Design Solution Definition Process 4

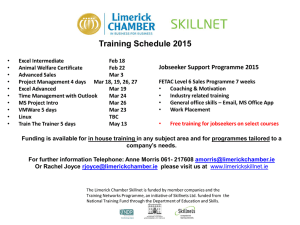

advertisement

Design Solution Definition Process Design Solution Definition • 4 4 Requirement 18 (Section 3.2.4.1) “The Center Directors or designees shall establish and maintain a process, to include activities, requirements, guidelines and documentation, for designing product solution definitions within the applicable WBS Model that satisfy the derived technical requirements.” Part I Part I (31 Mar 09) Andrew I-1 Design Solution Definition Purpose • 4 The Design Solution Definition Process is used to translate the outputs of the Logical Decomposition Process into a design solution definition Design Solution Definition: the specification of a rocket, for example Figure 4.3-2 Example of a PBS Part I Part I (31 Mar 09) Andrew I-2 Design Solution Importance 4 What we wanted • Define solution space • Develop design alternatives • Trade studies to analyze This image of a space shuttle has been removed due to copyright restrictions. – Alternate Design – Cost, performance, schedule • Select Design Solution • Drive down to lower level • Identify enabling products What we got This image of a space shuttle in a building complex has been removed due to copyright restrictions. Design with the end in mind! Part I Part I (31 Mar 09) Andrew I-3 Design Solution Questions 4 • What types of criteria are necessary to evaluate alternate design solutions? – – – – – – – Does it meet technical requirements? Is it compatible with the other system components? How difficult is it to produce? Can it be delivered within acceptable time frame? How reliable will it be? Which functions does this solution satisfy? How easy will it be to operate? Part I Part I (31 Mar 09) Andrew I-4 Design Solution Definition 4 • As alternative concepts are considered, the Design Solution Definition Process includes: – Transforming the defined logical decomposition models and their associated set of derived technical requirements into alternative solutions – Fully defining the selected alternative(s) into a design solution definition that will satisfy the technical requirements • This process is repeated at lower levels as additional subsystems need to be defined 3.2.4.2 – Design Solution Definition Purpose Part I Part I (31 Mar 09) Andrew I-5 Design Solution Methods 4 • Group and Partition functions with system elements System Functions Physical Elements Launch Vehicle Avionics X X Guide Deploy Solar Array Fuel Cell Antenna X X Communicate Power X X X X Recover Part I Part I (31 Mar 09) Andrew I-6 Trade Study Process Part I Part I (31 Mar 09) Andrew 4 I-7 Important Design Considerations Capabilities Functions System Performance Priorities Technical Effectiveness Reliability Maintainability Supportability System Availability 4 Other Considerations • Software • System Safety • Accessibility • Information Assurance • COTS • Disposal • Human Factors • Environ. Constraints System Effectiveness Producibility Operations Maintenance Process Efficiency Affordable Operational Effectiveness Logistics Life Cycle Cost/Total Ownership Cost Part I Part I (31 Mar 09) Andrew I-8 Design Solution Methods 4 • Analyzing each alternative to be able to select the preferred alternative • Once an alternative is selected or baselined, the Design Solution Definition Process will be used for: – Generating end products as a function of the hierarchy in the system structure • The output end product Design Solution Definition will be used for conducting product verification Part I Part I (31 Mar 09) Andrew I-9 Ares V Interfaces and Elements Altair Lunar Lander Gross Lift Off Mass: 3,704.5 t (8,167.1k lbm) Integrated Stack Length: 116 m (381 ft) Payload Adapter Payload Shroud 4 J–2X Loiter Skirt Interstage Solid Rocket Boosters (2) • Two recoverable 5.5-segment PBAN-fueled, steel-casing boosters (derived from current Ares I first stage Earth Departure Stage (EDS) • One Saturn-derived J–2X LOX/LH2 engine (expendable) • 10 m (33 ft) diameter stage • Aluminum-Lithium (Al-Li) tanks • Composite structures, Instrument Unit and Interstage Core Stage • Primary Ares V avionics system • Six Delta IV-derived RS–68B LOX/LH2 engines (expendable) • 10 m (33 ft) diameter stage • Composite structures • Aluminum-Lithium (Al-Li) tanks Part I Part I (31 Mar 09) Andrew Two representative configurations shown Multiple configurations for adding a 6th Engine being traded RS–68B Engines (6) I - 10 Open Systems & Enabling Product 4 • A system that implements specifications maintained by an open, public consensus process for interfaces, services, and support formats, to – Enable properly engineered components to be utilized across a wide range of systems with minimal change, – Interoperate with other components on local and remote systems, and – Interact with users in a manner that facilitates portability Part I Part I (31 Mar 09) Andrew I - 11 Design Solution Outputs Technical Data Package includes: • • • • Specifications Drawings Sketches Parts list Specific descriptive documentation for buying, building, coding or assembling & integrating end products is a function of lifecycle phase and location of WBS model in the system structure 4 System Specification ••• End Product Development Products Fabrication Integration Assembly products Test Products Operations Products Logistics Products ••• Subsystem Subsystem Subsystems: Initial Specifications for development of next lower level WBS models Part I Part I (31 Mar 09) Andrew Enabling Products: Expectations for initiation of development or procurement/reuse of enabling products I - 12 Modeling and Simulation (M&S) 4 • Can be an important tool for design process (Provided that models are sufficiently adequate descriptions of reality – they are valid) – Better understand and optimize performance • Multiple combinations and permutations – Fly or test more effectively early in the design • More experimentation and data generation without costly prototypes and tests • Can save Time and Resources. • Requires Experience and Skill M&S is used as a tool throughout the Systems Engineering Process Part I Part I (31 Mar 09) Andrew I - 13 Benefits of a Designing the Right system 4 • Meets stakeholder expectations • Meets cost/schedule and performance requirements • Operates as specified in ConOps Part I Part I (31 Mar 09) Andrew I - 14 Design Solution Definition – Best Practice Process Flow Diagram Activities 4 Output Input Part I Part I (31 Mar 09) Andrew I - 15 Summary 4 • The Design Solution Definition Process is used to translate the outputs of the Logical Decomposition Process into a design solution definition • Alternative design solutions must be defined and analyzed to select the best alternative that satisfies technical requirements • The form of the design solution definition depends on the product life cycle phase and its hierarchy in the system • The Technical Data Package allows for the building, coding, reusing, or buying of products Part I Part I (31 Mar 09) Andrew I - 16 Technical Solution Definition 4 Discussion • Where in the Solution Definition Process do we tend most to skip steps (where we should not)? • Do tight schedules mean we scrimp in the wrong places? Part I Part I (31 Mar 09) Andrew I - 17 MIT OpenCourseWare http://ocw.mit.edu 16.842 Fundamentals of Systems Engineering Fall 2009 For information about citing these materials or our Terms of Use, visit: http://ocw.mit.edu/terms.