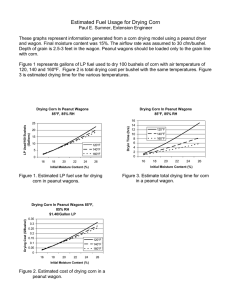

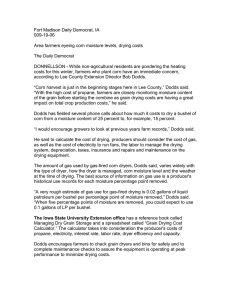

A biomass-fired grain dryer : system design, construction and performance

advertisement