Appendix F Project Health and Safety Plan

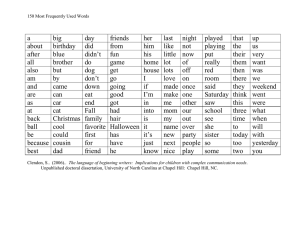

advertisement