INTEGRATED MEMS STRUCTURES AND CMOS CIRCUITS FOR BIOELECTRONIC N. Reeves

INTEGRATED MEMS STRUCTURES AND CMOS CIRCUITS FOR BIOELECTRONIC

INTERFACE WITH SINGLE CELLS

N. Reeves

†

, Y. Liu

‡

, N. M. Nelson

†

, S. Malhotra

†

, M. Loganathan

†

, J.-M. Lauenstein

†

,

J. Chaiyupatumpa

†

, E. Smela

‡

, P. A. Abshire

†

Electrical and Computer Engineering

†

and Mechanical Engineering

‡

University of Maryland, College Park, Maryland 20742, USA

{smela,pabshire}@glue.umd.edu

ABSTRACT

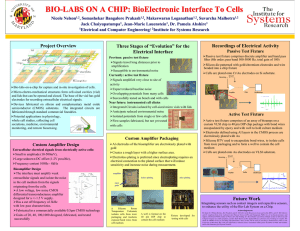

We describe a bioMEMS system for confining and electrically interfacing to single cells for long-term studies. The system comprises microvials that can be covered and uncovered by lids actuated by polypyrrole/gold hinges. Within each vial are integrated bio-amplifiers and/or other sensing circuits to form a biolab-on-a-chip. We have developed a process sequence for fabricating lidded microvials with actuated lids on

CMOS die. Initial testing of these “cell clinics” with bovine aortic smooth muscle cells yields successful sensing of the extracellular action potentials from bovine aortic smooth muscle cells using a custom VLSI bioamplifier.

1. INTRODUCTION

The integration of living cells with electronics can be used for fast medical diagnosis [1], pharmaceutical tests [2], and military or environmental applications such as detection of biological or chemical agents [3] (see [4] for a review). Using single cells instead of cell populations simplifies physiological studies of specific biochemical mechanisms and enables studies of individual responses such as metabolism or secretion [5]. This paper describes a biolab-on-a-chip that would be able to capture, immobilize, and electrically isolate cells in closable microvials. The microvials contain electrodes for noninvasive stimulation and recording of signals from cells.

We are currently working to expand the suite of sensor modalities available to study cell metabolism and growth, environment temperature and pH, and other variables of interest. Figure 1 shows three snapshots of one microvial closing.

Figure 1. From left to right: example vial without electrodes; partially closed lid; completely closed lid.

There have been several reports of stimulation and capture of single cells in the past several decades [6], with reports of simultaneously studying large numbers of single cells appearing recently. For example, Jenkner [7] was able to fabricate stimulation and recording electrodes small enough to be covered by only a single neuron. Medoro [8] reported a lab-on-a-chip impedance measurement system for cells based on closed dielectrophoretic cages.

Microfluidic methods have also been used for single cell capture [9], typically for application to cell sorting.

Difficulties with immobilization of some types of cells, like neurons, have been observed [10]. This is our primary motivation for constructing microvials with lids that can hold the cells. Additional advantages of physical barriers such as lidded microvials are the electrical isolation of cells within conductive cell medium, and the ability to monitor and control the environment around each cell.

Electrical properties have been characterized in many studies, such as eliciting an action potential from cell cultures with an electrical stimulus [11], impedance spectroscopy of biological tissue [12], and multi-electrode arrays for electrical stimulation of neurons [13]. These studies typically average responses from large populations of cells, but studying individual responses would be of an even greater value, as it would provide insight into variations among cells as well as statistical distributions of measured values.

2. LIDDED MICROVIAL FABRICATION

The prototype microvials are 100 P m x 100 P m on the inside and 10 P m to 20 P m in height, and they are made of

SU8 negative photoresist. Our goal is to fabricate vials of approximately the same size as a single cell, ~10-20 P m, to enable reliable recordings from arrays of different vials with exact positioning of the cell with respect to the electrodes. The microvials are closed by SU8/gold lids that are positioned by bilayer polymer actuators of polypyrrole (PPy) and gold. The SU8 makes the lid rigid.

Several generations of prototypes comprising arrays of

;,((( ,,, ,6&$6

153 cell clinics, have been fabricated on silicon wafers with electrodes leading to the hinges and to the interior of the vials. These structures have also been fabricated on top of custom VLSI circuitry designed to record signals from the cells within individual vials. All fabrication steps are performed at low temperature and are compatible with post-processing of the fabricated silicon die.

2.1. Actuated Hinge

Because cells have been found to escape even from deep microvials [10, 14], we have included a lid in the design that will close upon cell capture. A conjugated polymer bilayer is appropriate as a hinge because it is operable in biological fluids, has a large strain (3% in plane) that is enough to bend the hinge 180°, and requires only low voltages (less than 1 V p-p

) that are compatible with CMOS circuits and safe for the cells [15].

PPy is deposited over a layer of gold, which acts as the electrode through which potentials are applied as well as the constant volume layer of the bilayer, causing the bilayer to bend when the PPy changes volume. The PPy is electrochemically actuated: reducing the polymer pulls cations and solvent into the PPy, increasing the volume of the film, whereas oxidizing it expels the ions, decreasing the volume.

We are currently optimizing the hinge design parameters such as length, width, and layer thicknesses. The design requirements include completely covering the vial with the lid, adequate strength to withstand cell forces, and long lifetime.

2.2. Fabrication Process

Figure 2 illustrates the fabrication sequence for the lidded vials, showing two adjacent devices. (a) The first step is depositing and patterning a chromium layer onto an oxidized silicon wafer. The Cr serves as an adhesion layer between the Au and the substrate. Patterning it leaves openings for “differential adhesion,” a release method described in [16]. (b) The next step is evaporation of a gold structural layer, which defines the electrodes, hinges, and lids. The structural layer is optionally covered by a thin electroplated gold layer that roughens the surface to provide good mechanical interlocking between the PPy and gold. (c) PPy doped with dodecylbenzenesulfonate

(DBS¯) is electropolymerized (conditions are discussed in

[16]) on the hinge areas using a photoresist template; the

PPy is deposited where the resist is absent. (d) An SU-8 layer is patterned to create lids, vials, and insulation for the wires. (e) The gold layer is etched in the final step to release the hinges. The hinges are attached to the substrate over those areas covered by Cr, but free to bend in areas over the bare oxide (since Au does not stick to silicon or silicon dioxide).

Figure 2. a) Deposit and pattern adhesion layer of Cr/Au; b) evaporate and pattern structural Au layer; c) selectively electrodeposit PPy; d) deposit and pattern SU8; e) etch Au to release bilayer actuators and lids.

2.3. Integrating MEMS with CMOS Dice

We are developing techniques for fabricating the lidded vials on top of the bioamplifier die. We mount the small fabricated die (“tiny chip”) onto a handle wafer to enable standard microfabrication procedures.

Functional cell clinic prototypes comprising microvials and hinged lids have been fabricated on top of custom

VLSI circuitry (see Section 3) designed to record signals from the cells within individual vials. Photographs of a prototype in Figure 3 show an Au electrode inside an SU-

8 microvial and a hinged lid at two different positions as it moves from open to closed, confirming successful actuation. One of our longer-term goals is an on-chip potentiostat that will control the polymer actuators and complete the system-on-a-chip integration.

(a) (b)

Figure 3. Cell clinic fabricated on VLSI bioamplifier substrate. The different positions of the hinged lids in the two photos confirms successful actuation.

3. ELECTRICAL INTERFACE

3.1. Cell Manipulation

We are studying a variety of methods for loading cells into the microvials, including manual methods using pulled capillary tubes and electrical methods such as dielectrophoresis. We are also investigating the use of microfluidics to move cells along with medium into the microvials.

,,,

3.2. Custom VLSI Bioamplifier

A custom VLSI amplifier (Figure 4) has been designed for integration with the MEMS structures. An array of ten bioamplifiers has been fabricated in a commercially available 0.5 P m, 3-metal, 2-poly CMOS process, with each input taken differentially between electrodes defined in the VLSI layout and a common ground. The electrodes are “probe pads,” or openings in the top passivation layer that allow direct access to the metal layers. Electrodes have been fabricated in two sizes, 25 P m x 25 P m and 50

P m x 50 P m.

The circuit is an operational transconductance amplifier in a capacitive feedback configuration as described by [17], designed for a midband gain of 100 with supply voltages of +/-1.5 V. A large feedback resistance implemented by a

“pseudoresistor” pFET with gate connected to drain and bulk connected to source sets the low frequency cutoff, and the ratio of feedback capacitors sets the gain. The circuit has been successfully tested on the bench and with cultured cells (see section 3.3 below). The bioamplifier arrays were functionally tested in a probe station using a micromanipulator probe to provide input signals to the open pads. plated gold, which is biocompatible [19] and corrosionresistant. In addition, the electroless plating process creates a rough layer with a higher surface area.

Electroless plating is preferred for this purpose because electroplating requires an electrical connection to the plated surface that will reduce sensitivity and increase noise during measurement. We purchased the chemicals for electroless plating from Technic, Inc., and have successfully used their procedure to plate both unpackaged (bare die) and packaged (40 pin DIP) bioamplifiers.

Figure 4. The bioamplifier is an OTA with capacitive feedback as described by [17].

3.3. Bioamplifier Test Fixture

In order to test the operation of the bioamplifier in processing extracellular signals from cells, we developed the test fixture shown in Figure 5(a-b). The bioamplifier in a 40 pin DIP package was encapsulated with silicone, a small volume of cells was plated onto this fixture, the cells were left to adhere to the surface, and then signals were recorded. Figure 5 shows (a) photographs of a bioamplifier test fixture, (b) close-up views of three 25

P m x 25 P m electrodes and one bioamplifier circuit with cells, and (c) cells adhered to 150 P m x 50 P m Au/Cr electrodes over a passive Si substrate. These components will be described in more detail in the following sections.

3.3.1 Electroless Plating

The electrodes of the bioamplifier are fabricated using aluminum pads available in standard CMOS fabrication processes. Unfortunately, aluminum is not a suitable material for electrodes due to deficiencies such as poor corrosion resistance [18]. For this reason, we cover the open Al electrodes of the bioamplifier with electrolessly-

(a) (b) (c)

Figure 5. Bioamplifier test fixture: a) 40 pin DIP chip package with bond wires encapsulated by epoxy and with well to hold culture medium; b) inputs to bioamplifiers are

Au-plated electrodes; c) Au/Cr electrodes on a passive Si substrate covered with cells.

3.3.2 Packaging

Cell culture usually requires an aqueous medium to sustain cell viability. We encapsulated the bond wires with silicone to prevent shorting between them when aqueous medium is placed on the chip. We leave an opening in the center of the die using either a solid PDMS block, which must be removed after wards, or a hollow plastic pipette tip, which becomes part of the package.

Silicone was also used to construct a larger well (shown in

Figure 5(a)) to hold medium and isolate the packaging materials from the living cells.

3.3.3 Cell Plating

We use bovine aortic smooth muscle cells (BAOSMC) because they are electrically active and relatively easy to culture. We recorded signals from primary bovine aortic smooth muscle cells obtained from Cell Applications, Inc.

(San Diego, CA) which had proliferated through multiple generations. The test fixture was disinfected with 70% ethanol and then rinsed in sterile water. Cells were plated onto the fixture in sterile growth medium and allowed to adhere to the substrate for at least 12 hours in a humidified incubator at 37°C and a 5% CO

2

level. Testing was performed in non-sterile Hank’s balanced salt solution. The

,,,

ground electrode was provided by a gold wire placed in the extracellular medium.

3.3.4 Recorded Extracellular Electrical Activity

Extracellular signals from the cells are in the P V to mV range. The bioamplifier shown in Figure 4 amplifies the signals from the cells and directly drives an off-chip buffer amplifier configured for unity gain. The buffered signal is monitored using an oscilloscope, and data are acquired using a GPIB interface. An example of a recorded signal is shown in Figure 6.

50 P V

0.5 s

50 P V

50 ms

Figure 6. Extracellular electrical potential recorded from

BAOSMC cells using the bioamplifier test fixture.

The size and placement of the cell relative to the recording electrode plays an important role [20]. According to [20], the electrode should be smaller each individual cell in order to obtain proper sealing, which means it will have to be less than 15-20 P m. We will study the performance of different electrode configurations in the near future.

4. CONCLUSIONS

We have designed a platform for a biolab-on-a-chip that integrates actuation and sensing for long-term measurements on arrays of single cells. We have demonstrated functionality of all the components: the bioamplifier under bench test and in vitro conditions, the bioamplifier test fixture, and the “cell clinics” (on both silicon and VLSI circuit substrates). Integrated cell clinics will be tested with cells in the near future.

5. REFERENCES

[1] Kintzios, S., Pistola, E., Konstas, J., et al., "The Application of the Bioelectric Recognition Assay for the Detection of

Human and Plant Viruses: Definition of Operational

Parameters," Biosensors and Bioelectronics , vol. 16, pp. 467-

480, 2001.

[2] Parce, J.W., Owicki, J.C., Kercso, K.M., et al., "Detection of

Cell-Affecting Agents with a Silicon Biosensor," Science , vol.

246, pp. 243-247, 1989.

[3] Rogers, K.R. and Gerlach, C.L., "Update on Environmental

Biosensors," Env. Sci. Tech.

, vol. 33, pp. 500A-506A, 1999.

[4] Kovacs, G.T.A., "Electronic Sensors with Living Cellular

Components," Proc. IEEE , vol. 91, pp. 915-929, 2003.

[5] Chen, P., Xu, B., Tokranova, N., et al., "Amperometric

Detection of Quantal Catecholamine Secretion from Individual

Cells on Micromachined Silicon Chips," Analytical Chemistry , vol. 75, pp. 518-524, 2003.

[6] Petersen, K., "Biomedical Applications of MEMS," IEEE

EDM , New York City, 1996.

[7] Jenkner, M., Müller, B. and Fromherz, P., "Interfacing a

Silicon Chip to Parts of Snail Neurons Connected by Electrical

Synapses," Biological Cybernetics , vol. 84, pp. 239-249, 2001.

[8] Medoro, G., Manaresi, N., Leonardi, A., et al., "A Lab-on-a-

Chip for Cell Detection and Manipulation," IEEE Sensors , vol.

3, pp. 317-325, 2003.

[9] Beebe, D.J., "Microfabricated Fluidic Devices for Single-

Cell Handling and Analysis," Emerging Tools for Single-Cell

Analysis , vol. 5, pp. 95-113, 2000.

[10] Jager, E.W.H., Immerstrand, C., Peterson, K.H., et al.,

"The Cell Clinic: Closable Microvials for Single Cell Studies,"

Biomedical Microdevices , vol. 4, pp. 177-187, 2002.

[11] Whittington, R.H., Gilchrist, K.H., Giovangrandi, L., et al.,

"A Multi-Parameter, Feedback-Based Electrical Stimulation

System for Cardiomyocyte Cultures," Transducers '03 , 2003.

[12] Metz, S., Oppliger, F., Holzer, R., et al., "Fabrication and

Test of Implantable Thin-Film Electrodes for Stimulation and

Recording of Biological Signals," IEEE-EMBS Special Topic

Conf. on Microtech. in Medicine & Biology , Lyon, France, 2000.

[13] Rutten, W., Mouveroux, J.-M., Buitenweg, J., et al.,

"Neuroelectronic Interfacing with Cultured Multielectrode

Arrays toward a Cultured Probe," Proc. IEEE , vol. 89, pp. 1013-

1029, 2001.

[14] Pine, J., "Microdevices for Studies of Cultured Neural

Networks," Proc. AIP Conf.

, vol. 501, pp. 203-218, 2000.

[15] Smela, E., "Conjugated Polymer Actuators for Biomedical

Applications," Advanced Materials , vol. 15, pp. 481-494, 2003.

[16] Smela, E., "Microfabrication of PPy Microactuators and

Other Conjugated Polymer Devices," J. Micromech. Microeng.

, vol. 9, pp. 1-18, 1999.

[17] Harrison, R.R. and Charles, C., "A Low-Power Low-Noise

CMOS Amplifier for Neural Recording Applications," IEEE

JSSC , vol. 38, pp. 958-965, 2003.

[18] Kovacs, G.T.A., Micromachined Transducers Sourcebook .

WCB McGraw-Hill, Boston, 1998.

[19] Geddes, L.A., Electrodes and the Measurement of

Bioelectric Events . Wiley-Interscience, New York, 1972.

[20] Regehr, W.G., Pine, J., Cohan, C.S., et al., "Sealing

Cultured Invertebrate Neurons to Embedded Dish Electrodes

Facilitates Long-Term Stimulation and Recording," J. Neurosci.

Methods , vol. 30, pp. 91-106, 1989.

6. ACKNOWLEDGMENTS

We thank the MOSIS service for providing chip fabrication.

These circuits will be used for teaching a bioelectronics course at the University of Maryland. We thank the National Science

Foundation for support of this work through awards 0225489,

0238061, and 0139401. We thank the MERIT program at the

University of Maryland for support of coauthors JML and JC.

We thank the Bioprocess Scaleup Facility at the University of

Maryland and Chesapeake PERL, Inc. for their support with laboratory space and equipment as well as technical assistance with cell culturing. We thank Dr. Mark Martin of JHU Applied

Physics Lab for providing test samples and Dr. Reza Ghodssi for use of lab equipment.

,,,