Document 13479015

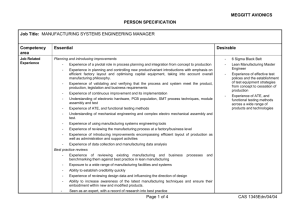

advertisement