Advance Journal of Food Science and Technology 10(10): 763-769, 2016

Advance Journal of Food Science and Technology 10(10): 763-769, 2016

DOI: 10.19026/ajfst.10.2258

ISSN: 2042-4868; e-ISSN: 2042-4876

© 2016 Maxwell Scientific Publication Corp.

Submitted: June 8, 2015 Accepted: July 8, 2015 Published: April 05, 2016

Research Article

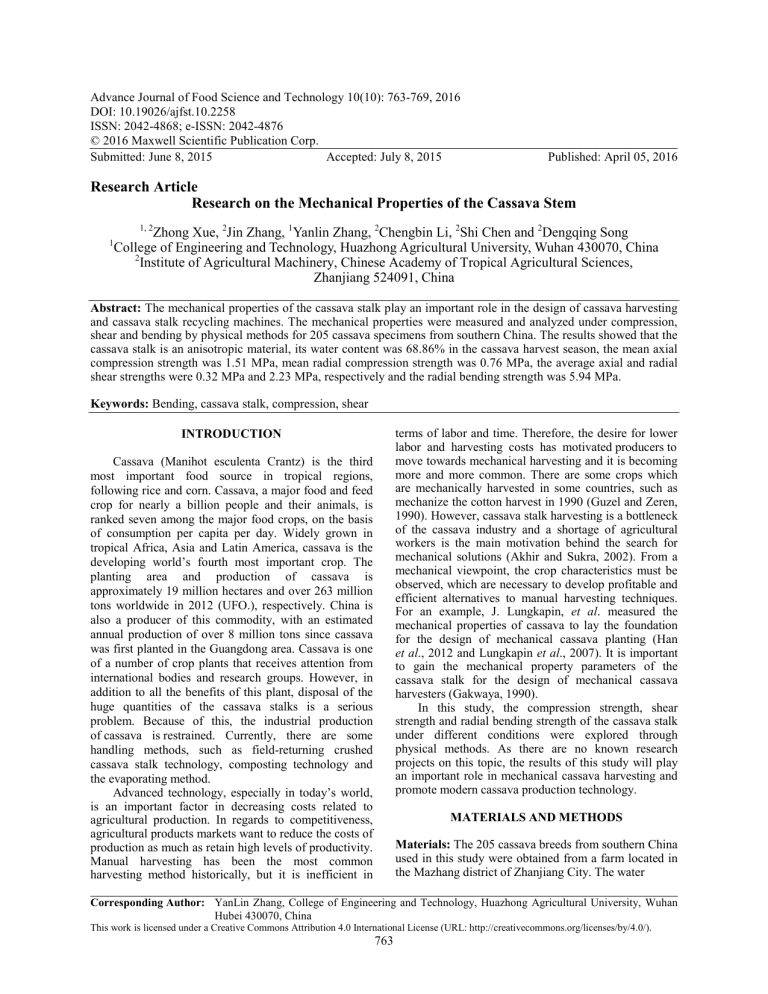

Research on the Mechanical Properties of the Cassava Stem

1, 2

Zhong Xue,

2

Jin Zhang,

1

Yanlin Zhang,

2

Chengbin Li,

2

Shi Chen and

2

Dengqing Song

1

College of Engineering and Technology, Huazhong Agricultural University, Wuhan 430070, China

2

Institute of Agricultural Machinery, Chinese Academy of Tropical Agricultural Sciences,

Zhanjiang 524091, China

Abstract: The mechanical properties of the cassava stalk play an important role in the design of cassava harvesting and cassava stalk recycling machines. The mechanical properties were measured and analyzed under compression, shear and bending by physical methods for 205 cassava specimens from southern China. The results showed that the cassava stalk is an anisotropic material, its water content was 68.86% in the cassava harvest season, the mean axial compression strength was 1.51 MPa, mean radial compression strength was 0.76 MPa, the average axial and radial shear strengths were 0.32 MPa and 2.23 MPa, respectively and the radial bending strength was 5.94 MPa.

Keywords: Bending, cassava stalk, compression, shear

INTRODUCTION

Cassava (Manihot esculenta Crantz) is the third most important food source in tropical regions, following rice and corn. Cassava, a major food and feed crop for nearly a billion people and their animals, is ranked seven among the major food crops, on the basis of consumption per capita per day. Widely grown in tropical Africa, Asia and Latin America, cassava is the developing world’s fourth most important crop. The planting area and production of cassava is approximately 19 million hectares and over 263 million tons worldwide in 2012 (UFO.), respectively. China is also a producer of this commodity, with an estimated annual production of over 8 million tons since cassava was first planted in the Guangdong area. Cassava is one of a number of crop plants that receives attention from international bodies and research groups. However, in addition to all the benefits of this plant, disposal of the huge quantities of the cassava stalks is a serious problem. Because of this, the industrial production of cassava is restrained. Currently, there are some handling methods, such as field-returning crushed cassava stalk technology, composting technology and the evaporating method.

Advanced technology, especially in today’s world, is an important factor in decreasing costs related to agricultural production. In regards to competitiveness, agricultural products markets want to reduce the costs of production as much as retain high levels of productivity.

Manual harvesting has been the most common harvesting method historically, but it is inefficient in terms of labor and time. Therefore, the desire for lower labor and harvesting costs has motivated producers to move towards mechanical harvesting and it is becoming more and more common. There are some crops which are mechanically harvested in some countries, such as mechanize the cotton harvest in 1990 (Guzel and Zeren,

1990). However, cassava stalk harvesting is a bottleneck of the cassava industry and a shortage of agricultural workers is the main motivation behind the search for mechanical solutions (Akhir and Sukra, 2002). From a mechanical viewpoint, the crop characteristics must be observed, which are necessary to develop profitable and efficient alternatives to manual harvesting techniques.

For an example, J. Lungkapin, et al . measured the mechanical properties of cassava to lay the foundation for the design of mechanical cassava planting (Han et al ., 2012 and Lungkapin et al ., 2007). It is important to gain the mechanical property parameters of the cassava stalk for the design of mechanical cassava harvesters (Gakwaya, 1990).

In this study, the compression strength, shear strength and radial bending strength of the cassava stalk under different conditions were explored through physical methods. As there are no known research projects on this topic, the results of this study will play an important role in mechanical cassava harvesting and promote modern cassava production technology.

MATERIALS AND METHODS

Materials: The 205 cassava breeds from southern China used in this study were obtained from a farm located in the Mazhang district of Zhanjiang City. The water

Corresponding Author: YanLin Zhang, College of Engineering and Technology, Huazhong Agricultural University, Wuhan

Hubei 430070, China

This work is licensed under a Creative Commons Attribution 4.0 International License (URL: http://creativecommons.org/licenses/by/4.0/).

763

Adv. J. Food Sci. Technol., 10(10): 763-769, 2016

Fig. 1: Structure of cassava stem

(a) Axial compression (b) Radial compression

Fig. 2: Diagram of cassava stem compression

(a) Axial shearing (b) Radial shearing

Fig. 3: Diagram of cassava stem shearing content of the typical cassava stalk was 69%, the structure of which is shown in Fig. 1.

Main apparatuses: The diameter of the cassava stem was measured by a digimatic vernier caliper (0.01 mm).

The compression strength, shear strength and radial bending strength of the cassava stem were measured by an electrical univers-al material testing machine (Changchun research institute for testing machine Co., Ltd, CSS- 44200). We testing the moisture content of the cassava stems collected in the experiment was 68.86%.

Sample pretreatment: The moisture contents of the cassava stems used in the experiments were stable, the roots of were mature and held starch and most leaves had fallen off when the cassava stems did not grow and were collected from December to January of next year.

The cassava stems had an average diameter of ±2 mm, with no deformations, disease or pests. The rough knots in the surfaces of the cassava stems were scabbled, but the wood fiber layer was not damaged. The smooth cassava stems were divided into three parts (top, middle and bottom).

Compression experiments: Each part with smooth ends was divided into two portions and chosen for axial and radial compression experiments. The dimensions of the smooth cassava stems used in the axial compression experiments were 40×D (diameter of the middle portion, in mm). The smooth cassava stems that were used in the radial compression experiments had dimensions of

160×D (diameter of the middle part, in mm). The related parameters of the biggest damage, corresponding

764

Fig. 4: Diagram of cassava stem bending maximum displacement, compressive modulus of elasticity and yield strength were determined by the electrical universal material testing machine. A diagram of the cassava stem compression is shown in Fig. 2.

Shear experiments: Each part with smooth ends was divided into two portions and used for the axial and radial compression experiments. The dimensions of the smooth cassava stem used in the axial shearing experiment were 20×D (diameter of the middle part, in mm). The dimensions of the smooth cassava stem in the radial shearing experiment were 160×D (diameter of the middle part, in mm). The related parameters of the biggest shearing force, the corresponding maximum displacement, shearing modulus of elasticity and yield strength were determined by the electrical universal material testing machine. A 1 mm blade was used in the experiments. A diagram of the cassava stem shearing is shown in Fig. 3.

Bending experiments: Each part with smooth ends was chosen to do radial compression experiments. The dimensions of the smooth cassava stem used in the radial compression experiment were 150×D (diameter of the middle, in mm). The cassava stem was installed by the fixtures in the universal material testing machine.

The fulcrum distance was 100 mm. The bending experiments were performed until the cassava stem was fractured. The related parameters of the biggest loading force, the corresponding maximum displacement, bending modulus of elasticity and yield strength were determined by the universal material testing machine. A diagram of the cassava stem bending is shown in Fig. 4.

EXPERIMENT DESIGN

Single-factor experiment: The loading position, direction and rate as a factor were selected to perform the experiment by the universal material testing machine. The parameters of compression and shearing were done through both axial and radial experiments.

The parameters of bending were done only by radial experiments.

Multiple-factor experiment: The multiple-factor experiment was done according to the full factorial design. The level of factor is shown in Table 1. Diagram

(A) was axial (A1) and radial (A2). Parts (B) including cassava stalk top (B1), middle (B2) and bottom (B3).

Data analysis: The collected and recorded data were processed with SAS8.1 version software. Means and

Table 1: The level of factor

Factors

Diagram (A)

Parts (B)

Loading rate (C)

Levels

A1

B1

20

Adv. J. Food Sci. Technol., 10(10): 763-769, 2016

A2

B2

50

B3

100 150 200

(a) Axial compression

(b) Radial compression

Fig. 5: Curve of cassava stem compression standard errors for each treatment were recorded. The data obtained were subjected to analysis of variance

The cassava stems underwent an elastic behavior at the beginning of the axial compression experiment. The

(ANOVA).

RESULTS

Compressed properties of the cassava stem:

Compression load and displacement relationship:

The compression load and displacement relationship was discussed under the conditions that the different parts of the cassava stems were compressed under different compression directions and the rate of loading was 50 mm/min. The results of the compression load and displacement relationship are shown in Fig. 5. compression load increased with time and the cassava stems crushed immediately after reaching the yield point. However, the crushed cassava stems could still hold a small amount of compression load, because they were destroyed perpendicularly to the axial cutting and its lignocelluloses had an axial distribution.

Both the compression load and deformation had a linear relationship at the beginning of the radial compression experiment and the compression strength of the cassava stem at the bottom was higher than at the top. The compression load increased with time. The cassava stems were crushed immediately after the

765

Adv. J. Food Sci. Technol., 10(10): 763-769, 2016

Table 2: Results of different factors in compression

Source

A

B

C

A*B

A*C

B*C

SS

1086439.45

22516683.85

3445250.55

5183780.05

1913352.57

524439.20

Error

Corrected

22908023.53

57577969.19

Total

M.S.: Mean of square; SS: Sum of squares

Table 3: Duncan’s multiple range test of factors

4

2

4

8

DF

1

2

98

119

M.S.

1086439.45

11258341.92

861312.64

2591890.02

478338.14

65554.90

233755.34

R-Square = 0.921658

Factors

A1

A2

B1

B2

B3

Means

1.51490

0.76981

1.29382

1.16162

1.29382

Numbers

60

60

40

40

40

F

4.65

48.16

3.68

11.09

2.05

0.28

Pr>F

0.0077

<0.0001

<0.0001

<0.0001

<0.0001

<0.0001

Duncan grouping

--------------------------------------------------------------a b c

0.05 a b

0.01

A

B

A

B

C compression load reached the limiting values and the destroyed cassava stems could not hold the compression load. This was due to the structure of the outer lignocelluloses shell being destroyed and the internal core could not withstand the compression load.

Compression analysis: The compression force of the cassava stem was done by multiple-factor experiment.

The results are shown in Table 2 and 3.

It was seen that the loading position, direction, rate and each other had striking differences on the damage of the cassava stems by the variance analysis (p<0.0001).

The main effect factors were analyzed by conducting multiple comparisons. It was found that the damage done by the axial compression was less than that of the radial compression and there was a profound difference.

Through testing, it was discovered that the loading force regions of the cassava stems were: the bottom of cassava stem, the middle and the top. The loading rate had an influence on the damage to the cassava stem.

It was found that the axial compressive strengths at the bottom of the cassava stem, in the middle and at the top were 1.75, 1.57 and 1.21 MPa, respectively and the average axial compressive strength was 1.51 MPa.

The radial compressive strengths of the cassava stem at the bottom, in the middle and at the top were 0.82, 0.74 and 0.73 MPa, respectively and the average radial compressive strength was 0.76 MPa. The axial compressive strength of the cassava stem was greater than the radial compressive strength, due to the lignocelluloses having an axial distribution and there was almost no strength in the internal core composition.

The compressive strengths of the cassava stem at the bottom, in the middle and at the top were different and the mechanical strength of the cassava stem decreased with the density, cortex and lignocelluloses of the cassava stem decreasing from the bottom to the top.

Shear property of cassava stem: in Fig. 6. force.

Shear and displacement relationship: The shearing load and displacement relationship was observed under the conditions that the different parts of cassava stem were sheared under different shearing directions and the rate of loading was 50 mm/min. The results of the shearing load and displacement relationship are shown

Both the shear load and deformation had a linear relationship at the beginning of the axial shearing experiment. The shearing load increased with time and it was observed that the shearing capacity of the cassava stems decreased when the shearing load was up to the limiting values. The cassava stems were sheared by axial cutting and its lignocelluloses, which had an axial distribution, could not withstand a greater shearing

Both the shearing load and deformation had a linear relationship at the beginning of the radial shearing experiment. The shearing load increased with time and the upper shells of the cassava stems were destroyed and the curve had a downward trend when the bearing capacity of the core compositions decreased. The bottom shell of the cassava stems began to force with time going and the curve had the trend of rise. The cassava stems were destroyed suddenly when the shearing load reached the limiting values and the destroyed cassava stems lost their compression resistance immediately.

Shearing analysis: The shearing force of the cassava stem was done by multiple-factor experiments. The results are shown in Table 4 and 5.

It was seen that the loading direction, position and rate had striking differences on the damage stress of the cassava stem by variance analysis (0.01). The main effect factors were analyzed by doing multiple comparisons. It was found that the damage of the axial

766

Adv. J. Food Sci. Technol., 10(10): 763-769, 2016

(a) Axial shearing

Fig. 6: Curve of cassava stem shearing

Table 4: Results of different factors in shearing

Source

A

B

C

A*B

A*C

B*C

Error

Corrected Total

SS

16293117.01

1935838.75

324353.40

1176425.52

224536.46

28783.17

1139653.90

21122708.21

M.S.: Mean of square; SS: Sum of squares

Table 5: Duncan’s multiple range test of factors

Factors

A1

A2

B1

B2

B3

Means

0.32247

2.22823

1.09973

1.29204

1.43429

(b) Radial shearing

DF

1

2

4

2

4

8

98

119

Numbers

60

60

40

40

40

767

M.S.

16293117.01

967919.38

81088.35

588212.76

56134.11

3597.90

11629.12

R-Square = 0.946046

F

1401.06

83.23

6.97

50.58

4.83

0.31

Pr>F

<0.0001

<0.0001

<0.0001

<0.0001

0.0014

<0.0001

Duncan grouping

---------------------------------------------------------------a b c

0.05 a b

0.01

A

B

A

B

C

Adv. J. Food Sci. Technol., 10(10): 763-769, 2016

Fig. 7: Curve of cassava stem bending compression was less than that of the radial compression and had a striking difference. It was discovered that the different loading force regions of the cassava stem are: the bottom, the middle and the top. The loading rate had an influence on the damage of the cassava stems.

The axial shearing strengths of the cassava stem at the bottom, in the middle portion and at the top were

0.36, 0.32 and 0.28 MPa, respectively; the average axial shearing strength was 0.32 MPa. It was discovered that the radial shearing strength of the cassava stem at the bottom, in the middle portion and at the top was 2.50,

2.25 and 1.91 MPa, respectively, with an average radial shearing strength of 2.23 MPa.

Bending properties of the cassava stem: The bending load and displacement relationship was observed under the conditions that the different parts of the cassava stem were bent under different shearing directions and the rate of loading was 50 mm/min. The results of the bending loads and displacement relationship are shown in Fig. 7.

Both the bending stress and deformation had a nonlinear relationship when the cassava stems were under a concentrated load. The bending load increased with time and the lower part of the cassava stems shell was destroyed when the bending load reached the limiting values. The curve showed a downward trend when the bearing capacity of the core composition could not withstand the bearing capacity. It was found that the bending strengths of the cassava stem at the bottom, in the middle and at the top were 6.89, 6.24 and 4.70 MPa, respectively and the average bending strength was 5.94

MPa.

CONCLUSION AND DISCUSSION

The moisture content of the cassava stems collected in the experiment was 69%. The average axial and radial

768 compressive strength of the cassava stems was 1.51

MPa and 0.76 MPa, respectively. The average axial and radial shearing strength of the cassava stem was 0.32

MPa and 2.23 MPa, respectively and the average bending strength of the cassava stem was 5.94 MPa.

The moisture content of the cassava stem had an effect on its mechanical properties, which was not considered in the test. However, the moisture content of the cassava stems was an important factor for its elasticity modulus and strength. The mechanical properties of the cassava stems were different under different moisture content conditions. Therefore, it is important to find out the optimal operational period according to the moisture content of the cassava stem during the cassava harvest season.

The shearing mode and cutters had an influence on the shearing effect, which were not considered in the test. It should be further studied, considering that the shearing mode (chopping shearing, sliding shearing and beveling shearing) had a large influence on the shearing effect.

ACKNOWLEDGMENT

This research work has been supported by National

Science Foundation of GuryDong Province-Creative talents join training project of Easten and Northwest

GuangDong (2014A030307034) the Special Fund for

Agro-scientific Research in the Public Interest (No.

201203072), the Natural Science Foundation of Hainan

Province (No. 513149).

REFERENCES

Akhir, H. Md. and A.B. Sukra, 2002. Cassava research and development in Asia: mechanization possibilities for cassava production. Proceedings of a Workshop held at Bangkok Exploring New

Opportunities for an Ancient crop, Thailand, Oct

28-Nov 1, 2002.

Adv. J. Food Sci. Technol., 10(10): 763-769, 2016

Gakwaya, T.K., 1990. The bending, crushing and buckling strength of cassava (Manihot utilissima) stem cuttings. Discov. Innovat., 02(01): 81-84.

Guzel, E. and Y. Zeren, 1990. Theory of free cutting and its application on cotton stalk. Agricultural

Mechanization in Asia, Africa and Latin America, pp: 55-58.

Han, M., Y. Kim, Y. Kim, B. Chung and G.W. Choi,

2012. Bioethanol production from optimized pretreatment of cassava stem [J]. Korean J. Chem.

Eng., 28(1):119-125.

Lungkapin, J., V.M. Salokhe, R. Kalsirisilp and H.

Nakashima, 2007. Laboratory studies of the stem cutting unit of a cassava planter. Agri. Eng. Int.

CIGRE-J. Manuscript PM 07 008, Vol. IX.

769