Mechanical Q & A 2000 General: Mecklenburg County Engineering & Building Standards

advertisement

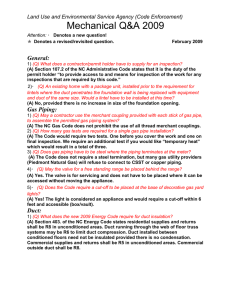

Mecklenburg County Engineering & Building Standards Mechanical Q & A 2000 Attention: 4 Denotes a new question! General: 1) 2) 3) 4) 5) 6) 4 August 2000 (Q) Should an inspector fail the residential HVAC mechanical contractor’s inspection, for missing equipment or defects in the installation of a secondary gas appliance installed by others (i.e. gas logs, gas grills, gas lights, etc)? (A) NO! Each contractor must stand on his own with respect to inspection requests, inspections and there associated results. (Exception; an inspector may elect to hold up the HVAC contractor’s inspection on Jobs missing secondary permits). (Q) What is the definition of a “Sleeping Room”? (A) SEE INTERPRETATION (Dec, 1999) (Q) Are installers/contractors allowed to cut wood framing when installing or replacing HVAC systems? (A) Yes! Provided that proper heading off of cut members/timbers is properly completed. The mechanical inspector may require framing to be inspected (permit) by the building inspector. Are contractors required to run load calculations on the installation/replacement of HVAC equipment? (A) Yes! Load calculations are always required! (Q) When should seismic concerns be addressed, in the field with a contractor or during the design phase with the engineer? (A) Seismic design is the responsibility of an engineer and shall be submitted with the construction documents during plan submittal. (Q) Is a contractor required to install the thermostat and all the register the final mechanical inspection (residential)? (A) The mechanical contractor is responsible for the installation of the thermostat and registers. The contractor may elect to install the thermostat at start-up to circumvent construction damage. The registers are typically not installed until after all floor coverings are installed. Due to construction schedules, these items may be installed after the final mechanical inspection. Mecklenburg County Engineering & Building Standards Mechanical Q & A 2000 Equipment 1) 2) 3) 4) 5) 6) 7) 8)4 (Q) Is the bottom of a furnace required to be blanked off (sealed) when utilizing side or rear returns? (A) YES! Volume III section 605 and Volume VII section 1901 require that duct systems be sealed and many manufacturers note the blanking off or sealing of the bottom of equipment in their installation instructions. (Q) Can the primary drain of equipment installed in a crawl space, exit the foundation “below exterior grade” and tie into a dry well or French drain? (A) NO! The condensate drain must exit the foundation above grade prior to connection to a French drain or dry well. (Q) Can an approved gas decorative appliance (gas logs) be installed under stairs in a residence/ (A) Yes! Gas appliance may be installed under stairs in a residence provided that the walls/stairs are covered with 5/8” thick drywall and sealed (mudded) (Q) Is PVC cleaner required on condensate piping? (A) Yes! (Q) May wood be used to support the air handler when installed inside a pan? (A) DOI states that it is acceptable provided the equipment is approved for zero clearance and the contractor uses treated wood. (Q) May a manufacturer of a listed product, alter their installation instructions by issuing a letter from their design engineer? (A) No! A letter altering installation instructions of listed products must come from the listing agency. (Q) Is it permissible to install a float switch in addition to the installation of a secondary condensate drain? (A) Yes! (Q) May an inspector disallow the use of a safety pan float switch in instances where a conventional condensate drain could have been installed? (A) No! The contractor has the right to install whichever he/she may choose. Mecklenburg County Engineering & Building Standards Mechanical Q & A 2000 Gas Piping: 1) 2) 3) 4) 5) 6) 7) 84 (Q) May an appliances 2 psi regulator (between the appliance and its gas cock) be installed on the rough inspection? (A) Yes! (Q) What is the proper way to test a new set of gas logs installed on its own 2 psi pipe system? (A) Install a test gauge (30 lb max) on the end of the 2 psi system at the meter location and pressure test back to the appliance. Placing the 2 psi regulator under test is prohibited. A spool piece IS REQUIRED to take its place. (Q) Does the Code allow the use of flex gas pipe connectors on outside appliances like a gas pack? (A) Yes! Provided they are approved for exterior installations. (Q) Where is the correct place to install an appliance drip leg (Furnace/Water heater)? (A) Manufacturer’s installation instructions usually require the sediment trap to be installed between the appliance and the 100% cutoff. (Q) What is the definition of conspicuous place as it is referenced in the Code for condensate disposal? (A) DOI States that it would be a place where you would not normally see water discharging (i.e., eves, over doors or windows etc) It can not discharge in the same location as the primary condensate drain. (Q) Is the use of steel gas piping for protection allowed on CSST flexible gas piping systems? (A) No! Not at the present time. (Q) Is the use of aluminum flexible conduit allowed in CSST gas pipe systems? (A) No! All CSST manufacturers require that “steel” flexible conduit be used where referenced in their respective installation instructions. (Q) What type of protection is required on copper/CSST piping installed outside a structure? (A) Copper and CSST gas piping installed outside must be protected with a PVC sleeve (schedule 40 min.) from a point 3 inches below grade to a point 36 inches above grade. (per DOI letter) Mecklenburg County Engineering & Building Standards Mechanical Q & A 2000 Duct Systems: 1) 2) 3) 4) 5) 6) 7) 8) 9) (Q) Are the inside seams of boots required to be sealed with mastic? (A) NO! ALL seams in duct systems are required to be sealed but nothing requires a boots seams to be sealed on the inside. The contractor/installer may elect to seal the outside seams instead. The downside is that an inspector reserves the right to spot check the boot seams to assure they are sealed and this would require the partial removal of the insulation. It would then be the contractors/installers responsibility to re-wrap the boot. (Q) May the installation of polyethylene plastic to cover the exposed earth, reduce the 4” duct clearance requirement of the Mechanical Code? (A) NO! A minimu of 4” is required. (Q) May 1.5” plastic web strap be used to support flex or fibrous duct? (A) Yes! Note: (DOI is currently looking at the flame spread rating and its applicability) ( Q) Is a sleeve required to join separate pieces of flex duct together? (A) Yes! The Air Diffusion Council (ADC) requires that a joining sleeve be used to connect separate pieces of flex duct. The liner is required to be secured with 2 wraps of UL181 tape and then a panduit strap is applied to the joint. The insulation wrap is secured in place with either 2 wraps of UL181 tape or a panduit strap or both. (Q) Does the Code allow flex duct to sag between hanger/supports? (A) Yes! The flex duct may sag a maximum of ½ inch per foot maximum. (Q) May a contractor install/cut in a starting collar to a factory formed radius fitting? (A) No! SMACNA requirements would not allow the installation of collars into a radius fitting. (Q) When installing flex duct runs, what must the installer due with the excessive flex? (A) Excessive flex must be removed from each duct run. Flex runs are required to be as direct as possible and ONLY the amount of flex to complete the run and its required radiuses is to be installed. May a single 16” flex duct be used for the supply or return on a 3 ton (36,000 BTU) piece of equipment? (A) No! Volume VII (1902.2 & 1903.1) requires the total unobstructed area of a return or supply air ducts or openings to a central A/C unit and/or heat pump shall be accordance with manufacturers installation instructions, BUT NOT LESS THAN 6 INCHES FOR EACH 1,000 Btu/h NOMINAL COOLING. (Q) How often must a boot be secured? (A) The boot must be secured to the structure on at least two opposing sides. A manufactured system is approved for use with ceiling grids. Mecklenburg County Engineering & Building Standards Mechanical Q & A 2000 Duct Systems: 10) (Q) Can white vinyl flex plastic pipe be used on bathroom exhaust fans? (A) No! Work performed under volume III would require exhaust duct to meet the requirements of chapter six (6) of volume III which would require UL 181 flex duct or metal piping of a nonabsorbent, moisture/corrosion resistant nature. Note: Volume VII currently does not have a restriction on white vinyl plastic pipe. 11) 4 (Q) May floor joists be panned and used as a return plenum? (A) Yes! Provided they meet the requirements set forth in 1901.1.1 section 6. (i.e. isolation from structure utilizing tight fitting stops and 2” nominal (1.5” actual) wood.) Mecklenburg County Engineering & Building Standards Mechanical Q & A 2000 Venting: 1) (Q) What is minimum clearance for B-Vent from combustible materials? (A) The minimum clearance from combustible material (ie, wood, shingles, drywall, etc) is 1”.