Radiant heating installations in Montana by Leroy C Horpedahl

advertisement

Radiant heating installations in Montana

by Leroy C Horpedahl

A THESIS Submitted to the Graduate Faculty in partial fulfillment of the requiremenrs for the degree

of Master of Science in Mechanical Engineering

Montana State University

© Copyright by Leroy C Horpedahl (1950)

Abstract:

Radiant heating is not something very new. The Romans used it over 2,000 years ago, but it was not

until 1908 that it was put on a commercial basis. There are many methods of supplying this form of

heat to a dwelling. It may be done by passing hot air through ducts in floors, walls, or ceilings, or it

may be accomplished by means of passing hot water through pipes in the same areas. This thesis

concerns only the latter.

Montana State College was granted a sum of $5,000 by the Danforth Foundation to be used toward the

erection of a campus chapel. Various departments have volunteered their services, both professional

and manual, to help make this chapel a reality at a minimum cost and at a maximum of student interest.

My contribution is the complete design of a radiant heating system for the chapel which is included in

this thesis.

Radiant floor panels used with hardwood floors have been the desire of many citizens, hence a

complete design and cost analysis is given with such a construction. This has been constructed and is in

satisfactory operation.

Much can he learned from the mistakes and suggestions of others, hence a survey of radiant heating

installations in Montana is included in this thesis. In connection with the survey, several inquiries were

made concerning proper floor coverings to use with heated floors, The results of the research conducted

on various types of floor coverings are also included in this thesis.

All calculations in this thesis were performed on a slide rule.

The Libraries

Montana State Universityo Bozeman

Bozeman, MT 59717-0332

S

B

h e .University

Special Collections

Telephone

o z e m a n

406-994-4242

GUIDELINES FOR USE OF MATERIALS

The Merrill G. Burlingame Special Collections of the MSU Libraries was established to collect and

preserve materials on Montana and its history. Books, newspapers, maps, diaries, letters,

photographs, architectural drawings, and rare books are all a part of the collection. These materials

require special handling and security. Their use is restricted to the Burton K. Wheeler Reading

Room. University Archives materials are subject to the same patron use guidelines.

Check-in Procedures

1.

Fill out a registration form and present positive identification.

2.

Place personal belongings such as coats and backpacks on our coat rack or on the window ledge.

3.

Complete a call slip for all materials you want to use. Special Collections stacks and files are

closed to the public.

z

.

U se of Materials

1.

Use care when handling materials to prevent damage.

2.

Use pencils or word processors only for note taking. Pens are prohibited.

3.

Do not trace or write on top of materials you are using.

4.

Please to not change the order in which manuscript or photographic materials are filed. If filing

errors are detected, bring them to our attention, and corrections will be made by our staff.

5.

Please consult with staff for photocopy requests and procedures.

6.

Use microform copy instead of paper copy whenever possible. Our staff will guide and assist

you. Paper copies can be made from microforms.

7.

Upon request, materials may be held on reserve; however, if they are not used within two weeks,

they will be returned to the stacks.

8.

Wear cotton gloves when handling photographs and negatives. Gloves are available from staff.

9.

Researchers are responsible for compliance with laws governing copyright and literary property

rights.

Check-Out Procedures

Materials may be left at your table. A staff member will unlock the door for you as you leave. All

possessions are subject to search by Libraries staff.

HOURS: Special Collections’ hours are 9:30 a.m. - 5:00 p.m ., Tuesday - Friday. We are closed on

holidays.

Rev. 9/94

R&DI&NT BBA2IRG IRSTALIATIQRS

IR MORTARA

by

LEROY C. HORfBDABL

A THESIS

SubmLtilled to the Graduate Baculty

la

partial fulfillment of the requirements

for the degree of

Master of Selsnoe In Moohanleal .Engineering

Montana State

GmS^anj" Ei:SaIiffng“SoSmrtte©

Jaxiy' Graduate/DlrisIon

-2-

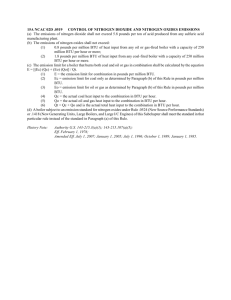

TABLE OF CONTENTS

ABSTRACT................ ...................... . ......... 3

RADINAT 1-EATING DESIGN FOR OANFORTH CHAPEL................. It.

Calculations using g-" tubing.......................... 5

General specifications................................ .

Calculations using 3/t " tubing,.......................

Layout of control system......... ....... ............ icj

Layout of panels using V> tubing.

............... ....20

Layout of panels using 3A " tubing.................... 21

Elevation views of Danforth Chapel.................... 22

RADIANT FLOOR PANELS /ITH VOOD FLOORS

Calculations................ ...

Construction...................

Cost analysis..................

Layout of control system.............................. 38

Layout of panels using short headers.................. 39

Layout of panels using long l eaders.... ..............

SURVEY OF MONTANA INSTALLATIONS............................ !p.

FLOOR COVERINGS OVER RADIANT PANELS........................ 55

LITERATURE CONSULTED....................................... 59

Ar iENDIa ................................................... .

9 4 6 #

'

Eadtairb heating Ig-. not .something very neWt. The Eomans

used it oven E5OOO yeans ago, but it was not until 1908 that it

was put on -a eamjaienoial basis* There are many methods of

supplying this form of heat to & deoiling* l t m a y b<& dona.by

passing hot air through duets: in floors, Walls5 or ceilings* or

it may be accompli shed by means of passing hot water through

pipes in the same areas„ This thesis concerns only the latter*

Montana State College was granted a sum of §5a000 by the

Panforth Foundation to be used toward the erection of a campus

chapel* Various departments have volunteered their services,

both professional and manual* to help make this.chapel a real­

ity at a minimum cost and at a maximum of student interest* My

contribution is the complete design, of a radiant heating system

for the chapel which is included in this thesis*

Radiant floor panels used with hardwood floors have been

the desire of many citizens* hence a complete design, and cost

analysis Is given with .such a construction* This has been

constructed and is in satisfactory operation*

Much can be learned from the mistakes and suggestions of

others* hence a survey -of radiant heating installations in

Montana is included in this thesis* In connection with the

survey* several inquiries were made concerning proper floor

coverings to use with heated floors*. The results, of the re­

search conducted on various types of floor coverings are also

included in this thesis*

All calculations in this thesis were performed on a slide

rule*

.A R&DIAMT EE&TIRG 8ZB37EM PQR A PROPOSED

DAI'JFORJPI O M i 5SL OH THE OAMPHS OF MOHTAM SfATS GOLLBG-E

In tlie design, Ole any building in Montanal9 careful con*alderatlon must ba given to the type of heating system used

with respeet to oost, msintalneaoe* and the ability to heat

during extreme weather conditions => In a more specific cases

such as the design of a chapel^ other conditions must also be

Included, such as quietness of operation^, comfort^ and earIuslon of elewenta which would tend to deviate from the modern­

istic theme of the contemporary chapel*

With these restrlc-

tions in mind, radiant heating was suggested and the following

do r>xfin. Is proposed*

&7o complete systems are shown a -one with

copper tubing and the other with 3/%." copper tubing.

selection of the

The

tubing system was chosen because of the

better heat distribution in the concrete floor with shorter

spacing distances» Also9 the cost was slightly less*

The first step in any heating design is to calculate the

heat loss of the building*

In radiant Installations* it la

necessary to break up the heat losses into each individual

room because the amount of panel installed in each room is a

function of the heat loss for that particular room*.

In this

particular case, recommendations for insulation and windows

were made in conjunction with the heat loss calculations at

the request of the architecto Heat loss calculations for both

single and double glass windows .were made to determine whether

single glass would be feasible e As the calculations which

follow show jj it would not be ix^aetieal here in Mcmtmia to use

the single glass over such a large area0 First of all* frost

formations would oeeur on the window with the resulting

moisture on the walls and floor below*

Secondly^ it would he

impossible to heat this chapel under extreme conditions with

just a floor panel using radiant heat without exceeding an

8^ °F floor temperature'o Wall or ceiling panels were not eon*

sidered in this design because of the nature of their eon*

Struetion0

She heat loss calculations with the necessary recornaend^

at ions and assumptions ^ follow 0

All heat transfer coeffi­

cients (XT) and resistances (R) were taken from the A SHFE

Guide (19^9)«

Heat !,ess Calculations

Ac Sanctuary and entry

I 0 Celling

R

Inside air film**

oo .

0 ,****«,»

0O'0 no 0 e O1e o. » e 0 &0 0 e0 0

000 O

% = 1/20*173 = 0*05 Btu/hr-3g,fto-*P

Ceiling area =

53 % 22*| « 2 z 6 * 5 n 2|- s 2| ~ lli|.9 sq* ft*.

Iieat loss * 1149 22 o05 % 90q * 5160 Btu/hr

~6~

2o- Walls

H

I^xsj»c3-@ aX p xaIxn#

^ @».o*^ ^ *» .ft * Q 0.6 0 6

2^y^32

» fro-# #“

0--*0*** **»* * *#**-ftft-.ft.ft*ft ... 1,055

25/32-" pine she athing»,,*&*,**. ,,*..*,.,. ,.* 0,98

I-Jp XiiILXX0X'ClI xjOOl o».0ft*f

t

.

-f

t

-oftO-ft**« *iiftft-O.e-a,oi.*#»ftftftl-l|-O80

25/ 32” pine sheathing»«.*■»

0,0 ft. Oft98

25^^32 ^peclv/ooci0jo."*-*»a.< dft>*ft*e »* a.**0** -0* 0.ft, 1.055

Qntstdle aap

^ v ^ o. o. on** #-o- o^ a 0 - »^n- oo »- *.ft. 0.167

« ' H

U = 1/1 9.6^3 = o05l Btu/kr-aq.fta- F

Wall apea

9& % 33.5 + 9& x 19 + 9i a 22*5 = 713 ea. ft.

Beat, loss > 713 x .051 Z .90 = 3270 Btn/hr

3. Doors (assnmed thickness I 3/l|.rf)

B = 0,51 Btu/hr~sq,ft.*F

Door area = 7 x 3 5 21 sq.eft»

Beat loss = 2 a 21 x *51 x 90 = 1928 Btu/hr

l{_. Stained glass window

Tl

1 ,13 BW/Br-sq.ft,-*P

Area - 9/ xc 6 = 57 sq.ft.

Beat loss = 57 % 1*13 x 90 = 5^800 Btn/hr

5« Skylights

U = »45 BtuZhr-SQftft00Bt

Area = 5 X 2*5 X 2*5 ~ 31.25 sq.ft*

Beat loss = 31.25 x .45 x 90 F 1,265 Btu/hr

6, Glass wall area.

. 1

Area"^ 6-J x 43 t 2-| x 50 = 4^4 sq. ft..

(Assuming the use of double glass)"

U - »45 Btu/hr-sq.ft.-°F

-7“

Heat lass

hol\. x ,i(-5' x 90 = l6>350 Btu/hr

7» Infiltration-— oracle method

Windows

Factor for average windownon-weather stripped—

39=3 cu. ft0/it. crack/hr

Two.. „ . 2-|-1 x 3 { " 22 ft. of crack

One... f.2%-* x 5 f = lj3 ft. of crack

Total.............. «37 ft.

37 % 39« 3 = I W t cu. ft^/hr

Doors

Factor..».,110.5 on* ft./ft. crack/hr

Two doors... .3 ’ x 7 1 - lf.0 ft. of crack

IpO x 110.5 " l^i{-20 cu. ft./hr

Total = I ^

f Wt20 = 5^874- an, ft^/hr

Volume of sanctuary and entry

1180 X 10 = 11,800 CU. ft.

This only gives -J air change per hr.4 therefore^

assume I air change per hr.

Heat loss = 11S:8QO x *018 x 90 = 19 a100 Btu/hr

m e r e *018 % .2^ x .075

and »;2k “ specific heat of air

.075 ~ density of air^ Ihs./cu. ft.

8., Floor (ground loss)

Heat loss a Btu/hr

Gorlxng. •00. *.. ».* * c»........ »».,*»...

WallS . . . . » 0 0 . .

. » » e .. . .

..»*, *

Doors

.

.

Stained glass window.»„...»............

5l8o

3270

I92S

5800

-8~

U-I^SS u?a3.X» esite.

1262

O6eefreeceeee^gfl ,16320

IllfXeX 'fcl’atios® e # e » » e e « » » e 4 , .

i © cal g e *» » « »ji„„ „, »•,

,19100

»»<,»,,-»<,.**»».«,»o

Btaa/lii5'

A-S-Sujne ground loss 15^ of total heat loss?.

12# s 22873 = 7930 Btu/hr

rotal % 7930 f 22873 a 6o»8o3 Btu/hr'

B» Sacristy

I 0 Gelling area

Area = 17 z 11& - 7 x 3 - l6o sq0 ft*

G “ o05 Btu/hr - sq.» ft* -,*?

Heat loss ^ l6o x &02 X 90 = 720. Btu/hr

S0 Wall area

Area = 11& z 9%. 4 & %

+ 10& % %

G = *05l Btu/hr w S q 11 ft*

4 261 sq. ft*

''

Boor area = 21 aq. ft.

Window area a 21 sq* ft.

.

•. ■

(Total area.s 261 - 21 - 21 = 219 aq. ft.

Heat loss - 219 x »O/l x 90 = 1000 Btu/hr

3 o- Door area

Area = 21 aq* ft*

G - »51 Btu/hr ~ sq» ft* -°P

Heat Ioaa = 21 x »21 % go = 96%. Btu/hr

'-i-» Window area (assume double glass)

Area = 2& % 8# a 21 aq* ft*

G = *1x2 Btu/hr * sq. ft, -°F

Heat loss = 21 x Ji$ x 90 = 820 Btu/hr

5t> Infiltration— crack.method

Windows

Factor— -39«3 on. ft./ft, crack/hr

One.....2/' x 2*|**' — 9^2 ft. of crack

39*3 % 9*3 = 373 on. ft.

Doors

Factor-— 111./ -Cd* ft«/ft,, crack/hr

One.*.*.3 *" x 7 + = 20 ft. of crack

110.2 s 20 = 2210 cu. ft.

Total % 373 + 2210'= 2283 on. ft,/hr

Volume of sacristy = 160 x 1.0 = l600 eu* ft.

Orack method gives approximately two air changes

per hr.

Use Infiltration by .crack method for

heat loss.

Beat loss = *018 a 2283 % 90 - # 9 0 Btn/hr

6. Floor (ground loss}

Beat Iossj. Btu/hr

OoxImg

720

Walls

* . « * * * . . . a * . * . . * * . * . , - * * . * . * - , . . 9 1000

Do ors ... no» * . * . * . # . **...*.. o- 9hlx

V^mdOVTS,

39O

Imxltration. * a

*. ** o*♦ a *.*.**.. I4.I90

Total

~'J'J/TC Dtu/nx

.

*

O

0

.

*

.

.

- I A - O

.

.

*

*

* , * . .

A

*

*

* »

O

0

0

0

a

*

*

0

* . . » , * <

*

A *

* 1, .

A *

*

*

.

A *

.

*

.

.

.

A *

*

.

»

*: *

*

.

.

o

. . *

o

o

O

- O O

a

*

* .... *

0

Assume ground loss = 12# of total heat loss

12# x 7724 == 1128 Btu/hr

Total % 772^ + 1128 % 8882 Btu/hr

Total Beat Loss For Chapel

Assumed Use of Double Blass in Bast Wall

Sanctuary and entrance

10

0 ©

'6 » ti- e d o a

2 Q1 vlftSt-Li^ o o tf»

■fr

o d-dd'o'd

tf-

e o o o o odd

O d d d e

oo - a e . 6 - o d < |"'0 Oito.ddO

O

i!)O-O-^0 o o » -a o d * * * ttd o, e e -<i d ti er d o ft d d- o d

.Stained glass v/indow^ o******** ^8OO

Slc^w-vL-Xg^l.tjS1oe- e otie *r o o*iO- » d-ditotin Ao d I2l0^'

I

O o

O iI a s s

Ta

I n f i l t r a t i o n * * , * * * » . ,

v/all

A# o*

^ o o »

8 D

^ l O O r o-a 0 e d o

p a o

o^osioaao

a * e 0 A d a e -O o a , * o o e * a a

1 9 1 0 0

T 9 1 0

J?oval &0 **a d o »» 0 * Oj» doe AO* a * do* 0 800 OI 33xi%/lir

Saerlety

1

d

2 a

OOXlXXl^ 0

d- ti i>-£• ft ft ti -* »■ ,0' fr ti *'»

I'^ 1 1 S a * * » t i - o r d e «

34

oe d a e

ft 0

0 e: 0 0. a 't

o o o o Aftodftfto

OOO r B a ' A f t o f t e - f t A f t o o e o - f t o a o

» o e e-

»a

720

1000

a b

V J l n d O ^ T S >d e a eft. ft O ft ft oftft' ft O o o d V f t f t f t f t e

5<. Infll tration* •* + ******* v,*^*'**-,

6 ^“Floor d ft o ft A 0 ft ft ft c. 0 a 6-o * 0. «. ft ft o d * f l * 0

Total 0 d o ft- a 0 «>. • ft O -ft o 0 e ft a o d e d 0 d e f t d-

!{1 9 0

1158

3: Btu/hr

Total heat Iosa0* » * * * » t f « * * « o « « » o * 69,685 Btu/hr

Total Heat Hoas For Ohapel

Assumed W e of Single Glass in Fast Wall

Sanotuary and entrance

5160

1928

3270

5800

5

S h y I X g i l t S o d e o o - o o o o o o 'oeOoOo-oft-o-o

1265

8-o GlxXSS wall OooegfrOo eg oOfrfrfr 000Oo- IpLlOO

7 0 Infxltration-o 0,0 ©0- o-o-o o.0 0 oo-°-00 -0 & 19100

O e r la a ig p

I o

o

* * o @»#

*■ # » ^ o < » o # @ 0 0 0 0 0

-OOOrS o , O 0 O o O O O e d o o O g

O d O O O -O 1-O.

3 O

IfifallsO O O O o O O O O O o - O Q O Of 0 O- >0 O O O 0-0 O o

Ito Stained glass win-doe0«,-»«..0..*.*,0

2-0

6

CF

F l O O r S

t i o - O f r O - o o o f r d o f r O - o - O f - g - o -O- 0 - 0 0 ' 0 0 6

Total 0

OQ- 0 O g- 0 0 0

0 OOfrOO

Btu/hr

O O ' O f r O O o-0 0 - 0

Sacristy

Oexling O f r O f r f r O - O 0-0 - 0 0 0 0 - 0 0 -6 f r f r O o O O O

0 Vfalls O o o 0 O 0 -O O O f r o OfrfrO- O O frfrd O O O O-ADoors O o ofr o f r f r o d O o d o e ofrfr.ofr 0 0 d . f r O O

I 0

d

3

720

1000

<b

If 0

xndon? Sfrfr

O O - O f r g f r f r f r O a-fr-fro-fr-d-fr-poofr-fr

5 0 Infxl u-raxxon ©0°*00 *«♦■ og,0o»0 *.t* % 190

6

0

F lO O r o . o f r f r o o f r f r f r f r . f r f r - o o f r f r o o o f r - o o a e o

1158

T O vul O o f r o

8882 Btu/hr

-O- frOo-frfri f r f r t t o o o o O-Ofr -O- * 0 0 6

Total heat loss 6 a

a a ® -e v *

a o*a

0

9 4 > W 5 Btu/hr

-IiDealgik of Ploop Panels

Hotel

Heat losses based on the use of double glass'in all

windows except stained glass mural*

Design temperature of water is U O r F with a 20*F temperature drop through the circuit*

•■

Depth of burp Is 2 inches *

A 0 Floor panel -

copper- tube 9" and. 6 ft 0*0»

I*. Sanctuarj and entry

Heat less - 60803 Btu/hr

Panel rating used = $0 Btu/hr-sq*. ft*

Floor panel area required -■ 60803 9 50 - 1215 sq, ft.

Actual floor area = ll60 sq* ft*

Use i I! copper tube 9 n and. S n 0*0*

Length of tube required » I0I3.O x 1*3 - 1352 ft*

120 x 2^0 = 2^0 ft*

Total**

e • e « o '«

9

« 0- « -0 «-

0

«0«>

4

*..*** 1592 ft*

2* Sacristy

Heat loss - 8882 Btu/hr

■

Panel rating used = 50 Btu/hr - sq* ft*

Floor panel area required ~ 888-2 r 50 “ 177 sq* ft*

Actual floor area ” 182 sq* ft*

Use

copper tube 9 H °»C0

Length, of tube required ~ .162 x 1*3 ~ 210 ft*

Total length of tube, required - 1592 t 210 - 1002 ft,

3* Circuits

Uoe oirouito of approaiimtaly 180 feet*

Mo* of circuits = 1802 * 180 = I^Approzlmatoly

Circuit #10„

r?

ir

a

f«o-o«dfoeoOOCO OO0OO0 18k Pt*

a-oOb'OOOCti-OOO-OOOOOOO 186 n

u

o o » oo-teco o Q» ocot t t eooo 173

ecteoooooooo. ^coe-oooo

181 n

Mf-DCf>oofoo O O Q - o p t i r o p o p - a o t i O t e t e - o - o c 170 ii

t

u.Co <> o- o o <>

O O O 1O P ^ O t e O O O 0 P Cr O oteteo

186 r?

?/'To o o e o o o o C f t e o t e o t e o o t e o t e t e o o o o t e 185 I?

IQl Il

ofiotitetyteOtkxko-teteooote-c-te

>y'9O aOti,ti-OO t e o t e o ^ o t e - o t e o o t e O t e A O o o 182 If

v/lO OGOOO o b- o O o O if c tete O'te^te-O - O O t e O 166 if

^JotalO O O Ote-teO-teteteOteCtete-teCftO-OOte

Ptx

o- y- e o

fi?

H D o- o o o <j o

-<

U

is

U

n

si

M

t?

N -C

o - =e o

ti

O

a

‘/ / ' 3

O

fi: o

e

tf

!!-o Supply nnd return hoadors

il.5<3 2" Ur0 I» pipe.-, If. ft a long oaohc

5 o Pump

Tj.oo 1-|M standaixl or l|-tt Mgli head

6 o ITater boat or

RociQBBnend use of hot water comforter similar to

dOif.-li as supplied by General Fittings Oo0 and

rated at lt.7O oq# ft. of hot water radiation (5 lb*

stooati)„

7 6 Valroo

Use stop and waste valves on the return header to

facilitate removal of air during the filling operation*

Dao gate valves on the supply header*

?be general apoclfieatioua, H a t of materials, and

cost fGllcnfO0

General Speolfieatiauaa

Beat Ioaa from the chapel is based an the insulation

quantities given 'beloiw

Any deviation trill possibly change

the entire s e t - u p heneo strict adherence is advised for aat**

lofaotory operation of the heating Systos0

I0 Insulation:

(1) Oeilingoa O-O^m rock wool or equivalent

(2 ) Walls® <.<>.«a

rock wool or equivalent

(3 ) FlooroaaaaaI tt fiber glass insulation at opposed

perimeter of slab® Extend 3 s inside along the

rack Wall0

II,a. Windows:

(I) Sanctuary„«„„double glowing throughout of a

^thormopaneN nature^ three operating -sections^

one over each door approximately 2 * 6 ” x 3 4 Orr

and on© in the end bay approximately 2 8 6 H %

2'

0".

(B) Skylights6ti®0.double glass (I8n airspace}®

(3 ) SacrIsty00&«„double glasingj one operating

section approximately 2 r 3 ff x 2 1 Gnc

IIl0

Poors?

(I) All doors are flush wood doors I"3Atn thick®

IF0 Floors z

(I) Ihe floor is to be constructed of a V 5 concrete

slab poured on. 6 !,t crashed rock or extremely coarse

gravel®

The floor must be poured separately from

the foundation and may havo- a concrete surface

finiSh5 tile^ linoleum5 or wood nailed to sleepers

embedded in the concrete®

it

A 3A A copper' tubing supply and return line

shall bo imbedded in the concrete from the heating

roomcto the east wall to be used with radiant base­

board* along the east wall of windows should it

become necessary.

VI.

Construction of the heating system will be done

b y the student# taking the radiant heating course

during the fall quarter under the direction of

Dr. Et F, Mulllkln* if agreeable.

VII. Bill of material* and cost;

I circulator (!&" atd. or 1&" high haad)....$ %9»00

I Indoor thermostat (Perfex line voltage)...

11»5>0

I converter (almllar to 00^*^* General

Fittings Co.)....

73.20

I floating thermostatic trap ( 3 / % $ . * ) ^ . 1 ^ . 0 0

I temperature regulator (no. 9 2 @~LC

Fulton Sylphoa^li*).........

80.00

I expansion tank (20 gal* ) • . . . . * * # . • .

16•00

I automatio air vont•••»«••••*•«••••***•••«•

10 shut—off valves (1/ 2 ®)* ........* *.**«.*«♦•*. *

l«30

13 •50

10 stop and waste valves ( l / 2 " 1 $ . 0 0

I supply W a d e r ()#. ft. of 2* W*I. plpe)^....

^.00

I return header U|. ft* of 2* W.I. pipe).....

$.00

ft. of 3/%" copper tubing type L........

20.00

90

I check valve

»»««••••••••••»•• ««•*«.

6.00

I reducing valv# and I relief valve

(combined)

I altitude gage (thermometer included)......

1800 ft. of i* copper tubing type

12.00

7*$0

282.00

4. shut-off valve*

^0*00

30 ft..

water pipe ® ^2^ per ft.*...*..*

12*60

Mxseel3.anions elbows, tees, etc ........... 8

IO0OO

fJ1Ou a I

V illa

O

O O O f l O O O O

O

O O

O

O O C O e

O f l O

fl

I,

O f l C C O O f l o O

O O

»

^O O 6 O O

O O

D

The prises quoted above are subject to edueatio&al discounts which can be received If ordered

through the Mechanical Engineering Department.

I3C.

The return header will be located In a pit

slightly b e l o w .the floor level to facilitate drainlag the system*

A sewer outlet will be located, in

the pit.

X*

:

The headers may be located along the north wall

instead, of the south wall as shown on the drawing.*

This will help prevent excessive heat in the utility

room.

Xltt

•

At each joint in the concrete, wrap each tube with

felt or some cloth-like material to prevent the tubes

from shearing off due to ground movement 0

Floor panel— 3/%" copper tube 12" and 9" 0,0.

I. Sanctuary and entry

Panel rating ■« j?0 Btu/hr

Heat loss and panel area same as with i-n tube P

Length of tube required - 9li„0 x I

200 % 1.3 *

T o ba l

c> 0 f l o o o . o 0

» on

o oo o

fl fl O O

so o .

9ii0 ft a

260 ft

1*200 ' f t

2o SaG&la&jr

Hoat Z033 and panel area oamo &o %ltb

tube

&@mgth of tube roqalzvd. = 162 a I = 162 fto

#otal length = 1 2 0 0 * 162 - 1362 ft*

3* Olroultg

Hoo G ircu ltg o f approzhuatoly 2&0 f t *

Ho0 Ox c i r c u i t a «* 1362 4 2S0 s approxim ately 5

O x r c t L i ‘0

,/Io o«croaai>oyiroa,oe»t>Q».cia-ao(y

2 7 9

f t

<3

^

-;'i-2 «

........

oAA

s.............

»e ooti.tiooco

SQO tf

Ei

!fjP*ooeott^o-ooiS Ooqfeo-Obtao-Qb 00

^

n

<

1

Q

6

O

O<ty0

0

4

0

t

k

O

e

O

9

C

t

i

o

x

y

v

oo

O

^

n

>/'5Q»6*0.0,6 16«Oo-OtiO OO.titiOOQ«O.O1 273 ^

l

IlOtnlo OtiO Otioabootbooa*otb% Gq eo&odo-IjyJt X1

Oo

4 o Supply and return imadors

0ac Stl Wti Xa p Ip o^ ii. ft a ©aeh

Je

I3ISiip

Woo 1§" Otandard or 1%" high hood

6* Water hoator

Hocoiiinicmd 1100 of hot vator coiwortor similar to

no* GGk-.^ ao supplied by Goaeral Fittings Go, and

rated at ^70 ag» ft* of hot trator radiation (J lb.

otoam*

7o Valwoa

Hoo atop and %aoto valvos on tho rotura. header to

facilitate removal of air during tho filling opera­

tion* Hso goto valvoa on the supply hoador*

Sbc coma gonorul spoolfloatiana ulll bo used for the 3/^"

tubing ao for tho &" tubing*

17

Llmt of material* and eomt;

I olrmulmtor

mtd* or 1^* M g h heed) B & &*..***..$ ^9*00

I indoor thmrmomtmt (Perfmx line v o l t a g * 1 1 * $ 0

I oonrartmr (mimllar to GG^-4* General Fitting# Co****

73*20

I floating thermoetatio trap UA")*.***....*.***..*** ' 4*00

I temperature regulator (no* 928-LG Fulton Sylphon-I^"

80*00

I expansion tank (20 gal*

16*00

I automati* air v

e

n

t

*

.

!$.*30

6 shut-off v&lv©a (3 A ” )*«.•*•***«»*•*•«*.»»»**»•*.*• *

11 *00

6 atop and w&afe® valyas* ••#•**•*«*•* «****».......... * **

12. 00

I supply header (% ft* of 2" #* I. pip#)*.*..*.*.**.*.

2*00

I return header (4 ft. of 2" #* I* pip#)**.*...*..*.**

2*00

1490 ft* o f 3/ 4 * sapper tubing type L

*

.

.

332*00

I check yalwa C1%" )*.*** ............ *.*## •* ***.*.*.«.*.

6*00

I reducing Tale# and relief *al*a (combined) &"..*.***

12.00

I altitude gage (thermometer included)*.....*..*,.**.*

7*20

4 8at# valwem (1"& ).* ***.**.. ##.***. **,

#..

4o* 00

per ft*.*....***.*.*.*****

12*60

Mlmeellaneoum teem, elbow#, ete.......................

10.00

30 ft* !&" eater pipe @

Total.

,1691*10

The coat of material# far the two #y#tema 1# slightly in

favor of the &* myatem, tut the added labor would put both of

Wamm about equal.

It i# reoemaanded that the &* mymtem be

u w d because the cloaer spacing will give a more uniform panel

-

18-

t*mp*r*tur* and the smaller tubing gives more turbulent flow

and henoe better heat transfer.

This shape! has been designed by the students of the

Montana State Gollege Department of Arohlteoture.

As many

departments as possible *111 eontribute toward its eonstruotion when sufficient funds are available*

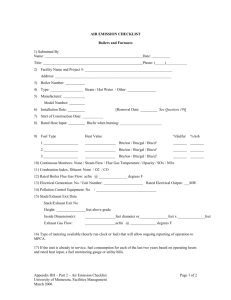

AIFi VENT

SXdr.____u.

i' REUEF VALVE

t

-- -t-'-i

TEMPERMUKE REGULATOR

'T H T j CE GAGE

f'."! .

Y MATER -•Ti

REDL :R G VAY E

——®,--‘

CHECK VALVE

DRAIN CGCK

— "&• L

ROOM THERMOSTAT

Y

MONTANA, STATE

COLLEGE

BOZEMAN, MONTANA

CONTROLS FOB DAAVFOFTH CMAPEL

HfATiNG SY ST E M

C R. SY

TH. BY

L. HOriPEUAHL

'd/Zo/sti C K g Y

A P R BY

DRAWING NO. M E 3/9

BRI.,G TUBE ' OUt

JF SLAB AND CAP —

TVC /4 :CTTS- TL5E:

FC-. FJSS-; ; BALi/ ,T

CkTSiCZ T E ' - - Z C F

WALLS

ElL Na

INSIDE

4 > MWfFAL

TEMP. +70 F.

WCOL I ’i SLi LAT U N

4 'TMWEBAL WCO l IUSULATi JN

F - rCm

i" FISER-SLfiSE I NSULAlir H At EXPOSED P E M M E T E S

VV'LDIWS IN EAST WALL AWC S A C B L S T f - DOUBLE GLAZZL

ALi- Li- v SC OF

out

h

COPPES

TUS<

BURIED

2

:

MONTANA

STATE

Cu LLEGE

_ _ BOZEMAN, MONTANA

BADfANT

HEATING

FOB

DALFiHTH

PMcfOSED

CHArEL

Cx, g y

AAL L T

•CA.E:

/F

D n/v,;. ;

-;n. M E 3 2 0

L..-J '

RriHj T'.irt'. ' ^

OF SLfk A-O CAP

---)

J ■ >■

cum VY HE-DEF

OiT-JCE TEriP -Z C sE

WAL - S

J " V iN En r

4 " MINERAL VVSOL I N S a. AT; J i

FL. %

I " FiBEE ~ Si. ASC. TNCLJ ' TV AT E X - J S VViM J S J j CAST VVAi- - AWO S A C f i i S T y — CJUS LE

/.-L C.A.CI'!. J CF

CJP.'' f p TL'B

Bvr--EL z "

e:Z:r'' .

JV

MAC MiV T

M 5ATW/G FGA

PFJ-CoEC

C 4NF:iTrl

Cp/iPFL

DR. BY L. H Q R P E D A H L

A^’

/i' CA. EY

TSLfY

SCALE % ^ /FT

APF 2Y

L-AW-LV1

S ,- I. M E SC/

aa

LUlLT-Ut

HOf

8- T. £ 6 U M W G

W O L T U

E

L

S C A L E

I

I

A

I

I 0 H

.

W

T (

I

T

/ 4" - C- 0 "

L

[ V

( C A L E

I

T

I 6 H

T

I

I - 0"

b

.1

N-

1

"

O _

U_ _ _ _ I

»

E

L

SCALE

W

.... ^ 6 "

I

Z

3

4

5

6

7

6

L

M S i C N

M A t i N

M 6 ~IL T M

I Y

E.

q J

i

u

o

M A S

Z l-Il"

8’- I"

4 ’- 4“

2‘- II"

5' - 6“

5 6 "

Z - 3"

5' - 8"

i

x

x

x

x

x

x

x

x

T

I

O

W

E

L

[

Y

M A L E

u

L

E

!

T U E M O

ti

B

A

6

N

/*"= I'- 0"

j-- _ U Z

T Y M

-IxZ

Z x 4-

M R C

-TWEkMOOAUG

- 3" HkC

- U 3

COLUMN

- Ix6

Il

Il

- A. "

*

fbOLT

'Y

STAINEb

GLASS

T U E M O M N E

H

4'- 5"

4'- 5"

b Y

ti.

J.

O T T E M

J H.

A---i f t T - L -- C 6 I I & C C

A

m

SIZE

Z 1- 9"

Z 1- 9"

6'-d"

6’- 4"

Z ' - 9"

6'- 4

M I L S T E i N

V

'1

l

A" - r-O"

u

S

T

--------- !

M U L L I O N

< E C T l OW L I

*

Il

)4

-0

I

A

4

U -

f>

G

L

- 4 ---- E

F

0

2 JUW So!

L

- X ____ 4 ___ L-

4-

E L E V A r i O H S

M

U

H

U

SECTION C-C

If

Stl E C T

OT

3

V

4I

T

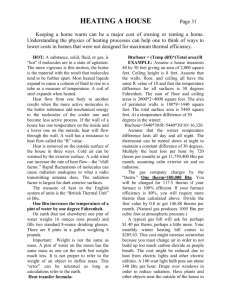

-23HEATING FOR A TYPICAL MONTANA

LOG BUNGALOW WITH HARDWOOD FLOORS

radiant

Most people associate radiant heat with a concrete floor

slab. The result is that they don't consider radiant panels

with hardwood floors.

They forget that wall and ceiling panels

even existJ In this particular design, wall and ceiling panels

were not ,feasible due to the particular interior finish of

rough logs, hence a floor panel was used.

Pig. I - Monte Benson Residence

The nature of construction of this residence was a full

basement bungalow of 9" log walls, the logs being sawed on two

sides.

The cracks were filled with "Hydroseal", an asphalt

base sealer, both inside and outside.

The basement was finish­

ed in the form of bedrooms to be heated from the panel in the

floor above.

Tlie first step in the heating design was to compute the

heat loss.

The computations are as follows.

"

_

_

_

_

_

_

_

_

GooffIolenta of Hottt Transfer (IT)

A s- Walls

H

I s IZlSliO Om f -LllSs c ti v o y f>u un <>Of, Od y y o o Dooo ti o d O O0606

2.0' 9 * l e g t r a il (assum o Bff average- th lo -k n o ss ) o-ol0a00

3 Oaide air fa Xlll0 d0 dCO 0u0a0.CO 0^an c0g 0y00OOvi 0Io Y

H ^ I 0Z773

H % lAo.773 » *093 Btn/br ^ sq*.

B s Windows

Is Single glassed «■ H % I 0.13 B.tu/hr ^ sqe. ft.* *»°F

2 * IbenrtOpane

H F 0lf.5 Bt’ti/br «< sq.*.- It90F

3* Single glazed (double bung}- « U a ^

Btu/br

C 6 Ceiling

sqs ft.9

H

1 -0' I u a x d,0 a x r f xlzii& q . *■&-# ^ o.9. » s * 0^ ^ ,0»- a »: 0 ^ .Cr.»:f> O&6 0 &

2*

- 30

10

3©

6,s

5/8 x Ir fXooring-o.0.*-0*^«-.»%&*

^ ««-*.

s* a■*0*0■»

2 roeIc v/ool.o o-0u^a<*o.0uUo99 0o-,<1a>>09^^9 y0u0y0

2 air anaoe 0c^ 0@060 o0000o.y000^*0«t>o-o»a 0ud 9

X. ^XZ3 S l Z O q 0n00 O'o-o-c/»--qqrV '»■:o"0o'u-»-0-§.■*yab e

Built-up rsofing (assumed thielmesa 3/8" )*«

7 * O u ts id e a i r

0*8Ol

rJ0IlO/

1*100

Xff020

O6277

z H m * 0 0 &0 c 0 <, ^ 0 0 <>0 ^ „ u 0 » 9 »»□ 0 0 d o 9 . *167

R » IX Z o t

H ? 1/11*378 = „09 Btn/br - sq& f t / ?

Sineo tbo Z n air spade is used for Ventilating purposes#

ealeuXato ttH lf from inside fe the air s.paee assuming tbo air

spaee is at outdoor conditions*

Use .tbo higher value of the.

two*

R

.

a x r f x lm 6 0%

. 9 6 @0» y y.u». s 6 ,%9 9 » o-9 .*'»,».* * 606

2o.. 5/8tf fir xlooring-o, 0** 6sp-a«spo-.oini,*0sa)6..o'0 & « &-IS- *8OX

3 o’ 2 rook wool,>0&o &c *6■©0000 000 0»®».»0000 n„ 0,,0«36/4.03

k0 Outsido air film (still air)*»,**.».*»***** *6O0

. I-*.' i n s i d e

R = W

H % l/90i{.2 “ 0*106 Btu/br « sqa. Xt0oF

Hao- H “ ol'O Btu/br »■ aq* ft*°F

B

D* Doe**

(Aateal th&ekna#* I 3/S*)

8 » *$1 B$a/br - *q* f&**P

R

B# Bathopoom wall

If & l/&t*2 * ,,Okie B W / b r *. *q* f%**P

P. Ioflltratlom

& # * * * & mdardbaag# pa* k** (groumd f l o w )

A m m a w i #1* a&wesg* p#*b** (baaaaaot )

0. Baaaaaat **lla and flee*#

B * *1 Btu/b* * #g* ft**F

»##% Ieea Galeatatlon#

Iaald* ^W#l#a taapa*#tu*a

a ?o^P

Outalla l*al#p teapaamtu*#

~ 20"P

IaalRe Raaamam t -daalawlMmgwNm&ta*#

+ 70 P

Outalda Rmaaamt daalge twqpmeatm*

+bO*R

A, Llalag Room

I* ## H a

A*a# e 20$ % 8$ ^ lb* a 8$ ^ 3 W *

% b6*) - 3$ x

6*8* - 2* * %*7* ~ 2* * 8* * 162 mg. ft.

Rmat lea# * 162 % »093 % 9@ = 1*3$6 Bte/b*

2. Plade##

Aema (tbaeaqpen*) * #* x b*7* - 22*9 aq* ft.

Sadt Ioaa - 22«9 %

90 = 92.9 Btu/br

3 3 26.9 aq» ft.

Araa (alagle g&a&ed) = (28* .%

Beat leas a 26*9 a 1*13 a 90 a 2^?%D Bto/br

3 o- Door

Area a 3 * x 6 *8 " a 20 sq0 ft*

a 918.Btu/hr

Beat Ioaa a 20 % $0

k-v OeillBg

. .Area a 20 z . % » .280

ft#.'.

Best Ieag ^ 280.% 90 »1 a. 2g20 B w / h r

50 IBfiltration

V & t w m a 20 X ill % 8 S 22lf,0 Ou0 ft*

Beat Ioaa = .018 % 1120 % 90 = 181$ Btu/br

6 o- Total heat Ieaa “ 10*278 Btu/hr

.Be Bedrecmi E@0. I

:-

Ie Walls

Aroa = 13 3/% % & + 9 3/% JK 8 * 2 1/3 % 3 5/6 » 2 3/3 a

2 2/3 % 173 aq. ft.

Beat less " 173 X .093 % 90 ™ lg% 6 Btu/hr

2.0 Windows ,

Area s 2 1 / 3 % 3.5/6.*- 2 1/3 % 2 2/3 = 15*2 sq. ft,.

Heat less ” 15*2 X. lol3 %. 90 3- l ff5i|-5 Btu/hr

' 3» OoiliBg

'

Area = 13 3/%-% 9

Heat 10.

m

= 1 3 % X 90 x

= 13% aq.

= l s2:05 Btu/hr

-2 7 -

k-c

W l t M a ~ 13 3/4 ac 9 3/4 % 8 - 1070 Ort0, tto

Baat Ieea = ,018 % 90/2 x 1070 - *81 a 1070 - 86? Btu/br

3a W t a l heat, loam & W & 3 Btu/hr

0» Bedroom Ho, 2

I* Walla

. Area = 10 # 8 * 3 ^ 2 / 3 2 x 8 » - (2 1/3 x 2 2/3 ) 2 =

lS? sqti ft6

Boat loss “ 167 x 90 x e,.093 “ lij-OO Btu/hr

2.» Wlmlows

Area - 2 (2 1/3 % 2 2/3) = 12*4 aq* ft*

Heat loss ■«, 12,4 x 90 X 1,13 —■126o Btu/hr

3* Ceiliag

Area = 10 X 12 3/12 = 124.2 Sq. ft*

Boat loss -s 124s2 x 90 X ,1 “•'1120 Btu/hr

4» 'lnflltratiom

Volume 3 1 0 x 1 2 ^/12 X 8 - 995 ou, ft,

Heut loss ” ,o:81 % 995 ~ 806 Btu/hr

3* W t a l beat loss * 4388 Btu/hr

B',. Bathroom

1» Walls

Area “ 8. x 5 ^ 2 x 2

2/3

34°7 sq* ft*

Hoat loss ” 34®7 x 90 x. ,0415 ” 130 Btu/hr

2* Wlaaew

.Area - 2 x 2 2/3 % 3+3 8q* ft*

Beat logs s

%. 90 % 1*13 % 239 Bto/hr

3* Ooiliag

Ai?ea s 2 x T ^ 32 Sq.« ft*

Beat Iaee = 3 2 ^ 90 x * l = 312 Btu/hr

%.» i&fllta&tioa

Valgme = 2 a. ? % 8 = 280 etu ft*

Beat Ioae = *81 % .280 a 22? Bta/be

2» Total heat loss « 1211 Btu/ly? ■

E* ICitehoa '

I* Wstil

Area = 9& a .8 * 2 1 / 3 ^ 2 . 2/3 = ? 0 a q * ft*

B&at lees a 70 ac 90 % *093 = 286 Bto/br

2a Windoxr

.x

A2*@a. = 2 1/3 % 2 2/3 = 6*2 eg* ft*

Heat less = 6*2 x 90 % 1*13 ~ 830 Btu/hn

3*. Ceiling

Area * g& x 13*878 = 132 aq* ft*

Beat Iesa ” 132 x 90 x *1 « 1187 Btu/hp

i|.o Infiltmtien

'

Volume s 9& x l 5l87& x 8 = lo22 on* ft*

Beat leas = 1023 % *81 = 82# Btavfbr

5.0; Total he at leas = 3%#8 Btn/hr

F b, Qfning room

I* Walls

Arm. = ll;& z 8 .* 9 7/12 x 8 - 2 x k 7/12 * 2 3/% x

2 2/3 = 3b63o2 s<&* ft*

Seat loss ~ 163*5 x *093 X 90 “ 1370 Btu/te*

Zs Oindeus

Area (thozmepcmo) s

a

= 22*9 aq* ft*

Seat .Iosa " 22,09 % j-0 x 90 & 919 Btaa/hr

Aroa (alagle glased) 9 2 1/3 % 2 2/3 * 6*2 aq* ft*

Seat Ioas % 6*2 a 1*13 % 90 =- 630 B t a / W

3* GolllBg

. Area » li|.% x 9 7/12 - I39 sq0 ft*

Seat .Ioaa * 139 % 90 at «1 ^ 12$%) Bta/hr

k-o X^filtmtlea

“ Ilii x 9 7/12 X .8 « 11X 0 ea*. ft*

Seat less " o8l x XllO « 900 Bty/br

5* Total heat Ioaa t 508O Btu/hr

0* Sail

I* Gelling

.. Area “ 7 x 3 ^ 2§ x Ii ~ 39 aq* ft*

Hoat loss. % 39 x 90 x *1 “ 391 Btu/hr

2» Total heat loss = 351 Btn/hr

H 0 Baaemeht entraBoe

I* Wall

Area " 8 x 3i « 2 2/3 x 6 2/3 = 10*3 aqe, ft*

3&&at X&8# a 10*3 2. 90 % *1 ^ 93 Btu/hr

2* Boor

. Area = 2 2/3 x 6 2/3 = 17*7 aq* ft*

HeatlOGa = % 7 * ? X 90 x *51 = 811 B&u/hr

3* Total heat loss ” 90% Bta/ha?

■

*«30**-

1» BasemdiBt

I* Walla

Jkrea = 2 (36 as 7&) .* 2 (30%. ?) - 10 .(1 z li) s

9I2 Sqa. ft,*

Heat leas = (.1) 2 x 30 # 9 1 2 = 9%72 Btn/hr

2 0 F lo e a *

Area * 30 % 3 & ? I 080 &%* ft*

Boat lea# & 1080 z *1 % 30 c 321*0 Bto/hr

3 o- WlBdiWS

Area » 2 (I.% Ii-) 1.0 » 2$ sq*. ft*

Seat, loss -. 90 x .23 x. 1*13 “ 23^0 Bta/te

XBflXtBatIem Casswae

als? ehmige/tir)

.Hoat less “■ 081/2 X 7-cS .# 1080 - 3273 Btu/hr

Total heat. Ieaa (groood. floor).*».*»**«**,*.6***30*767 Bto/hr

Total ilea's, less (lsasoiaeiit}.&0 «.»o-o-*»* *.% ao,-*o;«« »0-Ca-01^.5:327 Btu/iu?

fetal heat loss Chease Ja *■0- » . . . » %0

0

«.

0

a *

0 -1

<> 0 n „ * * $ <> 0 i

[.3^29^[- Bta/hB

Calculations .for Pipe length

Assume panel output .to be %0 Btu/hr ** sq, ft. to the

ground floor*

Tb calculate additional panel, output necessary te heat

the basements, do the following,$

Hoeessapy heat/hr - aq* ft* “ Ilt327/1060 ~ 13c/3 Btu/hr **

sq* ft* . ,*&

13 Btu/bp * sq* ft*

Total panel output

ko -t 13 “ 33 Btu/hp ^ gq. ft*

A* hiring Room, (area = 280 sq6 ft*)

fin tube-| 6" o$Gj

2 = S 26 ft*

Pt* of W b G a

B 0 Bedroom Ho* 'I (Area s %3hr sq.0, ft,)

§*

ta w s

6" o .c *

F t* o f t a w

= 7 0 7 3 /S J , # 2

= 25#

ft*

Ge, Bedroom Ho* 2 (area s 12i|, sq0 ft*)

' |w

tabes 6” OtiG ti

Pt* of tnbe F 6% 6/23 ^ 2 F 23% ft*

D* B a t W o o m (area ~ 32 sq0 ft*)

&" tubes. 6" OoOci

Ftti.of. tube “ d.736/22 x 2 - 63 ft®

E et Eitehoa. (area » 132 sq0.ft*)

tubes B lt 0 *0*

-

'

8/22 # 2 = 197 ft*

Ft* of tube F ^

F.C Biaifig' room (area u I39 aq* ft*)

i if .Wbos 6 n 0.oG*

Ft, of tube F 7162/22 2 2 F 26% ft*

Go Hall, (aroa F 39 aq* ft*)

tube; 12* 0*0*.

. Ft* of W W

a c#6/ 2 2 a: 2 * 3% ft*

H* Total ft* of tube

f

1272 ft*

I0 H-Ott of circuits - 1272/180 ft<,/circuit ~ -approx* 9 circuitsBoiler

A used, hot water beater using am oil burner was used to

sure installation cost and await the arrival of the natural

gas pipe lime, to Belgrade*

'This hot water heater has a

- 3 2 -

capacity of 6o gallons which is too large but due to its large

size, it had a low demand and hence a low price.

Circulator

Use a I?" std. B. & G.

Headers

Use two W.I. pipes (2")

Of particular importance in this design is the floor con­

struction as shown on the drawing.

Notice that a sub-floor

is laid over the floor joists followed by a layer of water­

proof sisalkraft paper.

One-inck by two-inch furring strips

were laid on top of the paper on 12 " centers with two tubes

between each furring strip.

After this was accomplished, a

layer of a poor grade of concrete was poured and leveled off

k

with the tops of the furring strips. Wlien the concrete was

thoroughly dry, the hardwood floor was laid.

Pig. 2 - Purring strips laid on sub-floor

-

33 -

Pig. 3 - Floor ready for layer of concrete

The object of the concrete, which was actually 25/32"

thick, was threefold.

First, its purpose was to carry the

heat away from the tubes by increasing the emlssivity factor.

A shiny copper tube has an emlssivity of about 0.15 as com­

pared to rough concrete of 0 .95 *

Secondly, it removed the

air space which is a good insulator.

Thirdly, the concrete

acted as a grill to spread the heat uniformly over the floor.

This installation was constructed and put into operation

in January 1950 and maintained a room temperature of 70*F.

while the outdoor temperature was - 35#F. with 120°F. water.

At the present time the unit is heated by an oil burning con­

ventional hot water heater until natural gas is piped into

Belgrade, Montana, the site of this residence.

The owner,

Monte Benson, is, in his own mind, convinced that his heating

system is cheaper to operate and has a cheaper installation

cost than any hot air system he could have installed.

In

-3 k -

Fige k - Boiler and nearly completed

return header

addition, his heating plant uses a space about Ip feet square

in the basement with no duct work to take up space and no

convection currents to carry dust and cause objectional drafts

throughout the house.

"An added feature", says Mr. Benson,

"is a warm bed to crawl into every nightJ"

Since the interior is all finished in natural log, it

would be extremely undesireable to have large quantities of

dust moving through the air and settling on the logs.

heat cuts convection down to a minimum.

Radiant

Interior decorating

-

i3 expensive.

35 -

With no air ducts to darken the walls with

the rising air currents, it is obvious that there would be a

saving in interior decorating in any radiantly heated home.

Also, there are no radiators or convectors to take up space

and interfere with the decorating scheme.

In this particular

case, they would distract severely from the rustic log cabin

theme.

With the present system, it appears as if the fire­

place is the only source of heat.

These are just a few of the

many advantages achieved by using radiant panels.

Fig. 5 - Interior of Benson Residence

The materials used and their cost is as follows:

Line voltage room thermostat......................... ^ 11.50

1600 ft. of

copper tubing @

ft...............

Sisalkraft paper............... ....................

232,00

12.00

Hot water heater.................................... . 150.00

Circulator Lg-" B. & 0. std...... .................. . .

58*00

300 gal. fuel tank with pipe and fittings............

i(.6,00

3 C

A-XS*

Cu .

'5.(3. TJO..Cl V O

^OlX'b

V'al'VG 0

^ o o o u O -J O o o y o o o r/ o D

0

o o o O o o O <> o O \P 3*3.41^0

O ,0, a- e tt O » 0 »■ *. e * a * »-« O B- 6 ».b> « e 0- * B » » Ji1« |6 e * * « & » O- O » * V=

Oombination noli of and roduoing Tcilvoy*»*4.***,.****»

2 WfrXo- boadonSf 3 Xto oaob C.2^

OcsBonn ***

^

B-BB u>Bo-b fraoBV BB-OV-^bb 0

^ 4 S*Q

11*7#

3#00

3 O &o•» b-.

0-»-0.-»b *o-y-0»* »■o'b &b &^ »O-B-B-B # o^O

dmr1x3iTig o'ujO-LjO0 00 =>0<>00oo 0y0 =>co0000 0-?000^%0o-^oo =>u^y ^0==:- 20fr00

S a n d

C I

^ y a n d j ^

Mx s g q H c m o o n s

a v *

b

- °= - a a -0 B » B - » 0 , CF -b . -b

to- Br - a

cog

5 ^ o i b o T i s •> 0 1 0 n 0 .-^ «=0 0 a 0 » o « ^ 0 o a y * o u *

b

tic f r 0 a B B B - V

b

- B B Br 4 » e a

b o

q

0

3

-t i O O

1 0 y QO

X o t a l fr fr B fr- ■»-B- to,B -Q to 0 B -O- B B. O= 9 O -B- B -B 0' 'B B -B- B- O O B B B B B B--» to'B =O1to -» d B B' O -O til to- tt-V p 3 / 3 = 0 O O

Most of the laboa nas dono by Mr* Benaona banco an exact

labor cost analysis was not mrailable „. EonoTers assmnlng

that two min conld install the ays tern in flto oight-hour days

$t #2*#0 por honr-f. the labor coat nonld. be 13200*00? making the

total installed cost #793 * 60 .

AA estimate for a hot air

system to boat the same hones was given as $900»GQ by a local

dealer*

It* of course3= would be accompanied by a large fur*

m e n with duets taking up valuable space and a higher main**

tainonco and operating coat with loss comfort end satisfaction*.

Xwo different header systems are shown*

Xhe short header

system was used with all the valves located In the basement*

This makes the filling operation and balancing much easier*

Xhe "main-type"' system locates all the valves on the ground

floor where they may be balanced or shut off*

Xhoy are so. ar~

ranged that all valves are located in closets or cupboards*

It Is necessary with this system- to rim. the headers through

the floor joists which Is; rather undesirable o

Xf the build­

ing Is cjuite Iarge3 it Is necessary to use the. itInainu system

to keep the circuits from getting too Idng4

system was used ,in the. Benson residence,*

The short ,header

Sotiee on the draw­

ings that each room has more than one .circuit passing through*

This gives extra control for obtaining the- room temperaturedesired*

In any design*, each room should have -at least one-

circuit of its own*

In order to prevent overheating the basement 3 enough re­

sistance to heat flow was placed, between the sub-floor and the

.basement celling to get the correct proportion downward 0

drawings follow0

The

38

S

>

§

S

to

MONTANA

STATE COLLEGE

BOZEMAN, MONT A N A

C O N T R O L S FOR BfNSON RESIDENCE

HEATING S Y S T E M

12/6/47

CK. S Y

APR Bf

DRAWING NO. M E 324

r c:‘K a s s r - Y ' X . g p

aras-o % -_ . o : 3 Z 3 -c.

x N

7

.-'

%

I

ICAL

FLOOR

‘A

H rrdw .IGL f l :"R

t upper r u t- , 3

xx T

v * ^ ,x - GONLrETE

" FuR- U STR - - / \Z

'U b F 0 R

----- F.03R J - 15 TF

x

AT'

---

CHfETHO LR

CONSTRUCTION

b o i U f; a r e a

- SU PPLY

HEADER

RETURN H E A D E B

DESIGN NOTES

OUTSIDE TEfIR RZDeF.

INSIDE TEMP. + 7 0 T

WAi.uS 9 " LOOE SAWiO O.N TWO SiUES

Al .

window s

W.T:-: .-W.'

except on east

-

double hung

CN LAST - TtjERMQPAWE

CJHCLI T S

CF

'/£ ' Q C F F E R

TUiAsN G

5.,^ T - C - - T . VA l C O N S U P 1-LY E N D CF EAC H C i H J U t T

S T O P AX;

. W A S T £ VALvT ON fit T-r.v t vL CV t-C. C i E C O j J

VALVES, HEADERS A N D BOILER LCUATru V BASE M t N T

A 1 L TUfiINu ON G "Ce N rEAS E X V - jT E rC-EN CM 3 " ALj HAiu LC- jL C E N TERS

LAVER OF SISAi-KRAFT PAPER AeCVt S L BFu CCn

ALL

I

V

'

N

MuNTAPvA

STATE

COLLEGE

BOZEMAN, MONTANA

BAOIANT MEAT,NG FOB MONTE BENSON

FFSuOLNCE, BELGRADE, M O N T A N A

DR. GY

L._HORP-CDARL

TP. Sr

---SCALE I '/2 = / FT.

CK BY

AFP. BY

D R A W •'MG

NO. M E 3 2 3

*

W i B K M d52 S=ZB - IX» 76

.CL

.

C".

>>

l

>

H-V-DV

\ FlOOR

C h P P E A TUbPfG: ,NCRETE

r J R P NG S T p i P S - / X Z.

HEADER

- Jub

:cp

i

TYP

:A_.

FLO -

C '

TON

8C%E S AREA

(RASEM fN T)

)

M z

nn

;

'•

S u -Pu.-'

.

HEAEEP1

i

-

DESIGN NOTES

OuTSjCE T e M R -£0°F

INiSfCC TEMP. +TO^F

W/__S

9"L0GS S A W E D ON T W C S I D E S

A l L / ;C '

EXCEPT '-V £AST — CG1

UBkE .-PNG

VV =U G O vVS ON EAST W A U L — T H E R M O P A N E

A L - C RCUtTS O F ' / z " C O P 0 E R T U B I N G

f" H E A D E R S C U T T H R O U G H J J - S T e A T C E N T E R

BOIuER L O C A T E D N B A S E M E N T

ALL T J G N S IN A" CENTERS c AC F P T K I T C H E N C M S ' C E t f T f R S

.

I

I

IN

M ONTANA

5 TAT:

COLLE-E

BOZEMAN, MONTANA

i

BAEIANT H E A T i n j FE,R M O N T '

FEHS- V

RcSfTfZZCc,BELOBACE,ML \ "ANA

:CP.BY

:TX 8 /

L. HOFPEEAt - L

IZ/ I S A fi C K. F Y

IA Pr. S>

i

A SURVEY OF SOME TYPICAL MONTANA

RADIANT HEATING INSTALLATIONS

Since radiant panel heating is comparatively new, it

seemed very worthwhile to make at least a partial survey of

such installations in Montana to get personal reactions as well

as technical and practical information concerning them.

Much

was learned from mistakes made and suggestions given by very

cooperative and friendly citizens.

The following is a group of brief discussions concerning

each installation visited.

Several others were surveyed but

were identical to some already visited, hence left out of this

discussion.

Plumbers and architects were also contacted, when­

ever possible, for their views on the subject of radiant heat.

Several types of construction seem adaptable to radiant

heat.

The residence of Professor L, 0. Brockman, Bozeman, is

a two story duplex using walls of l6M of rammed earth.

The

lower story is half below and half above the ground, taking ad­

vantage of a hillside beautifully*

The concrete basement floor

area covers 1)4.50 sq. ft. and uses 6 floor circuits of

copper

tubing with its own circulating pump controlled by a room ther­

mostat.

The second story of the duplex was heated by

tubing celling circuits covering the same area.

copper

The tubes were

on 8^M centers and were supplemented by radiant baseboards

under the windows on the south wall.

the entire length of the wall.

These windows extended

The ceiling circuits had their

—lj.2—

own pump which was controlled by a room thermostat.

The system

was fired by a natural gas 216,000 Btu input boiler located in

the basement.

Btu/hr.

The calculated heat loss of the house was 75*000

Total installed cost of the heating system was about

12/a of the cost of the house.

Comments by the Brockmans in­

dicated they would possibly like to install an outdoor thermo­

stat.

Also, they had a problem of solar radiation due to the

many windows on the south.

A great deal of natural circulation

was noticed which caused excessive heating.

would have prevented that.

A flow check valve

The fuel bill for this house was

$14.1.00 during the winter of 194-9-5>°*

Another radiantly heated Bozeman residence is that of the

Karl Swingles on Huffine Lane.

This is a one story, flat

roofed log home covering an area of 2550 sq. ft. and no limit

on "picture" windows.

At a cost of 10$® of the cost of the home,

radiant heat was installed using I" copper tubing on 12" centers

except in the living room where it was put on 6" centers.

All

circuits are in the If." concrete slab floor poured on 8" of

crushed rock.

The outside perimeter of the slab is insulated

with I" of asphalted felt.

ed with zonolite.

The pumice block foundation is fill­

Each circuit is fed by a supply and return

main header system and equipped with a balancing valve.

The

control system employs a room thermostat to operate the pump in­

termittently while the aquastat governs the flow of natural gas

to the 250,000 Btu input boiler.

Calculated heat loss of the

-

43 -

house was 120,000 Btu/hr.

Sourdough Creek, south of Bozeman Is the site of a

radiantly heated log cabin owned by the Nicholas Helburns.

Two

floor panels were used involving 1” W.I, pipe on 9" centers

buried in a 4 ” concrete slab.

Tlie floor slab was poured over

a sub-floor of 4 ” concrete using 6 parts zonolite and 4 parts

cement.

No insulation was put between the floor and the found­

ation, hence an early crop of daffodils occurs each spring!

An aquastat sets the oil-fired boiler temperature while the

room thermostat turns the burner on and off.

runs constantly.

The circulator

Cost for heating this 575 sq. ft. cabin, runs

about #150.00 per year.

As for comments, they were sold on

floor heating, especially with children.

Improvements suggest­

ed were the use of one-half as much piping under beds and run

circuits under cupboards and closets too.

They mentioned that

certain waxes failed to harden on the linoleum due to its heated

condition.

Installation cost ran about one-eighth of the cost

of the house.

Another residence using log construction is that of Pro­

fessor Roy Wiegand, Huffine Lane, Bozeman.

Ratio of the cost

of heating system to cost of the house ran about I to 10.

This

1900 sq. ft., one-story home has 10 floor panels which heat it

and its basement.

The basement, which covers half the floor

area, houses the 100,000 Btu input gas-fired boiler and auxilliary equipment.

Hardwood floors are used throughout the house

-a-

with -|-t! copper tubing placed on 8^" centers between the sub­

floor and the hardwood floor.

Purring strips are placed be­

tween the floors to support the finished floor.

At the time

of construction, the tubes were left in air spaces between the

floors but due to the low emissivity factor of the shiny copper

tubes and the insulating quality of the air space, the house

could not be heated although the water temperature was up to

210°P.

The water returned from the circuits at practically

the same temperature at which it entered.

The only solution

was to either tear up the hardwood floor and pour concrete or

some similar material around the tubes, or take up boards and

force the concrete under with a caulking gun.

method was used with excellent results.

The latter

Of course the moisture

caused the floors to bulge and warp but the heat brought every­

thing back to normal.

A room thermostat controlling the cir­

culator and an aquastat to govern the water temperature com­

pletes the control system.

Despite the misfortune of not put­

ting concrete around the circuits during construction, the

TLegands are sold 100$ on radiant heating.

The average years

fuel bill runs about #120.00.

The summer of 19^8 found Dr. H. F. Mullikin installing

radiant heat in his now one-story Boseman home.

Several sources

had released information stating that Montana homes could not

be heated radiantly by floor panels alone, hence this residence

has ceiling panels to furnish the heat and floor panels to keep

the concrete slab floor warm.

Fourteen celling circuits of

copper tubing were used together with 6 floor circuits of the

same size.

Each circuit was approximately 1^0 ft. long and

was valved at each end to short headers located in the boiler

room.

This method allows all balancing to be done at one lo­

cation and all valves are out of the way from possible tamper­

ing by children.

An indoor-outdoor control system is used

employing a three-way mixing valve allowing the water to by­

pass the boiler when equilibrium conditions occur.

An indoor

thermostat operates the circulator intermittently.

A day-

night clock thermostat, to cut down the temperature at night,

doesn’t seem to perform properly, probably due to the heat lag.

Domestic hot water is heated by the same gas-fired 210,000 Btu

boiler by means of a tankless heater furnishing an unlimited

supply of hot water.

Comments by Dr. Mullikin indicated he

would just as soon have all the heat in the floor to cut down

installation costs.

Aside from installation cost, the

Mullikins are well satisfied with radiant heating.

Probably the most unique installation in Montana is that

of IIirara Dotson, Rimini Route, Helena.

His system requires no

boiler because water from a natural hot spring is used, hence

the only operating cost is the power to operate the pumps and

controls.

This one story residence is H O x