Competitive adsorption of n-alkanes onto exposed and corrosion-protected hematite surfaces.

advertisement

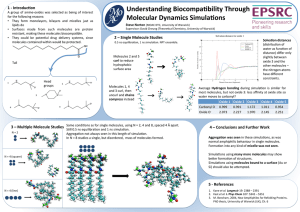

Competitive adsorption of n-alkanes … 29 July 2004 1/9 Competitive adsorption of n-alkanes onto exposed and corrosion-protected hematite surfaces. Miguel A. San-Miguel* and P. Mark Rodger Department of Chemistry, University of Warwick Coventry CV4 7AL, UK ABSTRACT Molecular dynamics simulations have been used to study the behaviour of a liquid mixture of octacosane and heptane between two planar hematite surfaces; one of the surfaces was coated by a monolayer of an oleic imidazoline (OI). It was found that the that octacosane could be inserted into the OI monolayer when it was aligned with the alkene tails of the OIs, but that the reaction rate for such an insertion was slow. A much more rapid process was the adsorption of the octacosane onto the exposed hematite surface, forming at least two layers and with a packing that was strongly reminiscent of the octacosane crystal structure. Keywords: Molecular Dynamics; Iron Oxide Surface; Corrosion Inhibitor Films; Wax; Alkane; Deposition; Solvent E-mail: smiguel@us.es and P.M.Rodger@warwick.ac.uk * Current address: ??? 1 Competitive adsorption of n-alkanes … 29 July 2004 2/9 1 INTRODUCTION There are a number of processes that affect the viability of oil and gas pipelines, including corrosion, scale deposition, wax deposition and clathrate hydrate formation.1,2 The industrial cost of preventing such problems is high, and so there is a considerable drive from the oil and gas industry to find cheap and effective additives to control these problems. Protecting pipelines from all these effects simultaneously, however, is an extremely complex problem.3 Most research has therefore been targeted at studying these processes independently, with separate research programmes to develop scale inhibitors, wax inhibitors, corrosion inhibitors or hydrate inhibitors. In each case there has been a focus on developing surface-active materials, usually in the form of polymeric or self-assembled monolayer coatings. The target for these coatings may be the pipe itself, as in the case of corrosion and scale inhibition; or the surface of the growing crystals, as in the case of hydrate and wax deposition. There has been considerable success in developing the separate inhibitors, and well tested lead compounds exist for corrosion,4,5scale,6 wax7 and hydrate inhibition.8,9 However, there is little or no understanding of the interplay between the different inhibition and deposition processes. It is clear that such interplay does occur. It has been found, for example, that threshold inhibitors for hydrate formation do not work effectively unless a corrosion inhibitor is also present.10 The interaction is not always synergistic and the balance between competitive and synergistic effects can be difficult to predict. A good example of this is the interdependence of corrosion and wax inhibition. Wax formation has been found to enhance the effectiveness of corrosion inhibitors (CIs), with indications that the wax can form an additional protective coating.10 Thus the use of wax inhibitors might be expected to reduce the efficacy of Langmuir film corrosion inhibitors. On the other hand, the paraffinic nature of common CIs11,12 may actively promote deposition of hydrocarbons onto the surface of the CI film. Without an understanding of the molecular mechanisms underlying this interplay, it will not be possible to design wax or corrosion inhibitors that will not exacerbate the complementary problem. Several recent molecular modelling studies have begun to shed light on the molecular processes associated with wax deposition. Simulations of liquid films of small alkanes on surfaces13,14 have shown that the hydrocarbon liquids form ordered layers at the solid surface, and with an enrichment of the longer alkanes at the solid surface 13. Simulations have also been performed with longer alkanes on iron oxide surfaces,15 and these have shown that the some iron oxide can provide a weak templating effect that is compatible with alkane crystal structure. Separate simulations have also been performed on CI films at oxide surfaces 16 However, to date, no efforts have been made to simulate the effect CI films may have on the structure of paraffin oils, or the consequent effects this may have for wax deposition. In this paper we present the results of a direct simulation wax deposition in the presence of a CI film. A slit pore model was used in which a hydrocarbon liquid was confined between two planar iron oxide surfaces. The liquid was a mixture of heptane (C7) and octacosane (C28), and one of the iron oxide surfaces was coated by a monolayer of an oleic imidazoline. 2 THE SYSTEM Molecular dynamics (MD) simulations were used to model an infinite film of liquid oil confined between two [10 11] hematite surfaces. One of the surfaces (referred to as the lower surface hereafter) was coated with a monolayer of oleic imidazoline (OI) molecules (1) (surface 2 Competitive adsorption of n-alkanes … 29 July 2004 3/9 coverage, 62.6 Å2 / molecule), while the second (upper) surface was the clean, anion terminated oxide surface. The oil was modelled as a mixture of n-octacosane (C28) and n-heptane (C7) Put a structural diagram of the OI here The design of the initial configuration for the simulations is shown in Figure 1. All simulations were conducted using an orthorhombic simulation cell, with z taken to be the direction normal to the surfaces; z will be described as the vertical dimension in this paper. Both iron oxide surfaces were the anionic termination of the [10 11] surface, with surface dimensions 43.5 × 40.3 Å (x × y) and were ??? Å thick. Ionic positions for these were taken from a previous study15 and were fully relaxed surface configurations. As the vibrational amplitudes for ions within the oxide are small under conditions pertinent to wax formation, the oxide surfaces were held rigid in the present study. Figure 1: initial simulation cell ... The OI coating was initially formed as a regular array of 28 molecules on the lower [10 11] surface (Figure 2). This has been shown to be a stable arrangement of the monolayer17 with surface coverage close to that observed experimentally. The octacosane molecules were inserted as an ordered layer taken from the crystal structure, and inserted more than 15 Å away from both the exposed oxide surface and the nearest point of the OI coating. The remaining vacant space was then filled with n-heptane molecules, with configuration taken from an equilibrated simulation of pure liquid heptane at 300 K and 1 bar. Simulations were performed at two different compositions. The first, system A, used 8 C28 and 288 C7 molecules, with the C28 molecules placed so that they were initially equidistant from both the exposed oxide surface and the OI coating (measured to the nearest point, i.e. the terminal CH3 group on the C12H24 chain). For the second, system B, a further ??? heptane molecules were inserted between the C28 layer and the exposed oxide surface to ensure that the octacosane started much closer to the OI coating than to the oxide surface. The resultant z dimensions (defined as the distance between the two surface layers of oxygen ions) was ??? and ??? Å for systems A and B, respectively. Figure 2: initial arrangement of OIs The intermolecular potentials were the same as those used in our earlier studies 15,18. Alkane chains (including the tail group of the OI) were modelled with a united atom potential, based on CHARMM22 but with parameters adjusted to give a better description of the crystal structure of n-alkanes.15. The CHARMM22 explicit atom potentials were used for the OI head group. Interactions between the iron oxide and the organic compounds were described by LennardJones potentials. All non-bonded interactions were truncated at 10 Å (> 2.5 σ). The electrostatic contribution to the forces was omitted from the calculations. In adopting this strategy we note that—within the united atom model for the solvent, wax molecules and CI tails—the most essential components of the system involve only neutral interaction sites. Furthermore, both the structure and dynamics of the CI film was found to be insensitive to the electrostatic interactions for the coverage, monolayer geometry, oxide surface and temperature used in this study.17 Thus the inclusion of coulombic forces would increase enormously the computer time required, but would not add further information about the influence of the corrosion inhibitor coating on wax deposition. 3 Competitive adsorption of n-alkanes … 29 July 2004 4/9 Simulations were performed with DL_POLY,19 using the NVT ensemble with Nose-Hoover thermostat. The temperature was 310 K [???], the thermal relaxation time was 0.1 ps and the time step was 1 fs. Two-dimensional periodic boundaries were used in the x-y plane. A typical set of input files is provided as supplementary material. The overall protocol followed in the simulations was: 3 (1) an initial configuration for the iron oxide surfaces, OI coating and C28 layer was constructed; (2) the requisite number of heptane molecules was added, avoiding any close overlap between any of the molecules; (3) a short (??? ps) simulation was conducted, during which the OI and C28 were kept immobile (frozen) while the liquid heptane was allowed to equilibrate; (4) a 4 ns NVT MD simulation, with all organic molecules fully mobile, was performed at 300 K for equilibration purposes; (5) extended MD simulations of up to 20 ns, again with all organic molecules fully mobile, were performed and the trajectory saved ever ??? ps for subsequent analysis. RESULTS AND DISCUSSION 3.1 SYSTEM A (55??? Å LIQUID LAYER) A series of configurations, taken from different times during the simulation of system A is presented in Figure 3; these snapshots provide a convenient “executive summary” of the overall results. Initially the long chain alkanes are located centrally between the two surfaces. The initial movement carries the molecules in all directions so that by 6 ns octacosane molecules can be found at both the OI coating and the exposed oxide surface. There appears to be little penetration of the alkanes into the OI monolayer, and over time these molecules diffuse back away from the OI layer. In contrast, the C28 alkanes that diffuse towards the exposed oxide surface adsorb onto this surface and begin to aggregate so that by 8 ns there is clear evidence of the beginnings of two layers of an embryonic wax crystal. Figure 3: snapshots of system A at 4 different times A more quantitative measure of the C28 behaviour can be obtained by calculating the average density of C28 molecules as a function of their height (i.e. the z coordinate). This has been calculated, based on the location of the centre of mass for each molecule, and the results are shown in Figure 4. To show the time evolution of the system more clearly, these z-densities have been averaged over successive 1 ns blocks of the trajectory. By 5 ns the distribution of C28 molecules is bimodal, with a very sharp peak at the exposed oxide surface (z > 50 Å), and a very broad peak spanning 10–40 Å. The OI coating extends about 15 Å out from the lower surface (i.e. 0 < z < 15 Å), so there is some penetration of the C28 into this layer, but the effect is small. By 8 ns, there are two sharp peaks in the C28 distribution at the exposed oxide surface, with a hint of a third peak developing. The gap between these peaks is 4.3 Å, which is very close the interlayer separation found in alkane crystals 15. In contrast, the broad peak above the OI film has disappeared by 8 ns, being replaced by a homogeneous background distribution spanning most of the liquid region (8 Å < z < 40 Å). There is a suggestion of small peaks 4 Competitive adsorption of n-alkanes … 29 July 2004 5/9 appearing within the OI layer, but these disappear when averaged over a longer time interval (the final 3 ns; see Figure 4), indicating that they are a transient feature. Figure 4: density profile of octacosane molecules across the z dimension It is interesting to note that the adsorption site and aggregate structure adopted by those C28 molecules that do adsorb onto the exposed oxide surface are precisely the site and geometry predicted from our earlier, more constrained, simulations of wax growth on this surface 15. In order to check the repeatability of these results, a second and analogous simulation was performed. This used the same initial positions for the C28 and OI molecules, but used a different arrangement of C7 molecules, and assigned different initial velocities to all molecules. The two sets of simulations were found to be very similar. In particular, we again saw no appreciable incorporation of the octacosane into the OI film, but strong adsorption onto the exposed oxide surface leading to the formation of two octacosane layers with a geometry that was strongly reminiscent of the octacosane crystal structure. 3.2 SYSTEM B (70??? Å LIQUID LAYER) In order to analyze more comprehensively what are the driving forces acting on the molecules towards one direction or the other, we devised a further experiment. An additional heptane solvent slab of 15 Å was introduced at height of 45 Å after 2 ns equilibration stage from starting the simulation in System A, in such a way that the wax molecules around the central region would see the CI tail film at shorter distance that the bare surface. The distance between the two oxide surfaces was then adjusted until the density of heptane at the centre of the liquid matched the final density observed in system A. The configuration of system B after 20 ns is shown in Figure 5. Once again, the adsorption of C28 onto the exposed hematite surface is clearly evident. Two layers are seen to form, with a structure similar to that observed for system A, although in this case a vacancy in the first C28 layer is apparent in Figure 5. For system B, one molecule is seen to be retained in the OI monolayer. This molecule has aligned with the OI tails and penetrated essentially to the oxide surface—in exactly the geometry required if the OI coating was going to promote wax deposition. As will be shown below, this is a long-lived incursion, being retained over the final 7 ns of the simulation. We note that for system A, all encounters between C28 molecules and the OI monolayer involved the wrong alignment, with the octacosane lying across the top of the OI layer rather than aligning with it. Thus, it may be that the alignment and penetration of long chain alkanes into the OI layer is favourable, but that the alignment stage represents and entropic bottle-neck, and so makes such adsorption events rare at the concentrations and temperatures considered here. Figure 5: final configuration of system B The dynamics of the C28 deposition processes can be see from the C28 z-density profiles (Figure 6) and the way the height of the centre of mass of each C28 molecule varies during the trajectory (Figure 7). The formation of the two layers at the exposed hematite surface takes longer than in system A, due to the larger distances over which they have to diffuse, but is almost complete by about 15 ns. The details of the trajectories (Figure 7) show that many of the C28 molecules diffuse initially towards the OI film (which was designed as the closer surface in system B) but subsequently diffuse away again. In contrast, encounters with the exposed oxide surface led resulted in adsorption of the octacosane with almost 100% efficiency. 5 Competitive adsorption of n-alkanes … 29 July 2004 6/9 Figure 6: z-density profile for C28, averaged over various time intervals. Figure 7: height of the centre of mass of each C28 molecule as a function of time. The conformation of the octacosane molecules has been monitored by calculating both the average end-to-end intramolecular distances and the percentage of gauche torsion angles. The results are shown, as a function of height, in Figure 8 and Figure 9. For reference we note that the OI head group occupies the region 0 Å < z < 5 Å, while the OI tails extend out to about 15 Å from the lower surface. Both figures show that the location of the longer alkane molecule makes a substantial difference to its conformation. End-to-end distances are smallest within the region of the OI monolayer, increasing to about 10 Å within the liquid heptane, but then increasing to about 30 Å when adsorbed to the upper surface (i.e. the exposed hematite surface). For comparison, the end-to-end distance of an all-trans C28 molecule is ???. These distances correlate well with the existence of gauche torsion angles, which was about 25% near the OI film and in liquid heptane, but decreased to les than 5% in the layer that deposited on the hematite surface. It is the existence of these gauche defects that is probably responsible for the slightly larger interlayer-distances found in the adsorbed octacosane compared with the crystal. This percentage decreases with time in the two adsorbed layers, suggesting that crystalline distances would be regained if much longer simulation times were accessible. Figure 8: ene-to-end distance of octacosane molecules as a function of height (z) Figure 9: percentage of gauche torsion angles in C28 as a function of height (z) Structuring effects have also been examined for the solvent (heptane); density profiles at various times are depicted in Figure 10. Up to four equally spaced layers, separated by 4.3 Å, are evident on the hematite. Three peaks, with similar spacing but much smaller amplitudes, are also evident within the tail group region of the OI film. Penetration of the heptane into the head-group region was observed, but was extremely rare. The solvent distribution is seen to equilibrate very rapidly and be stable in time. Some decrease is seen in the height of the two peaks adjacent to the hematite surface as the heptane is displaced by the adsorption of octacosane, but no other time dependence is evident in these profiles. Figure 10: density profiles for the heptane solvent These simulations also provide an opportunity to examine the structure of the the OI film, and in particular, to determine the alignment and tilt of the OI tails. The tilt angle, ,ϑ has been calculated as the angle between the surface normal, and the principal axis associated with the smallest eigenvalue of the moment of inertial tensor for the alkene tail of each molecule; ϑ = 0 (cos ϑ = 1) corresponds to the long axis of the tails aligning perpendicular to the surface. The distribution of tilt angles has been averaged over all OI molecules and over all configurations saved within various 1 ns windows of the trajectory, and the results are presented in Figure 11. Figure 11: tilt angles of OI tail groups at different times. AT all times there is a strong preponderance of tails oriented perpendicular to the lower surface:, with???% of the molecules having titl angles greater than .At 6 ns the distribution of tilt angles is br(cos ϑ > 0.8). At all times, there is also a small percentage (how many molecules?) that lie along the surface. At early times there is a significant number of tails that generate a broad distribution of tilt angles in the range [?°,?°], but this distribution steadily 6 Competitive adsorption of n-alkanes … 29 July 2004 7/9 declines over time, with a corresponding increase in the near-perpendicular region. It is interesting to note that this relaxation preceded the penetration of the one C28 molecule observed to remain within the OI film by the end of the 20 ns simulation. It is possible that this is merely coincidental, but it is also possible that the degree of alignment within the OI film is important in determining whether the OI film will act as a nucleation site for wax formation. More extensive simulations to investigate this possibility are in progress.17 4 CONCLUSIONS In this paper we have reported the results of a molecular dynamics simulation study into the interplay between wax precipitation and corrosion inhibition in oil pipelines. Multi-nanosecond simulations have been performed on a liquid mixture of short (C7) and long (C28) chain alkanes in the presence of both an exposed iron oxide surface (hematite, [10 11] ) and a monolayer film of an oleic imidazoline on iron oxide. The simulations revealed a strong tendency for the C28 molecules to adsorb onto the exposed hematite surface, spontaneously adopting an extended, all-trans geometry and aggregating into a layered structure reminiscent of the corresponding C28 crystal. The enthalpic driving force to such adsorption has been shown to be relatively weak15 and so there must be a significant entropic advantage to this behaviour. Preferential adsorption of larger molecules or particles at surfaces has certainly been found in other systems. Very little mixing was observed between the long chain alkanes and the OI film. This may suggest that OI films do not act as nucleation sites for the formation of wax deposits, but several other explanations are also possible, and further investigation is required. In particular, a single long-lived insertion of a C28 molecule into the OI film was observed, and was preserved for the final 1/3 of the total simulation time. This is suggestive that an aligned mixture of C28 and the OI tails within the OI monolayer is favourable, but that the rate of mixing is too slow to occur readily on the time- and length-scales currently accessible to molecular simulation. Indeed, the single event observed in this study did not occur until there was substantial alignment of the OI tails — an alignment that arose very slowly on the simulation timescale. More extensive simulations, probably at a higher concentration of waxforming molecules, are needed to establish whether this possibility is of more general significance. ACKNOWLEDGEMENTS This work was supported through EPSRC grant GR/L73739. 7 Competitive adsorption of n-alkanes … 29 July 2004 TABLES Table 1. CAPTION FIGURE Figure 1. Height of centre of mass for each wax molecule along the simulation. Figure 2. Snapshots at different time. Hexane molecules have been removed. Figure 3. Height of centre of mass of each wax molecule along time. Figure 4. Snapshot of final configuration after 20 ns. Figure 5. C28 density profiles at different times. Figure 6. End to end distance of wax molecules. Figure 7. Percentage of gauche defects against time. Figure 8. Percentage of gauche defects against height. Figure 9. Solvent density profiles. Figure 10. CI tilt angles at different times. Reference List 1 Misra, S.; Baruah, S.; Singh, K. Spe Production & Facilities 1995, 10, 50-54. 8 8/9 Competitive adsorption of n-alkanes … 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 29 July 2004 Mayer, M.; Crowe, T. Chemical Engineering Research & Design 1996, 74, 149-157. Tabatabaei, A. R.; Danesh, A.; Tohidi, B.; Todd, A. C. Ann.N.Y.Acad.Sci. 2000, 912, 392-402. Quraishi, M. A.; Jamal, D. Materials Chemistry and Physics 2001, 68, 283-287. Getmanskiy, M. D.; Zaharov, L. G.; Nam, O. S. Neftyanoe Khozyaistvo 1998, 65-66. Webb, P. J. C.; Nistad, T. A.; Knapstad, B.; Ravenscroff, P. D.; Collins, I. R. Spe Production & Facilities 1999, 14, 210-218. Hennessy, A. J.; Neville, A.; Roberts, K. J. Journal of Crystal Growth 1999, 199, 830-837. Argo, C. B.; Blain, R. A.; Osborne, C. G.; Priestley, I. D. Spe Production & Facilities 2000, 15, 130-134. Palermo, T.; Goodwin, S. P. Gas Hydrates: Challenges for the Future 2000, 912, 339-349. Harrob, D., BP Exploration, private communciations Chen, Y.; Jepson, W. P. Electrochimica Acta 1999, 44, 4453-4464. Klenerman, D.; Hodge, J.; Joseph, M. Corrosion Science 1994, 36, 301-313. Smith, P.; Lynden-Bell, R. M.; Smith, W. Molecular Physics 2000, 98, 255-260. Duffy, D. M.; Rodger, P. M. Physical Chemistry Chemical Physics 2001, 3, 3580-3585. San Miguel, M. A.; Rodger, P. M. Physical Chemistry Chemical Physics 2003, 5, 575-581. San Miguel, M. A.; Rodger, P. M. Journal of Molecular Structure-Theochem 2000, 506, 263-272. San Miguel, M. A. and Rodger, P. M. manuscript in preparation San Miguel, M. A.; Rodger, P. M. Molecular Simulation 2001, 26, 193-+. Smith, W.; Yong, C. W.; Rodger, P. M. Molecular Simulation 2002, 28, 385-471. 9 9/9 System A 0.30 Molecule density 0.25 0.20 0.15 0.10 0.05 0.00 0 5 10 15 20 25 30 35 40 45 50 Height Figure 1. Molecule density based on the position of the molecule centre of mass position during the last 3 ns (7 to 10 ns). 8 ns 7 ns 6 ns 5 ns CI Fe2O3 55 0 ns 6 ns 7 ns 8 ns Figure 2. Snapshots of side views of the system at four different times. Center of Mass displacements 70 60 Heigth (A) 50 40 30 20 10 0 1 0. 6 0. 1 1. 6 1. 1 2. 6 2. 1 3. 6 3. 1 4. 6 4. 5. 1 5. 6 1 6. 6. 6 1 7. 6 7. 1 8. 6 8. 1 9. 6 9. .1 10 .6 10 .1 11 .6 11 .1 12 .6 12 Time (ns) Figure 3. Height of centre of mass of each wax molecule along time. .1 13 .6 13 .1 14 .6 14 Figure 4. Snapshot of final configuration after 20 ns. Wax density 5 4.5 4 Density 3.5 3 2.5 2 1.5 1 0.5 0. 38 2 4. 04 8 7. 71 4 11 .3 8 15 .0 47 18 .7 13 22 .3 79 26 .0 45 29 .7 11 33 .3 78 37 .0 44 40 .7 1 44 .3 76 48 .0 42 51 .7 09 55 .3 75 59 .0 41 62 .7 07 66 .3 74 0 Height 5 ns 10 ns Figure 5. C28 density profiles at different times. 15 ns 20 ns 35 End_to_end distance 30 25 20 15 10 5 0 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 Height Figure 6. End to end distance of wax molecules. Gauche defects 35 30 % gauche 25 20 15 10 5 Time (ns) Figure 7. Percentage of gauche defects against time. 12 12 .7 13 .4 14 .1 14 .8 9. 9 10 .6 11 .3 9. 2 8. 5 7. 8 7. 1 6. 4 5 5. 7 4. 3 3. 6 2. 9 2. 2 1. 5 0. 8 0. 1 0 35 30 % gauche 25 20 15 10 5 0 0 5 10 15 20 25 30 35 40 45 50 55 60 65 Height Figure 8. Percentage of gauche defects against height. Density 4.5 4 3.5 Density 3 2.5 2 1.5 1 0.5 0. 38 2 4. 04 8 7. 71 4 11 .3 8 15 .0 47 18 .7 13 22 .3 79 26 .0 45 29 .7 11 33 .3 78 37 .0 44 40 .7 1 44 .3 76 48 .0 42 51 .7 09 55 .3 75 59 .0 41 62 .7 07 66 .3 74 0 Height (A) Figure 9. Solvent density profiles. 70 0.025 6 ns 0.020 10 ns Probability 15 ns 20 ns 0.015 0.010 0.005 0.000 0.0 0.2 0.4 0.6 cos(tilt angle) Figure 10. CI tilt angles at different times. 0.8 1.0