MT 348 ‐ Outline No. 1 ‐‐ 2009 MECHANICAL PROPERTIES I. Introduction

MT 348 ‐ Outline No.

1 ‐‐ 2009

MECHANICAL PROPERTIES

I.

Introduction

A.

Stresses and Strains, Normal and Shear Loading

B.

Elastic Behavior

II.

Stresses and Metal Failure

A.

ʺ Principal Stress ʺ Concept

B.

Plastic Yield Criteria

C.

Elastic Fracture Criteria

D.

Examples: Uniaxial Tension, Torsion

III.

Tensile Properties

A.

Engineering Stress and Strain

B.

Strength Characteristics

1.

Young ʹ s modulus

2.

proportional limit (upper yield point or yield point)

3.

yield strength

4.

ultimate tensile strength

C.

Ductility

1.

elongation at fracture

2.

reduction of area at fracture

D.

Example Calculations

IV.

Additional Mechanical Properties

A.

Creep

1.

creep strength

2.

rupture life

B.

Fatigue (S/N Curves Only)

1.

endurance limit

2.

fatigue strength

C.

Fracture

1.

impact strength

2.

fracture toughness

MT 348 ‐ Outline No.

2 ‐ 2009

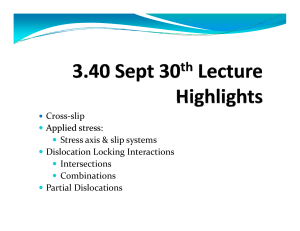

DISLOCATIONS AND SLIP PHENOMENA

I.

Introduction

A.

τ theoretical

vs.

τ observed

B.

Observation of Dislocations

1.

electron microscopy

2.

etch pitting

3.

slip lines

II.

Dislocation Configurations

A.

Edge Dislocations (b

⊥

t)

1.

definitions: burger ʹ s vector, burger ʹ s circuit, and tangent vector

2.

slip plane

B.

Screw Dislocations (b // t)

1.

ease of changing slip planes

C.

Mixed Dislocations

1.

glide loop

D.

Dislocation Sources

III.

Slip Phenomena

A.

Introduction

1.

slip system as a close ‐ packed direction in a close ‐ packed (or closest ‐ packed) plane

2.

changing slip planes a.

cross ‐ slip (screw dislocation) b.

climb (edge dislocation)

B.

Slip Systems in Metallic Crystals

C.

Resolved Shear Stress and Critical Resolved Shear Stress

1.

resolved shear stress

2.

τ

CRSS

3.

factors that affect

τ

CRSS

4.

calculate resolved shear stress by vector algebra

D.

Deformation in Single Crystals

MT 348 ‐ Outline No.

3 ‐ 2009

ELEMENTS OF GRAIN BOUNDARIES

I.

Introduction [6.1]

A.

Low Angle Boundaries [6.2]

B.

High Angle Boundaries [6.5, 6.8]

II.

Boundary Energy

A.

Grain Boundaries [6.5]

B.

Interphase Boundaries [6.9]

1.

force balance

2.

2 nd phase morphology (example: hot shortness)

III.

Grain Size [6.10]

A.

Measurement

1.

linear intercept method

2.

ASTM grain size number

B.

Mechanical Property Effects [6.11]

1.

strengthening (Hall ‐ Petch Equation)

2.

fabricability

MT 348 ‐ Outline No.

4 ‐ 2009

VACANCIES AND DIFFUSION

I.

Introduction

A.

Temperature Sensitive Processes

B.

Free Energy Decrease as ʺ Driving Force ʺ

1.

internal energy and enthalpy

2.

configurational entropy

II.

Vacancy Formation

A.

Setting up

Δ

G

B.

Calculating S k ln

P

B

P

A

C.

Minimizing

Δ

G

⎛

⎝ dn v

=

0

⎠

D.

The Result:

n v n v

=

Γ = e

−

Q r

RT

III.

Vacancy Motion

A.

Setting Up Calculation

B.

The Result:

Ae

−

Q m

RT

IV.

Solid ‐ State Diffusion

A.

Vacancy Mechanism ( Q f

+ Q m

)

B.

Interstitial Mechanism ( Q m

only)

MT 348 ‐ Outline No.

5 ‐ 2009

RECRYSTALLIZATION AND GRAIN GROWTH

I.

Introduction

A.

Cold Work / Stored Energy

B.

Release of Cold Work (Stages of Annealing)

II.

Recovery

A.

Subtle Microstructural Changes

1.

dislocation annihilation

2.

polygonization

3.

sub ‐ boundary coalescence

III.

Recrystallization

A.

Time and Temperature Dependence

1.

observations

2.

apparent activation energy, Q r

3.

ʺ recrystallization temperature ʺ

B.

Effect of Prior Strain on Recrystallization Rate

C.

Nucleation and Growth in Recrystallization

1.

ε

, T effects on nucleation

2.

ε

, T effects on growth

D.

Recrystallized Grain Size

1.

effect of prior strain

2.

effect of metal purity

3.

effect of initial grain size

E.

Dynamic Recrystallization (Hot Working)

IV.

Controlling Strength and Ductility by Working and Annealing Processes

A.

Forming Parameters

B.

Example Problems

V.

Grain Growth

A.

Driving Force

B.

Ideal Grain Growth Law ( D

2 =

D o

2 = kt )

C.

Factors Affecting Grain Growth

1.

temperature

2.

impurities or solute additions

3.

second phase particles

MT 348 ‐ Outline No.

6 –2009

SOLID SOLUTIONS

I.

Introduction

A.

Types of Solutions

1.

substitutional

2.

interstitial

B.

Intermediate Phases

1.

solid solution

2.

intermetallic compound

II.

Solubility Criteria

A.

Interstitial

1.

size considerations

2.

transition metal effect

3.

examples

B.

Substitutional

1.

size

2.

chemical similarity

3.

additional criteria

4.

examples

III.

Solid ‐ Solution Strengthening ‐ Solute/Dislocation Interactions

A.

Dislocation Stress Fields

1.

screw dislocation (shear stresses only)

2.

edge dislocation (shear and normal stresses)

B.

Solute Atom Stress Fields

1.

substitutional solute

2.

interstitial solute

C.

Stress Field Interactions

1.

edge dislocations/all solute atoms

2.

screw dislocations/interstitial solute only

3.

solute atmospheres

IV.

Solute Atmospheres and Mechanical Effects

A.

Yield Points in Low ‐ Carbon Steel

B.

Luders Bands and Stretcher Strains

MT 348 ‐ Outline No.

7 ‐ 2009

SOLIDIFICATION OF METALS

I.

Introduction

A.

The Liquid Phase

B.

Nucleation

C.

Metallic Glass

II.

Crystal Growth from the Liquid Phase

A.

Heat of Fusion

B.

Heat of Vaporization

C.

Liquid ‐ Solid Interface

III.

Liquid ‐ Solid Interface Instability

A.

Continuous Growth

B.

Lateral Growth

C.

Cellular Structure

D.

Dendritic Structure

IV.

Freezing in Alloys

A.

Scheil Equation

B.

Segregation

C.

Homogenization

MT 348 ‐ Outline No.

8 ‐ 2009

PRECIPITATION HARDENED IN ALLOYS

I.

Introduction

A.

Importance of Strengthening Technique

B.

Relative Effectiveness

C.

Basis of Technique

II.

Nucleation and Growth Theory

A.

Homogeneous Nucleation

1.

critical radius (r*)

2.

activation energy for nucleation (

Δ

G*)

3.

nucleation rate ( N )

B.

Heterogeneous Nucleation

C.

Growth Rate ( G )

D.

Transformation Rate

1.

microstructural result of high

III.

The Strengthening Mechanism of Precipitates

A.

Observations

B.

The Orowan Bowing Equation

C.

Coherency Effects

D.

Overaging

1.

loss of coherency

vs.

low

2.

particle coarsening ( ʺ Ostwald ripening ʺ )

E.

Additional Factors

1.

transition phases

2.

equilibrium phases and annealing

MT 348 ‐ Outline No.

9 ‐ 2009

METALLURGY OF STEELS

I.

The Iron ‐ Carbon Phase Diagram (pp.

562 ‐ 566)

A.

Equilibrium Phases

1.

austenite

2.

ferrite

3.

cementite (metastable)

B.

Eutectoid Decomposition (pp.

566 ‐ 574)

1.

the eutectoid reaction and pearlite

2.

pearlite growth

3.

hypoeutectoid compositions (< 0.8% C)

4.

hypereutectoid compositions (> 0.8% C)

C.

Ferritic ‐ Pearlitic Steels

1.

characteristics

2.

effect, carbon content

3.

effect, cooling rate

4.

effect, alloying

5.

AISI and SAE designations

D.

Isothermal Transformations Diagrams (pp.

583 ‐ 584, 591 ‐ 600)

1.

experimental determination

2.

examples (eutectoid, hypoeutectoid, hypereutectoid)

E.

Martensite Transformation (pp.

537 ‐ 540)

1.

mechanism

2.

microstructure and properties

3.

appearance on IT diagram

F.

Tempered Martensite (a misnomer) (pp.

639 ‐ 641)

1.

microstructure and properties

G.

Bainite Transformation (pp.

584 ‐ 591)

1.

mechanism and characteristics

2.

microstructure and properties a.

high magnification (similarity to tempered martensite) b.

low magnification

3.

austempering (isothermal transformation to bainite)

H.

Review and Practice

1.

steel transformations as nucleation and growth

2.

relation of IT diagram to phase diagram

3.

IT diagram, hypoeutectoid steel (Figure 18.37)

4.

hardenability

5.

IT diagram, hypoeutectoid low alloy steel (Figure 19.10)

I.

Continuous Cooling Diagrams

MT 348 –Outline No.

10 – 2009

THE HARDENING OF STEEL

A.

CCT vs.

IT Diagrams

B.

Characteristic Features of CCT Diagrams

1) transformation suppressed in temperature and time,

2) absence of bainite in transformation of plain carbon steels,

3) critical cooling rate,

4) bainite curves in low alloy steels

II.

Hardenability

A.

Introduction of Concept

B.

Measurement and Use of Hardenability

1.

critical diameter, D, and ideal critical diameter, DI .

2.

severity of quench, H

3.

Jominy end quench test

C.

Hardenability Variables

1.

prior

γ

grain size

2.

carbon content effect

3.

alloying effect

D.

Hardenability and Applications

1.

applications for high hardenability

2.

applications for low hardenability

III.

The Martensite Transformation

A.

Mechanism / Displacive Transformation

B.

Additional Factors

1.

tetragonality and mechanical properties,

2.

irreversibility of M reaction,

3.

carbon effect

4.

significance of retained

γ

,

5.

alloying effect,

6.

martensite hardness,

7.

lath and plate M

C.

Dimensional Changes and Quench Cracking

1.

positive transformation strain and stress,

2.

differential thermal contraction, 3) quenching stress vs

Δ

T,

3.

preventing quench cracking (small

Δ

T, martempering, reducing hardenability)

IV.

Tempering of Steel

A.

Basic Phenomena ( ʺ Stages ʺ )

B.

Microstructure and Properties

C.

Time and Temperature in Tempering

D.

Secondary Hardening