

1

kNu

i.

the v a r i a t i o n of kNu w i t h W m a y be

I

k N u ( W-0)

I .

(RNu)i=O

+

I

9(1/kNu)

9W •

Jo

k3Nu

(kNu)2 I 9W

NuBk

3W

O

W

1=0

(28)

O

O

Substituting into (27),

the wire resistance becomes:

V R- +&

aw

a rR r

CWz

S-TTkflNu aw

(29)

Where

I 9Nu

Nu SW

Thus,

if w e

measure

Rw

and

W

+

I Skfl

kaSW

(30)

Ji=O

and

fit

the

data

to

a

second

order

polynomial

R= A q +A-^W+ A 2

(31)

then the hot wire heat loss characteristics (Num ) may be determined from

the known coefficients Ag, A^, A 2 and (29).

The recovery temperature is

obtained from

the i n t e r c e p t A g = R a w m and the re s i stanc e-t e m p e r a t u r e

relation (16).

From

the coefficient A^ and the evaluation of kaw using

T aw, the Nusselt number at T=O is determined from:

_

a r R

aw &7ik.

The

coefficient

provides

$1

the coefficient G=-P^

(30) provides the Nusselt number for W/0.

(30) results

(32)

/

Performing

and integration of

the integration of

in:

N u ( T ) _ k aw

B x p L - ( A 2 Z A 1 )W]

(33)

The above analysis was used in the present investigation.

The data were

fitted to a second order polynomial using the method of least squares in

computer codes LOFLOW02 and HIFLOW02 written by Demetriades and modified

for this i n v e s t i g a t i o n to include

presented

by

Dewey

(eqn

(21)).

the end loss c o r r e c t i o n p r o c e d u r e

These

codes

are

included

in

the

appendices.

i

O

21

Recovery Temperature

As

noted

earlier

in

temperature may vary from

this

a value

in incompressible continuum flow

chapter,

equal

the

hot-wire

to the free

stream

recovery

temperature

to a value greater than the stagnation

t e m p e r a t u r e in f r e e - m o l e c u l e flow.

In c o n t i n u u m flow,

the r e c o v e r y

t e m p e r a t u r e is m a i n l y a f u n c t i o n of the M a c h number. In slip flow and

free-molecule

flow,

Knudse n n u m b e r

the recovery

as w e l l

as the

temperature

Mach

number.

is

also

dependent

on

the

Vrebalovich proposed a

normalized recovery ratio given by

tIw

tiC

(34)

" " I f-Ic

w h e r e t|c is the e x p e r i m e n t a l

c o n t i n u u m r e c o v e r y factor and

theoretical f r e e - m o l e c u l e r e c o v e r y factor.

is the

The n o r m a l i z e d reco v e r y

factor minimizes the Mach number effect as was shown by Vrebalovich for

M > .4 .

Normalized recovery temperature

data

c o m p i l e d by D e w e y from

several sources is shown in figure 6 .

F fM -

ilfiom

Knuditn

Figure 6 . Normalized recovery factor data

number,

K n 00

(reproduced from (3)).

O

22

O

CHAPTER 3

EXPERIMENTAL APPARATUS AND PROCEDURE

O

Hot-wire Probes

The h o t - w i r e probes,

the MSU/SWT lab.

s h o w n in

at

The primary probe body is a 2 inch length of 1/16 inch

diameter 2-hole alumina tubing.

of 1/32

figures 7-8, were f a b r i c a t e d

inch diameter 2-hole

The secondary body is a 1/2 inch length

alumina

tubing.

'Pyroceram

glass

cement,

m a n u f a c t u r e d by Co r n i n g Gla s s W o r k s , is used to atta c h the s e c o ndary

body to the primary body.

Current

.012 inch d i am eter arm cured

is supplied to

the hot-wire

The

p o l y t h e r m a l e z e c o p p e r leads arc w e l d e d

supports are shaped with

to provide a suitable

contact

surface

an acid etch and fine

for

the hot-wires.

leads

rubber applied

enter

hel p s

to

at

the

end

prolong

the

of the

life

of

primary

Pyroceram

the

body

lead

is

where

wires

O

the

through

O

continued use.

Hot-wires

O

sandpaper

applied to the forward end of the probe to provide a smooth rounded tip.

Silicon

O

through

(using a thermocouple welder) to the .003 inch diameter nickel hot-wire

supports.

O

used

in .this

experiment

w i t h d i a m e t e r s of 20 pin. and 50 pin.

were 90% Platinum-10%. Rhodium

A l i q u i d gold resin a t e w as u s e d

to attach the hot-wires to the support prongs.

After mounting,

the hot­

O

wires were baked at IOOO0F to burn off the organic vehicle of the liquid

gold as w e l l as to anneal

the h o t - w i r e ^in an effort to e l i m i n a t e the

O

strain gage effects reported by previous researchers.

A

constant

current

control

fabricated

especially

for

O

23

Figure 8.

Photographs of hot-wire element and supports.

O

24

turbulence r e s e a r c h at P h i l c o - F o r d A e r o n u t r o n i c w a s used to heat the

hot-wire.

The

constant

15, indi v i d u a l l y

current

control

system

adju s t a b l e p u s h b u t t o n current

(model

O

ADP-13) provides

settings.

Pushbutton

operation is designed for quick disconnect current change and is ideally

O

suitable for automated data recording with swiching transients of only a

fraction of a second.

ten

10,000

automotive

Power is supplied to the heating circuit

mil I i a m p - h o u r

batteries.

mercury

batteries

The m e a n v o l t a g e

or

three

and current

12V

through

350

and current

recording.

signals were

Th e digital

later in this

amplified

as much

O

outputs m a y be

simultaneously recorded from jacks located on the rear of the unit.

voltage

amp

The

as 10 times before

O

c o n v e r s i o n and data r e c o r d i n g are d i s c u s s e d

chapter.

O

Supersonic Wind TunneI

The M o n t a n a State U n i v e r s i t y S u p e r s o n i c W i n d Tunnel,

s h o w n in

figures 9 and 10 is an open circuit

continuous, flow facility,

as the working

Mach numbers of 3.0 over a Reynolds

using air

O

n u m b e r range

normal

fluid and producing

of 4 8 5 0 0 - 1 4 5 0 0 0

operating

per

conditions,

in.

the

(19000 — 57000

SWT

is

per

capable

cm.).

of

Un d e r

stagnation

O

temperatures as high as 145 0F (620C) and stagnation pressures as low as

3 00 m m Hg absolute.

Automatic or manual

control of the flow conditions

is m a i n t a i n e d f r o m the control console l o c a t e d in the test area.

The

O

r e c t a n g u l a r test se c t i o n has a cross s e c t i o n a l area of 3.1x3 .2 inches

(7.87x8.13 cm.).

nozz l e w a s

For this investigation,

utilized.

The v a r i a t i o n

the entire

of

the

Mach

length of the Laval

number

with

axial

O

p o s i t i o n is s h o w n in figure 11.

The test s e c t i o n is a c c e s s e d t h r o u g h

O

25

Figure 10.

Test area of MSU/SWT laboratory.

26

XlO

=M

(MACH NUMBER)

V STATIC PRESSURE MEASUREMENT (£=600mm.H o )

-- THEORY CAZAh )

X

-50

-40

-30

-20

-10

XlO 1=x

Figure 11.

(in.

FROM THROAT)

Variation of Mach number with axial location in M S U /SWT

nozzle.

27

re m o v a b l e

nozzle.

optical-quality

glass p a n e l s

extending

the

length of the

A detailed description of the SWT may be found in (25).

Low Velocitv Tunnel

The L o w V e l o c i t y A p p a r a t u s

(LVT),

S h o w n in figure 13,

operated suction venturi m a n u f actured by A e r o l a b

LVT has a 12 inch (30.48 cm) diameter plexiglas

operating over a Reynolds number range

per cm) at room

cm/s).

flow

Supply

test

is a fan

Company.

section capable of

of 4300— 23000 per in.

(1700— 9000

t e m p e r a t u r e w i t h a m a x i m u m v e l o c i t y of 56 ft/s (1700

This corresponds to a Mach number range of .007(M(.05.

in the test

diffuser behind

The mass

se c t i o n is c o n t r o l l e d by a l l o w i n g air to enter the

the

test

section

thereby

decreasing mass

ahead of the test section at the intake manifold.

Figure 12.

The

Low velocity tunnel (LVT)

flow

entering

Flow M easurement Apparatus

Flow c o n d i t i o n s for tests c o n d u c t e d in the S W T were d e t e r m i n e d

from two separate sets of measured flow properties.

For tests conducted

at M=3, the flow conditions were determined by measuring the stagnation

temperature and pressure

shock P 02/P 0.

The

tube

for

the pressure ratio across a normal

stagnation conditions

nozzle using a type J

pitot

(T0lPo) and

the

thermocouple

for

determination

of

were

measured upstream

temperature

the

measurement,

s t a g n a t i o n pressure.

of the

and a

The

pressure Po 2 w a s m e a s u r e d us i n g a .029 inch i. d.-.063 inch o.d. pitot

tube positioned

in the same vertical

plane

as the hot-wire as shown in

figure 13.

Figure 13.

Probe configuration; MSU / SWT (M=3.0).

For tests conducted in the range .18 < M <2.2, where the hot-wire was

traversed th r o u g h the throat,

the flow

measuring

ratio

the

total

pressure ratio P / P Q.

press u r e

c o n d i t i o n s were d e t e r m i n e d by

and the static pressure-stagnation

The s t a g n a t i o n p r o p e r t i e s w e r e m e a s u r e d in the

same manner as in the M=3 tests while the static pressure was determined

using a static pressure probe attached

parallel

to the hot-wire

distance between

the

probe

and

in the

shown in figure 14.

static probe and

a .032 in o.d.

and

Four

at

the

tip.

.0145

plane and

The separation

the hot-wire was .90 inches.

probe was fabricated from

sealed

same horizontal

hollow

inch

The

tube tapered to a point

static

pressure

taps

drilled around the perimeter a distance of .25 inches from the tip.

were

The

h o t - w i r e w a s al i g n e d such that the e l e m e n t w a s at the same u p s t r e a m

location as the static p r e s s u r e taps.

Figure 14.

The p r e s s u r e transducers w e r e

Probe configuration; MSU/ SWT ( .I 8<M<2.2).

located o utside

the tunnel and w e r e c o n n e c t e d to the total and static

pressure probes by flexible tubing e x t e n d i n g

a nd

exiting

The pressure

the

tunnel

transducers

through

ports

through

located

the h o l l o w

in

c o n s i s t e d of a D y n i s c o 0-15

the

psi

sting

diffuser.

t r ansducer

energized by 5 vdc and a Kulite 0-15 psi transducer energized by 10 vdc.

The signals were

amplified 30 and 100

before recording.

The probes w e r e

using an electromechanical

actuating

diffuser sections of the tunnel

The flow

times and were dynamically damped

axially and vertically postitioned

system located above

the

test and

as seen in figure 10.

c o n d i t i o n s in the v i c i n i t y

of the h o t - w i r e

for tests

conducted in the LV T (M=O) were determined using the ambient temperature

and a pitot-static probe positioned in the same vertical plane and below

the hot-wire

Figure 15.

as shown in figure 15.

Probe configuration;

The pitot-static tube consisted of

LVT (M=0).

c o ncentric tubes, the s m a l l e r of w h i c h w a s a .04 inch i.d. tube o p e n at

the tip for total p r e s s u r e m e a s u r e m e n t and the outer tube, a .120 inch

o.d.

tube with

eight .0145

inch

static pressure taps drilled around the

p e r i m e t e r a d i s t a n c e of .6 inches from

dynamic pressures

were

the probe tip.

The static and

indicated on an inclined micromanometer

with

a

scale to .6 inches of H 2O and accuracy to .001 inch H2O using alcohol as

the working fluid.

Calibration Oven

The

temperature-resistance

characteristics

of

the hot-wires

were

cali b r a t e d in the c a l i b r a t i o n oven.

The oven, m a n u f a c t u r e d by S i g m a

Systems,

regulated

measures

temperature.

Figure 16.

1000

in^

and

is

A s i x - p o s i t i o n probe holder,

Oven calibration equipment.

to

maintain

constant

s h o w n in figure 16, a l l o w s

O

32

the

simultaneous

calibration

of

six hot-wires.

A

seventh

position

on

O

the holder allows for the calibration of a shorted hot-wire probe which

was used to account, for. resistances in the probe other than the hot-wire

element.

The h o l d e r is e n c l o s e d w i t h i n a tin b ox to isolate the h o t ­

wires from

the oven.

vicinity

the light air currents

caused by a small

O

circulation fan in

A type J t h e r m o c o u p l e m o n i t o r s the oven t e m p e r a t u r e in the

of

the

hot

described on page

wire.

23

The h o t - w i r e s

are h e a t e d by

the ADP-13

O

w i t h v o l t a g e and c u r r e n t r e c o r d e d in the same

manner as in the flow calibrations.

O

Data Acquisition

The b l o c k d i a g r a m of figure 17 s h o w s the e l e c t r o n i c c o m p o n e n t s

used

in data

acquisition.

The

hot-wire

signals

from

the

cons t a n t

O

current control panel w e r e a m p l i f i e d b e f o r e c o n v e r s i o n to a digital

signal for storage.

t ransducers

were

The signals f r o m

likewise

resistor-capacitor

analog to digital

linearly

converts

proportional

(R/C)

the

static and total

pressure

a m p l i f i e d and dynamically supressed with a

c ircuit

prior

to

digital

conversion.

The

O

(A/D) c o n v e r t e r ( a Spectral D y n a m i c s mod e l SD-133)

the

analog

to the voltage

input

range

signal

of the

to

a

digital

specified input

signal

channel.

The

O

SD-133 is a c c u r a t e to I part per 1000 over the input channel v o l t a g e

range.

The output

from

the SD-133

was

then recorded directly to 5 inch

disk using the I n t e r t e k S u p e r b r a i n m i c r o c o m p u t e r and also to a Te x a s

Instruments

Silent

700 ASR

computer

terminal

which provided temporary

b ack-up storage on cassette tape as w e l l as a h a r d copy of the

data.

The

flow

above

procedure

was

applied

to

oven

O

calibrations,

LVT

O

O

33

POWER

SUPPLY

H O T - W IR E

PR ESSU R E

SENSORS

CONSTANT

CURRENT

ANEMOMETER

TRANSDUCER

NO. 2

A M P L IF IE R

NO. 2

A/D

NO. 3

NO. 4

CONVERTER

TEMPORARY

STORAGE'CASSETTE

HARD COPY

STORAGE:

5 - INCH

Figure 17.

D IS K

Data Aquisition equipment diagram.

POWER

SUPPLY

O

■ 34

calibrations,

O

and SWT flow calibrations.

Experimental Procedure

The p r o c e d u r e for p r e p a r i n g the h o t - w i r e p r o b e s is d e s c r i b e d in

O

detail in {26}.

The P t - I 0% Rh W o l l a s t i n w i r e s w e r e first e t c h e d to

remove the silver coating,

m i c r o s cope,

then mounted on the probe with

and a n n e a l e d to r e m o v e

the

thermal

stress

the aid of a

effects

that

O

occure at high overheat.

any wi r e s

Each wire was checked under the microscope and

s h o w i n g ob v i o u s

imperfections

or i m p r o p e r

mounting were

discarded.

O

The wires were then

resistance

oven calibrated

characteristics

calibration utilized an

from

to determine the temperature-

equation

overheat traverse

(16).

.

This

method

of

The wires were placed in

O

the c a l i b r a t i o n oven and the r e s i s t a n c e m e a s u r e d at f i f t e e n pre-set

current settings.

Using the ADP-I3 as described on page 23,

current measurements were

obtained at

twelve

constant

voltage and

temperatures

in

O

15° C

increments

rangeing

from

room

temperature to 190° C.

temperature,

the R v s. W data w e r e f i t t e d to a quadratic.

shows typical

R(W)

vs.

T oven calibration data.

At each

Figu r e 18

The intercept

(W=O) of

O

each polynomial

provides

the resistance

of that p a r t i c u l a r overheat traverse.

of the wire

at

the temperature

The R(W=O) vs. T data w e r e then

linearly fit to obtain the coefficients Rr (Q) and ar (1/°C) of equation

O

(16).

Figure 19

shows the resistance-temperature

intercept data of f i gure 18.

correlation using the

C a l i b r a t i o n s s h o w i n g rms d e viations of

R(W) greater than .1 in the quadratic fit were

discarded.

A summary of

O

coe f f i c i e n t s R r and a r for h o t - w i r e s

u s e d in this

i n v e s t i g a t i o n is

O

35

OIX (U)H

Figure 18.

Oven calibration overheat traverse data.

36

6. 5

PROBE

2 6 /5 /1

R0 (O0C)= 4 6 . 5 2 (OHM)

a.

=1.562 X 1 0 - 3 ( | / ° c )

6

O

X

g

5. 5

CC

5

4. 5

O

.5

I

1 .5

2

T (T) XlCrZ

Figure 19.

Resistance-temperature correlation obtained from the

intercept data (R(W=O)) of figure 18.

given in the appendices.

the 0VENCAL5

code

included in the

The reduction of data was

accomplished using

written by Demetriade s and F i shbaugher.

The code

is

appendices.

The flow c a l i b r a t i o n p r o c e s s is s i m i l a r to the oven c a l i b r a t i o n

described above.

The purpose

heat transfer and flow

The

flow

traverse.

calibration,

For

the

flow

calibration is to obtain

the

data for the d e t e r m i n a t i o n of N u q (Re Q ,M, S = 00).

like

calibrations

were recorded along with P,

flow properties.

of

the

oven calibration,

in the LVT,

T,

overheat

utilizes

the overheat

traverse

measurements

and P 0 for the determination of the mean

In the L V T tests, the R e y n o l d s n u m b e r w a s v a r i e d by

Q

37

r e g ulating

the

velocity

characteristics were

W

data

and

Tpjq(S) w as

in

the

test

section.

The

heat

transfer

O

then determined using a quadratic fit of the R vs.

equations

determined

iteration procedure.

(29)-(33).

from

The

equation

end-loss

(18) usi n g

correction

factor,

an interval

halving

O

Data r e d u c t i o n w a s f a c i l i t a t e d using the code

LOFLOW02 listed in the appendices.

The p r o c e d u r e for the S W T c a l i b r a t i o n s w a s identical to the L V T

O

calibration except that variation of Reynolds number was accomplished by

regulating the total pressure in the tunnel.

The data recorded for the

M = 3 .0 tests i n c l u d e d i, R, P q, P 02 ’ and T 0 w h i l e

i, R, P q, P,

were

throat

region

data

shown in figure 20.

recorded

Typical

flow

for

calibrations

calibration overheat

in

the

traverse

Data for the S W T c a l i b r a t i o n s w e r e

is

r e d u c e d using the

and T q

O

(.18 < M < 2.2).

code H I F L O W 02

O

listed in the appendices.

Measurements

using hot-wires

of

10 pin.

were

attempted,

however,

consistent w i r e b r e a k a g e in the S W T p r e v e n t e d the c o l l e c t i o n of data.

Wire

failure has been a persistant problem

w i r e s and is c a u s e d by

O

in research using fine hot­

a n u m b e r of f a c t o r s i n c l u d i n g high p r e s s u r e

O

loading and collisions with the hot-wire element by dust particles.

F i s h b a u g h e r {27} a p p r o x i m a t e d the h o t - w i r e stress l o a d i n g using

s i m p l i f i e d b e a m and cable theories.

He d e t e r m i n e d that the m a x i m u m

aspect ratio for each theory may be obtained from

I

beam theory

I.

2

rnd ;

L4-

cable theory

O

:

(35)

'uDpdJ

I

Tr CTyp' s in 6

d

2

(36)

O

Ccfd

O

R(OHIVI) XIO

38

Figure 20.

Typical flow calibration overheat traverse data.

O

39

w h e r e ^yp is the m a x i m u m y i e l d stress (48000 psi for P t - 10% Rh wire),

C q is the drag coefficient,

is the d y n a m i c

angle of deflection due to loading.

O

press u r e and 9 is the

The beam theory models the hot-wire

as a uniformly loaded beam w i t h fixed

supports

while

the cable

theory

O

uses small angle approximation and a uniform load distribution model.

A comparison of the above

theory with actual conditions encountered

in this investigation showed the following.

O

M = 3 .0

R e 0= I .2

P (j=2 psi (min. dynamic pressure of M= 3 tests)

Cq (free-molecule)=4 (from {8})

Cn (continuum)=9 (from {28})

Conditions:

x

O

Results:

£/d

Beam

.80

120

continuum

free-molecule

Cable (9=.I)

7

16

(9=1)

73

164

O

The beam theory gives a better approximation,

is

quite

conservative

calibrations, w i r e s

unavoidable wire

of

for

&/d<250

failure

wire

v i o l a t i n g the

had

for 20 pin.

greater than a b o u t 350.

maximum

these

conditions.

a

good

wires

In o r d e r for

£ / d of 350,

however,

the val u e

the predicted %!d

In

the

survivability

M= 3

rate

SW T

and

Q

generally ocurred for wires

the cable

theory to pr e d i c t a

of 9is g reater than unity,

thus

Q

a s s u m p t i o n of small a n gles in the d e v e l o p m e n t of (36).

Note that (35) and (36) do not d e p e n d on the d i a m e t e r of the hot-wire.

In

practice,

however,

higher

aspect ratio

wires

show

better

Q

survivability for larger diameter wires.

O

O

O

40

O

CHAPTER 4

RESULTS

O

General

The

p urpose

transfer

of

this

characteristics

investigation

of

Reynolds n u m b e r air flows.

small

appendices,

In particular,

determine

the

hot-wires

heat

in low

O

it w a s d e s i r e d to evaluate

data in low Reynolds

less than 3. The results,

are d i s c u s s e d under

to

configuration

Nusselt number and recovery temperature

of M a c h n u m b e r

was

air

flows

w h i c h are t a b u l a t e d in the

the s u b h e a d i n g s

O

of

1.

End loss corrected Nusselt number N u q (ReQ,M, S=00)

2.

End loss correction

3.

Recovery Temperature Ttaw= ( T awZT0 )

O

tJ^(S)

The following discussion presents the results of this experiment in

comparative

form

with

previous

investigations.

The

presented by Dewey have been verified by data from

corr e l a t i o n s

several

O

sources and

are used as a basis for comparison of the compressible flow data of this

study.

The

correlation of Collis

velo c i t y f l o w s

was

used for

and Williams

for

c o m p a r i s o n of data

incompressible

low

O