Advance Journal of Food Science and Technology 4(3): 126-129, 2012

advertisement

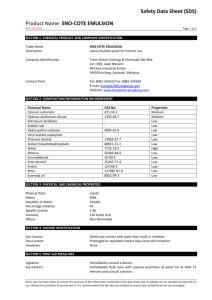

Advance Journal of Food Science and Technology 4(3): 126-129, 2012 ISSN: 2042-4876 © Maxwell Scientific Organization, 2012 Submitted: October 05, 2011 Accepted: March 02, 2012 Published: June 25, 2012 Effect of Salts on the Emulsifying Properties of Adansonia digitata (Baobab) Seed Flour H.O. Adubiaro, O. Olaofe and E.T. Akintayo Science and Technology Department, The Federal Polytechnical, Ado-Ekiti, Ekiti State, Nigeria Abstract: The effect of salts NaCl, CaCl2 KCl, CH3 CO2 Na and NaNO3 on the emulsifying properties of Adansonia digitata (Baobab) flour were investigated. Simple and objective means that allowed precise determination of the inversion point was used in investigating the capacity of the protein to emulsify fat. Its relative efficiency as emulsion stabilizer was also investigated. Results showed that the emulsion capacity decreased with increase in salt concentrations and also there was a decrease in emulsion stability as time increased and increase in stability as concentration increased. Keywords: Adansonia digitata, concentration, efficiency, emulsion, inversion, precise equipment, blender speeds, rate of oil addition, protein source and concentration, temperature, or type of oil affect emulsifying properties of proteins (Mcwatters and Cherry, 1981). No standardized tests exist for evaluating the emulsifying properties of proteins and in many cases there seems to be little correlation between results obtained in a model systems and those obtained in performance trails in food system. The method described in this work is a modification of the Crenwelge et al. (1974) method. It is simple and easily adaptable in that it enables formation of the emulsion inside a beaker and allows precise determination of the inversion point under standardized conditions by sensitive and objective means. The presence of salt may increase the total water content of the protein system at specific water activity values, although it may reduce the preferential binding of water to the protein (Sathe and Salunkhe, 1981). These effects are markedly dependent on the nature of the anion and cation components (Sathe and Salunkhe, 1981; Altschul and Wilcks, 1985). The effect of salt is significant because, in many foods, salt concentrations are approximately 0.2-0.3 M Altschul and Wilcks (1985). The aim of this investigation was to determine and compare the effect of NaCl, CaCl2, KCl, NaCH3CO2 and NaNO3 on the emulsifying properties of protein from Adansonia digitata (Baobab) so as to reveal its potentials for use as food emulsifiers. INTRODUCTION The continuous increase in population and inadequate supply of protein have in advertently increased the occurrence of malnutrition in developing countries (Siddhuraju et al., 1996). It is well documented that the developing countries (Nigeria inclusive) do not produce enough food and of the right nutritional qualities to meet daily needs. The dearth in food supply especially that of protein, is of such magnitude that the developing nations have to depend, mostly on cereal grains, starchy roots and tubers for their energy and protein needs (Aletor and Aladetimi, 1989). In view of above, the search for alternative source of protein from lesser known tree crops become imperative. However, successful applications of plant protein in food formulation depends largely on the functional properties of the protein (Milner, 1962). Emulsifying capacity and emulsion stability measurements are often used in functional characterization of proteins (Lin et al., 1974; Kinsella, 1979; Ige et al., 1984; Oshodi and Ekperigin, 1989). The technique most commonly employed for measuring the emulsion capacity of proteins is the model system, or modification of it, developed by Swift et al. (1961). This procedure involves the continuous addition of oil or melted fat to a protein dispersion during high speed mixing; oil is added until a sudden drop in emulsion viscosity occurs due to separation of oil and water into two phases. The volume of oil added until the “breakpoint” is reached is used to express emulsion capacity of a protein; these values may be expressed as total ml of oil emulsified, ml of oil per unit weight of sample, or ml of oil per unit of protein or nitrogen in the sample. Comparisons of results obtained from different studies is difficult because small variations in technique MATERIALS AND METHODS The Adansonia digitata seeds were collected from Fulani women after they had removed the pulp for use in making “Fura-da-nono” drink, in the Northern part of Nigeria. The seeds were sun-dried, de-shelled, powdered Corresponding Author: H.O. Adubiaro, Science and Technology Department, The Federal Polytechnical, Ado-Ekiti, Ekiti State, Nigeria 126 Adv. J. Food. Sci. Technol., 4(3): 126-129, 2012 Table 1: Effect of salts on emulsion capacity of Adansonia digitata (baobab). (Emulsion capacity ml of oil per g of soluble protein) Conc. of NaCH3 salt used %NaCl CaCl2 KCl COO NaNO3 0.0 320±3.1 320 ± 3.5 320 ± 4.8 320 ± 3.2 320 ± 4.0 0.5 290 ± 4.2 248 ± 4.8 284 ± 5.1 280 ± 2.6 194 ± 3.2 1.0 272 ± 3.6 222 ± 2.6 242 ± 3.6 252 ± 2.0 163 ± 4.0 2.0 205 ± 4.2 182 ± 6.3 206 ± 4.0 213 ± 3.2 152 ± 5.6 5.0 180 ± 3.1 103 ± 3.8 120 ± 3.1 182 ± 6.0 132 ± 4.8 10.0 100 ± 3.4 72 ± 3.2 93 ± 4.0 107 ± 4.0 70 ± 5.6 and stored in polythene bags until use. One hundred percent pure cotton seed oil (specific gravity 0.98 at 250ºC) was chosen as the oil phase for this study. The research was carried out in the year 2009 at Federal Polytechnic, Ado Ekiti, Ekiti State, Nigeria. Emulsifying capacity: Emulsions were formed inside a 600 mL beaker by use of continuous stirring apparatus; this apparatus consisted of a regulated/stabilized 6v power supply, a burette, a stirrer, a beaker with the emulsion and a digital milliameter. The stirrer consisted of a stainlesssteel rod holding a perspex bridge fixed to a 6v d.c motor spindle by means of a plastic adaptor. The motor itself was driven by a regulated and stabilised 6v d.c power supply. A milliameter monitored the current drawn by the stirrer motor to maintain a constant speed, the greater the viscosity of the emulsion the greater the current drawn. 1g of protein flour was made into a slurry of 25 mL of water in a Conical flask. The salts used were NaCl, CaCl2, KCl, NaCH3COO and NaNO3; all chemicals used were of analytical grade. The required concentrations of the different salt solutions used were 0.5, 1.0, 2.0, 5.0 and 10.0 w/v, respectively. The mixture was stirred for 30 min respectively. The mixture was stirred for 30 min in order to disperse the sample. Oil was then added at a rate of 1.00 mLs-1 from a burette until the emulsion collapsed, as indicated by a sharp fall in the motor current resulting from the sudden breakdown in viscosity. The volume of oil added up to this inversion point was noted and the emulsifying capacity expressed as ml of oil per g of protein. Table 2: Stirrer currents drawn at digitata (baobab) Conc. of salt used % NaCl CaCl2 (Curre MA) 0.0 862 ± 6.2 862 ± 3.2 0.5 800 ± 8.6 740 ± 3.6 1.0 764 ± 3.8 700 ± 4.0 2.0 680 ± 4.6 401 ± 3.8 5.0 334 ± 4.5 225 ± 5.2 10.0 200 ± 4.6 186 ± 4.6 the inversion points of Adansonia KCl NaCH3 COO NaNO3 862 ± 3.5 620 ± 4.0 520± 6.0 438 ± 3.8 125 ± 4.2 100 ± 4.0 862 ± 3.5 704 ± 6.2 658 ± 4.3 443 ± 5.0 203 ± 3.2 128 ± 5.6 862 ± 4.2 840 ± 3.6 760 ± 3.8 542 ± 3.5 216 ± 4.1 98 ± 2.3 Table 3: Emulsion stability of Adansonia digitata using NaCl Salt concentrations --------------------------------------------------------------------------Time (h) 0.0 0.5 1.0 2.0 5.0 10.0 0 15.9 17.6 22.0 25.1 27.0 26.4 0.5 15.0 17.4 21.1 23.0 26.0 24.2 1 15.0 17.0 18.5 20.0 25.0 24.2 5 13.1 17.0 18.0 19.2 24.8 23.4 10 8.2 10.4 14.5 15.8 20.1 23.4 24 8.0 10.0 14.3 15.3 19.0 23.4 48 7.6 8.8 14.0 15.1 18.4 22.8 72 5.0 7.0 14.0 15.0 18.0 22.6 120 5.0 7.0 10.4 13.0 14.5 16.5 144 0.0 3.4 6.0 9.3 11.3 16.0 168 0.0 3.0 4.0 7.1 9.1 12.1 336 0.0 0.0 1.3 4.5 5.0 8.4 Emulsion stability: The emulsion stability was determined by following the procedure used for the emulsifying capacity, except that 100 mL of oil was added rather than adding oil until the emulsion breakpoint. 1g slurry of protein in different concentration of salt was made as used for emulsifying capacity. One hundred mL aliquot of the Resultant Emulsion (RE) was measured into a 100 mL graduated cylinder and allowed to stand at room temperature (28 + 10ºC). The amount of oil separated was noted after 0, 0.5, 1, 5, 10, 24, 48, 72, 120, 144, 168 and 336 h, respectively. Table 4: Emulsion stability of Adansonia digitata using CaCl2 Salt concentrations -------------------------------------------------------------------------Time (h) 0.0 0.5 1.0 2.0 5.0 10.0 0 18.4 21.1 25.0 28.0 26.4 24.8 0.5 15.2 19.0 22.3 24.0 24.8 22.6 1 11.5 17.4 20.1 21.3 24.8 20.4 5 9.0 11.0 16.3 18.4 24.8 20.4 10 7.6 10.2 13.4 17.2 23.2 18.8 24 6.8 8.4 11.1 16.0 21.0 18.6 48 6.0 8.0 10.0 14.4 20.5 16.4 72 5.2 8.1 9.4 12.1 19.4 14.2 120 4.3 6.5 7.1 11.4 17.3 14.1 144 2.8 4.1 5.8 8.0 15.5 12.2 168 1.5 2.8 4.2 7.4 14.6 10.0 336 0.6 1.4 2.3 5.2 11.2 10.0 RESULTS AND DISCUSSION Table 1 shows the effect of salts on the emulsifying capacity and Table 2 gives the stirrer currents required by their emulsions near their inversion points. Table 1 revealed that for the Adansonia digitata (Baobab) flour, the emulsion capacity decreased with increase in salt concentrations which correspond with the currents required in Table 2. These results agree with those of other workers. Lin et al. (1974) on the emulsion capacity of sunflower and soyabean flours and protein concentrates/isolates; Sathe et al. (1982) on the emulsion capacity of lupin seed protein concentrates, Oshodi and Ojokan (1997) on the emulsion capacity of bovine plasma protein concentrates; Akintayo et al. (1998) on the emulsion capacities of pigeon pea, lima bean and African yam bean protein concentrates. The effect of salts on the emulsion stability of Adansonia digitata are shown in Table 3 (NaCl), 4 127 Adv. J. Food. Sci. Technol., 4(3): 126-129, 2012 Table 5: Emulsion stability of Adansonia digitata using Kcl Salt concentrations ------------------------------------------------------------------------Time (h) 0.0 0.5 1.0 2.0 5.0 10.0 0 17.8 20.6 23.2 29.1 32.0 34.6 0.5 15.4 19.2 21.4 25.2 28.0 32.8 1 14.3 16.4 20.2 23.1 25.4 32.8 5 12.9 13.5 17.4 19.0 22.1 30.0 10 10.2 13.0 15.1 18.4 20.4 28.4 24 9.1 11.4 13.0 15.1 19.3 27.8 48 7.0 9.0 10.4 11.2 18.0 25.6 72 6.0 7.6 8.0 10.0 17.4 24.2 120 4.2 7.0 8.0 8.6 16.5 20.0 144 3.8 5.8 6.4 7.9 14.2 18.2 168 3.0 5.2 5.0 6.0 11.0 14.1 336 2.4 3.2 4.6 5.4 9.5 13.2 the time increased. This corroborates the work of other researchers; Ogungbenle (2008) on the emulsion stability of gourd seed, white melon, yellow melon and Bulma cotton seed, also Adeyeye and Aye (2005) on the emulsion stability of Triticum durum flour. The decrease in emulsion stability as time increased might be due to increased contact leading to coalescence which thereby reduced stability (Parker, 1987). Three separate mechanisms that appear to be involved in the formation of a stable emulsion may be: C C C Table 6: Emulsion stability of Adansonia digitata using NaCH3COO Salt concentrations ---------------------------------------------------------------------------Time (h) 0.0 0.5 1.0 2.0 5.0 10.0 0 20.4 24.1 29.2 34.1 40.1 48.4 0.5 19.2 20.0 27.1 30.0 37.4 47.9 1 15.1 20.0 24.3 28.4 34.1 44.4 5 14.3 19.4 21.0 27.7 32.0 35.1 10 11.2 18.2 21.0 23.1 28.0 33.0 24 11.0 15.1 19.2 23.0 27.6 30.5 48 11.0 13.5 18.4 20.4 27.0 28.4 72 9.3 13.0 17.3 19.1 25.4 26.1 120 7.2 11.4 15.1 17.2 21.2 23.2 144 6.0 10.2 15.0 15.7 18.1 20.0 168 4.3 7.1 11.4 13.2 17.2 20.0 336 2.1 5.3 11.0 13.0 15.1 18.1 Reduction of interfacial tension Formation of a rigid interfacial film Electrical charge (Mcwatters and Cherry, 1981) CONCLUSION This work revealed that the Adansonia digitata flour is a good source of protein. Its good emulsify capacity and stability implied the usefulness of the flour in food formulation and utilization in food industries. Also since its emulsion capacity and stability were affected by salt concentrations then salting may be selectively used to improve or inhibit these functional properties of this sample. ACKNOWLEDGMENT Table 7: Emulsion stability of Adansonia digitata using NaNO3 Salt concentrations ------------------------------------------------------------------------Time (h) 0.0 0.5 1.0 2.0 5.0 10.0 0 16.2 18.0 22.4 24.6 34.5 43.1 0.5 15.4 17.3 21.0 23.2 31.0 41.4 1 13.2 16.8 19.6 21.1 30.4 38.5 5 11.5 14.3 17.2 20.4 26.5 32.1 10 8.9 11.2 16.4 16.1 23.2 28.4 24 8.3 10.0 16.0 15.4 21.1 25.3 48 7.0 9.2 12.9 13.2 19.4 21.4 72 4.5 6.0 12.1 13.0 17.9 20.1 120 3.2 4.2 9.2 11.4 15.2 19.0 144 1.3 3.8 7.0 9.2 14.1 15.7 168 0.4 1.7 5.2 7.1 9.7 11.4 336 0.0 1.3 3.1 5.2 6.4 9.2 The authors wish to acknowledge the technical assistance of Mr. J.E. Ukpong (Physics Electronics laboratory) of the Federal Polytechnic, Ado-Ekiti, Ekiti State. REFERENCES Adeyeye E.I. and P.A. Aye, 2005. Chemical composition and the Effect of salts on the food properties of Triticum durum Wholemeal flour. Pak. J. Nutr., 4(3): 187-196. Akintayo E.T., K.O. Esuoso and A.A. Oshodi, 1998. Emulsifying properties of some legume proteins. Int. J. Food Sci. Technol., 33: 239-246. Aletor, V.A. and O.O. Aladetimi, 1989. Compositional evaluation of some cowpea varieties and some underutilised edible legumes in Nigeria. Dich. Nahrung., 33(10): 999-1007. Altschul, A.M. and H.L. Wilcks, 1985. New Protein Foods: Food Science and Technology. F.L. Academic Press, Orlando. Crenwelge, D.D., C.W. Dill, P.T. Tybor and W.A. Landman, 1974. A comparison of the emulsification capacities of some protein concentrates. J. Food Sci., 39: 175-177. Ige, M.M., A.O. Ogunsua and O.L. Oke, 1984. Functional properties of the proteins of some Nigerian oil seeds: Conphor seeds and three varieties of melon seeds. J. Agric. Food Chem., 32: 822-825. (CaCl2), 5 (KCl), 6 (NaCH3COO) and 7 (NaNO3). The sample emulsion stability were studied under room temperature over a range of 0, 0.5, 1, 5, 10, 24, 48, 72, 120, 144, 168 and 336 h, respectively. The salt concentrations as 0.0, 0.5, 1.0, 2.0, 5.0 and 10.0 g, respectively. The capacity of protein to aid the formation and stabilization of emulsion is important for many applications in cake bakers, coffee whiteners, milk, mayonnaise, salad dressings, comminuted meats and frozen desserts (Kinsella et al., 1985). The degrees of water separation vary from salt to salt. However, the general trend for all the salt under consideration in this work is that there is increase in the volume of water separated with increase in salt concentration but there is a general decrease in the volume of oil separated (for each salt concentration) as 128 Adv. J. Food. Sci. Technol., 4(3): 126-129, 2012 Ogungbenle, H.N., 2008. Effects of salts concentrations on the functional properties of some legume flours. Pak. J. Nutr., 7: 453-458. Parker, N.S., 1987. Properties and functions of stabilising agents in food emulsions. Crit. Rev. Food Sci. Nutr., 25(4): 112-129. Sathe, S.K. and D.H. Salunkhe, 1981. Functional properties of the Great Northern Bean (Phaseolus vulgaris L.) proteins, emulsion, foaming, viscosity and gelation properties. J. Food Sci., 46: 71-74. Sathe, S.K., S.S. Deshpande and D.H. Salunkhe, 1982. Functional Properties of lupin seed (Lupinus mustabilis) proteins and concentrate. J. Food Sci., 47: 491-496. Siddhuraju, P., K. Vijayakumari and K. Janardhanan, 1996. Chemical Composition and protein quality of the little known legume, velvet bean (Mucuna pruriens). J. Agric. Food Chem., 44: 2636-2641. Swift, C.E., C. Lockett and A.J. Fryar, 1961. Communited meat emulsions-The capacity of meats for emulsifying fat. Food Technol., 15: 468-473. Kinsella, J.E., 1979. Functional properties of soy proteins. J. Am. Oil Chem. Soc., 56: 242-258. Kinsella, J.E., D. Srinivasan and G. Bruce, 1985. Physical, chemical and functional Properties of Oil Seed Protein with Emphasis on Soy Proteins. In: Altschul, A.M. and H.L. Wilcks, (Eds.), New Protein Foods. Academic Press, New York, 5p: 107. Lin M.J.Y., E.S. Humbert and F.W. Sosulki, 1974. Certain functional properties o f s u n f l o w e r me a l products. J. Food Sci., 39: 368-370. Mcwatters, K.H. and J.P. Cherry, 1981. Emulsification: Vegetable Protein. In: Cherry, J.P., (Ed.), American Chemical Society Symposium Series. 147, pp: 217. Milner, M., 1962. Protein food problems in developing countries. Food Technol., 16(5): 51-52. Oshodi A.A. and E. Ojokan, 1997. Effect of salts on some of the functional properties of bovine plasma protein concentrate. Food Chem., 59(3): 333-338. Oshodi, A.A. and M.M. Ekperigin, 1989. Functional properties of pigeon pea (Cajanus cajan) flour. Food Chem., 34: 187-191. 129