he t er v

advertisement

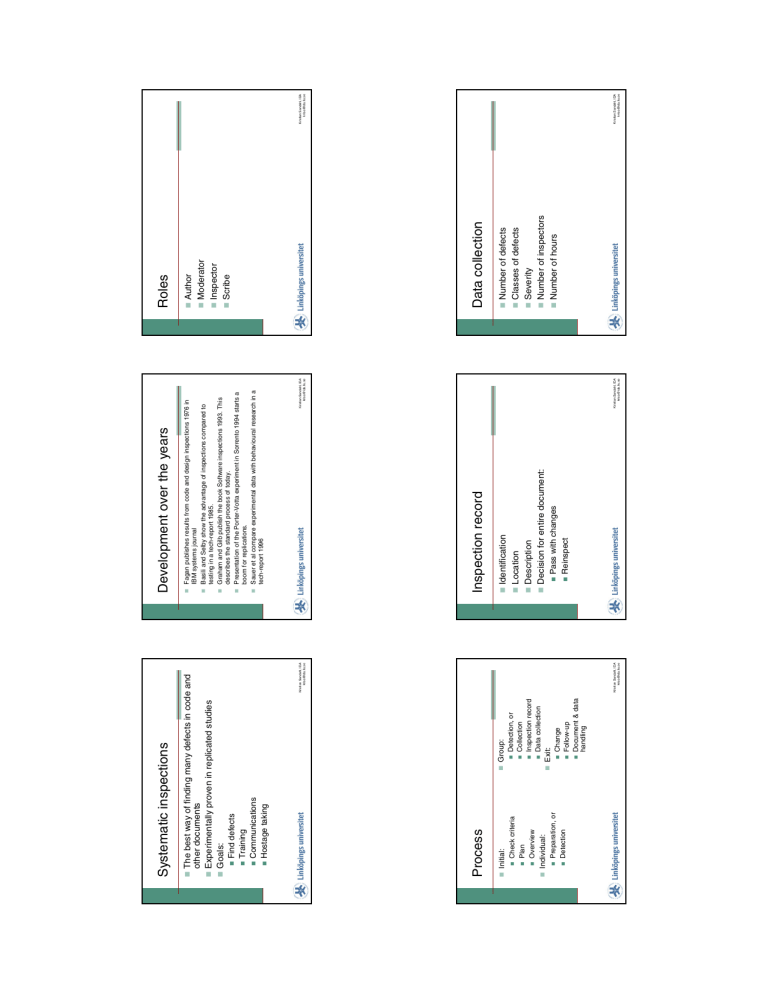

Find defects Training Communications Hostage taking Individual: Preparation, or Detection Initial: Check criteria Plan Overview Process Group: Detection, or Collection Inspection record Data collection Exit: Change Follow-up Document & data handling Kristian Sandahl, IDA krisa@ida.liu.se Kristian Sandahl, IDA krisa@ida.liu.se Number of inspectors Kristian Sandahl, IDA krisa@ida.liu.se Severity Decision for entire document: Number of hours Classes of defects Description Pass with changes Reinspect Number of defects Location Data collection Scribe Inspector Moderator Author Roles Identification Inspection record Kristian Sandahl, IDA krisa@ida.liu.se testing in a tech-report 1985. Graham and Gilb publish the book Software inspections 1993. This describes the standard process of today. Presentation of the Porter-Votta experiment in Sorrento 1994 starts a boom for replications. Sauer et al compare experimental data with behavioural research in a tech-report 1996 Basili and Selby show the advantage of inspections compared to IBM systems journal Fagan publishes results from code and design inspections 1976 in The best way of finding many defects in code and other documents Experimentally proven in replicated studies Goals: Development over the years Systematic inspections Kristian Sandahl, IDA krisa@ida.liu.se Kristian Sandahl, IDA krisa@ida.liu.se Id Kristian Sandahl, IDA krisa@ida.liu.se Majority values: up to 3.5 h preparation per document up to 3 h inspection time up to 4000 lines of code 2 to 6 people involved 90 percentile = 30 Median number of defects = 8 Kristian Sandahl, IDA krisa@ida.liu.se Kristian Sandahl, IDA krisa@ida.liu.se line (12 minutes per page) Size of document have negative effect on DFR, max recommendation 5000 lines A certain project is better than two of the others 4 inspectors seems best (not significant) Analysis performed by Henrik Berg, LiTH-MAT-Ex-199908 Preparation time per code line typically 0.005 hours per Usage-based Perspective-based Scenario Checklist 214 code inspections from 4 projects at Ericcson Kristian Sandahl, IDA krisa@ida.liu.se Class. Regression wrt defect detection ratio Description Reading techniques Practical investigation Loc. Our inspection record inspector 3 defects, frequent defects, or random defects Popular mind map: The Ishikawa diagram Parameters: Defect category Visible consequences Did-detect Introduced Main Should-detect cause Reason Performed regularly for severe inspector 1 inspector 3 Main cause Main cause Main cause Main cause Main cause Kristian Sandahl, IDA krisa@ida.liu.se Problem Kristian Sandahl, IDA krisa@ida.liu.se Fewer remaining defects inspector 2 Root-cause analysis Many remaining defects inspector 2 inspector 1 Capture-recapture Kristian Sandahl, IDA krisa@ida.liu.se False positives Kristian Sandahl, IDA krisa@ida.liu.se Inspection data Coding Kristian Sandahl, IDA krisa@ida.liu.se Inspection data Test-cases Inspection Inspection Inspection data data data Design number of inspectors, compare with testing Enthusiasts: Vary things, such as PI – DD, you got from that Kristian Sandahl, IDA krisa@ida.liu.se Record the result as we did, reflect on the value Improvement: reduce variation, increase precision Analysis Be at least 3 inspectors Control – adjust the process formal document Practice inspection on code from a lab, or a Appraisal – defect detection Assurance – prediction of defects Home assignment no 9 Inspections in quality assurance Defect list Two experts Audit Review Structured walk-through Good data recording Peer review Repository Desk check Weaker methods Good reading techniques Inspectors ”Optimal” method Calender time Person-hours Cost of quality Kristian Sandahl, IDA krisa@ida.liu.se