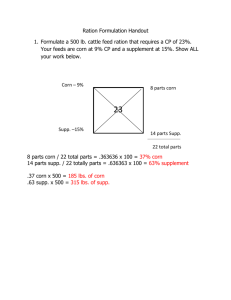

Effect of feed processing upon barley utilization by Robert H Anderson

advertisement