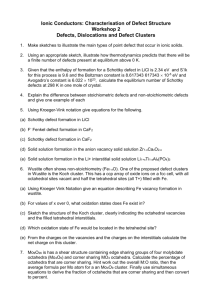

Information Systems and Cross-Enterprise Learning in Support of New Product Introduction

advertisement

Information Systems and Cross-Enterprise Learning

in Support of New Product Introduction

Enterprise Needs and Information Systems Based

Decision Management

Professor Ram Akella

Product and

Process

Development

Customer

Information Systems and Technology Management

University of California at Santa Cruz

Talk Outline

• A framework for solving ISTM problems

• Computer Based Process Learning and Information Systems

–Yield Management Systems

Sales and

Marketing

MIS Research Center

Carlson School of Management

University of Minnesota

February 20, 2004

• Incorporating Learning Into New Product Introduction through

competitive use of Information Systems

–An ontological framework (ongoing research)

• Enterprise Management and ISTM

IT

–B2B Exchanges: E-Business and Supply Chain Management

–IT Management, Outsourcing and Real Options

–Product Portfolios in High Tech and Food

Finance and Investment

E-Business and Supply

Chain Management

Outline of Talk: ISTM Framework

IS-based

Process Learning

Technology

Management

Information

Systems

Completed

Partially

completed

TBD

Partially

completed

Partially

completed

In progress

Complete,

in-progress

TBD

TBD

Integration

• Business Problem

– Business Need

– Technology Context

IT -based Product Process

Reengineering

An Ontology Framework

Enterprise management

B2B: E-Biz/SCM

IT Management, Outsourcing,

Product Portfolios, Real

Options

2

Computer-based Process Reengineering

Yield Management Systems

New product

introduction with

learning

1

• Technology Management

– Data to Information

– Information to Knowledge Management

• Information Systems

• Integration

3

5

1

IT-based Product Process Reengineering:

Business Need

Computer-based Process Reengineering

In-line Monitoring for Semiconductor ProductProcess Learning and Manufacturing

Isolation

• Need at KLA: Grow market and revenues

–Opportunity: Koreans claim that KLA in-line inspection

machines help dominate Japanese

–Need: Lack an internal understanding of

• Methodology: For rapid product and process learning

– How to use inspection machines to improve yield

per machine

• Economics: Of process and monitoring tools

– How many machines are worth buying to further

improve yield

• Information Systems: Not yet seen as a major need!

• Required to persuade customers, to sell more

machines

–Company size: $200M

• Business Problem

– Business Need

– Technology Context

Depo

Poly 1

Poly2

Metal 1

Metal 2

Off-line

Review

Etch

KLA KLA

Þ

Þ

2110

2110

or

In-line

ADC

Photo

• Technology Management

– Data to Information

– Information to Knowledge Management

Wafer

Probe

Wafer processing

Inspection

Classification

10 days

• Information Systems

• University Mission: Move area from “Black Art” to

30 days

Yield

• Integration

“Science”

6

7

Technology Implications for Speed and Accuracy of

Excursion Detection:

Review Methodologies and Images

Inspection: Defects on Wafers- Surrogates for

Yield in Monitoring

8

Excursion Detection of Killer Defects in the

Presence of Non-killers

Random defects

Equipment defect X

Process defect Y

Wafer Map

Image from

optical

Image from SEM

Defect trend chart at Poly in Fab A

1.4

Normalized defect D

1.2

Multiple defect types

• Killer defects – Kill die

• Non-killer defects – Do

not kill die

• Smaller pixel size ? finer

resolution, increased scan time

• Larger pixel size ? lower

resolution, faster scan time

9

0.6

0.4

0.2

0

Non-killers can “mask”

killer defects

Trade-offs

1

0.8

1

21

41

61

81

101

121

141

161

181

201

Wafer sequence

10

Excursions of killer defects(in red) can be masked on the SPC

chart of random defects by the non-killer defects (in green) 11

2

Sampling Strategy for Wafer Inspection and Defect

Review : Minimize Excursion Detection Time

Where?

% lots?

Wafers

per lot?

Computer-based Process Reengineering

Defects

Defect

to review? classification

Challenge

Poly

Poly 2

Þ

KLA

2110

Þ

KLA

2110

Via

Metal 2

UCL

?

<

Result

Generalizing Neyman-Pearson

results on minimizing risk of

not detecting an excursion,

with a constraint on probability

of false alarms

• Developed new model and

Model fab-wide yield

learning and optimize the

rate of learning and

investmentfor maximum

profitability

Integrating statistics used for

excursion detection with

queuing models for capturing

resource usage and the

resultant delays in integrated

inspection-review systems

• Developed and solved novel

Integrated defect type and

yield data not available,

difficulties

using heterogeneous

databases

Fab partnerships, BS/MS intern

training, 2 -3 years onsite data

extraction, data analysis and

Business Intelligence reports

on integrating disparate fab

databases

2

# of type

estimate

• Technology Management

– Data to Information

– Information to Knowledge Management

OoC

Process

In-control

Action Required

Model and detect a killer

defect type excursion when

it is masked by the

presence of other defect

types

1

• Business Problem

– Business Need

– Technology Context

Isolation

Process

Key Challenges in Framing and Solving Yield

Learning Problem

Excursion

Excursion

Occurs

Detected

Detection delay

Objective

To reduce the detection delay by trending individual defect types with

integrated wafer inspection and defect review strategy

• Methods : Decide how much inspection sampling and how much review sampling

• Economics: Decide how many machines of each type and associated personnel

analytics incorporating sampling

error

• Data to Information

•

• Information Systems

3

• Integration

12

IS-based Process Learning

13

Key Issues

• Validation of Solutions

• Information Systems

development and Integration to

achieve Business Intelligence

14

Conversion Of Defect Data To Yield Information

And Action

Firms unclear about “system” level functioning and performance

- Caught up in technology

- Data to information not clear to firms

- Information to knowledge is much worse

- Goal is not clear; consequently data and information systems

- Direct consequence – poor integration of information systems

- Concept of “meta model” needed rather than just “meta data”

• Business Problem

– Business Need

– Technology Context

models:

– Economically Optimized Yield

Learning

– Benefit of Ownership (in place

of traditional Cost of

Ownership)

Information to Knowledge

Management

Isolation

Poly1

Poly2

Metal1 Metal2

Market

• Technology Management

– Data to Information

– Information to Knowledge Management

Resources &

strategies

Validation

Inspection

Corrective

actions

Review &

classification

Root-cause

analysis

Source

identification

? DD(t) &

? Y(t)

Data/information flow

• Information Systems

• Integration

15

16

Goal

Detect killer defect excursion faster through

efficient integrated inspection-review cycles

Trade-off: Time versus benefit and cost

17

3

Defect Control Charts: Single-dimensional

Multi-dimensional Excursion Monitoring With

Defect Classification

Killer

Defect Distributions

Upper Control

Limit (UCL)

Control Chart

Probability

InControl

(INC)

f(x)

Out -ofControl

(OOC)

g(x)

In-control

x

Y

UCL

Þ

KLA

2110

y

Non-killer

^

x

>?

Þ

KLA

2110

Non-killers

z

m

Total defects

on wafer

Out-of-Control

# of random defects x

– s.t. false alarm probability ? ?is less than a pre-specified value

that determines whether in-control or out of control , when we have only

one defect type, by the Neyman-Pearson Lemma (the regions are given

by f(x)/g(x) < c, and UCL can be computed from this)

^ so that the decision surface is obtained, and

mean shifted version of f(x,z),

^ space

approximate it by a hyperplane in the (x,z)

19

Assessment: What is Technology Worth?

Computer-based Process Reengineering

• Business Problem

– Business Need

– Technology Context

Review accuracy (r = q = probability of misclassification)

150

OOC

100

50

IC

197

183

169

155

141

127

99

113

85

71

57

43

29

1

0

Prob. of missing excursion ?

Upper

Control

Limit (UCL)

15

Additional observations:

1. Increasing levels of sophistications can include misclassification probabilities,

fixed or adaptive control limits

2. We have used dynamic programming to generalize sequential sampling

approaches to these environments, with an appropriate sufficient statistic 20

B-Risk Vs. Review Sample Fraction at Different Review

Accuracies, with different review level compensation

250

200

Control), where ^x is the killer defect estimate

^

^ since g(x,z)

^ is a

5. Reorganize the terms with the density functions f(x,z)/g(x,z),

18

Multi-dimensional SPC Chart For

Integrated Inspection-review Sampling:

Killer And Non-killer Defects

^ z) (In Control) and g(x,z)

^ (Out of

3. Consider the joint density functions f(x,

standard result and using the Euler equation to determine the optimal policy

to minimize the probability of missed excursions (subject to a given

probability of false alarms)

Random Defect Sampling with Classification Errors

• Incomplete and imperfect defect information

• Fixed versus adaptive control limits

• This is achieved through a control chart with an Upper Control Limit UCL

Compute conditional distributions of killer defects , condit ional on

observed total defects z, and the fraction (or equivalently, number) sampled

4. Use a generalized Neyman-Pearson Lemma, extending the results of the

Random Defect Sampling with Perfect Classification:

• Incomplete but perfect defect information

• Fixed versus adaptive control limits

• Minimize excursion detection time => equivalent to

• Minimizing the probability of missing an excursion ????

1.

2. Use standard central limit theorem for normal approximations of distributions

UCL(z)

(sampled

defects) ,

equivalent to

f = fraction sampled)

Total Defect Count Approach:

Complete and Perfect Defect Information

# of random defects x

Killer defect count estimator

Killer defect

estimate

Killers on wafer

X

Development of Multi-dimensional Control Chart

0.7

To achieve b=0.3

r=q=70% need

review 50% defects

0.6

0.5

• Technology Management

– Data to Information

– Information to Knowledge Management

0.4

0.3

0.2

r = 70%

r = 80%

r = 90%

0.1

0

0

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

• Information Systems

1

• Integration

Review sample fraction

Total random defect count

21

22

23

4

Information to Knowledge: Yield Management and

Learning Model

Goals, Issues and Economics: In-Line Defect

Sampling Strategy

A Yield Learning Cycle-time Optimization Problem

Þ

KLA

2110

DATA

INFORMATION

Isolation

Poly1

Poly2

KNOWLEDGE

Inspection &

Review Tools?

Which & how

many?

Metal1 Metal2

Market

Validation

Inspection

Corrective

actions

Review &

classification

Root-cause

analysis

Source

identification

Tool

Settings

Where?

% lots?

Wafers

per lot?

Inspection

% Wafer?

Sensitivity?

Isolation

In-control

Beta

Risk

1.2

? DD(t) &

? Y(t)

Poly 2

Metal

Wafer

Defect

Inspection Review

h -h

1-???? 2

Source

Corrective

Identification

Action

IC

Time

T0

SI(h)

0.4

Via

SR(h,f)

or

SI(h,f)

T1

T2

for In-line ADC

The process of excursion-correction can be represented

by a renewal reward process with expected unit costs

Metal 2

• Cycle time of each learning loop determine the

overall learning rate

• Effect of learning bottlenecks and economics

E[AC]= E[C]

E[T]

24

Illustrative Objective Function and Decision

Variables

25

Solution highlights

Objective

To minimize the detection delay (including queuing) of an excurs ion

26

Results: Quantified Advantage of Integrated

Inspection-review Sampling Methodologies

Optimization of sampling, control limits, and choice of

machines (and personnel)

Min Td (h, m) ? T? ( h,m) ? E[?] ? TI ( h) ? TR( h,m)

h ,m

h

T? (h, m) ?

Delay due to the beta risk of SPC Chart

1? ? (m)

h

E[?] ?

Excursion time in the wafer inspection interval

2

2

2

(? ? ? S )

T I (h) ? ? S ? S

Total inspection time per wafer (M/G/1)

2(h? ? S )

(? 2 (m) ? ? 2R( m))

T R(h, m) ? ? R (m) ? R

Total review time per wafer (M/G/1)

2(h ? ? R( m))

Decision Variables:

• Control limits,

• Sample fraction for defect classification f

• Wafer inspection intervals h;

1

?

0.6

Via

Data/information flow

Prod.

Delay

Tool Depreciation and Labor Costs

Poly

Resources &

strategies

Þ

KLA

2110

Costs

8

Use supermodularity of cost function, which results in

monotone non-increasing (in control limit)

property of sampling interval

Equivalence of cost minimization, cycle time minimization

under constant false alarm levels

1 Optimal inspection sampling

plan (no review)

7

2 Optimal inspection and review

sampling plan (separately)

5

3 Optimal integrated inspectionreview sampling plan

3

This is based on stable demand

Use real options and zero level asset pricing to handle

demand and price uncertainties

?=

18%

6

4

2

1

Additional work on sample path approaches, for

optimizing lot sequencing (LIFO in place of ubiquitous

FIFO)

27

?=

55%

9

0

28

1

2

3

29

5

Results on Review Methodologies:

Economics of Technology Investments in Fab A

Summary of Technology Management

Contributions

Expected yield lost due

to excursions per year

• Development of a novel generalized control chart that is

useful in the new integrated inspection & review context:

Data to Information

$35,000,000

$30,000,000

17,397,793

13,816,845

$10,000,000

$5,000,000

$Optical

• Technology Management

– Data to Information

– Information to Knowledge Management

• Development and analysis of a new prescriptive model that

determines the optimal inspection & review policies to

maximize the yield learning rate for a fab: Information to

Knowledge

$15,000,000

Traditional

• Business Problem

– Business Need

– Technology Context

Our research contributions are three-fold:

38,481,819

$40,000,000

$25,000,000

$20,000,000

Computer-based Process Reengineering

• Information Systems

• Demonstration of the value of this model in actual fab

context through Information Systems Integration

SEM

30

Yield Management Systems Required to Integrate

Defect, Yield, and Lot Data Do NOT Communicate

• Integration

31

Key to Success: ISM Solution

32

Computer-based Process Reengineering

In place today

Partially in place

Not in place

WorkStream/

Informix DB

SAP loader for offline

created data

Offline summary

of orders

Offline summary of

reports

Management

reports

Management

reports

SAP loader for

offline created

data

•

5 key partner firms and two dozen facilities globally

•

Doctoral students

•

Masters and undergraduate interns at facilities,

extracting data, developing business intelligence,

and integrating information systems for several

years nonstop to produce ISM manuals for fabs!

Mini -DSS (Decision Support System) solutions.

• Business Problem

– Business Need

– Technology Context

• Technology Management

– Data to Information

– Information to Knowledge Management

Order (PM & CM)

MDS

(Equipment

Interface Table)

Oracle DB

RTD for prev.

maintenance

PM & CM order data

Planned wafer starts

Global SAP D B

(SQL)

KLA Yield

Management

Systems

Defect data

YIELD DATA

• Information Systems

• Integration

33

34

35

6

Integration: Yield Management Systems

Successes in $200M-$1B Growth of K-T

Remaining Challenge

QC stories – “ Data Drownage”

• Training of marketing and application engineers during

The real need is to develop a large scale unified Yield

Management System integrating:

Monterey retreat on methodology/economics

• Marketing,including product definition, and “collateral”

• The overall business need for enterprise profitability

including marketing and sales

•

•

•

•

•

•

• Defect, parametric, and yield data and processes

• Lot movement data and processes

• Knowledge Management for Yield Learning overlaid on

the Product Development Process

development, guidance to engineering

Global “Customer” interface on methodology!

Seminars worldwide to thousands!

Executive impact and awards (including stocks!)

Academic Impact

Resources: Multi-million dollar effort

Faculty from Engineering (Systems and Domain) and

Management from Stanford, Berkeley, Carnegie Mellon

36

Backups

37

Information Systems and Technology

Management (ISTM) to Solve Business Needs

38

IS-based Process Learning

Business Need: Technology context – use or development of technology

• Generic Business Problem in High Tech

Integration: Business intelligence to maximize enterprise profitability

• Technology Management (TM) Challenges

–Facilities are challenged to develop new products and

process technologies rapidly

–Methods for rapid product and process learning

–Economics of process and monitoring tools

• Technology Management

– Identify specific goals

– Delineate Business Processes

– Model Economic trade-offs

– Capture Strategic Information Needs

• Domain Knowledge

• Analytic Model

– Stochastic Optimization

– Economics

39

• Information Systems

– Procedural or software system

– Knowledge Management System to

enhance

– Local, enterprise, or value network

performance

• Information Systems (IS) Issues

–Enhancements and limitations imposed on Technology

Management by IS/IT

–Knowledge Management

• Context -based Business Intelligence

• Needs: Domain knowledge, software technology

PLATFORM

• Software,hardware, and networks

• Psychology

• Integration

–TM and IS/IT integration challenges, including data

–Human interactions with Decision Support Systems

40

41

7

REDEFINED GOAL: MINIMIZING TIME TO DETECT

AND FIX YIELD EXCURSION

State-of-the-Art YMS: data ConductorEP ®

Key Solution Concept

( AN EXCURSION @ ETCHER IN FAB A)

Event

Occurring

Event

Detected

50

InControl

Source

Isolated

17

Detection Delay

7

Source

Isolation

In type-based excursion detection the sampling distribution

statistics of the killer defect estimates, given the total defects

on the wafer, are described by:

• Simple random sampling results in approximately Normal

distribution with statistics:

Fix

Validated

20

2

9

Hours

E[ Xˆ | X , z ] ? X

1

m ?1

VAR ( Xˆ | X , z ) ? ( )(1 ?

) X (z ? X )

m

z? 1

E[ Xˆ | z] ? ?

Root

Corrective

Cause

Actions

Analysis

X| z

1

m ?1

V A R(Xˆ | z) ? ( )(1 ?

)(Z? X| z ? ( ? X2 | z ? ? 2X / z )) ? ? X2 | z

m

z ?1

FXˆ | z ( xˆ ) is determined by the distribution of X & Y, and the sampling scheme

Defect level

Goal

Optimize procedures and inspection-review machine

usage to reduce delay to detect and fix yield excursion

• Using defects as surrogates ( linking defects to yield is a

technology problem in electrical/computer engineering)

• Trending by individual defect types (killer, non-killer)

• The two- dimensional control “limit”

hyperplane can be

characterized in terms of these parameters in (X, z) or ( X̂, z), by

generalizing the Neyman-Pearson Result

• The estimated standard error of the killer defect estimates is a

function of m and z; i.e., VAR ( Xˆ | z) ? g ( m , z)

42

43

Semiconductor Manufacturing: In-Line Monitoring

Wafer

Preparation

Wafer

Fabrication

Silicon

Ingot

Lot

Wafer

Probing

Agenda

Packaging/

Testing

Wafer

Triggered Learning Process

from Production to Product

Development

In-line Process Control

Yield

Time (days)

0

10

20

30

Days

30

40

50

5

10

15

20

25

30

35

40

45

50

Process Flow

Isolation

Gate 1

Poly

Gate 2

Poly 2

Contact

Metal

Via

Metal 2

Time (days)

0

10 20

Motivation

Triggered Learning Process

Current Implementation

Managerial Insights

Bigger picture & Future Work

Chip

Die

30

40

44

John Voit Delphi

Ram Akella UC SC/Silicon Valley Center

Rajeev Kishore SUNY

Ramesh Ramaswamy SUNY

50

5

Days

TEST

45

47

8

Motivation

Many problems throughout the production, assembly, and customer use are

solved by different parts of the organization. The lessons lear ned are then

archived in different formats and different levels of detail. These lesson learned

are not formally communicated to NPD due to organizational boundaries (real or

perceived), diverse storage media, and access privileges. If communicated, the

documents are sometimes too long, or are written in a context th at is not

immediately understandable for NPD use or absorb. This can result in the NPD

activity launching products that contain past problems (Busby, 1 999; Von Hipple

& Tyre, 1994).

First Time

Quality

Triggered Learning Process

Other attempts

Safety &

Formal

Ergonomics OEM Complaints

Post-Mortems

• Tend to be long reports that require discipline to prepare. Forexample, Microsoft sites 3-6 months

to prepare a 10-100 page post- mortem ( Thomke & Fujimoto, 2000)

• Ambiguous on how NPD will integrate information into new programs

Design Reviews with downstream stakeholders

• Downstream personnel cannot readily relate to NPD artifacts (i.e .; digital models) (Black & Carlile,

2002)

• Cross organizational information transfer (verbal and written) h ave problem of context and jargon

causing poor communication (Uschold & Grunninger , 1996)

• Time between reviews causes ‘batched’ learning and a greater chance and cost of iteration (Ha &

Porteus, 1995)

General Lessons Learned Database

• no process to make sure reviewed

Long Term

Durability

GOAL: An ontology-assisted triggered learning process (TLP) for getting Lessons Learned

communicated and used in NPD activities.

Lessons Learned

Long Term

Durability

Safety &

Formal

Ergonomics OEM Complaints

First Time

Quality

Warranty

Warranty

NPD = New Product Development

OEM = Original Equipment Manufacturer

NDP

2 PDP Production

?3 Delphi

3 OEM

OEM

NDP

2 PDP Production

?3 Delphi

Field <3 yrs Field >3 yrs

48

Definitions

Field <3 yrs Field >3 yrs

50

Triggered Learning Process

Lessons Learned Ontology Model

Ontology – “a set of concepts (e.g. entities, attributes, processes), their definition and their interrelationships; this is referred to as a conceptualization” ( Uschold & Grunninger, 1996)

Trigger - An event, called a Lesson Learned, that is communicated and used by NPD

• Assumption: the lesson learned was a ‘big enough’ problem that it was documented in

some manner by a part of the organization.

3 OEM

OEM

49

L e s s o n

L e a r n e d

F

p

u

e

n c t i o n

c i f i c a t

1

i

F

a

E

o

n

i

f

l

f

M

e

c

o

t

N

1

C

o

1

1

N

S

1

d

1

e

{

N

|

S

{

|

S

t

r r e c t i v e

D e l e t e ( )

A d d ( )

A

M o d i f y ( )

e p | + | F e a

t

c

u

t

r

i

e

o

|

n

>

=

1

N

1

N

R o o t

t e p | +

C a u s e

| F e a t u r

0 . . N

0 . . N

e

|

>

=

1

}

}

TLP is a structured approach that

Feeds back lessons learned created by downstream organizationalpersonnel

To a staff that condenses these lessons learned into an ontology a n d

Communicates these items to NPD

NPD personnel reacts to this information as it arrives by incorp orating

it into the newL product

or process under development.

L e s s o n s

e a r n e d

0 . . N

F

0 . . N

i

r

s

t

Q u a l

i

T

t

i

y

m

e

E

S

a

f

r

g

o

e

t

n

y

o

&

F

m

i

3

O

E OM E

c

s

O

E

o

r

M

C

m

a

o

m

L

0 . . N

C l a s s

n a m e

a t t r i b u t e s

o p e r a t i o n s ( )

{ c o n s t r a i n t s }

C

F

0 . . N

u

e

r

a

r

t

e

u

r

n

e

l

a

i

s

0 . . N

C u

S

t

r

e

r

p

e

n

W

0 . . N

t

n

o

D

l

p

K E Y

A s s o c i a t i o n

H a s

O n e

t

n

u

g

r

a

T

b

i

y

r

e

l

i

r

t

m

y

s

a

r

r

s

r

a

n

t

y

t

s

N

2 D

PP

D

P

P? r 3 o

d D u ec

lt

ip

oh n i

M

F

i

e

l

d

<

3

y

F

i

e

l

d

>

3

s

Step #1

Feedback

Step #2

Update

Lessons

Learned

Ontology

Step #3

Communicate

Step #4 React

51

52

53

9

Perspectives/Context

Step 2: Update Ontology

Step 1: Feedback Details

TLP is consistent with the theory that organizational learning is triggered by external shocks

(e.g.; lessons learned) that makes adaptation necessary (Cyert & March, 1963)

NPD as a problem-solving activity ( Thomke & Fujimoto, 2000). Enterprise and Customer

requirements are considered problems that must be solved by new product and process

development. Often downstream lessons learned are manifestations of a failure to meet

downstream stakeholders requirements.

What: Documentation that was created

in resolving the problem for the value

stream

Staff used

• To summarize the

Lesson Learned in

the ontology

• “Attach” the Lesson

Learned documents

provided

When: Feedback is initiated once a lesson

is learned and a value stream problem is

resolved.

Who: Each production lessons learned

source is owned by a different organization

(function) within the enterprise

54

Step 3: Communicate

i=1

Step 4: Reaction

Only potentially

relevant lessons go to

the appropriate teams

i=3

R 41 = R 51 = 0

Lessons

Learned

Ontology

i=5

Rij = Relevance

of Source i to PD

Team (PDT) j

Rij ? [0,1]

Lesson

Learned

j=1

RXNijk = Reaction to

source i from PDT j

regarding lesson k

Root Cause Present

=> Failure Mode

1

j=2

New Product Line

Profit

Quality

1

j=3

j=5

57

2a. Check

()

Root Ca

use

1

2

Ro b. C

ot hec

Ca k()

us

e

Reaction Alternatives

1. Implement Current

Controls

2. Innovate product

features or process steps

3. Need to plan

4. Not relevant - Do Nothing

j=4

i=4

56

Control Loop

1. Communicate

(Root Cause, Corrective Action)

R 11 = R 21 = R 31 = 1

i=2

55

New

Product

Design

present

3a. If root cause

ctive Action

Require() Corre

3b. If root cause present

Require() Corrective Action

1

1

1

3

Lesson

Reused

N

Team not

responding

New

Features

Lessons

Learned

Ontology

1

1

New

Process

Design

1

RXN3j1 RXN3j2 RXN3j3

Manager

Monitors

Response

s

1

4

3

1

4

3

1

2

2

N

New

Steps

Innovation

58

59

10

Triggered Learning Take Aways

Current Implementation

Triggered Learning Take Aways

ACTIVE Knowledge Movement process

• Right People: Email to the people developing the next generationproducts

• Right Information: Real Stakeholder Dissatifiers

• Right Amount:

Feedback established in United States and Mexico Production Value Streams (4 production facilities)

Product Development teams in US and Mexico are reacting to the information

Plans to expand to European Production facilities and Product de velopment.

Execution

• Improves Design Reviews

– Batched leaning to triggered learning - do not wait until reviews to share downstream lessons.

– Reduces Surprises & Opinions based comments

• Supports flawless launched to ensure past mistakes not repeated

• Helps maintain FTTQ and Health & Safety gains made in Value Stre am by communicating current fixes

– Lesson Overview Ontology line item

– Detailed solution information if required: Attached documents

•

Right Time: When A Lesson is Learned (Trigger)

Knowledge Application

PDTs have a reaction plan to use the new information

Controls & Standard Management Ensure process is followed

•

LL Update

Personnel

U.S.A.

Lessons

Learned

Ontology

LL Update

Personnel

Mexico

60

Managerial Insights

61

Required Resources

Some Keys for Implementation

Feedback:

When is this systems most valuable?

• Product Maturity High (i.e.; many small issues)

• Past product highly relevant to new products

• High Cost of making or repeating mistakes

• Project time short & project teams highly utilized

• Number of independent future projects high

• Organization structure: Information Bucket Owners different that product process

developers

•

•

Information technology already present

Needed to spend time to develop process and get buy-in.

• Feedback People

– Minimal Impact

• Update People

– New Responsibilities

• Communication People

– Standard Management Responsibilities

• Reaction People

– Spend time now or spend time later

– Not new responsibility, but new information, not always enough time to address

issues

Add steps to current problem solving processes to send Lessons L earned to update person

Be on guard for those partial lessons learned

Update:

•

•

•

Development of the Ontology Structure

Populate with historical projects to prove concept and work out bugs

Not a Clerk Job, people must have some domain knowledge

Communicate:

•

Works Best when communication person is also the Manager of Reaction People

React:

•

•

•

63

62

Be patient.

Team will be getting information they never received before

Standard Management/coaching commitment in beginning must be high

64

65

11

A Bigger Picture

Interesting Research area slicing across traditional disciplines

•

•

•

•

•

Management Science

– Q: How do decision makers know when having system and staff is important?

– Tools: Analytic Queuing Models

Knowledge Management

– How do we get information to the people who need it?

– Tools: Organizational Design, Communication Processes.

Organization Learning

– How do groups and people learn?

– Tools: Observational studies, and experiments

Philosophy

– Q: How do we structure knowledge to best get our questions answered?

– Tools: Ontology, Taxonomy

Computer Science

– Q: How can this be an even more automatic/active system?

– Tools: Object oriented programming and systems.

66

Future Research & Work at Delphi

Bibliography

Increase scope of buckets and plants, deeper into supply chain

Link to “Double Loop” learning (Agyris, 1976). The idea is that a concentration of lessons

learned indicates a systematic problem, and Organization policy should be changed.

Argyris, C. 1976. Single-Loop and Double-Loop Models in Research on Decision Making. Administrative Science Quarterly, 21(3): 363-375.

Black, L. J., & Carlile, P. R. 2002. Managing Knowledge in a Product Devlopment Process: What to Do and When,Working Paper: 40.

Busby, J. S. 1999. Problems in error correction, learning and knowledge of performance in design organizations. IIE Transactions, 31: 49 -59.

Cyert, R. M., & March, J. G. 1963. A Behavioral Theory of the Firm. Englewood Cliffs, NJ: Prentice Hall.

Ha, A. Y., & Porteus, E. L. 1995. Optimal timing of reviews in concurrent design for manufacturability. Management Science, 41(9): 1431-1447.

Thomke , S., & Fujimoto, T. 2000. The Effect of " Front-Loading" Problem -Solving on Product Development Performance. Journal of Product Innovation Management,

17: 128 -142.

Uschold , M., & Gruninger, M. 1996. Ontologies: principles, methods, and applications. The Knowledge Engineering Review, 11(2): 93 -136.

v o n Hipple, E., & Tyre , M. 1994. How "learning by doing" is done: Problem identificati on in novel process equipment. Research Policy, 19: 1 -12.

67

68

12