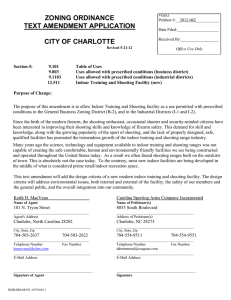

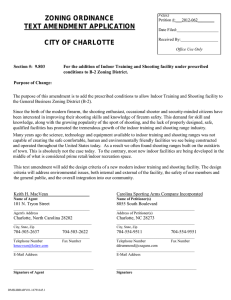

Workshop on Indoor Shooting Ranges: Responsible Care of Range Environment

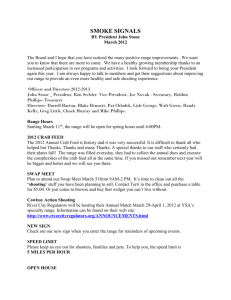

advertisement