An economic analysis of the 160 acre limitation in District... Project with policy implications

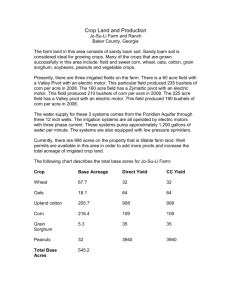

advertisement