Advance Journal of Food Science and Technology 4(2): 112-117, 2012

advertisement

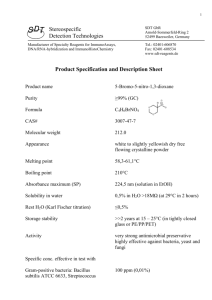

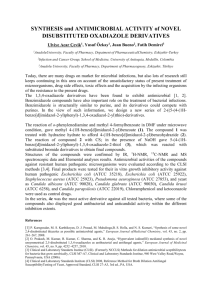

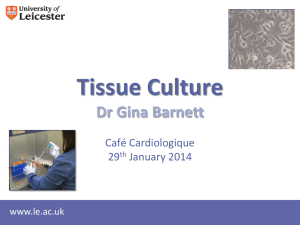

Advance Journal of Food Science and Technology 4(2): 112-117, 2012 ISSN: 2042-4876 © Maxwell Scientific Organization, 2012 Submitted: March 14, 2012 Accepted: March 26, 2012 Published: April 20, 2012 Production of Functional Kariesh Cheese by Microencapsulation of Bifidobacterium adolescentis ATCC 15704 A.M. Abd-Elhamid Department of Food and Dairy Science andTechnology, Faculty of Agriculture, Damanhour University, Damanhour, 22516, Egypt Abstract: Bifidobacterium adolescentis ATCC 15704 was microencapsulated with rennet gelation of milk proteins. Encapsulated and free Bifidobacterium adolescentis ATCC 15704 under simulated gastrointestinal conditions and bile tolerance were estimated. The survivability of encapsulated Bifidobacterium adolescentis ATCC 15704 and the changes of organic acids in Kariesh cheese during 2 weeks of cold storage were determined. The study demonstrated that microencapsulation using rennet gelation of milk proteins increased the survival of Bifidobacterium adolescentis ATCC 15704 in simulated gastric conditions. Furthermore, the results showed that, the survival of encapsulated Bifidobacterium adolescentis ATCC 15704 in bile solution was significantly enhanced (p<0.05) compared to the free Bifidobacterium adolescentis ATCC 15704. Microencapsulation protected Bifidobacterium adolescentis ATCC 15704 in Kariesh cheese during cold storage as compared to free Bifidobacterium adolescentis ATCC 15704. In addition, the capsules made from rennet gelation of milk proteins had a positive effect in organic acids during cold storage. Key words: Bifidobacterium, bile tolerance, microencapsulation, organic acids, Kariesh cheese products and in the gastrointestinal tract (Rao et al., 1989). It is a process by which cells are retained within an encapsulating matrix or membrane. The most widely used encapsulating material is alginate, direct compression encapsulation, and rennet-gelled protein encapsulation. Rennet could be used to prepare water-insoluble microcapsules based on milk-proteins without significant loss of cell during the encapsulation process. Microencapsulation protecting the cells during incubation under simulated gastric conditions at low pH (Heidebach et al., 2009). The objectives of this work were to prepare functional Kariesh cheese with encapsulated Bifidobacterium adolescentis ATCC 15704 in capsules made with rennet-gelled of milk proteins, to evaluate the survival of encapsulated cultures under simulated gastrointestinal conditions and to determined the changes of encapsulated Bifidobacterium and organic acids in Kariesh cheese during storage period. INTRODUTION Karish, Kariesh, or Kareish cheese is one of the most popular types of soft cheese consumed in Egypt. It contains most of the skim milk constituents including 16.70% protein, 3.98% sugar, 72.50% water and 0.1% fat. Karish cheese is made from skimmed buffalo, s or cow’s milk or a mixture of both. The increasing demand for it by Egyptian consumers is mainly attributed to its low price (Abd-El-Salam et al., 1984; Abou-Donia, 2008). Several approaches have been proposed to improve therapeutic effect of Kariesh cheese. One of the most common approaches is to modify the manufacturing procedure in order to increase the Bifidobacterium (El-Nemr et al., 2007). The main therapeutic benefits bifidobacteria is: immune enhancement; prevention of diarrhoeal diseaseand colon cancer; enhancement of immunity against intestinal infections; prevention of upper gastrointestinal tract diseases; and hypercholesterolaemia; improvement in lactose utilization; and stabilization of the gut mucosal barrier (Kailasapathy and Chin, 2000). The number of viable Bifidobacterium taken orally is decreased due to action of processing and storage conditions of the food containing them and to the action of gastric juice and bile salts. Bifidobacterium has poor survivability in dairy products as they do not tolerate exposure to highly acidic and aerated media (Muthukumarasamy et al., 2006). Microencapsulation techniques have been investigated for improving the viability of lactic acid bacteria when incorporated in dairy MATERIALS AND METHODS Strain: Bifidobacterium adolescentis ATCC 15704 was obtained from the Department of Dairy Microbiology (Animal Production Research Institute, Agriculture Research Center, Dokki, Egypt). Encapsulation procedure: The encapsulation technique was according to Heidebach et al. (2009). 112 Adv. J. Food Sci. Technol., 4(2): 112-117, 2012 experiment. The artificial juice, like gastric juice, was prepared with MRS broth without pepsin. The MRS broth was prepared by adjusting to pH 1.5 and 2.5 with HCl then sterilized by autoclaving for 15 min., at 121ºC. Fresh aqueous microcapsule-slurry (2.0 g) was added to MRS broth (pH 1.5 and 2.5) to a test-tube containing 18 mL of MRS broth without pepsin and vortexed for a few seconds. The test-tubes were incubated at 37ºC for 1, 2 and 3 h; respectively. The bacterial counts were determined using MRS medium. Three replicates of experiment were processed. (A) Enumeration of the free and encapsulated bacteria: Numbers of Bifidobacterium adolescentis ATCC 15704 was determined by plate counting using MRS agar with incubation at 37@C after 48 h; under anaerobic conditions using GasPak® (Dection Dickinson Microbiology System, Cocskeysville, MD). Encapsulated Bifidobacterium was enumerated in freshly prepared or previously acid-incubated capsules according Heidebach et al. (2009), 0.5 g of freshly prepared capsules or 10 mL of simulated gastric juice with capsules were diluted with double-distilled water to a total volume of 500 mL and homogenized by a stomacher at 7900 rpm for 2 min. Free cells were not homogenized after simulated gastric treatment. Each sample was assayed in triplicate. (B) Fig. 1: (A) Scanning electron photomicrograph of microcapsules. Bifidobacterium adolescentis ATCC 15704., (B) Section of milk protein-capsules showing: Bifidobacterium adolescentis ATCC 15704. Morphology examination of microcapsules: Samples of probiotic cells containing microcapsules were taken from the aqueous capsule-slurry and fixed for 1 h in 3% glutaraldehyed and dehydrated in graded series of ethanol (30-100). Sample were dried with acetone and amylacetate and then, coated with a thin layer of gold in a Fine coat JEOL (JFCL 1100E Ion Sputtering Device, Tokyo, Japan) Sputter coater. Coated samples were examined and photographed on JSM-5300, JEOL Scanning Microscope, Tokyo, Japan, with an accelerating voltage of 25 Kv at the Electron Microscopic Unit, Faculty of Science and Alexandria University (Fig. 1). Kariesh cheese preparation: Skimmed buffalo's milk (15 g fat/L) was obtained from Damanhour Agriculture Secondary School, Damanhour, Egypt and a buffalo's skim milk was pasteurization at 65±1ºC for 30 min, and then cooled to 32±1ºC. The treated milk inoculated with mesophilic lactic acid starter for cheese, which was added in ratio 2% in milk at 32±1ºC until curding. The formed curd was ladled into wooden frames lined with muslin cloth, 1% salt was dispersed. After 6 h; resting of the curd, the curd was divided into two portions. Bifidobacterium adolescentis ATCC 15704 (1%W/V) was added to the two portions as free (control) or encapsulated, and the curd pressed by suitable weights. Resultant cheese was stored at refrigerated temperature 9 ±1ºC for 14 days (El-Nemr et al. 2007); and Bifidobacterium strain was counted on MRS medium supplemented with neomycin sulphate 100 mg/L, naladixic acid 15 mg/L and lithium chloride 3 g/L (ElnasrPharmaceutical Chemicals Co., Abu Zaabal, Egypt.) , the plates were incubated under anaerobic conditions using GasPak® (Dection Dickinson Microbiology System, Cocskeysville, MD) at 37±1ºC for 48 h; the selectivity of the growth conditions was confirmed by morphology of cells from single colonies under a microscope (Lapierre et al., 1992). The Kariesh cheese making experiment was repeated three times. Survival of encapsulated Bifidobacterium adolescentis ATCC 15704 in bile solutions: The strain propagated previously in MRS broth (Elnasr-Pharmaceutical Chemicals Co., Abu Zaabal, Egypt) for 18 h; at their optimum temperature were inoculated individually by 1% into MRS broth supplemented with different concentrations (0.15, 0.30 and 0.40%, respectively) of bile salts (B8631, Sigma-Aldrich Chemical Co; St. Louis, Missouri) in triplicate and incubated at their optimum temperature. The growth was examined at zero time, after 3 and 6 h; by the changes in the total counts of the tested strains (Kim and Worobo, 2000). Three replicates of experiment were processed. Survival of encapsulated Bifidobacterium adolescentis ATCC 15704 in simulated gastric juices: An artificial juice like intestinal as recommended by Kim and Worobo (2000) at different pH values were used in this 113 Adv. J. Food Sci. Technol., 4(2): 112-117, 2012 Determination of organic acids: Lactic and acetic acids were determined using HPLC (Beckman) according Akalin et al. (2002). For preparation of sample, 4 g of cheese samples was added to 25 mL of 0.1 N H2SO4 homogenized and centrifuged at 5000×g for 10 min. the supernatant was filtered through Whatman No 1 filter paper and through a 0.20 :m membrane filter, and 2 mL aliquots were stored in HPLC vials at-20ºC until HPLC analysis. Operating conditions were: mobile phase, aqueous 0.6% (w/v) (NH4)2HPO4 (0.038 M)-0.2% (v/v) acetonitrile (0.049 M) adjusted to pH 2.24 with H3PO4; flow rate 0.5 mL/min and ambient column temperature. An ODS ultrasphere C18 (300×5mm) column (USA) was used. The mobile phase was prepsred by dissolving analytical-grade (NH4)2HPO4 in distilled water, HPLCgrade acetonitrile and H2SO4. The detector was set at 214 nm. HPLC-grade reagents were used as standards (Sigma Chemical Co., St. Louis, MO/USA). Solvents were degassed under vacuum. Both solvents and standard solutions were filterd through a 0.20 :m membrane filter. Quantitation was based on the external standard method (Bevilacqua and Califano, 1989). Log CFU g-1 Encapsulated bifidobacterium adolescent is ATCC 15704 0.15% Encapsulated bifidobacterium adolescent is ATCC 15704 0.30% Encapsulated bifidobacterium adolescent is ATCC 15704 0.40% 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Free bifidobacterium adolescent is ATCC 15704 0.15% Free bifidobacterium adolescent is ATCC 15704 0.30% free bifidobacterium adolescent is ATCC 15704 0.30% Zero time After 3 hrs. After 6 hrs. Fig. 2: Survival of encapsulated and free Bifidobacterium adolescentis ATCC 15704 in different concentration of high bile. Error bars give the standard deviation(Average of 3 replicates). resistance to bile effect was dependent on buffering capacity of protein in addition to protecting the cells during exposure to high concentrations of bile salt (Heidebach et al., 2009). Ding and Shah (2009) suggested that when free probiotic bacteria were exposed to taurocholic acid, viability was reduced by 6.36 log CFU/mL, whereas only 3.63, 3.27 and 4.12 log CFU/mL was lost in probiotic organisms encapsulated in alginate, xanthan gum and carrageenan gum, respectively. While, encapsulation of Bifidobacterium using 2% alginate enhanced the survival of Bifidobacterium by 16.6% (Sridar and Kailasapathy, 2003). Statistical analysis method: Data were analyzed using the Statistical Analysis System software package (SAS, 2000). Analyses of variance were performed using ANOVA procedures. Significant differences between mean were determined using Duncan’s multiple range test. RESULTS AND DISCUSSION Survival of encapsulated Bifidobacterium adolescentis ATCC 15704 in bile solutions: The bile salts secreted into the human small intestine consist of sodium chenodeoxycholate, sodium deoxycholate and sodium cholate. These substances can destabilize membrane integrity in bacterial cell. The strains of probiotic bacteria should be resistant to the action of bile salts and be able to colonise the intestine surface. The in vivo bile concentration in the intestine is lower, which could affect lactic acid cultures (Olejnik et al., 2005). As show in Fig. 2 the viability of free Bifidobacterium adolescentis ATCC 15704 decreased from 10.15 to 5.83 , from 10.15 to 5.19 and from 10.15 to 4.57 log CFU/g, respectivily at 0.15, 0.30 and 0.40% bile salt concentration after 6 h; incubation at 37ºC. Howevere, the viability of encapsulated Bifidobacterium adolescentis ATCC 15704 was significantly better, with regard to bile tolerance, than free Bifidobacterium adolescentis ATCC 15704. The microcapsulation increased the survival of Bifidobacterium adolescentis ATCC 15704 in bile solution. In conclusion, the acquired Survival of encapsulated Bifidobacterium adolescentis ATCC 15704 in simulated gastric juices: Low pH significantly decreased bacterial viability. Natural concentration of HCl in stomach reaches 170 mM and the minimum pH is about 1. After ingestion of a standard meal the pH value in stomach could increase to 7, which then declines to acidic values gradually, depending of the buffer capacity of the meals (Russell et al., 1993). Ekmekcioglu (2002) defined the time to decline one pH value to be about 10-20 min; full gastric emptying lasts up to 4 h; especially when meals are rich in fiber and fat. As shown in Fig. 3 the viability of free Bifidobacterium adolescentis ATCC 15704 significantly decreased (at p<0.05) after incubation at pH 1.5. The highest reduction of viability appeared after the first hour of incubating, while the viability encapsulated Bifidobacterium adolescentis ATCC 15704 attained the highest tolerance to low pH and its viability after 3 h; of incubation decreased to 6.78 and 7.14 log CFU/g at pH 1.5 and 2.5, respectively. Statistical analysis of results 114 Log CFU g-1 Adv. J. Food Sci. Technol., 4(2): 112-117, 2012 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 monitored over a storage period for 2 weeks for change in viable cell count. Table 1 showed the Bifidobacterium adolescentis ATCC 15704 count in the Kariesh cheese. In the case of free Bifidobacterium adolescentis ATCC 15704, the cell numbers dropped substantially to 6.10 log CFU/g by 2 weeks of storage at 9ºC. Furthermore the encapsulated state of the same strain showed a decrease to 8.12 log CFU/g, which might be attributed to the microencapsulation. There is a significant differences (p<0.05) between the free and encapsulated state in Kariesh cheese at the end of 2 weeks storage. From Table 1; it can be further seen that for Bifidobacterium adolescentis ATCC 15704 survival to a greater extent in the encapsulated state compared to the free Bifidobacterium adolescentis ATCC 15704 sample. This might be ascribed to capsules that tend to be synergistic in gelling and as a result may help in providing additional protection to the entrapped bacterial cells (Sultana et al., 2000; Jayalalitha et al., 2011). Encapsulated bifidobacterium adolescent is ATCC 15704 1.5 Encapsulated bifidobacterium adolescent is ATCC 15704 2.5 free bifidobacterium adolescent is ATCC 15704 1.5 Free bifidobacterium adolescent is ATCC 15704 2.5 Zero time After 1 hrs. After 2 hrs. After 3 hrs. Fig. 3: Survival of encapsulated and free Bifidobacterium adolescentis ATCC 15704 in over 6 h; of expsure to different concentration of acid. Error bars give the standard deviation (Average of 3 replicates). obtained in this exeriment revealed significant differences at p<0.05 between encapsulated and free Bifidobacterium adolescentis ATCC 15704 viability. Encapsulation in milk-protein-capsules greatly improved the survival rate of Bifidobacterium lactis compared to free cells under similar conditions at pH 2.5 (Heidebach et al., 2009). Sultana et al. (2000) reported that survival cells of Lactobacillus casei entrapped in alginate-starch beads decreased 2 log CFU/g after their incubation in simulated high acid gastric conditions and high bile during 3 h; at 37ºC. The binary blends of sodium alginate : amidated low-methoxyl pectin (1:2, 1:4, 1:6 ratios) help in providing additional protection to entrapped Lactobacillus casei cells against simulated gastriotesinal conditions (Sandoval-Castilla et al., 2010). Changes in free and encapsulated oraganic acids of kariesh cheese during cold storage: Organic acids formed as result of bacterial metabolism and hydrolysis of fat lactose, milk proteins and citrate during manufacture and storage of cheese (Ong and Shah, 2009). The initial acetic and lactic acids of Kariesh cheese made with free and encapsulated Bifidobacterium adolescentis ATCC 15704 were 0.63 and 3.94 g/kg, respictivly while at the end of storage (after 2 weeks) were 1.39 and 5.71 g/kg, respectively (Table 1). This might be due to utilization of lactose by Bifidobacterium,which can ferment the lactose result in 3 moL of acetic acid and 2 moL of lactic acid per 2 moL of glucose (Scardovi and Trovatelli, 1965). Compared with encapsulated Bifidobacterium adolescentis ATCC 15704, the acetic and lactic acids were 1.10 and 4.77 g/kg, respictivly after 2 weeks of cold storage. This might be due to the microcapsulation, which effectively protected the Bifidobacterium from acidic environmental in Kariesh cheese during cold storage. The goal of encapsulation was to create a micro-environment, in which the bacteria will survive during processing and storage and be released at Survival of encapsulated Bifidobacterium adolescentis ATCC 15704 in kariesh cheese during cold storage: Encapsulation is often defined as a way to protect bacteria against several enviromental factors (Anal and Singh, 2007; Champagne and Fustier, 2007). In this study, free or encapsulated Bifidobacterium adolescentis ATCC 15704 were used separately with the Kariesh cheese starter culture. Kariesh cheese was Table 1: Changes of chemical composition in kariesh cheeses made with encapsulated and free Bifidobacterium adolescentis ATCC 15704 during cold storage Variables Storage period Bifidobacterium (Log at 9@C (days) pH value CFU/g) adolescentis Acetic acid (g/kg) Lactic acid (g/kg) free Bifidobacterium adolescentis 0 4.67c 7.96d 0.49e 3.10f ATCC 15704 (control) 7 4.58d 7.01e 0.62d 4.00d 15 4.53e 6.10f 1.10b 4.77b encapsulated Bifidobacterium 0 4.79a 9.12a 0.63d 3.94e adolescentis ATCC 15704 7 4.71b 8.73b 0.93c 4.61c 15 4.61c 8.12c 1.39a 5.71a Means followed by the same superscript are not significantly different at p<0.05 115 Adv. J. Food Sci. Technol., 4(2): 112-117, 2012 El-Nemr, T.M., S.A. Awad, B. Gehan and J.R. Jjuuko, 2007. Utilization of oligosaccharides from sweet lupin (Lupinus termis) as a prebiotic into kaeish cheese analog. Proceeding of the 10th Egyptian conference for Dairy Science and Technology, 19-21, November 2007, 377-390, Cairo-Egypt. Heidebach, T., P. Först and U. Kulozik, 2009. Microencapsulation of probiotic cells by means of rennet-gelation of milk proteins. Food Hydrocolloids, 23: 1670-1677. Jayalalitha, V., P.R. Doria, B. Dhanalakshmi, A. Elango and C.N. Kumar, 2011. Improving the viability of probiotic in yoghurt through different methods of encapsulation. Egypt. J. Dairy Sci., 39: 39-44. Kailasapathy, K. and J. Chin, 2000. Survival and therapeutic potential of probiotic organisms with reference to Lactobacillus acidophilus and Bifidobacterium spp. Immunol. Cell Biol., 78: 80-88 Kim, S.O. and R.W. Worobo, 2000. Characterization and purification of a bacteriocin produced by a potential probiotic culture, Lactobacillus acidophilus 30 SC. J. Dairy Sci., 83: 2747-2752. Lapierre, L., P. Undeland and L.J. Cox, 1992. Lithium Chloride-Sodium Propionate Agar for the enumeration of Bifidobacteria in fermented dairy products. J. Dairy Sci., 75: 1192-1196. Muthukumarasamy, P., P.W. Allan and A.R. Holley, 2006. Stability of Lactobacillus reuteri in different types of microcapsules. J. Food Sci., 71(1): 20-24. Olejnik, A., M. Lewandowska, M. Obarsk and W. Grajek, 2005. Tolerance of Lactobacillus and Bifidobacterium strains to low pH, bile salts and digestive enzymes. Topic Food Sci. Technol., 1: 1-11. Ong, L. and N.P. Shah, 2009. Probiotic Cheddar cheese: Influence of ripening temperatures on survival of probiotic microorganisms, cheese composition and organic acid profiles. LWT-Food Sci. Technol., 42: 1260-1268. Rao, A.V., N. Shiwnarain and I. Maharaj, 1989. Survival of microencapsulated Bifidobacterium pseudolongum in simulated gastric and intestinal juices. Can. Insti. Sci. Technol. J., 22(4): 345-349. Russell, T.L., R.R. Berardi, J.L. Barnett, L.C. Dermentzoglou, K.M. Jarvenpaa, S.P. Schmaltz and B. Dressman, 1993. Upper gastrointestinal pH in seventy-nine healthy, elderly, North American men and women. Pharm. Res., 10: 187-196. Sandoval-Castilla, O., C. Labato-Calleros, H.S. Garc\aGalindo, J. Alvarez-Ram\rez and E.J. Vernon-Carter, 2010. Textural properties alginate-pectin beads and survivability of entrapped Lactobacillus casei in simulated gastrointestinal conditions and yoghurt. Food Res. Int., 43: 111-117. SAS, 2000. SAS User,s Guide.Version 4.02. Cary, NC, SAS Inst., USA. appropriate sites (e.g., small intestine) in the digestive tract (Anal and Singh, 2007). CONCLUSION Microencapsulation in protein milk micro particles successfully improved the survival of Bifidobacteriu adolescentis ATCC 15704 in bile solutions and protected the Bifidobacterium adolescentis ATCC 15704 in the gastrointestinal tract. In addition, the microencapsulation significantly increased the survival of Bifidobacterium adolescentis ATCC 15704 in Kariesh cheese during cold storage. The numbers of Bifidobacterium adolescentis ATCC 15704 in encapsulated state were 8.12 log CFU/g at the end of two weeks of cold storage. This viable cell number was higher than that recommended by the International Dairy Federation (107 CFU/g), indicating that the high initial number of probiotic could provide the recommmended number in the final product. Moreover, it could be concluded that the use of milk-proteins in microcapsulation of Bifidobacterium adolescentis ATCC 15704 could increase the acetic and lactic acids during storage. REFRENCES Abd-El-Salam, M.H., S. El-Shibiny and H.A. El-Alamy, 1984. Production of skim milk (Kareish cheese) from ultrafiltered reconstituted milk. Egyptian J. Dairy Sci., 12(1): 111-115. Abou-Donia, S.A., 2008. Origin, history and manufacturing process of Egyptian dairy products: An overview. Alexandria J. Food Sci. Technol., 5(1): 51-62. Akalin, A.S., S. Gonc and Y. Akbas, 2002. Variation in organic acids content during ripening of pickled white cheese. J. Dairy Sci., 85: 1670-1676. Anal, A. and H. Singh, 2007. Recent advances in microencapsulation of probiotics for industrial applications and targeted delivery. Trends Food Sci. Technol., 18: 240-251. Bevilacqua, A.E. and A.N. Califano, 1989. Determination of organic acids in dairy products by highperformance liquid chromatography. J. Food Sci., 54: 1076-1079. Champagne, C.P. and P. Fustier, 2007. Microencapsulation for the improved delivery of bioactive compounds into foods. Curr. Opin. Biotech., 18: 184-190. Ding, W.K. and N.P. Shah, 2009. Effect of various encapsulating materials on the stability of probiotic bacteria. J. Food Sci., 74(2): 100-107. Ekmekcioglu, G., 2002. A physiological approach for preparing and conducting intestinal bioavailability studies using experimental systems. Food Chem., 76: 225-230. 116 Adv. J. Food Sci. Technol., 4(2): 112-117, 2012 Sultana, K., G. Godward, N. Reynolds, R. Aumugaswamy, P. Peiris and K. Kailasapathy, 2000. Encapsulation of probiotic bacteria with alginate-starch and evaluation of survival in simulated gastrointestinal conditions and in yoghurt. Int. J. Food Microbiol., 62: 47-55. Scardovi, V. and L.D. Trovatelli, 1965. The fructose-6phosphate shunt as a peculiar pattern of hexose degradation in the genus Bifidobacterium. Anal. Microbiol. Enzymol., 15: 19-27. Sridar, N. and K. Kailasapathy, 2003. Studies on the effect of encapsulation on survival of probiotic microorganisms under high acid and bile conditions. J. Food Sci. Technol., 40: 458-460. 117