Proceedings of 7th Annual American Business Research Conference

advertisement

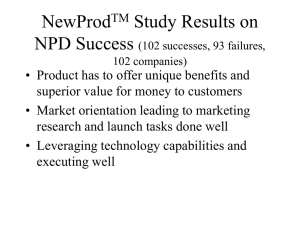

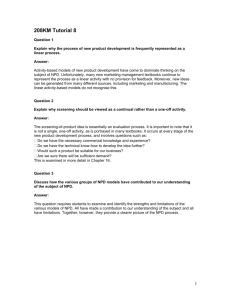

Proceedings of 7th Annual American Business Research Conference 23 - 24 July 2015, Sheraton LaGuardia East Hotel, New York, USA, ISBN: 978-1-922069-79-5 New Product Development Managing Cost Approach. A Case Study at the Furniture Sector Trigkas Marios1, Papadopoulos Ioannis2 and Karagouni Glykeria2 The present paper refers to the presentation of a case study regarding the NPD process through the lens of cost and project management approach, in the furniture industry in Greece. The design and development of new products are nowadays approached under a wider point of view, instead of simply referring to the products’ characteristics. It is a practical implementation of NPD process in order to achieve time to market and cost effectiveness of the development of a green and smart furniture. We investigate the process of a Green and Smart (GSF) new product development, under the context of a related research project for developing an innovative product. Our findings show that, the NPD may follow a sequential or a concurrent process, depending on the complexity of the project and the available resources of a team/firm, aiming to cost reduction and performance. The designing and manufacturing phases, are the two most important phases of the whole process, with resources demands, mainly in costs and time, to hold the greater percentage of the total available budget of the project. Project management, team members knowledge and technical skills along with alliances of research institutes and firms, play also a crucial role for a successful and cost effective NPD according to customers’ needs. Keywords: NPD, Cost Oriented NPD, Time to Market NPD, NPD Efficiency, GSF, Furniture Field of Research: Management 1. Introduction Till recently, the NPD (New Product Development) process focused on the determination of the characteristics that a product should incorporate in order to meet specific functional standards imposed by manufacturing procedures and operational constraints of firms. However, the design and development of new products are nowadays approached under a wider point of view; instead of simply referring to the products’ characteristics, several “external” factors are taken into consideration, such as: • Customer needs • Quality • The reduction of production’s cost and evaluation • The assembling and distribution processes • Environmental impacts during and after the production process • Further use and recycling • Products’ Life Cycle Furthermore, new product development is seen as crucial for the long-term survival and growth of the firm (Baumol, 2002). Academic literature is increasingly getting interested in NPD processes within firms (Damanpour, 1991; Brown and Eisenhardt, 1995; Cooper, 1999; Ernst, 2002; Barczak et al., 2009). The common finding of related theoretical and empirical findings highlights the structural design of the NPD process as one of the critical factors in achieving successful innovation (Cooper, 1 Aristotle University of Thessaloniki – Department of Forestry & Natural Environment, Lab. of Forest Economics, Finikas Thessaloniki, building B, 55134 mtrigkas@for.auth. 2 Technological Educational Institute of Thessaly, Department of Wood & Furniture Design and Technology, V. Griva 11, Karditsa. Greece, 43100, papad@teilar.gr karagg@teilar.gr Proceedings of 7th Annual American Business Research Conference 23 - 24 July 2015, Sheraton LaGuardia East Hotel, New York, USA, ISBN: 978-1-922069-79-5 2003). In particular, the implementation of structural mechanisms such as cross-functional structures (Griffin, 1997; Song et al., 1997), stage-gate processes (Canez et al., 2007; Cooper, 1996), and formalized NPD procedures (Schmidt et al., 2009) have been found to positively influence the innovation performance of firms. Several researches (Olsen et al., 2001; Song and Xie, 2000) have provided evidence that within a particular NPD project the product innovativeness moderates the relationship between the effectiveness of the structure (i.e., formal or cross-functional) and the performance of the NPD project. Thus, a central question that rises is whether an NPD project that is mainly financed by external funding, could be designed and implemented in an efficient and effective way, based on cost orientation among several phases, time to market approach and project management, in order to meet the needs of a low tech sector and of an emerging market. Based on this question, the present research, focuses on a NPD in the furniture sector, presenting in a practical approach through a case study, the development of a Green and Smart Furniture (GSF) project, giving specific attention to the design and cost management of the project, in order to deliver successful innovation. 2. MANAGERIAL APSPECTS ON NPD 2.1 NPD in general The generic product development process follows α “market-pull” process (Urlich and Eppinger, 2000). Phase 0: Phase 1: Planning Concept Developme nt Phase 2: SystemLevel Design Phase 3: Detail Design Phase 4: Testing Refinement Phase 5: Production Ramp-Up Furthermore, one type of Concept Development is called the front-end process. This process: (Source: Urlich and Eppinger, 2000. New product design and development) Besides the above steps, there are three more activities involved in the whole process: 1. Economic analysis 2. Benchmarking of competitive products 3. Modeling and prototyping Another issue concerning NPD regards the development of alliances and networks in order to expand resource bases and face strong competitive counterparts at global level. Towards this direction, NPD processes involve the development of networks, joint ventures and outsourcing schemes (Staudenmayer et al., 2005). The imperative need of project teams seems to indicate that knowledge and skills of experts are a perquisite in order to develop novel products (Badir et al., 2008). This need may even mean that members of a new product development team each come from potentially different firms and organizations (i.e. research centers and laboratories), have to communicate and coordinate with one another in order to accomplish their development activities in an effective way Proceedings of 7th Annual American Business Research Conference 23 - 24 July 2015, Sheraton LaGuardia East Hotel, New York, USA, ISBN: 978-1-922069-79-5 (Staudenmayer et al., 2005). The level of communication and interaction is actually crucial in successful new products’ launch (Badir et al., 2003; Gerwin, 2004; Ulrich and Eppinger, 2000). Prior research has provided evidence on the positive impact of firms’ strategic alliances on innovativeness (Trigkas et al., 2012; Shan et al., 1994). External collaborators and consultants required are differentiating according to the NPD technique and process flow that is going to be used. Industrial experience at empirical, sectoral and managerial level is also very important (Kitsios, 2000). However, the main role of consultants and team leaders is the organization, leadership and training of project teams and the control of project activities, until the firm has the capability to run a project by itself. 2.2 Cost and time to market NPD orientation Besides design and the role of cost and / or time in manufacturing or the entire development process as the most critical variables, several other factors appear to play critical roles in NPD processes such as the management of the NPD process, the cross-functional nature of the NPD team, the external and internal communication of the team, the skills and knowledge of the project manager and the degree of customer and supplier involvement (Brown and Eisenhardt 1995; Krishnan and Ulrich 2001). Bajaj et al. (2002) focus on three drivers related to the management of the design phase of NPD: i) ii) iii) the degree of specialization input in design, the degree of oversight by the project manager in the design phase and the intensity of customer interaction during design The structure of NPD project management is decisive for success or failure in a company. With more complex products (large number of parts, many functions, etc.) or products with high process complexity (for example, a difficult production process sequence), it is necessary to execute operation steps as in Concurrent Engineering. In other words, the steps are executed in parallel to satisfy, on one hand, the requirements of the system complexity and, on the other hand, the demands of time and process sequence optimization. Time scheduling and capacity planning have overtaxed design and development for decades and recent investigations show need for improving these activities. Investigations of product development methodology have shown repeatedly that considerable time and expense can be saved by making the correct decisions in the early product development stages. Many firms have begun to adopt concurrent new product development (NPD) processes in which product design phases occur in a non-linear and iterative manner. While concurrent NPD processes increase flexibility and reduce time-to-market as compared to traditional sequential processes, concurrency increases task uncertainty since the product design process begins before all important product features and specifications have been established. Such changes can result in costly redesign and rework. Extensive research (Gopalakrishnan et al., 2015; Wouters et al., 2009; Booker et al., 2007; Cooper, 2002; Davila & Wouters, 2004) suggests target costing, where product design teams are assigned specific cost goals, is an effective method of controlling costs in sequential NPD. Other researchers (Trigkas et al., 2012, Swink et al., 2006) approach the operationalization of holistic new product development (NPD) project performance, employing a sequential data envelopment analysis (DEA) methodology that simultaneously incorporates multiple factors including new product development cost, product cost, product quality, and project lead time. The results support that tradeoffs among NPD performance outcomes, are manifested more strongly in highly efficient projects Proceedings of 7th Annual American Business Research Conference 23 - 24 July 2015, Sheraton LaGuardia East Hotel, New York, USA, ISBN: 978-1-922069-79-5 when compared to inefficient projects. These methodologies are also used in order to propose benchmarking techniques and best practice approach for NPD and innovation management. 3. THE GREEN AND SMART FURNITURE – G.S.F. CASE STUDY 3.1 The GSF project in general The aim of the specific NPD project is the development of intelligent and purely ecological furniture that can improve the existing way of in-house activities and operation regarding the furniture, utilizing modern technologies not only for the manufacturing and material and final product traceability, but also at the furniture’s use. At the same time, this very furniture will provide the sustenance or even the vivification of the natural way of life and manageability by all possible users (elderly, children, people with special needs etc.) The project is: a) the first worldwide to attempt the manufacture of a final furniture product which will be both smart and ecological and b) follows a structured methodology of new product development (NPD by Ulrich and Eppinger. The natural object of the project includes six (6) Work packages, (i) organizing the process of New GSF Product Development - Preparatory work, (ii) determination of GSF market in Greece and its tendencies (Targeting and trend analysis), (iii) design of eco-logical - GS domestic furniture, (iv) production Technology of eco-logical GS domestic furniture, (v) economic analyses and (vi) promotion and communication of eco - logical furniture, which constitute distinguishable activity groups of resembling nature with considerable synergy and complementarity, while at the same time they maintain a relative independence among them, in order to make their partially overlapping development feasible. The project follows the process of NPD, as described by Ulrich and Eppinger. This particular methodology is followed by the biggest enterprises in the world and is considered one of the most effective ones, as long as it concerns both the process and the achievement of the desirable results. The steps and the applied methodology of the GSF project are the following: • New product development planning (time planning - process) of the GSF project (Design Brief), product lists, timetables etc) • A study of all relative provisions that are in effect internationally for the certification, in order that the final result is compatible with the current legislation. • Market research of both the sector enterprises on their intention to manufacture and promote and consumers for their intention to buy eco-logical furniture, • Design of eco-logical domestic furniture through a considerable number of drawings /ideas/concepts from special furniture designers, members of the main research team and exterior collaborators and the appointment of the best, • Registration of relative patents for the best drawings that will result, • creation of functional prototypes and pilot production of at least one of the above mentioned using the available equipment of the Department of Wood & Furniture Design and Technology and recording of all processes (eg production problems, necessary modifications, new solutions etc) • Use of pilot product by volunteer customer/s and evaluation of their experience of it • Analysis of production technology of the specific furniture with a particular emphasis on the quality control and the formulation of basic manufacturing principles and directives, Proceedings of 7th Annual American Business Research Conference 23 - 24 July 2015, Sheraton LaGuardia East Hotel, New York, USA, ISBN: 978-1-922069-79-5 • • Formulation of an effective marketing plan for their promotion in the Greek and international market Creation of a core of values that will serve the branding of the GS furniture, exploiting the total design (Branding by design). 3.2 Management structure and procedures The achievement of the proposed objectives and deliverables is also supported by the advanced equipment of the Department of Wood and Furniture Design and Technology, TEI of Larissa, which is analytically presented bellow and is considered as very sufficient. For the implementation of WP-1 “Organizing the process of new GSF Product Development Preparatory work”, WP-2 “Determination of GSF market in Greece and its tendencies”, WP-5 “Economic analyses” and WP-6 “Promotion and communication of eco - logical furniture", the project will utilize the equipment of the Laboratory of Applied Marketing, Administration and Economy. The equipment refers to modern PCs equipped with special programs as: SPSS ver. 17.0 for the statistical analysis of the questionnaires, GMMSO2 for the marketing research, DEA (Data Envelopment of Analysis) for the realisation of special economic analyses, Innovation Inventory for the evaluation of the economic viability of the innovative concept etc. Corresponding electronic equipment also exists in the Laboratories of the Departments of a) Business Administration of Athens University of Economics and Business, b) Business Administration of TEI of Larissa, which will collaborate with the research team. For the implementation of the most activities of WP3 “Design of eco-logical - GS domestic furniture”, the research team will use the equipment of a) the Laboratory of Furniture Industrial Design and b) Furniture Design (CAD), which allocate modern PCs equipped with most new versions of furniture design software (CAD-CAM, Pytha etc), rapid prototyper (3D printer) for furniture model creation, plotters, scanners and printers. For the achievement of the majority of activities of WP4 “Production Technology of eco-logical GS domestic furniture” the research team will use the equipment of the Laboratory of a) Furniture Manufacture Technology and b) Quality Control of the Department of Wood and Furniture Design and Technology, TEI of Larissa. Additionally, the research team may use the equipment of the relative Laboratory of the Department of Electrical Engineering, TEI of Larissa with a specialization and experience on "intelligent" products and constructions. 3.3 Cost management The following tables depict the timetable of each working package, analytical deliverables, costs per working package/objective/category/time and project reporting. As it is observed, the development of the GSF product, follows a sequential procedure, beginning with the organization of the process for the NPD, with market study to follow along with the rest of the development phases. The objectives of the two first phases of the project are the overall planning of the project and more precisely the methodical organization of research in order to focus in the manufacture of eco-logical furniture based on the existing international standards in regard to product quality, the existing legislation and the requirements of consumers. Moreover, these phases are aiming at a broad briefing round the ecological furniture and the acquisition and diffusion of know-how Proceedings of 7th Annual American Business Research Conference 23 - 24 July 2015, Sheraton LaGuardia East Hotel, New York, USA, ISBN: 978-1-922069-79-5 that is required by all main and supporting teams’ members, all stakeholders as well as the public. The market study and trend analysis play a fundamental role during this first phases of the GSF development, targeting both enterprises and consumers, aiming at the explicit formulation of manufacturing criteria as well as the production process planning and the final products. It constitutes a particularly useful guide for the enterprises of the furniture sector. The next two stages of the GSF development, design and manufacturing of GSF are a bit differentiating, regarding the sequence of execution. As shown in Table 1 parts of these two phases are implemented in parallel, in accordance to satisfy the requirements of the product complexity and the demands of time and process sequence optimization. Furthermore, cost saving is achieved, since a nonlinear interaction between team members occurs, focusing to the desired product’s characteristics and the technological requirements for the building of a prototype. Table 1. Timetable of working packages and analytical activities of GSF project Title Activities 2013 WP1 "Organizing the process of New GSF Product Development Preparatory work" Α1.1. Scientific planning Α1.2. Literature review Α1.3. Collection of relative legislation and regulations Α1.4. Case studies and parallel scenario Α1.5. Design Brief Α1.6. Establishment of evaluation criteria per project phase Α1.7. Organization of a workshop for all stakeholders "Determination of GSF market WP2 in Greece and its tendencies (Targeting and trend analysis)" Α2.1. Choice of the sample and formation of questionnaires Α2.2. Use of pre-questionnaires and finalization of the content of final questionnaires Α2.3 Conduct of the market research, Α2.4. Results elaboration and a report of these with conclusions Α2.5. Publication of results WP3 "Design of eco-logical - GS domestic furniture" Α3.1. Establishment of final design criteria /objectives and characteristics of GS furniture Α3.2. Creation and registration of ideas / proposals in 2-D (sketches) and 3D Α3.3. Analysis and valuation of ideas/proposals from the evaluation committee Α3.4. 3-D Design of the prevailing ideas /proposals and choice of suitable materials and mechanisms Α3.5. Final valuation and selection of only one or two ideas /proposals Α3.6. Filing of the final design study and manufacturing drawings of selected proposal(s) Α3.7. Patenting of the selected proposal(s) / idea(s) and final manufacturing drawings at NPR (OBI) Α3.8. Publication of selected ideas /proposals in sector-journals Year 2014 2015 Proceedings of 7th Annual American Business Research Conference 23 - 24 July 2015, Sheraton LaGuardia East Hotel, New York, USA, ISBN: 978-1-922069-79-5 WP4 "Production Technology of ecological GS domestic furniture" Α4.1. Manufacture of functional prototype(s) and prototype(s) for pilot production for recording the whole process Α4.2. Determination of the production technology Α4.3 Determination of assembly (ies) Α4.4. Determination of use of most suitable timber species Α4.5 Determination and choice of the suitable raw and secondary material that will ensure the "ecologic character" of the furniture Α4.6. Determination and supply of essential technological – electronic equipment that will ensure the "smartness" of the furniture Α4.7. Application of the essential processes of quality controls Α4.8 Recording of impressions and observations by the furniture’s voluntary use WP5 "Economic analyses" Α5.1 Collection of basic data Α5.2 Methodology development Α5.3 Feasibility study of production and estimation of manufacturing costs Α5.4 Cost accounting of production Α5.5 Business plan for mass production Α5.6 Research paper Α5.7 Workshop Organisation and realisation WP6 "Promotion and communication of eco - logical furniture" Α6.1. Determination of marketing objectives for the 1st "oiko - logical" - GF furniture, and determination of new niche markets Α6.2. Determination of the marketing strategy for the innovative product Α6.3. Determination of channels for internal and exterior communication Α6.4. Effective communication activities Α6.5. Study on brand strategy Α6.6. Publication of a relative newsletter Α6.7. Activities for collaborations with government owned institutions and other educational institutions Next, table 2 summarizes the costs of each step regarding the GSF development. Thus, if we consider the three (3) first working packages as an integrated designing phase, WP 4 as the manufacturing phase and WP’s 5 and 6 as the business planning phase, we can argue that this phase is more cost intensive, holding the 42.9% of the total budget of the project. This fact is in accordance to several investigations of product development methodology, which have shown repeatedly that considerable time and expense can be saved by making the correct decisions in the early product development stages (during clarification of the task and the first concept development). If more emphasis is placed on "up-front" efforts, fewer iterations and improvements are needed later. Shortening product development times requires investing more time and capacity in the early stages of product development than was done previously. Therefore, preplanning and early identification of critical properties of future products are needed for avoiding iterative loops. This also enables product planners to react quickly to market changes. Proceedings of 7th Annual American Business Research Conference 23 - 24 July 2015, Sheraton LaGuardia East Hotel, New York, USA, ISBN: 978-1-922069-79-5 Table 2. Cost allocated per work package. Title Activities 2013 WP1 WP2 WP3 WP4 Year 2014 2015 "Organizing the process of New GSF Product Development - Preparatory work" "Determination of GSF market in Greece and its tendencies (Targeting and trend analysis)" "Design of eco-logical - GS domestic furniture" "Production Technology of eco-logical GS domestic furniture" WP5 "Economic analyses" WP6 "Promotion and communication of eco logical furniture" Cost (€) 8,600 12,400 17,600 19,300 16,400 15,700 TOTAL 90,000 Levering our analysis and according to the next Table 3, we the majority of the GSF costs has to do mainly with personnel costs, at a percentage of 60% of the total budget of the project, while the rest are mainly administrative and promotion/dissemination costs. These personnel costs are dealing with the main research group of the GSF project and external collaborators from different research fields and organizations, at the concept of a networking product development. Based to these data, we can argue that the GSF project achieves a very satisfactory cost reduction regarding the desired equipment for the development and manufacturing of a GSF prototype, practically the related budget is zero! This is due to the open innovation process adopted to the project and the networking and alliance nature of the project, regarding the involvement of specialized research institutes in the specific field. Thus, the GSF project combined competencies from wood technology, ICT technology, furniture technology, design, electronics, NPD and innovation management, marketing, and all necessary research methodologies to design and later produce the innovative eco-smart piece of furniture. This is crucial for the Greek furniture sector and the Greek SME’s in general, in order to move towards radical innovations, using outsourcing and achieving them with a very efficient way, if we consider their limited liquidity and the capability in using sources and investments. Table 3. Cost allocated per category and year. Category A1. Personnel Costs (Main Research Group) A2. Personnel Costs (External Collaborators) A3. Travel and Subsistence A4. Equipment/Hardware/Software Costs A5. Consumables A6. Office Consumables A7. Publicity Costs A8. Various cost* Total cost covered by LLP** (total A1A8) 2013 2014 2015 TOTAL 5,700 5,800 18,000 29,500 7,000 11,100 6,400 24,500 5,200 0 0 1,100 2,000 0 2,000 0 8,000 1,500 300 4,500 5,800 0 0 2,400 2,700 500 13,000 0 8,000 5,000 5,000 5,000 21,000 33,200 35,800 90,000 The main cost category regarding personnel involved in the GSF project is further analyzed as shown in the nest Table 4. We can also note that the greater percentage (26.2%) of these costs, are dealing Proceedings of 7th Annual American Business Research Conference 23 - 24 July 2015, Sheraton LaGuardia East Hotel, New York, USA, ISBN: 978-1-922069-79-5 with the design phase, while only a 9.1% refers to the manufacturing phase. This fact also, leads us to the conclusion that the GSF project is a design oriented project, allowing an efficient and effective NPD. Another issue, regarding the management of the GSF project is that the project managers monitored the GSF by tracking specific tasks performed by the design and the manufacturing team. We observe that, according to Table 1, the project management adopts varying levels of oversight, having a high degree of micro-management, especially during the designing phase. This is due to the assumption that, project managers in general, confirm that projects with higher design budgets required proportionately higher number of tasks to be monitored (Bajaj, et al. 2002). Table 4. Cost Cost categories 1. Personnel Costs (Main Research Group) 2. Personnel Costs (External Collaborators) 3. Travel Expenses 4.Equipment/Hardware/Soft ware Costs 5. Consumables and Stationery 6. Dissemination costs 7. Other costs WP1 WP2 WP3 WP4 WP5 WP6 2,800 2,900 4,400 2,800 8,300 8,300 Budget/cat egory (€) 29,500 2,900 4,100 6,500 5,400 3,800 1,800 24,500 1,200 4,000 1,000 1,000 2,300 3,500 13,000 0 0 0 8,000 0 0 8,000 500 600 1,200 300 800 1,600 5,000 1,200 800 0 1,300 1,200 500 5,000 0 0 4,500 500 0 0 5,000 categories of the GSF project per working package. CONCLUSIONS During new product development (NPD) firms make critical design and sourcing decisions that determine the new product’s cost, performance, competitive position, and profitability. The purchase price of materials and components for the new product provides only part of the picture for design and sourcing decisions. This case study provides evidence that the type of NPD process moderates the effectiveness of cost goals in motivating cost reduction performance, with the designing phase to play the most significant role, regarding the development of green and smart furniture product. The NPD may follow a sequential or a concurrent process, depending on the complexity of the project and the available resources of a team/firm, aiming to cost reduction and performance. The present study could add to the existing academic literature by presenting a practical implementation of a NPD process, at a low tech sector such as the furniture sector, with important recommendations given to the operations management and project managers, that concurrent NPD processes could be implemented to reduce time-to-market in response to increasing global competition. Similarly, target costing has been recommended in the cost management literature as an important tool to ensure newly designed products can be introduced at a competitive market price (Wouters, et al. 2009). The results point also to the importance of project management experience, management commitment, and cross-functional integration in achieving a high level of efficiency. We hope that NPD managers will consider our practical suggestions and that our results may motivate researchers to continue exploring the NPD process in a wide variety of organizational settings, especially in low tech sectors, where resources are limited. Proceedings of 7th Annual American Business Research Conference 23 - 24 July 2015, Sheraton LaGuardia East Hotel, New York, USA, ISBN: 978-1-922069-79-5 Aknowledgements This research has been co-financed by the European Union (European Social Fund - ESF) and Greek national funds through the Operational Program "Education and Lifelong Learning" of the National Strategic Reference Framework (NSRF) - Research Funding Program: ARCHIMEDES III. Investing in knowledge society through the European Social Fund. References Badir, Y., Büchel, B. and Tucci, C.L., (2008), “The role of communication and coordination between “network lead companies” and their strategic partners in determining NPD project performance”, International Journal of Technology Management, Vol. 44, No. 1/2. Badir, Y., Founou, R., Stricker, C. and Bourquin, V. (2003), “Management of global large-scale projects through a federation of multiple web-based workflow management system”, Project Management Journal, Vol.34, No. 3, pp. 40–47. Bajaj, A., Kekre, S. and Srinivasan, K. (2002), “Managing NPD: Cost and Schedule Performance in Design and Manufacturing”, Carnegie Mellon University Pittsburgh, PA 15213, June 24. Barczak, G., Griffin, A. and Kahn, K.B. (2009), “Perspective: trends and drivers of success in NPD practices: results of the 2003 PDMA best practices study”, Journal of Product Innovation Management, Vol.26, pp. 3–23. Baumol, W. J. (2002), In: “The Free –Market Innovation Machine”, Princeton University Press, Princeton. Booker, D. M., Drake, A. R. and Heitger, R. (2007), “New product development: How cost information precision affects designer focus and behavior in a multiple objective setting”, Behavioral Research in Accounting, Vol.19, pp.19–41. Brown,S. L., Eisenhardt, K. M., (1995), “Product development: past research, present findings, and future directions”, Academy of Management Review, Vol. 20, No. 2, pp. 343–378. Canez, L., Puig ,L., Quintero, R. and Garfias, M. (2007), “Linking technology acquisition to a gated NPD process”, Research Technology Management, Vol. 50, No. 4, pp. 49–55. Cooper, R. (2002), “Target costing for new product development’, Cost Management, Vol. 16, No. 3, pp. 5–12. Cooper, R. G. (1996), “New products: what separates the winners from the Losers?”, in: Rosenau Jr., M. D. (Ed.), PDMA Handbook for New Product Development. John Wiley, New York. Cooper, R. G. (1999), “The invisible success factors in product innovation”, Journal of Product Innovation Management, Vol.16, pp. 115–133. Cooper, R. G. (2003), “Overcoming the crunchin’ resources for new product development”, Research Technology Management, Vol.46, No. 3, p. 48. Damanpour, F. (1991), ‘Organizational innovation: a meta-analysis of the effects of determinant and moderators”, Academy of Management Journal, Vol.34, pp.555–590. Davila, T., and Wouters, M. (2004), “Designing cost-competitive technology products through cost management”, Accounting Horizons, Vol. 18, No. 1, pp. 13–36. Ernst, H. (2002), “Success factors of new product development: a review of the empirical literature”, International Journal of Management Reviews, Vol. 4, No. 1, pp. 1–40. Gerwin, D. (2004), “Coordinating new product development in strategic alliances”, Academy of Management Review, Vol. 29, No. 2, pp. 241–257. Gopalakrishnan, M., Libby, T., Samuels, J.A. and Swenson, D. (2015), “The effect of cost goal specificity and new product development process on cost reduction performance”, Accounting, Organizations and Society, Vol. 42, pp.1–11. Griffin, A. (1997), “PDMA research on new product development practices: updating trends and benchmarking best practices”, Journal of Product Innovation Management, Vol.14, pp. 429–458. Proceedings of 7th Annual American Business Research Conference 23 - 24 July 2015, Sheraton LaGuardia East Hotel, New York, USA, ISBN: 978-1-922069-79-5 Kitsios, F. (2000), “NPD and design. Report on INNOREGIO: Dissemination of innovation development technologies”, Department of Production and Management Mechanics, Faculty of Engineering of Crete. Krishnan, V. and Ulrich, K. (2001), “Product Development Decisions: A Review of the Literature”, Management Science, Vol. 47, No. 1, pp.1-21. Olsen, M., Walker, C., Ruekert, W. and Bonner, M., (2001), “Patterns of cooperation during new product development among marketing, operations and R&D: implications for project performance”, Journal of Product Innovation Management, Vol. 18, pp. 258–271. Schmidt, B., Sarangee, K. and Montoya, M. (2009), “Exploring new product development project review practices”, Journal of Product Innovation Management, Vol. 26, No. 5, pp. 520–535. Shan, W., Walker, G. and Kogut, B. (1994), “Interfirm cooperation and startup innovation in the biotechnology industry”, Strategic Management Journal, Vol.15, No. 5, pp. 387–394. Song, X. M. and Xie, J. (2000), “Does innovativeness moderate the relationship between crossfunctional integration and product performance?”, Journal of international marketing, Vol. 8, No. 4, pp. 61–89. Song, X. M., Montoya-Weiss, M. and Schmidt, .B. (1997), “Antecedents and consequences of crossfunctional cooperation: a comparison of R&D, manufacturing and marketing perspectives”, Journal of Product Innovation Management, Vol. 14, pp. 35–47. Staudenmayer, N., Tripsas, M. and Tucci, L. (2005), “Inter firm modularity and its implications for product development”, Journal of Product Innovation Management Vol. 22, pp. 303–321. Swink, M., Talluri, S. and Pandejpong, T. (2006), “Faster, better, cheaper: A study of NPD project efficiency and performance tradeoffs”, Journal of Operations Management, Vol.24, pp. 542–562 Trigkas, M., Papadopoulos, I., Karagouni, G. (2012), “Economic efficiency of wood and furniture innovation system”, European Journal of Innovation Management, Vol. 15, No. 2, pp. 150 – 176. Ulrich, K., Eppinger, S. (2000), “Product Design and Development” 2nd Edition, McGraw Hill, New York, N.Y. Wouters, M., Anderson, J., Narus, J. and Wynstra, F. (2009), “Improving sourcing decisions in NPD projects: Monetary quantification of points of difference”, Journal of Operations Management, Vol.27, pp. 64–77.