Experiments on the free shear layer between adjacent supersonic streams

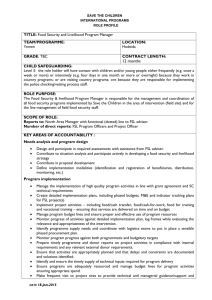

advertisement

Experiments on the free shear layer between adjacent supersonic streams

by Timothy L Brower

A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science in

Mechanical Engineering

Montana State University

© Copyright by Timothy L Brower (1983)

Abstract:

A closed-form analytical theory has been developed to predict the flow field of two-dimensional,

laminar, non-equilibrium free shear layers, shed from the trailing edge of a thin flat plate serving as a

partition separating two dissimilar parallel flows. A Mach 3 supersonic nozzle in combination with

either a Mach 1.6 or a Mach 2 supersonic nozzle were used to produce a free shear layer. The

investigation was designed to provide experimental evidence by which free shear layer theories may be

checked. A comparison of theoretical/experimental mean flow properties in the laminar,

non-equilibrium region of the free shear layer were made. The theory showed good agreement

qualitatively, but poor agreement quantitatively when compared to experimental data. The theoretically

assumed initial velocity profile showed a 35 % difference in thickness compared to the experimental

thickness. The theory predicts free shear layer thickness and minimum velocity growth rates that

parallel the experimental results, although a quantitative error of between 20-50 % exists. EXPERIMENTS ON TEE FREE SHEAR LAYER

BETWEEN ADJACENT SUPERSONIC STREAMS

by

Timothy

L Brower

A t h e s i s subm itted in p a r t i a l f u l f i l l m e n t

of the r e q u i r e m e n t s f o r the degree

of

Master

of

Science

in

Mechanical

Engineering

MONTANA STATE UNI VE R S I T Y

Bozeman, Montana

March

1983

m a in

l ib

.

1439%

Ccp-A

APPROVAL

of

a

thesis

Timothy

submitted

by

L Brower

T h i s t h e s i s h a s b e e n r e a d by e a c h m em b er of t h e t h e s i s

c o m m i t t e e and h a s b e e n f o u n d t o be s a t i s f a c t o r y r e g a r d i n g

content, English usage, form at, c ita tio n s , b ib lio g rap h ic

s t y l e , and c o n s i s t e n c y , and i s r e a d y f o r s u b m i s s i o n to the

C o l l e g e of G r a d u a t e S t u d i e s .

____ 3//6 / 7 S

Date

Chairperson,

Approved

for

the

Major

Graduate

Committee

Department

____ t / j j / j J .

Date

Head,

Approved

3

Date

-

?

?

for

the

College

of

Major

Department

Graduate

- O

Graduate

__

Dean

Studies

iii

STATEMENT OF P E R MI S S I O N TO USE

In

the

presenting

requirem ents

U n iv e rsity ,

available

I

to

quotations

is

for

from

this

under

thesis

degree

of

accurate

Montana

sh all

the

allowable

fu lfillm en t

at

L ibrary

rules

are

that

fo r

this

professor,

in

his

or

the

is

the m a t e r i a l

allowed

the

p artial

State

make

L ibraryi

without

of

it

Brief

special

acknowledgement

of

made.

of

m aterial

in

m aster's

th at

provided

reproduction

in

a

agree

P e r m is s io n

when,

thesis

borrowers

perm ission,

source

this

opinion

for

thesis

may

absence,

of

thesis

my w r i t t e n

by

either,

scholarly

in t h is

without

e x te n s ive

from

or

be

granted

by

my

the

Director

of

Libraries

the

purposes.

for

q u o ta tio n

proposed

An y

financial

permission.

use

copying

gain

or

shall

major

of

use

the

of

n o t be

V

ACKNOWLEDGEMENT

The

author

contribution

Eis

to

with

Anthony

the

Rompel

Harry

and

Barry

committee

members

Research

and

for

Special

c h ild re n

for

the

his

machine

wind

tunnel

Glenn

for

and

the

McCullough

thanks

during

his

his

shop

their

guidance

and

crew

for

their

m odifications .

for

their

p articip atio n

and

Bob

reviewed

U.S.

Air

in

W arrington

this

Engineering

financial

V ic to ria

encouragement

for

investigation.

and

Townes

Mechanical

U niversity

follow ing

assistance

equipment.

Townes,

design.

The

of

laboratory

the

Demetriades,

the

Williamson

construction

to

investigation.

throughout

Gordon

John

indebted

this

advisor,

cooperation

expert

is

the

nozzle

served

as

thesis.

Department

Force

of

Office

Montana

of

State

S cientific

assistance.

go

to

his

and

Skylar

this

graduate

wife

for

Cindi

th e ir

program.

and

his

two

support

and

vi

TABLE OF CONTENTS

Page

L I S T OF T A B L E S .............................................. ................................................... .....

LIST

,viii

OF F I G U R E S ...................................................................................................... i x

NOMENCLATURE

xiii

1.

I N T R O D U C T I O N ...............................................................

2.

THEORETI CAL REVI EW

3.

EXPERI MENTAL A P P R O A C H ...........................................................................

11

4.

EXPERI MENTAL APPARATUS AND P R O C E D U R E ....................... ..... .

Wind T u n n e l

...................................................................................... ..... .

P i t o t P r o b e ............................

S c h lie re n O p tical System. . . . . .

....................................

S t a ti c P re ssu re Probe

. .

. . ..........................................

T o tal T em perature Probe

...................................

H ot-F ilm Anemometer

.....................

Probe

P ositioning

................................................ . . . . . .

Data C o l l e c t i o n

. . . . . . . .................................................... 2 0

12

12

12

17

17

18

19

19

5.

EXPERI MENTAL DES I GN

.................................................................................

23

W i n d T u n n e l M o d i f i c a t i o n ...............................................................

23

Configuration I

........................................................................................ 26

C o n f i g u r a t i o n 1 1 ........................................................................................ 26

C o n f i g u r a t i o n I I I .................................................................................. 2 9

C o n f i g u r a t i o n I V ........................................................................................ 3 1

D iffuser M odification

. ...............................................................

35

6.

RESULTS

. . . . . . . . . . . . . . . . . . . . .

40

T r a i l i n g Edge B o u n d a r y L a y e r . . . . . . . . . . .

42

F r e e S h e a r L a y e r Me a n F l o w M e a s u r e m e n t s

. . . . .

49

T r a n s i t i o n D e t e r m i n a t i o n .............................

58

C o m p a r i s o n w i t h T h e o r y .......................................................................... 7 1

C o n f i g u r a t i o n I I I .............................................

72

C o n f i g u r a t i o n I V ........................................................................................ 75

7.

C O N C L U S I O N S ....................................................

.

.

.

.

.

.

.

.

.

I

.

.

.

.

.

............................ .....

.

.

4

78

vii

TABLE OF CONTENTS— Continued

Page

A P P E N D I C E S ......................................................................................................................... 81

AP PENDI X A

- Transition

AP P ENDI X B

- Tunnel

AP PENDI X C

—Wa v e

S t r u c t u r e s .......................................................................... 88

AP PENDI X D

- Data

Layer

R eduction Program ForBoundary

P r o f i l e s .....................................................................

90

- Data

Layer

Reduction

Profiles

93

AP PENDI X E

REFERENCES

CI TED

.

Theory

Vibration

Comparison

...........................

82

.............................................................

86

Program For Free Shear

.........................................................

96

viii

L I S T OF TABLES

Page

1.

Nozzle

configurations

2.

Nozzle

c o o r d i n a t e s .................................................... .....

3.

Optimum

4.

Boundary

layer

laminar

5.

Boundary

layer

8/6,

6.

Boundary

layer

and

7.

Summar y

operating

of

......................................................................

conditions

region

measured

edge

transition

.

34

..............................................

41

...............................................

42

v .

theory

.

.

25

. . . .

45

p r o p e r t i e s .................................... 51

determination

.............................

71

ix

L I S T OF F I GURES

Page

1.

Nomenclature

2.

FSL

development

3 .

FSL

development

4.

5.

6.

and

definitions

of

the

r

= 0

...........................

7

r

=

6^

= ©2 . .

7

T h e o r e t i c a l FSL d e v e l o p m e n t a t r = I a n d

r = . 5 .................................................... ...............................................................

9

at

at

y ' = 0 and

y'

= 0

and

T h e o r e t i c a l FSL d e v e l o p m e n t

v e l o c i t y g r o w t h a t y' = 0

2

major

13

Photograph

8.

Pitot

9.

S t a t i c p r e s s u r e v. d o w n s t r e a m d i s t a n c e p l o t

used to i n t e r p o l a t e unknown p r e s s u r e v a l u e s

c l o s e t o t h e T . E ..........................................................................................18

static

probe

collection

wind

10

7.

and

modified

I,

. . . .

a t r = 0 and minimum

. . . .....................................

Diagram of t h e wind t u n n e l showing

c o m p o n e n t s .........................................................

of

FSL

t u n n e l .............................

14

s c h e m a t i c .....................................

10.

Data

11.

Schematic

12.

Nomenclature

13.

S c h l i e r e n p h o t o g r a p h of C o n f i g u r a t i o n s I I and

I I a ................................................................................................................................ 2 8

14.

Photograph

15.

Schlieren

16.

Configuration

pieces 'butted'

IV s

slow -side

design.

together to form nozzle

17.

Photograph

Configuration

18.

Schlieren

of

block-diagram

tunnel

for

of

of

.

22

..................................

24

F S L ...........................................

27

m odification

deflected

Configuration

Photograph

photograph

................................ .....

15

of

of

III

..................................

Configuration

III

. . .

IV

32

Two

. . . .

I V ............................... ....

Configuration

30

. . .

33

.

33

.

36

X

LIST OF FIGURES— Con tinued

Page

19.

Configuration

20.

Configuration

21.

Schematic

22.

P q v . RMS B . L . t r a n s i t i o n t r a c e

Configuration III

.............................

23.

of

III

flow

IV

uniform ity

flow

variable

uniform ity

................................

37

. . . . . . . . .

37

d i f f u s e r ..................................... .....

39

for

........................

43

P q v . RMS B . L . t r a n s i t i o n t r a c e f o r

C o n f i g u r a t i o n I V . . .......................................................................

24.

Experim ental

25.

E x p e r i m e n t a l B.L.

5

v.

theory

. ... .....................................

46

26.

E x p e r i m e n t a l B.L.

G

v.

theory

............................................

46

27.

E x p e r i m e n t a l B. L .

comparison

to

Blasius

p r o f i l e ............................................................................................................47

28.

G r a p h i c a l c o m p a r i s o n o f t h e o r e t i c a l v.

experim ental p r o p e r t ie s e n te r in g the i n te g r a l

d e f i n i n g 0 ..................................................................................................

.

48

29.

Configuration

.

50

30.

Configuration

31.

Mach

No.

v.

downstream d istan ce

in

FSL

32.

Velocity

v.

downstream d istan ce

in

F S L .....................

52

33.

Reynolds

No.

in

53

34i

C onfiguration I I I ty p ical p ro p ertie s through

F S L ............................................................................................

55

C o n f i g u r a t i o n IV t y p i c a l

F S L ...................................................

55

35.

36.

37.

Velocity

I I I

B.L.

43

p r o f i l e s ................................................

III

pressure

IV p r e s s u r e

v.

gradients

gradients

downstream

distance

properties

. .

44

. . .

............................

. . . . .

FSL. . .

v.

y-position

in

FSL

52

through

p l o t v . y - p o s i t i o n i n FSL C o n f i g u r a t i o n

..............................................................................

Velocity plot

IV . . . .

50

56

Configuration

56

xi

LIST OF FIGURES— Continued

Page

3 8.

h v.

...........................

57

39.

S c h l i e r e n p h o t o g r a p h of C o n f i g u r a t i o n I I I

t r a n s i t i o n d e t e r m i n a t i o n ................................................................

60

Edge and p l a n v i e w of a low s p e e d

( incom pressible) mixing la y e r.

Scale:

s t r e a m w i s e d i m e n s i o n o f p i c t u r e i s 15 c m.

.

61

.............................................

64

40.

x for

Configurations

41.

Configuration III

Spectra

42.

C o n f i g u r a t i o n IV

Spectra

43.

Configuration III

RMS

44.

C o n f i g u r a t i o n IV

RMS v .

45.

Configuration III

175

46.

C o n f i g u r a t i o n IV

17 5 KHz .

47.

48.

III

v.

v.

x

KHz .

and

x

v .

x

x

.

IV

.

.

........................................................65

.................................................

66

...................................................................67

signal

.........................

68

4

.

69

G rap h ic a l r e s u l t s showing C o n f ig u ra tio n I I I

h o t - f i l m t r a n s i t i o n a l p o i n t s ................................................

70

G r a p h i c a l r e s u l t s s h o w i n g C o n f i g u r a t i o n IV

h o t - f i l m t r a n s i t i o n a l p o i n t s ....................................................

70

signal

v. x

v.

x

.

.

.

49.

T h e o r e t i c a l v . e x p e r i m e n t a l mini mum v e l o c i t y

g r o w t h i n F S L o f C o n f i g u r a t i o n I I I .......................................... 73

50.

T h e o r e t i c a l v . e x p e r i m e n t a l FSL d e v e l o p m e n t

a t x ' = 0 o f C o n f i g u r a t i o n I I I ...............................................74

51.

T h e o r e t i c a l v . e x p e r i m e n t a l FSL d e v e l o p m e n t

a t x ' = 0 . 0 5 6 and x ' = 0 . 1 1 2 of C o n f i g u r a t i o n

I I I ......................................................................................................................... 7 5

52.

T h e o r e t i c a l v . e x p e r i m e n t a l mi ni mum v e l o c i t y

g r o w t h i n F S L o f C o n f i g u r a t i o n I V ...........................................76

53.

T h e o r e t i c a l v . e x p e r i m e n t a l FSL d e v e l o p m e n t

a t x '

= O a n d x '

= 0 . 0 5 9 ................................................................

54.

Experimental tr a n s itio n point for

C o n f i g u r a t i o n I I I ................................................................................. 84

77

x ii

LIST OF FIGURES— Continued

Page

55 .

56.

57 .

Experimental tr a n s itio n point

C o n f i g u r a t i o n IV

.............................

Frequency v . in te n s ity

accelerometer attached

for

85

s p e c t r a from

above the t e s t

N o n - d i m e n s io n a l graph showing

w a v e l e n g t h t o be p r o p o r t i o n a l

t h i c k n e s s ....................................................

section

.

.

87

.

89

t h e wave s t r u c t u r e

t o t h e FSL

Xiii

NOMENCLATURE

Symbol

D e s c r i p t i on

DSL

:

Dividing

f

:

Frequency

FSL

:

Free

stream

shear

h

FSL

M

Ma c h n u m b e r

line

layer

thickness

P

:

Mo me n t u m

P0

:

Stagnation

Ps

:

Static

r

:

Speed

Re

:

Reynolds

Re '

:

Unit

Re '

:

(R ef1 + R e ' 2 ) /2

SWT

:

Supersonic

T

:

Temperature

T0

=

Stagnation

T.E.

:

Trailing

U

:

Velocity

Us

:

Velocity

x

:

D i s ta n c e from the T.E.

(x p o s i t i v e downstream)

:

Sa me

:

Non-dimensional

x

*

x '

thickness

ratio

/©2

pressure

pressure

ratio

U2 / U J

Number

Reynolds

as

Number

Wind T u n n e l

,

Temperature

Edge

on

the

DSL

x

x

*

x iv

NOMENCLATURE— Continue d

Symbol

:

y

De s c r i p t i o n

Distance

normal

to

y

Compressible

y '

Non-dimensional

y

a

Deflected

of

5

Boundary

layer

6

Mo me n t u m

thickness

P

©i

P

Density

X

Non-dimensional

( U^ + U2 ) , a l s o

FSL

transformed

angle

y

FSL

thickness

at

at

T.E.

T»E.

+ e2

s p e e d r a t i o ( U^ ~ U2 ) /

w av elen g th in Appendix

(

)l

:

F a s t —s i d e

property

(

^2

:

Slow-side

property

(

>e

=

Free

stream

property

XV

ABSTRACT

A c l o s e d - f o r m a n a l y t i c a l t h e o r y has been d e ve lope d to

p r e d i c t the flow f i e l d of t w o - d i m e n s io n a l , l a m i n a r , nonequilibrium free shear layers,

shed from the t r a i l i n g edge

of a t h i n f l a t p l a t e s e r v i n g as a p a r t i t i o n s e p a r a t i n g two

dissim ilar parallel

flows.

A Mach 3 s u p e r s o n i c n o z z l e i n

c o m b i n a t i o n w i t h e i t h e r a Mach 1.6 or a Mach 2 s u p e r s o n i c

nozzle

were

used

to

produce

a free

shear

layer.

The

i n v e s t i g a t i o n was d e s i g n e d t o p r o v i d e e x p e r i m e n t a l e v i d e n c e

by w h ic h f r e e

shear layer theories

may b e c h e c k e d .

A

c o m p a r i s o n of t h e o r e t i c a l / e x p e r i m e n t a l mean f l o w p r o p e r t i e s

in th e l a m i n a r , n o n - e q u i l i b r i u m r e g i o n of th e f r e e s h e a r

la y e r were

made.

The t h e o r y

showed

good

agreem ent

q u alitativ ely ,

but poor

agreement

q u an titativ ely

when

compared to e x p e rim e n tal data.

The t h e o r e t i c a l l y a s s u m e d

in itia l

velocity

profile

showed

a 35 % d i f f e r e n c e

in

th ic k n e s s compared to the e x p e rim e n ta l th ic k n e s s.

The

theory p red icts

f r e e s h e a r l a y e r t h i c kn e s s and minimum

velocity

growth

rates

that

p arallel

the

experim ental

r e s u l t s , a l t h o u g h a q u a n t i t a t i v e e r r o r of b e t w e e n 2 0 -5 0 %

exists.

I

CHAPTER I

INTRODUCTION

An a n a l y t i c a l

{ 11 ^

to

theory

predict

the

non-equilibrium

tra ilin g

edge

separating

two

shear

(FSL)

by

layer

solid

I.

diagram

nozzle

applied

The

theory

region

Figure

and

also

of

I

a

combination

of

the

p ro files

of

the

two

p r o file

in

trough

depth

progressively

decreases

with

until

the

the

finally

equilibrium

^The

References

trough

as

is

the

coalesce

greatest

increasing

disappears

(self-sim ilar)

and

in

at

shown

in

of

a

5 and

6.

velocity

into

a single

region

the

the

distance

the

confined

diagram

Chapters

(T.E.),

decrease)

free

nomenclature

n o n -e q u ilibrium

(velocity

term

not

layer

in

the

non-equilibrium

general

detail

flows

The

is

the

from

a p a rtitio n

The

schem atic

edge

p arallel

trough

The

in

to

a

as

flow

shear

of

tra ilin g

a

profile.

free

shed

flows.

the

applies

the

two-dim ensional,

serving

q u alitativ e

F SL .

by

since

by D e m e t r i a d e s

layers,

p arallel

consists

the

identified

plate

described

Downstream

of

shear

flat

is

developed

field

free

d issim ilar

(n o n - s i m il a r )

Figure

a thin

walls.

been

flow

laminar,

of

has

is

velocity

T.E.

and

downstream

profile

becomes

profile.

symbol

{ } w i l l ’ denote

refe re n c e s

cited .

c i t e d are found fo llo w in g the a p p e n d ic e s.

2

GENERAL

TROUGH

FREE SHEAR

LAYER

" I * r 02

^T02

SLOW-SIDE

PARTITION

FAST-SIDE

pOl • mI

NON-EQUILIBRIUM

REGION

CONFIGURATION

TE.

IV

INITIAL

PROFILE

EQ U IL IB RIU M /SEL F-SIM IL A R

REGION

FSL

DEVELOPMENT

EQUILIBRIUM

PROFILE

NON-EQUILIBRIUM

PROFILE

\

x inchlcm)

Figure

I.

Nomenclature

l a y e r (FSL).

1.0(2.54)

and

2.0(5.08)

definitions

of

the

3 .0(7.62)

FSL

free

shear

3

Two-dimensional

injection

engines,

is

system s,

as

well

d e sira b le

addressing

shear

high

the

have

mentioned

in

shear

flows

power

half

closed-form

using

jets

optim ization

of

and

region

and

jet

It

so lu tio n s

of

the

free

interest

has

been

or n u m e ric a l

gas-dynamic

mass

wakes.

a n a ly tic

Particular

th eo retical

in

systems

non-equilibrium

abovei

appear

laser

classical

laminar,

shown

design

as

to

the

layers

recently

for

free

and

methods

chemical

laser

systems„

The

State

following

U niversity

provide

the

A

shear

in

layer

the

of

performed

Wind T u n n e l ,

evidence

comparison

properties

free

Supersonic

experim ental

validated.

flow

investigation,

by

be

was

the

Montana

designed

theories

can

theoretical/experim ental

lam inar,

will

which

at

made.

n o n - e q u i l ibrum

to

be

mean

region

of

4

CHAPTER 2

THEORETICAL REVIEW

Investigation

1879,

as

Lord

other

fluid

to

FSL

near-wake

initial

and

a

addressed,

lim ited

velocity

an

was

laminar

compressible

stream

of

Denison

case where

to

num erical

form

In

in

{6}

extended

the

= 0.

solution

Kubota

method

m ixing

Denison

with

velocity

in

for

layer

and Baum's

the

and

Dewey

{7}

the

constant

with

a

fin ite

mean

{3}

a

assumed

Blasius

profile

a

{4},

the

{5}

flow

in

far

proposed

zero

a

boundary

of

an

air

model.

analysis

to

thickness

at the

are

layer

developed

in itia l

flow

incompressible

results

pressure,

and

solved

n e a r —w a k e

shear

as

numerically

profiles

Chapman's

of

jets

Tollm ien

Chapman

tem perature

in

Goldstein

be

(starting

the

the

predicting

1950

theory

for

to

x

early

were

equations

problem.

at

as

Goldstein

profiles

predict

separation.

equation.

free

time

1930

the boundary la y e r had a f i n i t e

of

integral

to

Baum

point

a

that

noted

plate.

arb itrary

and

until

distribution

a

thickness)

not

U2 = 0)

began

instabilities

differential

asym ptotic

flat

layers

noted

velocity

behind

layer

At

flow

sin g u larity

used

{2}

shear

but

(h alf-jet,

the

1931

Rayleigh

governing

compute

free

m otions,

properties

the

of

a

the

lim ited

momentum

momentum-

two-dimensional,

thickness.

Two

5

d ifferent

expressions

above

one

I),

a

and

therefore

single

below

the

theory

by D e m e t r i a d e s

without

{I },

the

boundary

parallel

velocity

dealt

{1},

with

theory

of

the

were

and

streams.

The

shear

not

layer,

(DSL,

one

Figure

represented

by

is

( G^

on

/

imposed

are

constant,

that

and

the

that

reacting.

Prandt I

theory

the

The

(0

that

the

fluid

flow

Number

two

As

linear

p r o file

detailed

flow

by

profile

exponential.

fields

two

merging

jo in in g

velocity

The

the

at

to

have

little

provides

an

analytical

two

the

shape

said

entire

the

the

62’

com pressibility

profiles.

solution

T .E .

of

the

affect

at

distance).

including

re stric tio n s

symmetry

initial

proposed

analytical

generated

FSL

profiles

to

investigation,

flow

flow

be

Dem e t r i a d e s '

I,

the

to

(downstream

closed-form

in

the

assumed

large

this

a closed-form

wake

velocity

x

in

superposes

lay ers

arbitrarily

Figure

the

stream line

profiles

gives

initial

in

for

dividing

discontinuities

consisting

is

the

used

expression.

The

in

were

of

/

<

of

I^),

M

<

x

heat

00

).

the

pressure

flow

is

is

must

I.

flow

equilibrium

range

^i

lam inar

A

transfer

is

be

Tq2 ) or

everywhere

two-dim ensional,

homogeneous

com puter

no

restric tio n s

assumed

laminar,

are

in

distance),

(Tq^ /

only

and

shown

There

(downstream

p arallel

also

field

region.

The

chem ically

expression

steady

code,

and

and

non­

have

prepared

a

by

6

Demetiriade s

y, with

{I } ,

inputs

provides

of

P =

The

non-dim ensional

the

physical

Reynolds

mean

flow

/ D2 » r = ^ 2 ^

downstream

downstream

Number

distributions

distance

distance

and

the

^Ol ^

x,

square

of

x and

an^ x'•

02

x ' is

divided

in

defined

by

the

both

as

average

momentum

thickne sses.

x ' = x * /p^Re'

where

P = ©^

distance.

the

fast

just

The

and

of

cases

r

= O and

= O (base

flow,

#

is

the

the

the

tra ilin g

edge.

and

total

and

is

of

the

present

r = I

are

shown

near-wake)

and

the

momentum-integral

TJ s

The

( TJ s

defined

= TJ/ Uj )

p resen t

agreem ent

solution.

compares

Kuriki

on

the

from

compared

the

{10}

r

= I

theory

using

to

(wake)

with

Figure

for

of

and

also

case.

Figure

experimental

{11}

and

Number.

The

from

a n d Ba u m

and

Dewey,

uses

a

{5} .

shows

(taken

r

{1}),

Chapman

Ti g ,

points

also

3.

theory

Baum's

3

lim iting

Denison

Kubota

Chapm an’s

and

Mach

the

from

free

Tq ^ and

2 (taken

of

I,

U^,

2 and

Dem etriades'

Denison

and D e m e tr ia d e s

are

of

Figure

adjacent

Figures

method

{8}

in

fast-side

solution

DSL.

M ills

theory,

The

(exact)

thicknesses

The

theory

in

case.

numerical

= O is

the

downstream

shown

tem peratures

the

y'

momentum

layers,

presents

also

dim ensional

boundary

respectfully,

Comparisons

2

©2 a r e

slow-side

v elo cities

T ^

an^

6 ^ and

upstream

stream

©2 ,

+ ©2

good

num erical

from

taken

by

{9}),

Sato—

G oldstein's

{12

I

SYMBOL

METHOD

SOURCE

------------ NUMERICAL DENNISON - BAUM

.................

MOMENTUM DEWEY-KUBOTA

INTEGRAL

(QUADRATIC)

T

T

T

T

PRESENT THEORY [l]

-GOLDSTEIN (INCOMPRESSIBLE) -

ALL M 1

r «0

0 6 9 2 (MILLS)

O 5 9 (CHAPMAN)__ T

PRESENT

THEORY

Ue-U(O)

: MILLS u , - I CHAPMAN u ,

.1 -

O

Figure

2.

FSL d e v e l o p m e n t

and r = O.

at

y '

= O

Figure

• SATO-KURIKI, M=O

O DEMETRIADES' SERIES 100, M*4

ADEMETRIADES' SERIES 200, M=4

— I------- 1--------- 1_____ I_____ I_____L_

.2

4

.6

.8

I

1.2

x'

3.

FSL d e v e l o p m e n t a t

and r = I , 6 = 0 .

y'

= O

8

and

13}

shown

incompressible

in

Figures

Aside

l i t t l e

from

or

no

3

theory

as

such

follow ing

two

to

cases

the

of

ratio

A brief

at

need

r

this

time

of

shows

p ro files

in

r

= I

late ra l

compressible

r

y '

layers

are

shear

to

validate

Dem etriades.

to

verify

ratio

~ I.

Dem etriades

be

the

—

)

case

ratio

divided

by

and

is

both

theory

momentum

is

in

by way of

of

the

also

two

velocity

in

plotted

distance

the

a

The

predicts

accom plished

development

Th e U/

(y),

the

temperature

what

=

of

shown

by

cases,

properties

the

non-dim ensional

y

theory

and/or

w ith

( D^

the

so lu tio n s

.9

and w i l l

4

to

lim iting

free

attem pt

and

the

( U2 = . 5 U^ ) c a s e .

of

therefore

w ill

Figure

the

flow

region

.8

example

mean

presented

graphs.

(the

a c c e ssib le

one

P and

agreement

aforem entioned

is

=

The

evident.

the

experiments

thickness

.5

is

n o n -e q u ilibrium

The

order

the

data

available.

using

2 and

re a d ily

experim ental

lam inar,

theory.

the

against

defined

as

r

=

y'

the

momentum

thicknesses),

also

FSL

= y / ( 0 1 + @2 )

f

y =

p/pg

dy

0

Figure

5

velocity

r

= .5

shows

growth

and

r

the

at

r

y'

=

0

case

and

= 0 progressing

= 0 cases.

the

downstream

minimum

for

r

= I,

9

t • .9 9

Figure

4.

Theoretical

F SL d e v e l o p m e n t

at

r

I

and

r

10

Figure

5.

T h e o r e t i c a l FSL d e v e l o p m e n t

v e l o c i t y gr o wt h at y ' = 0.

at

r

= 0 and

mi ni mum

11

CHAPTER 3

EXPERIMENTAL APPROACH

The

code,

the

latter

developed

flow

field

equilibrium

necessary

The

Wind

at

local

various

mean

stream

the

FSL

the

such

in

campus

fully

layer

describes

its

non­

provide

this

a

Mach

of

code

the

and

( i .e * U/U^)

the

State

profiles

momentum

through

the

T.E.

as

well

the

provided

as

free

M ^ , Re ' ^ > R e ' 2 > U ^ a n d

Finally,

a

Supersonic

layer

traverses

of

3

M ontana

supplied

furnished

and

into

computer

in

w ill

Boundary

as

a

validity.

downstream

properties

curves

which

shear

V ertical

region.

references

inputs

edge

©2 ) •

measurements

th e o r e tic a l

as

Montana.

properties

laminar

pre sented

on

x stations

flow

flow

Transition

and

free

conducted

tr a ilin g

(0^

{1}

experimental

were

lo cated

2

investigation

needed

their

the

thicknesses

the

of

This

Bozeman,

at

Chapter

a lam inar

experiments

U niversity,

taken

of

parameters

Tunnel

of

by D e m e t r i a d e s

region.

justification

FSL

portion

evidence

graphical

of

the

U2 •

lim its

of

comparisons

of

experim ental

p o in ts

are

12

CHAPTER 4

EXPERIMENTAL APPARATUS AND PROCEDURE

W ind T n n n e l

The

Montana

(MSU/ SWT)

as

continuous

The

seen

is

Numbers

o

14 5 F

o

(605

control

The

of

high

336

with

are

about

18

x

(46

optical-quality

th ro a t

to

description

of

+1

a

8.13

from

can

be

pressures

abs.

at

up

and

to

and

+1

autom atically

cross

cm.)

o

F

from

sectional

and

a

upstream

A

found

of

of

made

of

the

more

in

area

length

sid e w alls

en tran ce.

( MS U/ S WT)

hours

area.

Rem ovable

stretch

several

fluid.

tem peratures

or

has

Tunnel

circu it,

working

mm E g .

test

section

d iffu s e r

the

for

Wind

open

stagnation

at

x

an

the

supply

the

(7.87

is

as

manually

in

cm.).

glass

the

and

points

test

in.

air

Supply

located

3.2

in.

4

K).

7

operating

controlled

console

in.

as

Supersonic

6 and

using

of

set

rectangular

3.1

Figures

tunnel

as

R or

respectively,

U niversity's

capable

tem peratures,

a

in

flow,

MSU/ SWT

Mach

State

nozzle

d e ta ile d

{14}.

P L t ojt P r o b iC

The

mean

used,

p ito t

flow

one

probe

was

m easurem ents.

for

the

the

principal

Two d i f f e r e n t

tra ilin g

edge

instrum ent

pitot

boundary

in

probes

layer

the

were

profiles

13

EXHAUST

S IL E N CE R

PUMPS

MOTOR

MOTOR CONTROL

y -----DESSICANT BED

Z

/ ----- DRYER

_.

Z / — T H R O T T L E VALVE

Z -A IR

BELLOWS

\

T E S T AREA

INLET

/

/

STILLING TANK

SUBSONIC D I F F U S E R - Z

CONTROL CONSOLE

T E S T SECTION

Figure

6.

(shown

as

shear

Diagram

of

components .

probe

layer

no.

were

diam eter

0.004

of

to

0.003

measurements

o u tside

and

(spanw ise)

rationale

response

(probe

(0.01

(0.008

taken

of

time

using

of

two

a 0.003

cm.)

0.005

probe

for

with

at

in.

the

probes

would

be

(B.L.)

outside

layer

cm.)

an

a

(FSL)

initial

which

to

(0.013

free

chem ically

with

tip

the

an

was

probe

major

layer

shear

(0.02

d ifferen t

in.

probe

Free

in.

etched

other

which

a pitot

0.008

showing

Boundary

a pitot

with

of

the

2).

cm.).

chem ically

tunnel

8),

no.

in.

dim ension

for

Figure

with

in.

were

wind

taken

diam eter

flattened

in

p ro files

measurements

etched

I

the

was

lateral

cm.).

The

was

that

the

too

slow

and

Figure

7.

Photograph

of

modified

wind

tunnel.

15

PITOT

PROBE

NO. I

.57

Figure

8.

Pitot

and

static

probe

schematic.

16

not

appropriate

p ro files.

The

response

time

resolution

This

in

is

In

profile

p ito t

0.04

c m. )

where

the

was

less

than

200.

the

actual

to

account

The

larger

into

for

p ito t

for

an

to

by

immersed

the

outside

15.7

v o lts

dynam ically

converter.

is

in

discussed

a

Number

low

the

reading

low

data

were

tubes

and

the

of

Model

flow

the

before

the

latter

100

part

to

and

data

of

this

a

the

< y

<

diameter

of

this

overestimate

curve

into

{16}

was

program

progressively

a

bullet-shaped

transducer

The

tim es

an

(Kulite

transducer

leads

transducer

connected

Th e A/D c o n v e r t e r

in

The

in

to

(0

flows

to

{15 }

affect.

electrical

a m p lified

being

wall

X T E-1-190-5A ).

and h a d

made

computer

to

pressure

tunnel.

d. c.,

reduction

attached

= 30}.

used

on p r o b e

known

Number

lateral

observed.

was

Number

telescoped

encapsulated

C o rp .,

was

A correction

Reynolds

probes

were

the

based

is

the

Demetriades

sizes

to

Reynolds

B .L .

dia.)

to

FSL

reduced

(probe

correction

close

the

a

0.005

probe

up

afforded

interference

readings

reading.

the

Semi-conductor

was

{16},

pressure

diam eter

housing

with

Reynolds

p ito t

incorporated

p ito t

probe

In

and

/

making

probe

according

and

pressure

pitot

half

width)

varying

accordance

the

than

(FSL

points

flattened

adequate

B .L .

type,

data

in.

more

{0.15

where

flow

many

0.005

by

of

the

considered

a study

single

for

was

and

extending

energized

damped

analog/digital

collecting

Chapter.

process

17

S ch lleren

O ^ tleal

An 8 - i n c h

the

quality

such

as

of

System

portable

Schlieren

the

and

flow

transition

continuous

strobe,

to

investigation.

in h eren t

detailed

bulb,

viewing

shear

flow s,

exposures,

light

other

showing

using

of

Schlieren

the

the

flow

one

speed

13

a

spark

throughout

the

differences

continuous

Figures

verify

sources,

density

in

to

of

a high

the

appear

explanation

used

details

Two

the

was

cap ab ilities

Photographs

to

photograph

photograph

turbulence.

illum ination

provided

System

and

and

spark

15.

System

is

A more

given

in

{14} .

Static

Pressure

Static

in.

its

cm.)

0 .0 1 5

the

hole

of

as

that

For

shown

of

the

in

shown

0.10

was

the

less

probe

in

pitot

(0.254

9.

probe.

0.35

tip.

cm.)

in.

this

region,

from

Signal

with

around

of

one

(0,89

cm.)

This

in.

a 0.02

8,

d rilled

0.35

interpolated

Figure

with

Figure

holes

in.

than

taken

in

d rille d

profiles

were

were

diam eter

w ith in

edge

edge.

values

downstream

as

f ir s t

tube,

cm.)

m easurements

trailing

pressure

same

(0.038

leading

prohibited

the

in.

The

measurements

diam eter

circum feren ce

another.

from

pressure

(0.051

three

Probe

distance

downstream

the

known

recording

of

static

values

was

the

18

I

Ps (mm hg)

I

~T~

CONFIGURATION

Jil

IV

EXPERIMENTAL

I

I

ESTIMATES

(INTERPOLATED)

A

O

0

SL

-

A

Z

Z

^

3L

%

T

|

I

Figure

T olal

9.

I

3

(x)

S t a t i c p r e s s u r e v. downstream d i s t a n c e p l o t

used

to

interpolate

unknown p r e s s u r e

values

clo se to the T.E.

Temper i i u r£

The

total

thermocouple

connected

tunnel.

I

2

in.

4 cm.

6

DOWNSTREAM DISTANCE

2

I

to

The

includes

originally

a

PffihA

tem perature

bead,

0.005

a d ig ital

data

in.

consisted

(0.013

tem perature

reduction

tem perature

documented

probe

in

v.

in

indicator

program,

Reynolds

(17).

cm.)

of

shown

in

Number

a

type

K

diam eter,

outside

Appendix

the

E,

calibration

19

H o t - F J liI m AniCmomiCtiiCiT

A hot-film

anemometer

indications

of

provided

means

to

in

flow

a

fluctuations

its

tip.

0.002

The

in.

deposited

of

0.02

probe

was

1213

x

the

in.

in.

to

amplifier

for

measurements

and

500

limit,

and

since

300

Zrobe,

KHz .

KHz ,

of

of

x

edge

of

500

a range

heat

transfer

0.05

in

cm.)

dimension

glass

a Transmetrics

used

The

frequency

setting

in

in

was

was

{18}

or

The

a n ADP

with

window

used

between

3 Hz

as

range

and

tip

rod.

series

used

to

ground

6401

and

experiment

seen

from

approximately

signals.tended

also

away

platinum,

Kimax

this

film

temperatu re / veIocity

diameter

KHz

turbulence

The

wedge

combinations.

The

qualitative

double

circuit

in

give

a

either

heating

various

all

way

to

turbulence.

the

(0.005

cm. )

connected

hot-wire

by

leading

(0.05

to

measure

consisted

0.02

the

used

tran sitio n

film

on

a

the

was

an

upper

between

50

{19}.

P o s i t i o n i ng

All

probes

immersed

electromechanical

section

in

Figure

ceiling

of

the

hollow

shaft

leads.

The

v e rtica lly

horizontal

7.

Four

struts,

the

system

was

were

system,

horizontally

positioning

flow

provided

supported

actuating

and

the

actuating

tunnel,

that

in

seen

above

extending

vertical

probe,

the

same

mechanically

the

positioning

the

by an

test

through

transducer

enabled

in

positioned

probes

plane.

adjusted,

the

of

a

and

wire

to

move

While

vertical

20

positioning

is

was

explained

fully

as

automated.

follows,

taken

The

from

vertical

{1}

positioning

(Section

6.3.6).

For t he mean f l o w m e a s u r e m e n t s t he d a t a wer e

o b t a i n e d i n t h e f o r m of p r o f i l e s , i . e . t r a v e r s e s

a l o n g y a t c o n s t a n t x.

T h e SWT e l e c t r o m e c h a n i c a l

a c t u a t o r s y s t e m a l l o w e d t h i s t r a v e r s e t o be done

fully

autom atically.

The v e r t i c a l

motion

is

geared

to

a flywheel

with

adjustable

spoke s

p r o tr u d in g from i t s p e ri p h e ry which p e r i o d i c a l l y

i n t e r r u p t a p h o t o d e t e c t o r beam, ea ch i n t e r r u p t i o n

t r a n s m i t t i n g a n e l e c t r i c r e a d c o m m a n d t o t h e SWT

Data System.

Ey a d j u s t i n g t h e a n g u l a r s e p a r a t i o n

o f t h e s p o k e s a r o u n d t h e f l y w h e e l , a r e a d c omma nd

a t each of t he v e r t i c a l s t e p s m e n t i o n e d above is

obtained.

In a d d i t i o n , and to e n s u r e a d e q u a t e

response

time

for

the

sensor,

the

system

a u to m a tic a lly produces a pause between sensor

arrival

a t a hew v e r t i c a l

point

and the r e a d

c ommand a t t h a t p o i n t ,

the pause being t y p i c a l l y

15 s e c o n d s i n l e n g t h .

The

use

of

pitot,

provided

all

the

mean

theory.

In

taking

positioned

=

0)

and

reading

other

within

probes

to

this.

I)

and

flow

FSL

downstream

This

positive

until

temperature

needed

the

the

the

taken

negative

y

at

to

pitot

the

probe

was

total

y

in

probes

verify

trailing

became

electronically

were

to

of

position

positioned

FSL p r o f i l e s

from

total

properties

v e rtic a lly

minimized.

were

and

measurements,

7 mils

adjusted

was

static

edge

(x

pressure

= 0

and

all

relationship

increasing

x (Figure

always.

DjsLtjL C o l l e c t i o n

The

relayed

leads

signals

of

the

electro n ically

outside

the

by

pitot

way

tunnel

and

of

to

static

probes

the

transducer

an

a m p lifie r.

and

were

its

Upon

21

a m p l i f i c a t i o n ,

the

s ig n a l

was

resistance/capacitance

( E C)

unsteadiness,

analog

(Spectral

was

in

then

Dynamics

counts

Recording

S ile n t

to

700

available),

Corp.

and

was

AS R

circu it

Mo d e l

to

to

digital

SD-133).

( A/ D)

The

d ig itally

displayed

on

cassettes

via

computer

5-inch

disks

via

of

the

transducer

before

and

after

converter

and

output

recorded.

Instruments

(hard

an

a

signal

latters

a Texas

term in a l

on

th ro u g h

dampen

was

done

and

an

p a sse d

copy

Intertek

also

Superbrain

microcomputer.

The

signal

frequently,

using

a linear

corresponded

regression

to

pressure

P( mm E g )

where

A and B were

y-intercept

were

an

of

input

into

Appendices

D and

collection

approach

Data

replaced

The

E.

by

h o t-film

magnetic

tape

by

a latter

time

for

in

the

following

A being

the

reduction

shown

the

Type

diagram

in

the

sig n als

a H o n e y w e l l .7600

analysis.

The

constants

the

given

in

above

data

probe

was

arrangement

was

10.

temperature

Digital

were

count

and B the

programs

transducer

2809

Each

slope

showing

Figure

total

measurements,

+ B

the

is

of

calibrated

wa y:

calibration.

data

was

routine.

pressure

only

a n Ome g a

series

= A * (counts)

by

stored,

counts

calculator

A block

acquired

sim ilarly

each

constants,

the

in

Thermometer.

recorded

Recorder

on

and

0.5-inch

replayed

at

POWER

SUPPLY

SENSING

PROBE

PITOT/STATIC

POWER

SUPPLY

_____________ I __________

Y-ACTUATOR

POSITIONING

TRANSDUCER

A

AMPLIFIER

PHOTO

DETECTOR/

FLYW HEEL

DAMPER

A /D

CONVERTER

'

ELECTRONIC

TIM ER

Figure

10.

Data

STORAGE*

5-IN C H DISC

collection

block-diagram.

STORAGE=

CASSETTE/

HARD COPY

23

CHAPTER 5

EXPERIMENTAL DESIGN

TunnjiJL M o d j . f ^ c . a J : . i o n

In

the

dimensional

The

M S U / S WT

DeLaval

present

parallel

joining

therefore,

s o me

(10.2

channel,

tunnel's

the

and

11),

tunnel

a

4

for

in.

gate

Figure

and

of

11

creating

a

ceiling

this

forming

its

principal

referred

axis,

to

subscripted

The

3 nozzle

as

air

on

a flat

forming

with

its

s l o w —s i d e

a

Ma c h

3

was

The

in

the

upper

top

of

ceiling.

channel

and

(FSL),

7

manually

Figure

to

is

its

wind

machined

3

11.

channel

consisted

s p litte r

It

in.

(Figures

Ma c h

parallel

two

stagnation

channel

the

flow.

the

controlled

The

plate,

of

throat

shown

3

A 4

a hole

stream.

two-

layer

top

at

a

for

required.

splitting

the

called

the

as

Ma c h

shear

was

at

stream

nozzles.

and

the

air

positioned

surface

floor

a free

the

a plate

half

uniform

terminating

above

second

shows

contoured

and

second

valve,

two

form

modification

tank

a

a

mode,

investigation

originating

provided

pressure

op eratin g

provides

to

tunnel

stagnation

into

by

Nozzle

experimental

flows

cm. )

normal

the

plate

S WT ’ s

hereafter

properties

are

"2" .

lower

channel

block

for

its

consisted

floor

and

of

half

the

the

flat

original

s p litte r

Ma c h

plate

4

4

GATE

VALVE

DIA.

O 2 4 6 8 IO

SECONDARY

AIR

INCH

SPLITTER

PLATE"^

STAGNATION

UPPER

(SLOW-SIDE)

NOZZLE

TANK

PRIMARY

AIR

Figure

11.

Schematic of tunnel modification.

LOWERz

(FAST-SIDE)

NOZZLE

25

for

its

c e ilin g .

properties

(spanwise)

edge

are

line

(T .E.) of

Four

called

These

The

subscripted

at

which

the

fast/slow -side

nozzle

and

flow

a

two

,

"I"

flows

(or

.

The

join

is

f a s t-s id e )

horizontal

the

trailing

plate.

nozzle

combinations

their

channel

by

the

s p litte r

"Configurations"

sections

lov/er.

were

combinations,

used

are

in

this

described

parameters

are

in

hereafter

investigation.

the

following

summarized

in

Table

I .

TABLE

I.

NOZZLE

I

CONFIGURATIONS.

II

M1 d e s i g n

3

3

actual

3

3

3

3

Nozzle I co n to u r 3

contour3

design

1.56

1.6

1.47

Mj a c t u a l

Nozzle 2

straight

contour

X1 , i n ( c m ) 1 0 . 4 ( 2 6 . 4 ) 1 0 ( 2 5 . 4 )

Xj , i n ( c m ) 4 . 2 ( 1 0 . 5 ) 3 . 7 ( 9 . 4 )

1.

2.

3.

4.

IIa

2.7

contour3

1.6

1.74

contour

5(12.7)

3.7(9.4)

III

IV

2.7

2.7

2.65

2.8

contour3

contour3

2.25

1.6

2.15

1.67

contour3

contour3

6.$5(16.9) 6.71(17)

4.8(12.2)

3 .76(9,5)

Conventional v e rtic a l mill

C o n v e n t i o n a l v e r t i c a l m i l l , m o d i f i e d by hand sanding

Numerically controlled mill

D i s t a n c e measur ed downstream from noz zl e t h r o a t

26

C o n f j.£ura..t_ion. %

Configuration

shake-down

model

slow-side

1.5

with

The

the

overall

were

to

f a s t —s i d e

the

design

tunnel

flow

problems

attributed

to

the

Configu r a t ion

ch aracteristics

aiding

code

the

A conventional

flow

II

12)

Mg -

achieved

tap

a flow

were

design

at

as

already

and

readings

observations

associated

nozzle

give

measurements

pressure

above

to

was

a

(straight)

nozzle

quantitative

consisted

give

Mg

was

used

as

that

of

Mach

1.5

of

the

deflection

with

the

thought

that

FSL.

to

be

time.

1.5

mill

by.

slow-side

flow.

method

in

the

the

used

The

{20}

to

Configuration,

code.

nozzle

Although

the

13.

a

nozzles.

the

quality

seen in the

Figure

of

coordinates

machine

achieved,

as c a n b e

develop

contoured

computer

was

to

nozzle

subsequent

was

flow

a contoured

outlined

and

acceptable

this

=

of

provided

this

generated

of

3

flow

and

was

combination,

Mach

problems

to

{21}

was n o t

photograph

this

Schlieren

Figure

vertical

approximately

the

flow.

straight

design

coordinates

in

7,

II

designed

computer

designed

static

mentioned

Configuration

nozzle

ratio

No

in Figure

non-contoured

the

ceiling

in

seen

Supersonic

choking

(defined

a

was

checked^

from

a

nozzle

tunnel.

supersonic

noted

of

area

ones,

was

aside

confirm

angle

The

in

made

flow

havi ng, an

following

installed

c a n be

consisting

nozzle

flow.

I , which

of

Schlieren

Small

shock

/

/

EXPANSION

FAN

/

/

Re e 2

/

/

/

pO 2

DEFLECTED

FREE

SHEAR

LAYER

PARTITION

M l l Re

SHOCK

WAVE

Figure

12.

Nomenclature

for deflected F S L .

S)

-J

Figure

13.

Schlieren

photograph

of

Configurations

II

and

IIa.

29

waves

emanating

form

a

well

ceiling

cut

downstream

of

the

of

and

F SL .

The

throughout

bottom

to

the

nozzle

assure

I

a laminar

B. L.

would

(i.e.

Using

as

^Q^/P^)

shock

a

stated

from

c m. )

by

nozzle

problems

also

which

( a = 0)

id e n tif ie d

be

a

Configuration

at

T.E.

bottom

in the

in

l im it a ti o n

5 in.

the

up s t r e a m

mismatched

downstream

the

must

was

in

exist

waves

arrived

are

r a t ^c

slow-side

nozzle

was

as

a

it

a

This

Controled

on

11 a ,

the

(12.7

c m. )

channel.

by

Mill,

wind

Figure

that

tunnel

a

6).

** q I ^

I

ratio

before

diffuser

{23}.

M2 = 2 . 2 5

a Bridgeport

in

I>o 2 /f^ I

pressure

condition,

time

ratio

in

thought

the

theoretical

the

driving

supersonic

minimum

after

shown

was

swallowed

chosen.

Numerically

as

A minimum

in

at

dependence

{22},

flow.

I>0 2 ^ 1

Special

milled

moved

pressure,

the

II

c m. )

respective

to

tunnel

(1.9

a horizontal

seen

In

tunnel

inlet

dominate

normal

III

showed

pump

Originally,

achieve

be

(20.3

choking

was

in.

was

the

the

to

III

calculations

the

w ill

was

Configuration

(Pj»

to

off

created

along

experiment.

block

Confie u ra t ion

loads

problem

and

in.

coalesced

0.75

nozzle

8

exhibited

able

choking

C o n fig u ratio n

almost

distributions

being

about

the

under

surface

reflected

FSL

Since

tunnel

in not

The

T.E.

nozzle

that

the

deflected

pressure

resulted

shock

through

the

it

channels.

upper

cantilevered

T .E .,

static

the

defined

and

aluminum

from

Series

conjunction

with

30

a CNC B a n d i t

nozzle.

Table

2

shown

in

measured

cm. )

and

11

Micro-computer,

The

slow-side

and

a

photograph

Figure

4.82

the

nozzle

in.

14.

From

(12.2

tra ilin g

used

coordinates

of

this

nozzle

cm.),

edge

were

the

used

nozzle

throat

width

thickness

to

was

s hown

trailin g

3 .1 0

0.015

cm.).

Figure 14.

are

the

combination

to

was

contour

Photograph of Configuration III.

in.

in.

in

is

edge

(7.87

(0.038

31

Tunne I

choking

configuration

Schlieren

plate

for

and

the

at

no

of

flow

velocity

Confi g u r a t ion

that

the

used

In

as

shown

pieces

mentioned

T.E.

was

butted

in

th is

shown

was

this

added

support

II.

observed.

nozzle

I % (Figure

in

sp litte r

Configuration

was

the

of

The

combination

19).

3.71

c m. ) .

The

a FSL

(Numeric-Control) Mill

was

m illin g

nozzle,

of

the

of

steel

use

from

of

(9.4

c m. ) .

the

deflection

2.

flow

From

(a),

width,

of

made

fashion

was

the

a ffe c t

II.

Figure

nozzle

choking

the

prevented

thickness

angle

was

Configuration

in

the

and

c a n tile v e r

The

T.E.

steel

streamwise

provided

in.

of

the

for

latter

The

in Table

problem

for

a

is

II,

aluminum

machinability

are

and

versus

in

nozzle

cm. )

used

Configuration

v e r t i c a l

description

this

of

together

nozzle

the

(7.87

and

noted

the

of

in.

however,

the

16.

measured

(0.038

of

machine

coordinates

3.1

provided

t h e , N.C.

Figure

in

photograph

as

increased

throat

a redesign

steel

and

to

and

in

d e fle c tio n

nozzle

1018

view

needed

two

The

from

w ith

obtained

deflection

conventional

contouring.

in

15.

within

IV was

material

versus

accuracy

se v ere

IV

h o t —r o l l e d

nozzle

plate

emerging

Configuration

in

affect

uniformity

as

a ~ 0 was

nozzle

splitter

the

not

Figure

the

cantilever

Therefore

shows

a FSL o f

photography

thickness

quality

was

17,

throat

as

A

and

to

before,

was

0.015

not

corrected

about

10

in.

degrees

33

FLOW

Figure

Figure

16.

17.

C o n f i g u r a t i o n IV s I o w - s i d e d e s i g n .

Two

p i e c e s ' b u t t e d ' t o g e t h e r t o form n o z z l e .

Photograph of Configuration IV.

34

TABLE

2 .

NOZZLE COORDINATES.

MACB = 1 . 6

(Configurations II,

IIa ,

I V)

MACH = 2 . 2 5

(Configuration III)

X(inch)

Y( i n c h )

X( i n c h )

Y( i n c h )

0.0000

0.6805

0.8880

1.0546

1.1526

1.2547

1.4253

1.5865

1.6775

1.8853

2.0942

2.4740

2.8414

3.2729

3 .7 1 1 7

0.3500

0.2571

0.2298

0.2081

0.1954

0.1822

0.1607

0 .1 4 1 1

0.1303

0.1069

0.0852

0.0512

0.0263

0.0076

0.0000

0.0000

0.5222

0.6402

0.7571

0.8269

0.9019

0.9769

1 .1 0 1 8

1.1687

1.3457

1.6859

2.2734

3.0805

4.8184

5.3578

0.8786

0.7239

0.6889

0.6544

0.6339

0.6120

0.5902

0.5543

0.5354

0.4867

0.3991

0.2703

0.1392

0.0068

0.0000

35

was

present*

A deflected

well

defined

the

T.E.

shock

to

respectively,

Configuration,

provided

stated

for

an

in

the

assumption

just

As

shown

The

in

the

theory

in

of

is

exit

Figure

{23}

in

the

plane

the

after

plot

that

the

of

velocity

the