Proceedings of Annual Paris Business and Social Science Research Conference

advertisement

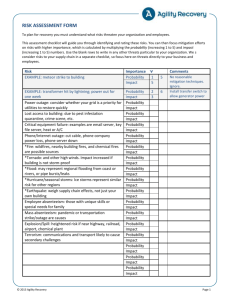

Proceedings of Annual Paris Business and Social Science Research Conference 7 - 8 August 2014, Hotel Crowne Plaza Republique, Paris, France, ISBN: 978-1-922069-57-3 Mitigating Supply Chain Risk through Building Critical Agile Supply Chain Capabilities An-Yuan Chang In order to achieve a higher level of performance in globalization business environments, companies need to design a robust supply chain, which allows the companies to interact with suppliers and customers and works together to achieve greater success. However, the expanded business operational activities have exposed supply chains to involve more risk factors. Companies should prepare themselves to cope with all unexpected risks and develop effective strategies to mitigate the risks. Supply chain agility facilitates a firm to react swiftly to volatile marketplaces and uncertain demands, thereby enabling the firm to be more efficient in synchronizing demand with supply, and thus help to establish a superior competitive position. Therefore supply chain agility has been considered as an effective approach to mitigate supply chain risks. However, so far, no such an operational model associated with how to mitigate risks by using agility strategy has been proposed in literature. This research will push the concept of risk and agility together and forward in an integrated way. It can provide effective agility capabilities to mitigate the supply chain risks. The purpose of this research is to construct an integrated model combining quality function deployment (QFD), mixed multiple criteria decision making (MCDM) approaches and graph theory and matrix approach (GTMA) to prioritize effective supply chain agility capabilities to enable supply chain systems more competitive in risk environment. Using this integrated model risk factors and agility capabilities will be defined in accordance with our research propose and a more comprehensive measurement approach for supply chain risks mitigation by using agility capabilities will be illustrated. An extension of the traditional QFD approach is another underlying theme of this research. This integrated approach attempts to remedy the incomplete situation of the traditional QFD, in which the dependencies among the voices of customer are not considered. Furthermore, not only GTMA is firstly combined with QFD in this research, but also it is the first attempt in the literature to combine GTMA with fuzzy extent analytical hierarchy process (FEAHP) and grey relational analysis (GRA) in the MCDM approach and in the risks mitigation model of a supply chain system. Keywords: Supply Chain Risk, Supply Chain Agility, Extended QFD, FEAHP, GRA, GTMA _________________________________________________________________________ An-Yuan Chang, Department of Industrial Management and Institute of Industrial Engineering and Management, National Formosa University, 64, Wun Hwa Road, Hu Wei, Yunlin 632, Taiwan, R.O.C.