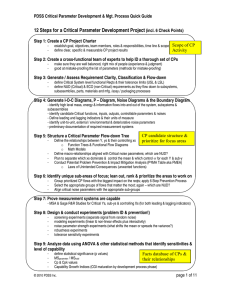

Critical Parameter Development & Mgt. Deriving Capability Indices from “Scratch”

advertisement

Critical Parameter Development & Mgt. Deriving Capability Indices from “Scratch” Agenda Demonstrate the 4 simple steps for deriving a Cp Index from Sample Data How it impacts the 7 Checks for Criticality! Measurable? Stable? Adjustable? Interactive? Sensitive? Robust? Capable? Design Capability Studies, Copyright 2006, PDSS Inc. 2 Step 1: Measurement of samples of functions Measure the function by taking data as random, independent, stable samples of a function within the design… Individuals 35 UCL=32.89 25 MU=20.39 15 5 Observation0 LCL=7.887 10 20 30 Function’s Distribution During a Design Functional Capability Study we gather design Functional Response data Design Capability Studies, Copyright 2006, PDSS Inc. 3 Step 2: Assign Natural Tolerance Limits to the Function’s Distribution… Upper Control Limit Lower Control Limit Function’s Distribution +3s -3s Y 99.73% of the FR’s data fall within the Control Limits (+/- 3 Std. Devs. = Natural Tolerances of the Function) Design Capability Studies, Copyright 2006, PDSS Inc. 4 Step 3: Assign Customer-based Tolerance Limits to the Function’s Distribution… Lower Specification Limit LCL UCL Upper Specification Limit Function’s Distribution -6s +3s -3s +6s Y 99.9999998% of the FR’s data fall within the Spec. Limits (+/- 6 Std. Devs. = Customer-based Tolerances of the Function) Design Capability Studies, Copyright 2006, PDSS Inc. 5 Step 4: Recognize the design latitude between the Control & Spec. Limits… Lower Specification Limit LCL UCL Upper Specification Limit Function’s Distribution -6s +3s -3s +6s Y Each side of the Function’s distribution has 3s of latitude between the Control Limits & Spec. Limits, when the mean is centered on the VOC Target Value… Design Capability Studies, Copyright 2006, PDSS Inc. 6 What is Cp? Cp is the ratio of…. Lower Specification Limit Mean is centered on the desired Target. Desired Target Upper Specification Limit +6s -6s Y 6xσ Function’s Distribution Design Capability Studies, Copyright 2006, PDSS Inc. 7 Short Term Capability Performance LSL USL -6σ +6σ Measured Design Performance Mean stays on target in the absence of assignable causes of “noise” Design Capability Studies, Copyright 2006, PDSS Inc. USL − LSL Cp = 6σ Y = Target -3σ +3σ Natural Tolerances This is what you develop & measure in the Design Phase… 8 What is Cpk? Cpk is the ratio of…. Mean - LSL 3xσ Function’s Distribution Design Capability Studies, Copyright 2006, PDSS Inc. Desired Target USL - Mean Mean shifts 3xσ Function’s Distribution 9 Long Term Capability Performance Y is 1.5s off-Target USL +6σ LSL -6σ Shifted Design Performance Y − LSL USL − Y Cpk = Min , 3σ 3σ 1.5σ + & - Mean Shifts are caused by assignable causes of “noise” Design Capability Studies, Copyright 2006, PDSS Inc. -3σ +3σ Natural Tolerances This is what you intentionally create & measure in the Optimize Phase… 10 Forcing Cpk = Cp: Adjustability! Function Adjustment Parameters are FR Mean Shifters… driving k = 0! Cpk : Off-Target Performance due to Unwanted Variation Intro to CPD&M, Copyright 2010, PDSS Inc. Cp: Mean Adjusted to VOC Target 11 Maximizing Cp: Linking Robustness & Adjustability! Functional Robustness Parameters are FR Variance Reducers FAPs are CFR Mean Shifters Robust against Variation Intro to CPD&M, Copyright 2010, PDSS Inc. Mean Adjusted to VOC Target 12 Required KP Mgt. Data for any form of Capability Assessment Gage R&R All FRs or Functional Spec.s must have a capable measurement process documented & in use G age name : D ate of s tudy: R eported by : To lera nc e: Mis c : G ag e R &R (ANO VA) f or Thic kn ess C om ponents of Variation B y Part Percent 1 00 8 .3 %C o nt rib utio n %S tu dy Var %To le ra nce 8 .2 8 .1 50 8 .0 7 .9 0 Ga ge R& R R ep ea t R e p ro d Pa rt P art-t o-P art Sample Range Fre d 2 3 5 6 7 8 9 10 8 .3 M ary 8 .2 U C L =0 .1 4 5 9 8 .1 0 .1 R = 0 .0 5 66 7 8 .0 LCL=0 0 .0 7 .9 Op e ra tor Fre d 0 Xbar Chart by Operator Jo e J oe M ary Operator*Part Interac tion 8 .1 U C L =8 .1 0 2 M e a n= 8. 0 44 8 .0 O p e ra tor 8 .2 M ary Average Fre d 8 .2 Sample Mean 4 By Operator Jo e L C L = 7. 98 6 7 .9 Fre d J oe M a ry 8 .1 8 .0 7 .9 Pa rt 0 Gage R&R Study 1 2 3 4 5 6 7 8 9 10 I & MR Chart Individual Value I and MR Chart for C2 UCL=5.917 5 0 Mean=-0.03816 -5 LCL=-5.994 Subgroup 0 50 100 10 Moving Range Each FR or Functional Spec. is placed under stable SPC so the Cp can be routinely quantified for Phase-by-Phase growth & Life Cycle stability characterization 1 R C hart by O perator 0 .2 UCL=7.316 5 R=2.239 LCL=0 0 Capability Study P r oc es s C a p a b ilit y A na ly s is fo r C 2 LSL P ro c es s D at a US L All FRs & Functional Spec.s are Capable typically w/ target of Cp = 2 & Cpk of 1.5 Intro to CPD&M, Copyright 2010, PDSS Inc. U SL 1 2 .0 00 0 T arg e t W ith in * LSL 8 .0 00 0 M e an 9 .9 76 6 S a m ple N O ve ra l l 10 0 S t D e v (W ith in) 0 . 44 7 13 4 S t D e v (O ve ra ll) 0 . 45 8 18 6 Po te n tia l (W it hin ) C ap a bility Cp 1 .4 9 C PU 1 .5 1 C PL 1 .4 7 C pk 1 .4 7 C pm * O v era ll C a p ab ilit y 8 9 10 O b se rve d P e rfo rm a n ce 11 E xp. "W ith in " P e rfo rm an c e 12 Ex p. "O ve rall" P e rfo rm a n c e Pp 1 .4 6 P PM < L S L 0 .0 0 P P M < LS L 4 . 92 P P M < LS L PPU 1 .4 7 P PM > U S L 0 .0 0 P P M > US L 3 . 02 P P M > US L PPL 1 .4 4 P PM T ot al 0 .0 0 P P M To ta l 7 . 94 P P M To ta l Ppk 1 .4 4 13 8 .0 1 5 .0 3 1 3 .0 4 Y as a Function of Controlling Xs For a given Y there can be numerous controlling Xs…. There can be 3 ways for a controlling X to influence Y: Xi dominates the Mean… for Adjusting Xj dominates the Standard Deviation… for Robustness Xk co-contributes to both the Mean & σ... You pick! The question CPD&M asks is “do you know how Xs affect Ys in light of the 7 Checks??? - Which ones are out of control!?!? Design Capability Studies, Copyright 2006, PDSS Inc. 14 Summary You should be able to repeat this explanation It is important for you to be able to do this for anyone you work with. An organization practicing CPD&M must understand Capability How it degrades.... how it grows & matures due to intentional investment in KP development tasks.... How it is calculated.... What it means in the context of CPD&M.... Design Capability Studies, Copyright 2006, PDSS Inc. 15 MIT OpenCourseWare http://ocw.mit.edu ESD.33 Systems Engineering Summer 2010 For information about citing these materials or our Terms of Use, visit: http://ocw.mit.edu/terms.