Microprocessor controlled hydraulic load unit by Mohammad Taghi Karami

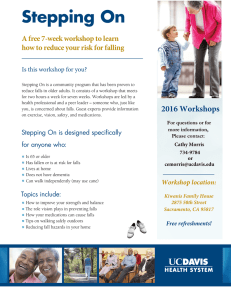

advertisement