Catching up with 2014 NC Electrical Code Updates from

advertisement

Catching up with 2014 NC

Electrical Code

Updates from

Part One – 2014

Enactment, 2014 NC

Amendments and

NFPA TIAs and Errata

Currently we have been advised by NCDOI that the 2014 NC

Electrical Code will go into effect on April 1st, 2016.

NCDOI:

http://www.ncdoi.com/OSFM/Engineering_and_Codes/Documents/2014%

20Edition%20-%20Effective%20April%201%202016.pdf ; 2014 NC

Electrical Code

NFPA: http://www.nfpa.org/codes-and-standards/free-access ; 2011 NEC,

2011 TIAs, 2011 Errata, 2014 NEC, 2014 TIAs, 2014 Errata

Date:

December 31, 2015

To:

All customers

From:

Jim Bartl, Director of Code Enforcement

Re:

2014 NC Electrical Code effective date

In the NC Building Code Council (BCC) meeting of December 15, the Council adopted the new 2014 NC Electrical Code. In doing so, the

BCC set an effective date of April 1, 2016, subject to the NC Rule Review Commission offering no changes to the BCC approved 2014 NC

Electrical Code.

Department policy on the transition period as applied to the 2014 NC Electrical Code

The Department maintains a code transition policy dating to 1997, which allows a 90-day grace period for projects under review, provided

they gain a permit within 90 days of the code effective date. We will apply this policy to the new 2014 NC Electrical Code. Consequently,

projects with permit applications prior to April 1, 2016 may use the current 2011 NC Electrical Code, provided they gain a permit by June

30, 2016. All other projects must use the new 2014 NC Electrical Code for project permit applications on or after April 1, 2014.

The Department’s 1997 policy provides two exceptions to the above transition period, which also apply here.

Exception 1: if a project requires lengthy review by City, State or Federal agencies, the Code Enforcement Director or his designee will

select the appropriate year code to apply to the project.

Exception 2: if a project is multi-phased, with construction time in excess of twelve (12) months, the applicable year code will be selected

by the Code Enforcement Director or his designee at the preliminary code review meeting.

It is very important that professionals monitor their work closely to carefully determine when a project’s design basis must switch to the new

2014 NC Electrical Code to comply with the above transition period and the Department’s related policy. While state law requires us to

issue a permit on any project compliant with the effective code, the burden is on the owner’s team to estimate when your permit will be

issued. Projects not covered by Exception 1 or Exception 2 above, and not permitted by June 30, 2016 must comply with the 2014 NC

Electrical Code, regardless of when they entered the system for permitting.

Feel free to contact me, Director of Plan Review & Permitting Patrick Granson or Electrical Code Administrator Gary Mullis, if you have

questions on the 2014 NC Electrical Code effective dates.

Item 6.1: Retain language from 2011 NEC for 110.26

(E) (2) – No Cost Impact (NEW AMENDMENT)

AMENDMENT 110.26(E)(2)

Amend NEC 2014, page 41:

(2) Outdoor.

(a) Installation Requirements. Outdoor electrical equipment shall be

installed in suitable enclosures and shall be protected from accidental

contact by unauthorized personnel, or by vehicular traffic, or by

accidental spillage or leakage from piping systems. The working

clearance space shall include the zone described in 110.26(A). No

architectural appurtenance or other equipment shall be located in this

zone.

(b) Deleted.

Item 6.2: Retain Existing NC Electrical Code Amendment to 210.8(A)

(3) – No Cost Impact

Amend NEC 2014, page 54:

(3) Outdoors

Exception No. 1 to (3): Receptacles that are not readily accessible

and are supplied by a branch circuit dedicated to electric snowmelting, deicing, or pipeline and vessel heating equipment shall be

permitted to be installed in accordance with 426.28 or 427.22, as

applicable.

Exception No. 2 to (3): A single outlet receptacle supplied by

dedicated branch circuit which is located and identified for specific

use by a sewage lift pump.

Item 6.3: Retain language from 2011 NEC for

210.8(A) (7) {residential GFCI requirements} – No

Cost Impact (NEW AMENDMENT)

AMENDMENT 210.8(A)(7)

Amend NEC 2014, page 54:

(7) Sinks — located in areas other than kitchens where receptacles

are installed within 1.8 m (6 ft.) of the outside edge of the sink.

Item 6.4: Remove GFCI requirement for

kitchen dishwasher branch circuit. This was

not a requirement in the 2011 NEC. – No Cost

Impact (NEW AMENDMENT)

AMENDMENT 210.8(D)

Amend NEC 2014, page 55:

210.8(D) Kitchen Dishwasher Branch Circuit. Deleted

Item 6.5: Retain location requirements from 2011 NEC for

AFCI Protection and remove term “readily”. – No Cost

Impact (NEW AMENDMENT)

Amend NEC 2014, page 56:

210.12 Arc-Fault Circuit-Interrupter Protection. Arc-fault circuitinterrupter protection shall be provided as required in 210.12(A) (B),

and (C). The arc-fault circuit interrupter shall be installed in an

accessible location.

(A) Dwelling Units. All 120-volt, single-phase, 15- and 20-ampere

branch circuits supplying outlets or devices installed in dwelling unit

kitchens, family rooms, dining rooms, living rooms, parlors, libraries,

dens, bedrooms, sunrooms, recreation rooms, closets, hallways, or

similar rooms or areas shall be protected by any of the means

described in 210.12(A)(1) through (6):

Item 6.7: Revise to reflect NC Electrical Code Amendment

with January 1, 2015 effective date. - No Cost Impact (NO

CHANGE)

Amend NEC 2014, page 62:

210.52 (I) Foyers. Foyers that are not part of a hallway in

accordance with 210.52(H) and that have an area that is greater

than 5.6 m2 (60 ft2) shall have at least one receptacle.

Item 6.8: Retain Existing NC Electrical Code Amendment to

250.50 – No Cost Impact (NO CHANGE)

Amend NEC 2014, page 117:

250.50 Grounding Electrode System. All grounding electrodes as described in

250.52(A)(1) through (A)(7) that are available at each building or structure served

shall be bonded together to form the grounding electrode system. Where none of

these grounding electrodes exist, one or more of the grounding electrodes

specified in 250.52(A)(4) through (A)(8) shall be installed and used.

Item 6.9: Modify 250.53 (A) (2) to match D-1 Agenda Item

– No Cost Impact (NO CHANGE)

Amend NEC 2014, page 118:

(2) Supplemental Electrode Required.

Exception No. 1: If a single, rod, pipe, or plate grounding electrode

has a resistance to earth of 25 ohms or less, the supplemental

electrode shall not be required.

Exception No. 2: The supplemental ground electrode shall not be

required at temporary electrical service installation (saw service

pole) at construction site for one and two-family residences,

provided the temporary electrical service does not exceed 150

volts to ground or 100A.

Item 6.10: Retain Table and Language of 2011 NEC related to sizing of Dwelling

Services and Feeders – No Cost Impact (NEW AMENDMENT)

AMENDMENT 310.15(B)(7)

Amend NEC 2014, page 160:

(7) 120/240-Volt, 3-Wire, Single-Phase Dwelling Services and Feeders.

For individual dwelling units of one-family, two-family, and multifamily

dwellings, conductors, as listed in Table 310.15(B)(7), shall be permitted as

120/240-volt, 3-wire, single-phase service-entrance conductors, service-lateral

conductors, and feeder conductors that serve as the main power feeder to

each dwelling unit and are installed in raceway or cable with or without an

equipment grounding conductor. For application of this section, the main

power feeder shall be the feeder between the main disconnect and the

panelboard that supplies, either by branch circuits or by feeders, or both, all

loads that are part or associated with the dwelling unit. The feeder conductors

to a dwelling unit shall not be required to have an allowable ampacity rating

greater than their service-entrance conductors. The grounded conductor shall

be permitted to be smaller than the ungrounded conductors, provided the

requirements of 215.2, 220.61, and 230.42 are met.

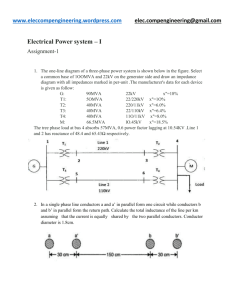

Table 310.15(B)(7) Conductor Types and Sizes for

120/240-Volt, 3-Wire, Single-Phase Dwelling Services and Feeders. Conductor

Types RHH, RHW, RHW-2, THHN, THHW, THW, THW-2, THWN, THWN-2, XHHW,

XHHW-2, SE, USE, USE-2

Service or

Feeder

Rating

(Amperes)

Copper

Aluminum

or

CopperClad

Aluminu

m

100

4

2

110

3

1

125

2

1/0

150

1

2/0

175

1/0

3/0

200

2/0

4/0

225

3/0

250

250

4/0

300

300

250

350

350

350

500

400

400

600

Item 6.11: Retain Existing NC Electrical Code Amendment

to 334.15 (C) – No Cost Impact (NO CHANGE)

Amend NEC 2014, page 204:

(C) In Unfinished Basements. Where cable is run at angles with joist in

unfinished basements it shall be permissible to secure cables not smaller than

two 6 AWG or three 8 AWG conductors directly to the lower edges of the

joists. Smaller cables shall be run either through bored holes in joists or on

running boards. Nonmetallic-sheathed cable installed on the wall of an

unfinished basement shall be permitted to be installed in a listed conduit or

tubing or shall be protected in accordance with 300.4. Conduit or tubing shall

be provided with an insulating bushing or adapter at the point the cable

enters the raceway. The sheath of the nonmetallic-sheathed cable sheath

shall extend through the conduit or tubing and into the outlet or device box

not less than 6 mm (1/4 in.). The cable shall be secured within 300 mm (12 in.)

of the point where the cable enters the conduit or tubing. Metal conduit,

tubing, and metal outlet boxes shall be connected to an equipment

grounding conductor complying with the provisions of 250.86 and 250.148.

Item 6.12: Revise to reflect NC Electrical Code Amendment with January 1,

2015 effective date. – No Cost Impact (NO CHANGE)

AMENDMENT 404.2(C)(8)

Amend NEC 2014, page 278:

(8) Where installed in residential one- and two- family dwellings.

Item 6.13: Remove term “readily” from 406.4 (D) and add new exception – No

Cost Impact (NEW AMENDMENT)

Amend NEC 2014, page 282:

(D) Replacements. Replacement of receptacles shall comply with 406.4(D)(1)

through (D)(6), as applicable. Arc-fault circuit-interrupter type and ground-fault

circuit-interrupter type receptacles shall be installed in an accessible location.

(4) Arc-Fault Circuit-Interrupter Protection. Where a receptacle

outlet is supplied by a branch circuit that requires arc-fault circuitinterrupter protection as specified elsewhere in this Code, a

replacement receptacle at this outlet shall be one of the following:

(1) A listed outlet branch-circuit type arc-fault circuit-interrupter

receptacle

(2) A receptacle protected by a listed outlet branch-circuit type

arc-fault circuit-interrupter type receptacle

(3) A receptacle protected by a listed combination type arc-fault

circuit-interrupter type circuit breaker

This requirement becomes effective January 1, 2014.

Exception: Non-grounding type receptacles.

Item 6.14: For one- and two-family residences, remove term

“readily” from 422.5 – No Cost Impact (NEW AMENDMENT)

Amend NEC 2014, page 303:

422.5 Ground-Fault Circuit-Interrupter (GFCI) Protection. The device

providing GFCI protection required in this article shall be readily

accessible.

Exception: For one- and two-family residences, the device providing

the GFCI protection required in this article shall be accessible.

Article 10 - ADMINISTRATIVE SECTION

10.1 TITLE

These Administrative Regulations along with the requirements included in the 2014 Edition of the National Electrical Code (NFiPA70 - 2014) as adopted by the North Carolina Building Code Council on December 15, 2015, to be effective April 1, 2016, with the

following amendments: (1) 110.26(E)(2), (2) 210.8(A)(3) (Exception No. 2), (3) 210.8(A)(7), (4) 210.8(D), (5) 210.12(A), (6) 210.52(I), (7)

250.50, (8) 250.53(A)(2) (Exception No. 2), (9) 310.15(B)(7), (10) 334.15(C), (11) 404.2(C)(8), (12) 406.4(D), (13) 422.5 shall be known

as the North Carolina Electrical Code, and may be cited as such or as the State Electrical Code; and will be referred to herein as

“the code” or “this code”.

10.2 SCOPE

Article 80 Administration and Enforcement of the code is hereby not adopted and does not apply for this code. For Scope and

Exceptions to Applicability of Technical Codes, refer to the North Carolina Administrative Code and Policies.

10.3 PURPOSE

The purpose of the code is to provide minimum standards, provisions and requirements of safe and stable design, methods of

construction and uses of materials in buildings or structures hereafter erected, constructed, enlarged, altered, repaired, moved,

converted to other uses of demolished and to regulate the electrical systems, equipment, maintenance, use and occupancy of

all buildings or structures. All regulations contained in this code have a reasonable and substantial connection with the public

health, safety, morals, or general welfare, and their provisions shall be construed liberally to those ends.

10.4 ADMINISTRATION

For administrative regulations pertaining to inspection (rough-ins and finals), permits and Certificates of Electrical Compliance, see

When the provisions of other

codes are determined to be contrary to the requirements of this code, this

code shall prevail.

local ordinances and the North Carolina Administrative Code and Policies.

TIAs

Reference: 516.3(A)(1)(a) and 516.10(A)

TIA 14-1

(SC 13-8-16/TIA Log #1096)

Note: Text of the TIA issued and incorporated into the text of 516.3(A)(1)(a) and 516.10(A), therefore no separate

publication is necessary.

1. Remove the indication that 516.3(A)(1)(a) is to be deleted and renumber as needed. This is an error in ROC Comment

14-67 to read as follows:

(A) Zone Classification of Locations.

(1) For the purposes of this Article, the Zone system of electrical area classification shall be applied as follows:

(a) The inside of open or closed containers or vessels shall be considered a Class I, Zone 0 location.

(b) A Class I, Division 1 location shall be permitted to be alternatively classified as a Class I, Zone 1 location.

(c) A Class I, Division 2 location shall be permitted to be alternatively classified as a Class I, Zone 2 location.

(d) A Class II, Division 1 location shall be permitted to be alternatively classified as a Zone 21 location.

(e) A Class II, Division 2 location shall be permitted to be alternatively classified as a Zone 22 location. [33: 6.2.2]

2. Change the second to last sentence of 516.10(A) and add an informational note as shown in ROC Comment 14-67 to

read as follows:

The installation of electrostatic spraying equipment shall comply with 516.10(A)(1) through (A)(10). Spray equipment

shall be listed except as otherwise permitted. All automatic electrostatic equipment systems shall comply with

516.4(A)(1) through (A)(9).

Informational Note: For more information on listing and approval of electrostatic spray equipment, see NFPA 332011, Standard for Spray Application Using Flammable or Combustible Materials, Section 11.5. NFPA 33 permits

certain electrostatic spray equipment to be approved for use when additional mitigation equipment is employed.

Issue Date: August 1, 2013

Effective Date: August 20, 2013

TIAs

Reference: 445.20

TIA 14-2

(SC 13-10-5/TIA Log #1117)

1. Revise 445.20 to read as follows:

445.20 Ground-Fault Circuit Interrupter Protection for Receptacles on 15 kW or Smaller Portable

Generators. All

125-volt, single-phase, 15-and 20-ampere receptacle outlets that are a part of a 15-kW or smaller

portable generator either

shall have ground-fault circuit-interrupter protection for personnel integral to the generator or receptacle

or shall not be

available for use when the 125/250-volt locking-type receptacle is in use. If the generator was

manufactured or

remanufactured prior to January 1, 2015, listed cord sets or devices incorporating listed ground-fault

circuit-interrupter

protection for personnel identified for portable use shall be permitted. If the generator does not have a

125/250-volt

locking-type receptacle, this requirement shall not apply.

Issue Date: October 22, 2013

Effective Date: November 11, 2013

TIAs

Reference: Table 820.154(a)

TIA 14-3

(SC 14-3-8/TIA Log #1120)

Revise Table 820.154(a) as follows:

(PRINT COPY FROM NFPA WEBSITE)

TIAs

Reference: 520.45

TIA 14-4

(SC 14-8-16 / TIA Log #1151)

1. Revise 520.45 to read as follows:

520.45 Receptacles. Receptacles for electrical equipment on stages

shall be rated in amperes. Conductors supplying receptacles

shall be in accordance with Articles 310 and 400. Section 406.15 shall

not apply.

TIAs

Reference: 530.21(A)

TIA 14-5

(SC 14-8-17 / TIA Log #1152)

1. Revise 530.21(A) to read as follows:

530.21 Plugs and Receptacles.

(A) Rating. Plugs and receptacles, including cord connectors and flanged

surface devices, shall be rated in amperes. The voltage

rating of the plugs and receptacles shall be not less than the nominal circuit

voltage. Plug and receptacle ampere ratings for ac

circuits shall not be less than the feeder or branch-circuit overcurrent device

ampere rating. Table 210.21(B)(2) shall not apply.

Section 406.15 shall not apply.

TIAs

Reference: 590.6(A)(1)

TIA 14-6

(SC 14-8-15 / TIA Log #1133)

1. Revise 590.6(A)(1) to read as follows:

590.6 Ground-Fault Protection for Personnel.

(A) Receptacle Outlets.

(1) Receptacle Outlets Not Part of Permanent Wiring. All 125-volt, single-phase, 15, 20-, and 30-ampere receptacle outlets that are not a part of the permanent

wiring of the building or structure and that are in use by personnel shall have

ground-fault circuit-interrupter protection for personnel. In addition to this

required ground-fault circuit-interrupter protection, listed cord sets or devices

incorporating listed ground-fault circuit-interrupter protection for personnel

identified for portable use shall be permitted.

TIAs

Reference: 517.41(E)

TIA 14-7

(SC 14-10-2 / TIA Log #1157)

1. Revise Article 517.41(E) to read as follows:

(E) Receptacle Identification. The cover plates for the electrical

receptacles or the electrical receptacles themselves supplied from

the essential electrical system shall have a distinctive color or marking

so as to be readily identifiable. [99:6.5.2.2.4.2]

TIAs

Reference: 625.17(B)

TIA 14-8

(SC 15-4-5 / TIA Log #1162)

1. Revise Section 625.17(B) to read as follows:

(B) Output Cable to the Electric Vehicle. The output cable to the

electric vehicle shall be Type EV, EVJ, EVE, EVJE, EVT, or EVJT flexible

cable as specified in Table 400.4. The output cable shall have an

ampacity as specified in Table 400.5(A)(1) or, for 8 AWG and larger, in

the 60°C columns of Table 400.5(A)(2).

ERRATA

Reference: Various

Errata No.: 70-14-1

The National Electrical Code Correlating Committee notes the following errors

in the 2014 edition of NFPA 70, National Electrical Code.

How to Use this Errata Sheet

This is a list of errata to the first printing of the 2014 NEC®.

1. In Section 200.7, remove shading from the first line of the title. Add shading to

“or Gray” in the second line.

2. In Table 220.3, on list item “Electric vehicle charging system branch-circuit

and feeder calculations,” change the section reference to 625.41.

3. Revise the title of Table 220.44 as follows: “Table 220.44 Demand Factors for

Non-Dwelling Receptacle Loads”

ERRATA

4. In Section 400.4, insert as first sentence “Flexible cords and flexible cables

shall conform to the description in Table 400.4.”

5. In heading above 400.30, Part II should be Part III.

6. In 422.51(A), delete “identified for portable use”.

7. Replace Section 490.48 with the following:

490.48. Substation Design, Documentation, and Required Diagram. (print from

NFPA website)

(A) Design and Documentation. Substations shall be designed by a qualified

licensed professional engineer. Where components or the entirety of the

substation are listed by a qualified electrical testing laboratory, documentation

of internal design features subject to the listing investigation shall not be

required. The design shall address but not be limited to the following topics and

the documentation of this design shall be made available to the authority

having jurisdiction.

ERRATA

(1) Clearances and exits

(2) Electrical enclosures

(3) Securing and support of electrical equipment

(4) Fire protection

(5) Safety ground connection provisions

(6) Guarding live parts

(7) Transformers and voltage regulation equipment

(8) Conductor insulation, electrical and mechanical protection, isolation, and terminations

(9) Application, arrangement, and disconnection of circuit breakers, switches, and fuses

(10) Provisions for oil filled equipment

(11) Switchgear

(12) Surge arrestors

ERRATA

(B) Diagram. A permanent single-line diagram of the switchgear shall be provided in a readily

visible

location within the same room or enclosed area with the switchgear and this diagram shall

clearly

identify interlocks, isolation means, and all possible sources of voltage to the installation under

normal or emergency conditions, and the marking on the switchgear shall cross-reference the

diagram.

Exception: Where the equipment consists solely of a single cubicle or metal enclosed unit

substation

containing only one set of high-voltage switching devices, diagrams shall not be required.

8. Section identifier at the top of page 390 should read “500.9”.

9. Change the references in 506.9(C)(2), Exception, from various sections in 506.9 (D) to

506.9(C) to read as follows:

Exception: Associated apparatus NOT suitable for installation in a hazardous (classified)

location shall be required to be marked only with 506.9(C)(2)(2), (3), and (5), but BOTH the

symbol AEx in 506.9(C)(2)(2) and the symbol for the type of protection in 506.9(C)(2)(3) shall be

enclosed within the same square brackets; for example, [AEx iaD] or [AEx ia] IIIC.

ERRATA

10. Revise title of Article 516 to read as follows: Spray Application, Dipping, Coating, and Printing

Processes Using Flammable or Combustible Materials

11. Replace Figure 516.3(D)(2) with the following: (PRINT FROM NFPA WEBSITE)

12. In Section 625.17(A)(1), change the cross-reference from 625.17(B)(1) to 625.17(B).

13. In Section 645.15, delete the second sentence, which reads: “Power systems derived within listed

information technology equipment that supply information technology systems through receptacles

or cable

assemblies supplied as part of this equipment shall not be considered separately derived for the

purpose of

applying 250.30.”

14. Delete Section 690.7(F).

15. Change reference in last line of Section 690.56(A) to 690.31(G)

16. Delete Figure 700.2 and text reference in definition of Emergency Systems.

17. Delete Figure 701.2 and text reference in definition of Legally Required Standby Systems.

18. Delete Figure 702.2 and text reference in definition of Optional Standby Systems.

19. Delete Figure 708.2 and text reference in definition of Critical Operations Power Systems.

20. At top of page 664, upper left hand corner, change “(C)” to “705.12”

ERRATA

Reference: Various

Errata No.: 70-14-2

The National Electrical Code Correlating Committee notes the following errors in the 2014 edition of

NFPA 70, National Electrical Code.

1. In 210.8, change the reference in the first sentence from “210.8(A) through (C)” to “210.8(A)

through (D).”

2. In 225.36, Article 250, change the cross-reference to read “250.32(B) Exception No. 1.”

3. In 300.3(C)(2), change the cross-reference from “C(300.3)(2)(a) through (C)(2)(d)” to

“300.3(C)(2)(a) through (C)(2)(d).”

4. In 230.62(B), change “110.27 (1)” to “110.27 (A)(1).”

5. In 250.102(C)(2), the Informational Note referencing Chapter 9 should appear at the end of Table

250.102(C)(1).

6. In 310.10(E), change the first word to “Nonshielded.”

7. Revise the first sentence in 314.15 to read as follows:

“Boxes, conduit bodies, outlet box hoods, and fittings installed in wet locations shall be listed for use

in wet locations.”

8. In 368.2, change “copper aluminum” to “copper or aluminum.”

ERRATA

9. In 386.10(3), change the cross-reference from “645.29(1)” to “645.5(E)(2).”

10. In 392.80(A)(3)(2), delete the cross-reference to “392.22(D).”

11. In 404.3(A), Exception No. 2, change “110.27(1)” to “110.27(A)(1).”

12. In 409.3, delete the second “409.”

13. In the Title of Article 411, delete the hyphen between “Class” and “2.”

14. In 450.5, the cross-reference to “250.32(B) Exception” should read “250.32(B) Exception No. 1.”

15. In 480.9(C), change the cross-reference from “110.27” to “110.26.”

16. Revise 501.15(B)(2), Exception No. 2(1), as follows:

(1) The unclassified location is outdoors, located or the unclassified location is indoors and the

conduit system is entirely in one room.

17. In 501.130(B)(4,) Exception, change the cross-reference from “B(501.130)(1)” to “501.130(B)(1).”

18. In 502.140(A)(2), change the cross-reference from “A(502.10)(2)” to “502.10(A)(2).”

ERRATA

19. In 505.9(D)(1), Exception No. 2, change “Class 1” to “Class I.”

20. In 506.6(A), change the cross-reference from “506.6(B)(1)” to “500.6(B)(1).”

21. In 506.6(B), change the cross-references from “506.6(B)(2) and 506.6(B)(3)” to “500.6(B)(2)

and 500.6(B)(3).”

22. In 514.3(C)(2), change the cross-references from “Tables 514.3(B)(1)(1) and 514.3(B)(2)(2)” to

“Table 514.3(B)(1) and Table 514.3(B)(2).”

23. In 514.3(D)(1), change the cross-reference from “Table 514.3(B)(1)(1)” to “Table 514.3(B)(1).”

24. In 516.3(C)(7), change the cross-reference from “Figure 516.3(D)(4)” to “Figure 516.3(D)(5).”

25. In 517.19(C)(2), shade the entire section and change the cross-reference to “517.19(C)(1).”

26. In 553.8(C), change the cross-references from “250.119(A)(2)(2) and (A)(2)(3)” to

“250.119(A)(2)(b) and (A)(2)(c).”

27. In 620.21(A)(1)(c), Exception, change “A(620.21)(1)(c)(1)” to “620.21(A)(1)(c)(1).”

28. In 645.3(B), change the cross-reference from “820.113(C)(C)” to “820.113(C)” and delete

shading of the “(C).”

ERRATA

29. In 645.4, change the cross-reference from “Parts I and V of Article 725” to “Parts I and V of Article

770.”

30. In 646.19, change cross-references from “646.20(1) and (2)” to “646.19(1) and (2).”

31. Delete the Exception in 680.25(A)(1).

32. Revise 680.25(B) to read as follows:

(B) Grounding. An equipment grounding conductor shall be installed with the feeder conductors

between the grounding terminal of the pool equipment panelboard and the grounding terminal of

the applicable service equipment or source of a separately derived system. For other than (1)

existing feeders covered in 680.25(A), exception, or (2) feeders to separate buildings that do not

utilize an insulated equipment grounding conductor in accordance with 680.25(B)(2), this

equipment grounding conductor shall be insulated.

33. In Table 690.7, first column, change the fifth entry from “4” to “0.”

34. In 690.47(C)(2), change the cross-reference from “250.64(C)(C)(2)” to “250.64(C)(2).”

35. At the end of 694.18(C), after the label, add the following: “The warning sign(s) or label(s) shall

comply with 110.21(B).”

36. In 725.179(D), Informational Note, delete the coding text before the word “Informational.”

37. In 725.179(F)(1), delete the cross-references to “725.154(D)(1) and (E).”

38. In 725.179(F)(2), delete the cross-references to “725.154(D)(1) and (E) and (F)(1).”

ERRATA

39. In 770.100(A)(4), Exception, change the cross-reference from “B(770.100)(3)(2)” to

“770.100(B)(3)(2).”

40. In 770.179(E)(2), change the cross-reference from “E(770.179)(1)” to “770.179(E)(1).”

41. In 770.179, delete the following:

In addition, the overall covering of a field-assembled optical fiber cable shall have a surface

marking indicating the specific optical fiber conductors with which it is listed and the optical

fiber conductors shall have a permanent marking such as a marker tape indicating the overall

covering with which they are listed. The overall covering of a field-assembled optical fiber

cable shall meet the listing requirements for optical fiber raceways.

42. Replace 770.179(F) with the following:

770.179(F) Field-Assembled Optical Fiber Cables. Field-assembled optical fiber cable shall

comply with 770.179(F)(1) through (4).

(1) The specific combination of jacket and optical fibers intended to be installed as a fieldassembled optical fiber cable shall be listed in accordance with 770.179(A), (B), or (D) and shall

be marked in accordance with Table 770.179.

(2) The jacket of a field-assembled optical fiber cable shall have a surface marking indicating

the specific optical fibers with which it is listed for use.

ERRATA

(3) The optical fibers shall have a permanent marking, such as a marker tape,

indicating the jacket with which they are listed for use.

(4) The jacket without fibers shall meet the listing requirements for

communications raceways in 800.182(A), (B), or

(C) in accordance with the cable marking.

43. In 800.44(B), Informational Note; 820.44(E)(3), Informational Note; 830.44,

Informational Note before 830.44(A); and 840.44(B), Informational Note,

change the title of the reference to “National Electrical Safety Code.”

Issue Date: December 3, 2013

ERRATA

Reference: Various

Errata No.: 70-14-3

The National Electrical Code Correlating Committee notes the following errors in the 2014

edition of NFPA 70, National Electrical Code.

1. 210.19(A), Informational Note No. 4. Change the reference in the last sentence to

“Informational Note 2 of 215.2(A)(1)(b).”

2. Table 310.15(B)(3)(c). Revise second entry in the first column to read “Above roof 13 mm (1⁄2

in.)–90 mm (31⁄2 in.).”

3. 406.9(B)(1). Revise the first sentence by inserting “, 125 and 250 volts” after “amperes”.

4. 409.1, Informational note. Change the reference to read: ANSI/UL 508A.

5. 600.33(A). Revise first sentence to read “Listed Class 2 cable that complies with Table

725.154…”

6. 690.12(4). Change the reference to 690.56(C)

7. 690.15(D). Delete entire section. This is a duplicate of 690.13(D)

8. 725.154(A). Revise first sentence as follows: The substitutions for Class 2 and Class 3 cables

listed in Table 725.154(A) and illustrated in Figure 725.154(A) shall be permitted.

ERRATA

9. Add table as follows:

Table 725.154(A) Cable Substitutions (PRINT FROM NFPA WEBSITE)

10. Table C.9(A) Change the third trade size from 1 3/4 to 3/4.

Change the metric equivalent from (2) to (21).

Issue Date: April 21, 2014

ERRATA

Reference: 517.18(A), Exception No. 2 and 690.13(A) Exception

Errata No.: 70-14-4

The National Electrical Code Correlating Committee notes the

following errors in the 2014 edition of NFPA 70, National Electrical

Code.

1. 517.18(A), Exception No. 2. Change second cross reference from

517.18(B)(2) to 517.10(B(2).

2. 690.13(A), Exception. Change cross reference from 690.31(F) to

690.31(G).

Issue Date: July 29, 2014

ERRATA

Reference: 517.18(A), Exception No. 2 and 690.13(A) Exception

Errata No.: 70-14-4

The National Electrical Code Correlating Committee notes the

following errors in the 2014 edition of NFPA 70, National Electrical

Code.

1. 517.18(A), Exception No. 2. Change second cross reference from

517.18(B)(2) to 517.10(B(2).

2. 690.13(A), Exception. Change cross reference from 690.31(F) to

690.31(G).

Issue Date: July 29, 2014

PART TWO –

SIGNIFICANT

CHANGES OF THE

NCEC 2014 THROUGH

ARTICLE 285

CODE WIDE CHANGES

were approximately 3,745 proposals and 1,625 public comments

submitted for modifications to the 2014 edition of the NEC.

There

Field-Applied

Hazard Markings. 110.21(B) was added to include

specific requirements for warning labels and similar markings where

required or specified elsewhere in the Code.

Lockable

Disconnecting Means. New 110.25 was added to deliver a

“one-stop” location providing consistent requirements for a lockable

disconnecting means.

Requirements

for dc Systems Integrated Throughout NEC. Direct current

(dc) applications are experiencing a re-emergence because of such

things as electric vehicle charging, solar photovoltaic (PV) systems,

microgrids, wind-generated electric systems, etc.

Barnes

“Switchgear”

Incorporated Throughout the NEC. The previous definition for

“Metal-Enclosed Power Switchgear” was modified and retitled to simply

“Switchgear” to make it inclusive of all types of switchgear under the purview

of the NEC.

Definitions

Relocated to Article 100. Several existing definitions which

appeared in the definitions of a particular article have been relocated to

Article 100 as these terms are also found in other articles, not just the article

where the previous definition was located.

600

Volts to 1000 Volts. Numerous changes throughout the NEC from the 600

volts threshold to 1000 volts.

New

Articles. Four new articles added to the 2014 NEC.

CODE-WIDE CHANGES (CONT.)

The 2014 code in 110.16 now refers us to 110.21 B for labeling

and ANSI Z535.4 compliance is noted as a standard.

This requires the extensive labeling we now have to be comparable

to a uniform to a national standard. As with many issues previously

the hope is now that all have a reliable standard. Some who skirted

their responsibilities before now have a clear standard to follow.

Kale

indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

DANGER

indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

WARNING

indicates a hazardous situation which, if not avoided, may result in

minor or moderate injury.

CAUTION

Per changes to 110.26 C 3 we now have the following.

The

ampere value related to provisions for “Personnel Doors”

for “Entrance to and Egress from Working Space” was lowered

to 800 amperes from 1200 amperes.

The

term “listed panic hardware” replaces the previous list of

specific hardware provided at this requirement.

Serious

injury and fatalities have occurred involving electrical

equipment rated at below 1200 amperes.

This

same panic hardware change occurred at 110.33(A)(3) for

equipment with a voltage rating over 600 volts.

Rains

200.4 B has been added.

New

provisions added requiring grouping the common neutral

conductor for multiple circuits with its associated ungrounded

conductors when contained in the same enclosure.

New

exceptions were also added to relax this grouping

requirement where the grouping is obvious or where looped

conductors or conductors simply pass through the enclosure.

Neutral

conductors are typically terminated on a common neutral

terminal bar making tracing these neutral conductors more

difficult than tracing the ungrounded conductors.

West

200.6(A)(3) Means of Identifying Grounded Conductors has

changed.

Revision

permits three continuous white “or gray” stripes along the

grounded conductor’s entire length (on other than green

insulation) for identification of sizes 6 AWG or smaller.

Gray

coloring for grounded conductors is frequently requested for

277/480 volt circuits.

White

“or gray” stripes will offer more choices to installers.

Same

change occurred at the following locations:

200.6(B)(3)

200.7(A)(2)

200.6(E)

200.7(C)

200.7

200.7(C)(1)

200.7(C)(2)

Barnes

210.5(C)(2) Branch Circuits Supplied From Direct Current Systems

New branch circuit identification requirements added for dc

systems.

For sizes 6 AWG and smaller, red for positive dc conductors and

black for negative dc conductors.

For branch circuits supplied from a dc system operating at more

than 50 volts, each ungrounded conductor of 4 AWG or larger is

to be identified by polarity at all termination, connection, and

splice points by marking tape, tagging, or other approved

means.

Direct current (dc) applications are experiencing a reemergence in the electrical industry because of such things as

electric vehicle charging, solar photovoltaic (PV) systems,

Kale

microgrids, wind generated electric systems, etc.

NEC 210.8(A)(7) GFCI: Dwelling Unit Sinks

GFCI protection required for all 125-volt, single-phase, 15- and 20ampere receptacles installed within 1.8 m (6 ft) of all dwelling unit

sinks (including kitchen sinks). Revision removes the term “located in

areas other than kitchens.” Rule will now include the garbage

disposal receptacle located in the cabinet under a kitchen sink,

receptacle located behind a refrigerator, or a general lighting

branch circuit living room receptacle located on the back side of a

kitchen sink bar area if they are located within 1.8 m (6 ft) of the

kitchen sink.

NC 210.8(A) (7) Sinks — located in areas other than kitchens where

receptacles are installed within 1.8 m (6 ft) of the outside edge of

the sink.

NEC 210.8(D) Dwelling Unit Kitchen Dishwasher Branch Circuit

GFCI protection now required for all outlets that supply dishwashers installed in dwelling units.

Includes both receptacle and hard-wired outlet for dishwasher.

Modern-day electronically controlled dishwashers can experience “end of life” failures that can result

in increased risk of electrical shock.

GFCI protection for outlets supplying dishwashers can mitigate these increased risk of electrical shock.

NC Item 6.4: Remove GFCI requirement for kitchen

dishwasher branch circuit. This was not a requirement in the

2011 NEC. – No Cost Impact (NEW AMENDMENT)

210.8 (D) Kitchen Dishwasher Branch Circuit. GFCI protection

shall be provided for outlets that supply dishwashers installed in

dwelling unit locations.

210.8(A)(9) Dwelling Unit Bathtubs or Shower Stalls

GFCI protection now required where receptacles are installed within 1.8 m (6

ft) of the outside edge of dwelling unit “Bathtubs or Shower Stalls.”

Bathtubs or shower stalls are not always located in an area that meets the

Article 100 definition of a “bathroom.”

Bathroom is “an area including a basin with one or more of the following: a

toilet, a urinal, a tub, a shower, a bidet, or similar plumbing fixtures.”

Example: a room or area connected to a dwelling unit bedroom with a

bathtub or shower stall as the only plumbing fixture in that particular room or

area with a basin sink and toilet provided in another common area of the

dwelling.

West

210.8(A)(10) GFCI: Laundry Areas

All dwelling unit “Laundry Areas” now require GFCI protection for

125-volt, single phase, 15-and 20-ampere receptacles (regardless

of presence of a sink or distance from same).

A laundry room sink is no longer the driving factor whether GFCI

protection is required or not.

GFCI protection in laundry areas addresses increased shock

hazard risk and is consistent with other NEC requirements for GFCI

protection of receptacles in areas in close proximity of water.

Increased usage of GFCI protection for personnel at receptacles

of residential homes is a highly effective means of further reducing

the potential for electrical shock hazards.

West

210.8(B)(8) GFCI: Garages, Service Bays, and Similar Areas

GFCI protection required for all 125-volt, single-phase, 15- and 20ampere receptacles installed in all non-dwelling unit garages,

service bays, and similar areas (other than vehicle exhibition halls

and showrooms).

The phrase, “where electrical diagnostic equipment, electrical

hand tools, or portable lighting equipment are to be used” was

deleted.

Many commercial garages have receptacles installed for

purposes other-than the use of hand tools such as electric engine

block heaters or battery charging equipment.

Does not apply to such things as auto, power equipment (lawn

mowers), or recreational vehicle dealership showrooms.

Barnes

NEC 210.12 AFCI Protection

New provision added to require all AFCI devices required by 210.12 to be installed in a readily accessible

location. Aligns with the “readily accessible” requirements for GFCI devices covered at 210.8. Primarily

related to occupant or user accessibility to the monthly testing and reset features of AFCI devices. Will aid

and facilitate the ability to reset the AFCI device in the event the AFCI detects an arcing event.

NC Item 6.5: Retain location requirements from 2011 NEC for AFCI

Protection and remove term “readily”. – No Cost Impact (NEW

AMENDMENT)

210.12 Arc-Fault Circuit-Interrupter Protection. Arc-fault circuit-interrupter

protection shall be provided as required in 210.12(A) (B), and (C). The arc-fault

circuit interrupter shall be installed in an readily accessible location.

(A) Dwelling Units. All 120-volt, single-phase, 15- and 20-ampere branch

circuits supplying outlets or devices installed in dwelling unit kitchens, family

rooms, dining rooms, living rooms, parlors, libraries, dens, bedrooms,

sunrooms, recreation rooms, closets, hallways, laundry areas, or similar rooms

or areas shall be protected by any of the means described in 210.12(A)(1)

through (6):

Kale

210.12(A)(1) – (6) AFCI Protection

AFCI protection methods were expanded and language put into

a list format.

Provisions for outlet branch circuit (OBC) AFCI devices were

expanded.

The first two previous exceptions were revised to positive

language and put into a list format of six provisions for providing

AFCI protection.

Rains

210.12(B) Ex. Branch Circuit Extensions or Modifications Dwelling Units

Existing branch circuit conductors can be extended up to 1.8 m (6

ft.) without AFCI protection where no additional outlets or devices

are installed for when modified or extended.

Examples where situation does not require an AFCI device to be

installed:

Extending branch circuit conductors within an enclosure for the

purposes of replacing a device or utilization equipment.

Extending a branch circuit a short distance to a panelboard being

replaced or upgraded.

West

210.12(C) AFCI: DORMITORY UNITS

All

120-volt, single phase, 15- and 20-ampere branch circuits

supplying outlets installed in dormitory unit bedrooms, living

rooms, hallways, closets, and similar rooms are now required to

be provided with AFCI protection.

These

confined living quarter conditions can lead to damage

or misuse of the extension cords which in many cases are

undersized for the applied load such as a microwave oven.

Dorm

occupants should be afforded the same level of AFCI

protection provided to those who reside in a dwelling unit.

Barnes

210.13 GFPE: BRANCH CIRCUITS

GFP

of equipment now required for branch circuit disconnects

meeting provisions described at 230.95.

New section requires each branch circuit disconnect rated 1000

amperes or more and installed on solidly grounded wye electrical

systems of more than 150 volts to ground (but not exceeding 600

volts) to be provided with GFPE.

New language for branch circuits was crafted after the existing

language at 215.10 for feeders.

Exceptions were also added for GFP provisions:

creating additional or increased hazards

already provided on the supply side of branch circuit

Kale

210.17 ELECTRIC VEHICLE BRANCH CIRCUIT

Outlet(s)

installed for the purpose of charging electric vehicles

required to be supplied by a separate branch circuit with no

other outlets.

Charging

an electric vehicle (EV) with an existing 120 volt

receptacle outlet will typically overload an existing general

purpose branch circuit.

It

should be noted that this new requirement does not demand

that an outlet(s) for the specific and sole purpose of charging EV

equipment be installed.

A

new I-Note was also added giving guidance to 625.2 for the

Rains

definition of an “Electric Vehicle.”

210.52(E)(1) AND (E)(2) OUTDOOR OUTLETS

The

requirements for outdoor receptacles at dwellings have

been revised to permit the required receptacle outlets to be

“readily accessible from grade.”

This

provision was revised by removing the “while standing at

grade level” requirement.

This

change will allow the deck or porch receptacle outlet to

serve as one of the required outdoor receptacle outlets if it is

“readily accessible from grade” with the deck or porch

permitted to serve as “grade.”

Same

revision to individual units of multifamily dwellings (with

individual exterior entrance/egress).

West

210.52(E)(3) BALCONIES, DECKS AND PORCHES

The

requirement for a receptacle located at “Balconies, Decks,

and Porches” has been revised to require the balcony, deck or

porch to be attached to the dwelling.

Requirements

for the outdoor receptacle outlet to be installed

“within the perimeter” of the balcony, deck or porch have been

eliminated.

“Detached”

decks and such do not pose the same threat of

extension cords being ran through windows and doorways as

their “attached” counterparts.

Barnes

210.52(G) BASEMENTS, GARAGES, AND ACCESSORY BUILDINGS

“Basements,

Garages, and Accessory Buildings” receptacle provisions

revised into list format.

210.52(G)(1)

Garages

210.52(G)(2)

Accessory Buildings

201.52(G)(3)

Basements

Branch

circuit supplying garage receptacle(s) to supply only the garage.

Receptacle

required for each car space in a garage.

This

is an effort to recognize the possibility of electric vehicle (EV) and plugin hybrid electric vehicle (PHEV) charging in these garages.

Kale

210.64 ELECTRICAL SERVICE AREAS

New

provision requiring 125 volt, single-phase, 15-or 20-ampere

receptacle outlet to be installed at “Electrical Service Areas.”

At

least one 125 volt, single-phase, 15-or 20-ampere receptacle outlet

is now required to be installed within 15 m (50 ft) of all electrical

service areas.

Test

equipment such as portable electrical data acquisition

equipment is often needed for monitoring and servicing electrical

equipment in service areas.

Exception

was added for one- and two-family dwelling services.

Rains

Table 220.3 Additional Load Calculation

References

New line item added to Table 220.3 for “Electric Vehicle

Charging Equipment” and a reference to 625.14.

This will help clarify the load calculation requirements

for electric vehicle (EV) charging loads (considered as

continuous).

Electric vehicles and their charging stations are a

growing trend in the electrical industry.

This will give a direct and necessary link from Article 220

(calculations) to Article 625 for EV charging systems.

West

EATON CHARGERS

225.52(A) Disconnecting Means Location

The requirements pertaining to the disconnecting means for

services rated over 1000 volt have been incorporated into the

requirements for the disconnecting means of outside branch

circuits and feeders.

225.52(A) applies to the location of the disconnecting means for

an outside branch circuit of feeder.

Growing trend in the electrical industry to utilize more branch

circuits and feeder rated over 1000 volts.

Revision incorporates the same language at 230.205(C) dealing

with a service disconnecting means ability to be electrically

operated by a readily accessible, remote-control device. Barnes

230.30 Installation and Wiring Methods (Underground

Service Conductors)

230.30 was divided into two subsections:

(A) “Insulation”

(B) “Wiring Methods”

List of acceptable wiring methods for “Underground Service

Conductors” was added.

List includes all the cables and conductors that are identified in

Chapter 3 as suitable for use as both service conductors and for

direct burial.

This section is referring to the conductors from the service point to

the service disconnecting means, which is the definition of

Kale

“Service Conductors.”

230.44 Cable Trays Containing Service-Entrance

Conductors

Cable Trays containing service-entrance conductors required to

include warning labels with these labels spaced at intervals not to

exceed 3.0 m (10 ft.).

This requirement is very similar to the requirement at 392.18(H) for

warning label at cable trays containing conductors rated over

600 volts.

Warning label spacing is reasonable as service-entrance

conductors do not have overcurrent protection ahead of these

conductors.

This warning label spacing requirement will aid in the ability to

trace the service-entrance conductors throughout the building.

Rains

230.82(3) Equipment Connected to the Supply Side of

Service Disconnect

Provisions for a meter disconnect switch was revised by adding a

label requirement to indicate:

METER DISCONNECT - NOT SERVICE EQUIPMENT

230.82 lists several items that the Code permits to be installed

ahead of or on the line side of a service disconnecting means.

A meter disconnect switch is permitted ahead of the service

disconnect but is not the service disconnecting means.

Meter disconnect switches are often times confused with the

service disconnecting means.

The service disconnect marking is sometimes placed at the meter

disconnecting switch in error.

West

240.21(B)(1) Feeder Taps Not Over 3 m (10 ft.) Long

Tap conductor ampacity for feeder taps [not over 3 m (10 ft.) long]

required to be not less than the rating of the equipment containing

an overcurrent device(s).

“Equipment containing an overcurrent device(s)” replaces

“device.”

A new exception was also added for listed equipment, such as

surge protective devices, power monitoring equipment and

metering equipment, etc. allowed to be supplied with tap

conductors without overcurrent protection.

This same change also occurred at 240.21(C)(2) for transformer

Barnes

secondary conductors not over 3.0 m (10 ft.) long.

240.21(B)(1) Feeder Taps Not Over 3 m (10 ft.) Long

Conductors are permitted to be tapped, without overcurrent protection at the

tap, if the length of the tap conductors does not exceed 3 m (10 ft.) and the

tap conductors comply with all the following:

Ampacity cannot be less than the combined calculated loads on the

circuits supplied by the tap conductors.

Ampacity cannot be less than the rating of the equipment containing an

overcurrent device(s) supplied by the tap conductors.

Do not extend beyond the panelboard, etc. they supply.

Generally, required to be enclosed in a raceway.

If the tap conductors leave the enclosure in which the tap is made, the

ampacity of the tap conductors cannot be less than one-tenth of the

rating of the overcurrent device protecting the feeder conductors. Kale

240.87 Arc Energy Reduction

Title was changed from “Non instantaneous Trip” to “Arc Energy Reduction”

and section was revised for usability and formatted into subdivisions.

Revision clarifies that this rule applies only to circuit breakers that are

intentionally delayed under short-circuit conditions and that these circuit

breakers do not have an instantaneous trip settings.

No override setting higher than the potential arc current.

A limitation to the size of breaker (1200 ampere) required to comply with this

section was added.

Two additional methods for reducing arc energy were added to the list of

methods:

Energy-reducing active arc-flash mitigation system.

An approved equivalent means.

Rains

250.21(C) Marking - Ungrounded Systems

Ungrounded systems required to be legibly marked

"Caution Ungrounded System Operating -____ Volts

Between Conductors.“

Coincides with similar provisions at 408.3(F)(2) for a

switchboard, switchgear, or panelboard.

Marking requirements for ungrounded systems were

added in two separate places in the 2011 NEC

[250.21(C) and 408.3(F)(2)].

These two provisions for marking of ungrounded systems

need to contain the same labeling requirements.

West

250.64(D)(1) Common GEC: Multiple Disconnecting

Means

Revision was added to address busbar specifications and where buildings

or structures are supplied by a feeder (not just services).

Title of 250.64(D) was changed from “Services with Multiple Disconnecting

Means Enclosures” to “Building or Structure with Multiple Disconnecting

Means in Separate Enclosures.”

Multiple disconnecting means can occur at a separate building or structure

supplied by a feeder(s), not just at a building or structure supplied by a

service.

Text was also revised to include some specifications for a common GEC

busbar for making the conductor taps [not less than 6 mm thick × 50 mm

wide (¼ in. thick × 2 in. wide)].

Common GCE busbar must be “of sufficient length to accommodate the

number of terminations necessary for the installation.”

Barnes

250.68(C) Grounding Electrode Connections

The title of 250.68(C) has been changed to “Grounding Electrode

Connections.”

Provisions for metal structure steel used to as a conductor to interconnect

electrodes have been revised (prescriptive language has been removed).

An above-grade structural metal frame of a building can serve as a

conductor without having to be connected directly to a grounding

electrode or qualify as a grounding electrode as previously required.

Structural metal frame of a building should be treated the same as metallic

water piping without having to meet qualifying conditions of a grounding

electrode.

Interior metal water piping and the metal structural frame of a building are

permitted as a means of interconnecting electrodes that are part of the

grounding electrode system.

Kale

Table 250.102(C) Sizing Grounded Conductors, Main

Bonding Jumpers, Etc.

New Table 250.102(C) added for sizing grounded conductors,

main bonding jumpers, system-bonding jumpers, and supplyside bonding jumpers (rather than Table 250.66).

References to this new table were revised throughout Article

250.

Table 250.66 is titled for GECs with a max. required conductor of

3/0 copper or 250 kcmil aluminum.

Table 250.122 will continue to be used for sizing fault-return

carrying conductors, such as equipment grounding conductors,

if the supply conductors have overcurrent protection on the

Rains

supply side.

250.130(C) Nongrounding Receptacle Replacement or

Branch Circuit Extensions

Connection to an equipment grounding conductor that is part of another

branch circuit that originates from the enclosure where the branch circuit for

the receptacle or branch circuit originates is permitted for replacement of

non-grounding-type receptacles with grounding-type receptacles and for

branch-circuit extensions.

This is simply an extension of the present list item (3) that allows connecting to

the equipment grounding terminal bar in the related panelboard.

Allowing a connection back to the same enclosure or panelboard that serves

the receptacle branch circuit will typically provide a shorter, more effective

equipment grounding or ground-fault return path.

West

250.166 Size of Direct-Current Grounding Electrode

Conductor

A maximum size requirement of 3/0 copper or 250 kcmil aluminum for

grounding electrode conductor of dc systems was added at 250.166.

This correlates with the maximum size requirements for ac system grounding

electrode conductor as specified at 250.66 and Table 250.66.

No maximum size was provided at 250.166 except for grounding electrode

conductors that are the sole connection to grounding electrodes.

This new provision is intended to provide practical sizing requirements for

larger dc systems with large neutral conductors as is the case with an ac

system.

Barnes

250.167 Direct-Current Ground-Fault Detection

New section added for “Direct-Current Ground-Fault Detection”

requiring ground-fault detection on dc ungrounded systems.

New requirements address grounded systems, ungrounded

systems, and marking rules for each.

These new provisions require ground-fault detection for

ungrounded dc systems and permits ground-fault detection for

grounded dc systems.

New marking requirements call for system to be legibly marked

to indicate the type of grounding provisions provided at the dc

Kale

source or the first disconnecting means of the dc system.

Digital Ground Fault

Monitor/ Ground Detector

for Ungrounded AC/DC

Systems

Courtesy of Bender Inc.

Digital Ground Fault

Monitor/ Ground Relay for

Grounded AC/DC Systems

250.186 Ground-Fault Circuit Conductor Brought to Service

Equipment

New 250.186 to require services (over 1000 volts) to have a grounded

conductor to be brought to the service for a grounded system.

Ungrounded systems (over 1000 volts) will require a supply-side

bonding jumper brought to the service.

Same requirements as 250.24(C) for services 1000 volts or below.

Primary concern is to provide a very low impedance ground-fault

return path from any point on the wiring system where a ground fault

may occur to the electrical supply source.

West

250.194 Grounding and Bonding of Fences and Other Metal

Structures

New section added for bonding and grounding metal fences and

other metal structures around substations.

These fences are accessible to the general public and must be

grounded to limit the rise of hazardous voltage potential on the

fence to the surrounding earth.

For situations where step and touch voltage potential

considerations indicate additional grounding and bonding design is

necessary, alternate designs performed under engineering

Barnes

supervision is permitted.

285.13 Type 4 and Other Component Type Surge Protective

Devices

Type 4 component assemblies and Type 5 SPDs are incomplete

devices that are only acceptable when provided as part of listed

equipment.

This section provides clarity that component SPD(s) are not to be

installed in the field.

PART THREE –

SIGNIFICANT

CHANGES OF THE

NCEC 2014 CHAPTER

THREE

300.22(C)(1) Wiring Methods for Environmental Air

Spaces (Plenums)

Cable ties used to secure cables in plenums must be listed as having fire

resistant and low smoke producing characteristics.

A new informational note was also added that will provide pertinent

information related to low smoke and heat release properties for

nonmetallic cable ties.

Plenum grade nonmetallic cable ties are readily available in the marketplace today that can achieve compliance with this new provision.

Kale

300.38 Raceways in Wet Locations Above grade

Interior of raceways installed in wet locations above grade are

now considered to be a wet location for installations of over

1000 volts, nominal.

This will bring aboveground installation requirements for over

1000 volts consistent with the requirements in 300.9 for 1000 volts

and under.

The mere existence of condensation alone should render the

interior of these raceways a wet location when these raceways

are installed in wet locations, above grade or below, regardless

of the voltage involved.

Enclosures and raceways installed in wet location installations

must have conductors and cables installed that are listed and

identified for wet locations.

Table 310.15(B)(3)(a) More Than Three Current-Carrying

Conductors

Title

of 310.15(B)(3)(a) and corresponding table was changed to

“More Than Three Current-Carrying Conductors in a Raceway or

Cable.”

Note

to Table 310.15(B)(3)(a) was revised to make it clear that

table applies to spare conductors but does not apply to

conductors that cannot be simultaneously energized.

Ampacity

adjustment correction factor is required for three or

more current carrying conductors that are installed or bundled

together without maintaining spacing as well as those in a

Rains

raceway or cable.

310.15(B)(3)(C) RACEWAYS AND CABLES EXPOSED TO

SUNLIGHT ON ROOFTOPS

The

title and parent text at 310.15(B)(3)(c) has been revised for clarity from

“Circular Raceways Exposed to Sunlight on Rooftops” to “Raceways and

Cables Exposed to Sunlight on Rooftops.”

Provisions

for cables installed on or above rooftops have been added as well

[previous language indicated that the cable(s) had to be installed in a

raceway].

new exception was also added allowing Type XHHW-2 conductors

(thermoset insulated conductor) to be installed in raceways or cables on

rooftops without having to apply an ambient temperature adjustment

correction factor for these conductors.

West

A

314.15 Damp or Wet Locations

All “outlet box hood” covers are required to be listed for use in a

wet location, not just “extra duty” outlet box hood covers installed

in a wet locations.

The term “outlet box hoods” was added at this section, making

boxes, conduit bodies, outlet box hoods, and fittings installed in

wet locations to now be required to be listed for use in wet

locations.

Previous language at 406.9(B)(1) required “extra duty” outlet box

hoods installed in a wet location to be listed for use in a wet

location.

314.15 only required boxes, conduit bodies, and fittings installed in

wet locations to be listed for use in wet locations.

Barnes

314.15 Damp or Wet Locations

Approved drainage openings permitted to be installed

in the field in boxes or conduit bodies listed for use in

damp or wet locations in accordance with

manufacturer’s instructions.

These weep holes cannot be larger than 6 mm (1/4 in.).

Weep holes in the bottom of boxes installed in wet

locations improves the safety and durability of electrical

installations.

Without these weep holes, the inside of cast aluminum

boxes and other metallic enclosures can degrade over

time due to moisture condensation.

Kale

314.25 Covers and Canopies

Drywall screws are not permitted to be used to attach box

covers or other equipment fastened to a box.

Screws used for this purpose are now required to be either

machine screws matching the thread gauge or of a size that is

integral to the box (in accordance with the manufacturer’s

instructions).

The use of drywall screws is unacceptable and can result in

damage to the box and inadequate support of the attached

luminaire or equipment itself.

Similar provisions have been introduced at 404.10(B) for

mounting of switches and 406.5 for mounting of receptacles.

Rains

314.27(A)(1) Vertical Surface Luminaire Outlets

The title was changed from “Wall Outlets” to “Vertical Surface

Outlets” as not all vertical surfaces where luminaire or

lampholders are mounted are necessarily in or on a “wall.”

New language was also added to reflect that luminaires or

lampholders can be mounted “on” a vertical service as well as

“in” a vertical service.

The previous language only addressed boxes mounted “in a

wall.”

An example of a “vertical” surface-mounted luminaire would be

a luminaire mounted on the side of a square post in the middle

of a large room or area.

314.27(A)(2) Boxes at Ceiling-Mounted Luminaire Outlets

Outlet boxes used to support ceiling-mounted luminaires that

weigh more than 23 kg (50 lb.) are now required to be marked

with the maximum weight the box will support on the “interior of

the box.”

Allows the installer and the electrical inspector an opportunity to

review this information at the time of installation without having to

climb into the attic to retrieve this information.

In some cases, the exterior of the outlet box is not accessible

after a certain point in the building construction process.

Ceiling-mounted outlet box supporting a luminaire weighing

more than 23 kg (50 lb.) is required to be listed and marked for

the maximum weight that particular outlet box is designed to

support.

324.41 FLOOR COVERINGS (FLAT CONDUCTOR CABLE)

The maximum size modular carpet square permitted to be

cover floor-mounted flat conductor cable (Type FCC cable)

has been increased from 914 mm (36 in.) square to 1.0 m (39.37

in.) square.

This will allow the use of standard-sized modular carpet products

sized based on the International System of Units (SI units) of

measure.

This revision will not disqualify the use of the readily available

smaller 914 mm (36 in.) carpet squares [based on the (US)

Customary Units of measurement (foot, pound, inches, etc.)].

A flat conductor cable system is designed to provide a

completely accessible, flexible wiring system for installation

West

under carpet squares.

330.30(B) Securing (Type MC Cable)

Type MC cable is now permitted to be secured in

intervals not exceeding 3 m (10 ft.) for vertical

installations when listed and identified for such use and

containing ungrounded conductors 250 kcmil and larger.

Type MC cables are generally required to be secured at

intervals not exceeding 1.8 m (6 ft.).

Type MC cable with integral conductor supports offers

the installer an alternative and productive method for

commercial vertical installs in high-rise buildings.

Barnes

330.30(D)(3) Unsupported Type MC Cable

MC cable permitted to be unsupported where the cable is

made of the interlocked armor type in lengths not exceeding 900

mm (3 ft.) from the last point of support.

Type

This

would apply where flexibility is necessary to minimize the

transmission of vibration from equipment or to provide flexibility for

equipment that requires movement after installation.

This

new allowance brings Type MC cable in line with other similar

flexibility provisions for other wiring methods such as Type AC

cable, flexible metal conduit (Type FMC), liquidtight flexible metal

conduit (Type LFMC), and liquidtight flexible nonmetallic conduit

Barnes

(Type LFNC).

334.40(B) Devices of Insulating Material (Type NM Cable)

Nonmetallic-sheathed cable interconnectors have been

recognized to be used without a box and concealed where

used for “repair wiring” rather than “rewiring” in existing

buildings.

Listed “nonmetallic sheathed cable interconnector devices”

replaces the term “tap devices” to zero in on the specific type of

device permitted in this application.

When using Type NM cable, 300.15 generally requires a box to

be installed at each conductor splice point, outlet point, switch

point, junction point, termination point, or pull point.

Type NM cable interconnectors are insulating enclosures which

when connected to Type NM cable form both a mechanical

Kale

and electrical connection.

334.40(B) DEVICES OF INSULATING MATERIAL (TYPE NM

CABLE) (CONT.)

Further revision made a clear distinction between “rewiring”

and “repair wiring” in existing buildings.

Rewire is typically defined as replacing existing wiring with new

wiring.

If an electrician has the accessibility and availability to replace

existing wiring with new wiring, there would be no need for a

device such as a nonmetallic-sheathed cable interconnector.

“Repair wiring” seems to be justified for the application of a

nonmetallic-sheathed cable interconnector.

An example of an area where these concealed nonmetallic sheathed cable interconnectors might be used would be in

flooded areas.

356.12 Uses Not Permitted - LFNC

Previous List Item (4) for “Uses Not Permitted” for liquidtight

flexible nonmetallic conduit (LFNC) has been deleted.

This will allow LFNC as an acceptable wiring method for

applications where the voltage involved is greater than 600 volts.

UL Certification Guide Information (White Book), DXOQ, does not

limit LFNC to 600 volts.

LFNC is an acceptable wiring method for signs with voltage

ratings over 600 volts [see 600.32(A)].

Permitted as a wiring method enclosing leads to a motor from a

separated junction box for all voltage applications [see

Rains

430.245(B)].

Liquidtight flexible

nonmetallic conduit (LFNC)

376.22 Number of Conductors and Ampacity (Metal

Wireways)

Ampacity adjustment factors for more than three currentcarrying conductors in a raceway shall only apply to metal

wireways where the number of current-carrying conductors

exceeds 30 at any cross section of the wireway.

Does not apply to simply 30 or more current-carrying conductors

total in the wireway.

It was never intended for the adjustment factors of

310.15(B)(3)(a) to apply once there were more than 30

conductors total in the wireway as opposed to at a cross

sectional area.

West

376.56(B)(1) and (B)(5) Power Distribution Blocks (Wireways)

Power distribution blocks (PDB) installed in wireways ahead of the

service main (line side) must be "listed for the purpose.“

PDBs are generally listed for and required to be used only on the

load side of service equipment.

Conductors in wireways required to be arranged so that power

distribution block terminals are unobstructed after their

installation.

This new PDB unobstruction provision will bring consistency with

the provisions for PDBs installed in pull or junction boxes.

Barnes

392.18(H) Ex. Cable Tray Marking

Marking requirement for cable trays containing conductors rated

over 600 volts has been relaxed for industrial establishments with

maintenance, supervision, and qualified persons servicing the

installation.

Main requirement is for a cable tray contains conductor rated over

600 volts to have permanent and legible warning labels located in

a readily visible location at least every 3 m (10 ft.).

The existence of trained, qualified persons at supervised industrial

establishments, makes it not always necessary to provide warning

labels at cable trays containing conductors rated over 600 volts.

Some of these industrial cable tray installations may be at elevated

locations where the warning labels cannot even be seen from the

floor.

Kale

Article 393 Low Voltage Suspended Ceiling Power

Distribution Systems

A new article was added to address low-voltage Class 2 ac and dc volt

supplied equipment (lighting and power) connected to ceiling grids,

floors and walls built for this purpose.

New article addresses equipment with similar features to track lighting but

includes the wiring and power supply requirements.

New article provides specific requirements for safe installations of low

voltage, power limited power distribution, for power to lighting and nonlighting loads.

The growing interest in alternative energy sources (e.g. PV, wind turbines,

batteries, fuel cells, etc.) and the increase of low voltage, low power

devices (sensors, LV lighting, IT equipment, AV equipment, etc.), has

created a significant need this new article.

Rains

399.2 DEFINITIONS: OUTDOOR OVERHEAD CONDUCTORS

Outdoor Overhead Conductors - Single conductors, insulated,

covered, or bare, installed outdoors on support structures in free

air.

Definition of “Outdoor Overhead Conductors” was revised to

include the term “in free air” to ensure that the definition clearly

indicated that wiring installed under the scope of Article 399 is

not installed in raceways, etc.

This revised definition should clarify the conductors that Article

399 represent as being the conductors outside (in free air) used

for transmission and distribution of electrical power to utilization

equipment that transition from traditional indoor wiring methods

such as wireways, raceways, busway conduit systems, etc. West

Thank you for your partnership to

build a safe and thriving

community!

Gary Mullis, Electrical Code Administrator

Mecklenburg County Code Enforcement

2145 Suttle Ave., Charlotte, NC 28208

980-314-3098

gary.mullis@mecklenburgcountync.gov