Research Journal of Applied Sciences, Engineering and Technology 6(15): 2757-2763,... ISSN: 2040-7459; e-ISSN: 2040-7467

advertisement

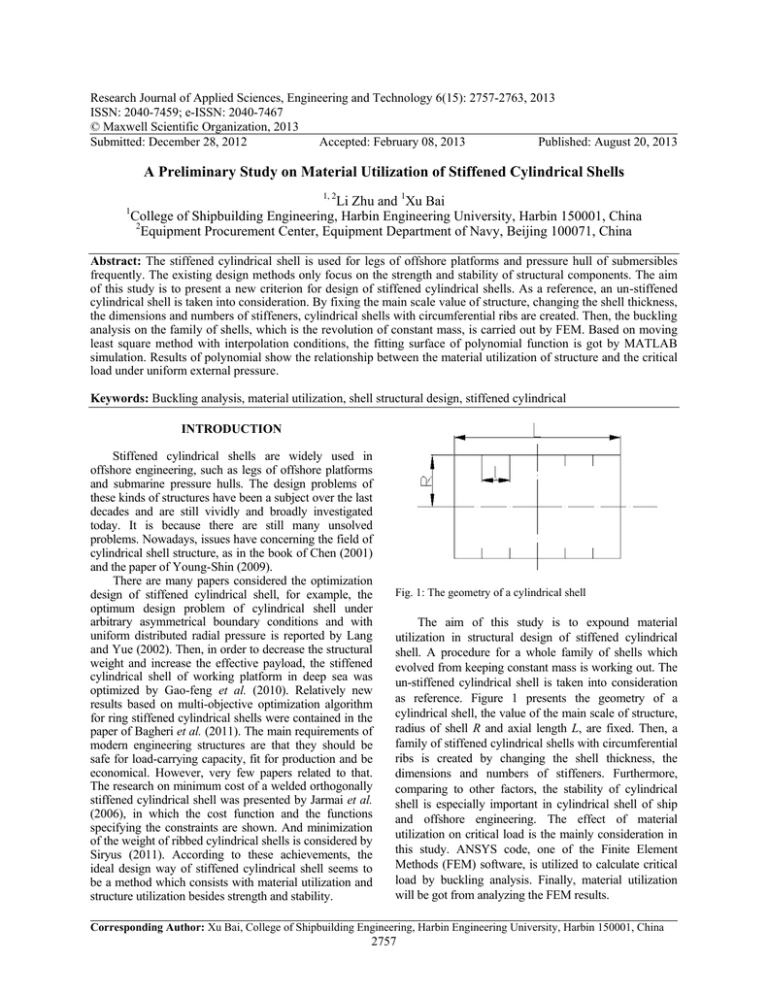

Research Journal of Applied Sciences, Engineering and Technology 6(15): 2757-2763, 2013 ISSN: 2040-7459; e-ISSN: 2040-7467 © Maxwell Scientific Organization, 2013 Submitted: December 28, 2012 Accepted: February 08, 2013 Published: August 20, 2013 A Preliminary Study on Material Utilization of Stiffened Cylindrical Shells 1, 2 Li Zhu and 1Xu Bai College of Shipbuilding Engineering, Harbin Engineering University, Harbin 150001, China 2 Equipment Procurement Center, Equipment Department of Navy, Beijing 100071, China 1 Abstract: The stiffened cylindrical shell is used for legs of offshore platforms and pressure hull of submersibles frequently. The existing design methods only focus on the strength and stability of structural components. The aim of this study is to present a new criterion for design of stiffened cylindrical shells. As a reference, an un-stiffened cylindrical shell is taken into consideration. By fixing the main scale value of structure, changing the shell thickness, the dimensions and numbers of stiffeners, cylindrical shells with circumferential ribs are created. Then, the buckling analysis on the family of shells, which is the revolution of constant mass, is carried out by FEM. Based on moving least square method with interpolation conditions, the fitting surface of polynomial function is got by MATLAB simulation. Results of polynomial show the relationship between the material utilization of structure and the critical load under uniform external pressure. Keywords: Buckling analysis, material utilization, shell structural design, stiffened cylindrical INTRODUCTION Stiffened cylindrical shells are widely used in offshore engineering, such as legs of offshore platforms and submarine pressure hulls. The design problems of these kinds of structures have been a subject over the last decades and are still vividly and broadly investigated today. It is because there are still many unsolved problems. Nowadays, issues have concerning the field of cylindrical shell structure, as in the book of Chen (2001) and the paper of Young-Shin (2009). There are many papers considered the optimization design of stiffened cylindrical shell, for example, the optimum design problem of cylindrical shell under arbitrary asymmetrical boundary conditions and with uniform distributed radial pressure is reported by Lang and Yue (2002). Then, in order to decrease the structural weight and increase the effective payload, the stiffened cylindrical shell of working platform in deep sea was optimized by Gao-feng et al. (2010). Relatively new results based on multi-objective optimization algorithm for ring stiffened cylindrical shells were contained in the paper of Bagheri et al. (2011). The main requirements of modern engineering structures are that they should be safe for load-carrying capacity, fit for production and be economical. However, very few papers related to that. The research on minimum cost of a welded orthogonally stiffened cylindrical shell was presented by Jarmai et al. (2006), in which the cost function and the functions specifying the constraints are shown. And minimization of the weight of ribbed cylindrical shells is considered by Siryus (2011). According to these achievements, the ideal design way of stiffened cylindrical shell seems to be a method which consists with material utilization and structure utilization besides strength and stability. Fig. 1: The geometry of a cylindrical shell The aim of this study is to expound material utilization in structural design of stiffened cylindrical shell. A procedure for a whole family of shells which evolved from keeping constant mass is working out. The un-stiffened cylindrical shell is taken into consideration as reference. Figure 1 presents the geometry of a cylindrical shell, the value of the main scale of structure, radius of shell R and axial length L, are fixed. Then, a family of stiffened cylindrical shells with circumferential ribs is created by changing the shell thickness, the dimensions and numbers of stiffeners. Furthermore, comparing to other factors, the stability of cylindrical shell is especially important in cylindrical shell of ship and offshore engineering. The effect of material utilization on critical load is the mainly consideration in this study. ANSYS code, one of the Finite Element Methods (FEM) software, is utilized to calculate critical load by buckling analysis. Finally, material utilization will be got from analyzing the FEM results. Corresponding Author: Xu Bai, College of Shipbuilding Engineering, Harbin Engineering University, Harbin 150001, China 2757 Res. J. Appl. Sci. Eng. Technol., 6(15): 2757-2763, 2013 STIFFENED CYLINDRICAL SHELLS WITH CONSTANT MASS Firstly, create a family of stiffened cylindrical shells which evolved from keeping constant mass. As a reference, a column of ends both fixed is constructed and loaded by uniform external pressure. Then, square crosssection ribs are welded inside of the shell by circumferential fillet welds. Hence, mass of the stiffened cylindrical shell shown in Fig. 2 is approximately given by: = ms 2π R ρ s ( tL + nA ) (1) Fig. 2: Cylindrical shell with ring stiffened The following variables will be introduced when 𝑡𝑡0 represents the thickness of unstiffened cylindrical shell: t A = ,y t0 t0 L (2) Y = x Introducing variables (2) into Eq. (1) gives, after reordering: x + ny − 1 = 0 (3) 1.0 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 n=1 n=2 n=4 n=8 0 Solving this quadratic equation the following formula for variable n arises: n= (1 − x ) / y (4) As it was mentioned above the axial length L of the shells and the radius R are constant. And then, it is clear that changing parameters x and y, a series lines represented shells with constant mass can be got. An example is shown in Fig. 3. The value of x and y obtained from the Eq. (3) and (4) provided the stiffened cylindrical shell with the considered mass. In Fig. 3, the stiffened cylindrical shells are the intersection points of the constant mass lines with the coordinate axis. Summing up, it is clear now that by assuming the value of x and y, the other parameters of the shell is obtained. From the Fig. 3, the point (x = 1 and y = 0) represents an un-stiffened cylindrical shell. The intersection points of each line with the axis of coordinates represent stiffened cylindrical shells. Besides these points, others are corresponding to stiffened cylindrical shells with different geometry. Considering the longitudinal coordinate, all points in this line represent illegal parameters of shells. So it is not need to be considered here. An example will be shown now. As a reference an un-stiffened cylindrical shell of the mass is chosen. The 0.1 0.2 0.3 0.4 0.5 X 0.6 0.7 0.8 0.9 1.0 Fig. 3: A family of constant mass lines for different ribs Table 1: A family of shells with constant mass 𝑚𝑚𝑠𝑠 = 1183.2 kg L = 2000 mm 𝑡𝑡0 = 20 mm R = 600 mm Constant values --------------------------------------------------------------------Parameter n=1 n=2 n=3 n=4 2 a A (mm ) 4000 2000 1000 500 t (mm) 18 18 18 18 b A (mm2 ) 8000 4000 2000 1000 t (mm) 16 16 16 16 2 c A (mm ) 12000 6000 3000 1500 t (mm) 14 14 14 14 d A (mm2 ) 16000 8000 4000 2000 t (mm) 12 12 12 12 e A (mm2 ) 20000 10000 5000 2500 t (mm) 10 10 10 10 f A (mm2 ) 24000 12000 6000 3000 t (mm) 8 8 8 8 g A (mm2 ) 28000 14000 7000 3500 t (mm) 6 6 6 6 radius of the shell is R = 600 mm and the thickness is 𝑡𝑡0 = 20 mm. This determines the value L = 2000 mm. And the properties of the material are: E= 2.05 × 105 MPa,υ = 0.3, ρ = 7.85 g / cm3 Now by choosing arbitrary values of the number of ribs n and calculating values of parameters A and t by expressions (2) and (4), it is possible to got a family of stiffened cylindrical shells which evolved from keeping constant mass. These shells are shown in Table 1. 2758 Res. J. Appl. Sci. Eng. Technol., 6(15): 2757-2763, 2013 FEM ANALYSES A buckling analysis has been carried out in order to show how the material of the cylindrical shell influences the critical load under uniform external pressure. So a family of stiffened cylindrical shells with constant mass has been considered. The analysis was carried out by ANSYS procedure. A Solid 45 finite solid element has been chosen with eight nodes and six degrees of freedom in each node. The boundary conditions imposed in the analysis are shown in Fig. 4. The movement of a normal edge direction and a rotation is allowed. A shell is loaded with uniform external pressure only. Because the applied pressure value equals unity (p = 1 MPa) and no preload (dead load) was applied, the eigenvalue obtained from the analysis is corresponds to the buckling load directly. The material specification is the same as in the examples above, it is: Fig. 4: Boundary conditions E= 2.05 ×105 MPa,υ = 0.3, ρ = 7.85 g / cm3 The first step, a mesh convergence analysis was made by un-stiffened cylindrical shell under the same condition. Figure 5 shows the buckling shape of the unstiffened cylindrical shell as an example. The results are Fig. 5: Buckling shape of unstiffened cylindrical shell (a) Change of load (b) Relative change of load Fig. 6: Mesh convergence analysis for unstiffened cylindrical shell 140 Relative change of Pcr (%) 0.08 Pcr (MPa) 120 100 80 60 40 20 4000 8000 12000 16000 20000 24000 28000 Number of elements 32000 (a) Change of load 0.07 0.06 0.05 0.04 0.03 0.02 5000 10000 15000 20000 25000 30000 Number of elements (b) Relative change of load Fig. 7: Mesh convergence analysis for stiffened cylindrical shell 2759 35000 Res. J. Appl. Sci. Eng. Technol., 6(15): 2757-2763, 2013 POLYNOMIAL FUNCTIONS t = 10 mm 50 t = 12 mm t = 16 mm 70 60 t = 14 mm Different shell thickness t = 18 mm Critical load (MPa) 90 80 40 30 20 10 0 2 1 3 4 5 Number of ribs 6 7 8 Fig. 8: Parts of the FEM analysis results shown in Fig. 6. It was decided that 30,000 finite elements of the shell would be enough for the analysis. And the analysis results of f8 of the stiffened cylindrical shell also present 30,000 finite elements showed in Fig. 7. The second step, the family of stiffened cylindrical shells with constant mass was examined. The FEM analysis results are shown in Fig. 8. The a4 of stiffened cylindrical shell is corresponds to the critical load obtained from ANSYS, which equals p cr = 37.782 MPa. Similar value, that is, p cr = 36.254 MPa, gives by comprehensive consideration of the Eq. (5) and (6). The critical load of local buckling: p= 0.6 Et 2 u − 0.37 R 2 (5) The buckling load is one of the most important objectively design variable of an externally pressurized stiffened cylindrical shell. It integrates structural parameters which react the bearing capacity. The relationship between the structure parameters and buckling load is nonlinear strongly. The simulation results are not identical with the real value and the relationship between material distribution and buckling load cannot be got from Eq. (5) and (6) directly. So, a similar polynomial function which reflects the changing trend of these discrete data points needs to be got by surface fitting. Surface fitting is a data processing method, which uses a continuous surface to depict the functional relation among space discrete points. It can be constructed by the least square method which does not need to go through all the data points. Recently, moving least square method is proposed for fitting the data. Compared with the traditional least square method, it has obvious advantages and is used broad in the data fitting and analysis. In this study, the fitting surface needs to go through one key point, so the interpolation conditions of the moving least square method should be considered. According to the paper of Feng-Mei et al. (2011), in the moving least square method, the objective polynomial function can be expressed as: = f ( x) m α ( x) p ( x) ∑= i =1 And the critical pressure of general buckling is given by: α 2 2 2+ (α + n ) t E p= 2 2 n − 1 + 0.5α 2 1.68 2 R βt 2 n 1 − ( ) 3 αU (1 + β ) R i i pT ( x )α ( x ) (7) The coefficients are: 4 α ( x ) = α1 ( x ) ,α 2 ( x ) ,...,α m ( x ) (6) The basic function is: The non-dimensional parameters relating to the design variables and constants are defined according to theory and experiments as follows: u= T 0.6427l Rt p ( x ) = p1 ( x ) , p2 ( x ) ,..., pm ( x ) Considering the complete polynomial basis, such as: Linear base: = p( x) β = lt / F T x, y ) ( m (1,= T 3) Quadratic base: α =πR / L = p( x) ( = U 0.535Lt 3 / I R ( t + F / l ) / l ) And it can verify that parameters m = 2, n = 6 in expression (6) gives the smallest value. x, y, x , xy, y ) ( m 6 ) (1,= 2 2 T In order to obtain a more accurately local approximation, the difference of the weighted square between local approximations f (x i ) and point value should be minimum. In the paper of Xiao-Hong et al. 2760 Res. J. Appl. Sci. Eng. Technol., 6(15): 2757-2763, 2013 (2005) and Ni et al. (2010), the discretely weighted norm of residual is: n J= ∑ w ( x − xi ) pT ( xi )α ( x ) − yi 2 so, the objective function is substituted by Eq. (12) through (11): = f ( x) (8) i =1 i =1 w (x-𝑥𝑥𝑖𝑖 ) is the weight function of the points x i while n is the number of points in the solving domain and f (x) is the fitting function. Usually, the circle is chosen as the support domain the spline function is constructed to be the weight function. Let s' = x-x i , s = s'/r, then the cubic spline function is: 1 2 2 3 3 − 4s + 4s , s ≤ 2 4 1 4 w ( s ) = − 4s + 4s 2 − s 3 , < s < 1 3 2 3 0, s > 1 m = φ y ∑ (9) k i ψ k ( x )Y i (12) where, Ψ 𝑘𝑘 (x) is the shape function and k is the order of basic function: = ψ k ( x ) = φ1k ,φ2k ,...,φnk pT ( x ) A−1 ( x ) B ( x ) (13) While the fitting function should go through some key points, the moving least square method with interpolation conditions is applied to construct the fitting surface formula. Supposing there are a set of scattered nodes (𝑥𝑥𝑖𝑖 , 𝑦𝑦𝑖𝑖 , 𝑧𝑧𝑖𝑖 ), i = 1, 2,.., n and the interpolation conditions are (𝑥𝑥𝑠𝑠 , 𝑦𝑦𝑠𝑠 , 𝑧𝑧𝑠𝑠 ), s = 1, 2,.., t, t≤n. P (x, y) is the fitting surface constructed by the moving least square method, then, the fitting surface with interpolation conditions can be written as: t when J takes the minimum value, matrix form of Eq. (8) is as follows: J= ( Pa ( x ) − Y ) W ( x ) ( Pa ( x ) − Y ) T = z P ( x, y ) − ∑ ls ( x, y ) δ s where, (10) = ls ( x ) where, Y = ( y1 , y2 ,..., yn ) T • • • a (x) is obtained by the least square method: B ( x ) = PTW ( x ) j =1 s≠ j j s j j s j This formula can also be considered as the modification of the moving least square fitting formula where the correction function is ∑𝑡𝑡𝑠𝑠=1 𝑙𝑙𝑠𝑠 (x) 𝛿𝛿𝑥𝑥 . So, in this study, the main processes of fitting function are: p1 ( x1 ) p2 ( x1 ) ... pm ( x1 ) p (x ) P= 1 2 ... pm ( xn ) p1 ( xn ) A ( x ) = PTW ( x ) P t δ s P ( xs , y s ) − z s = = wi w ( x − xi ) where, (x − x ) ( y − y ) ∏(x − x ) ⋅ ( y − y ) s = 1,2,..., t W ( x ) = diag ( w1 ( x ) , w2 ( x ) ,..., wn ( x ) ) a ( x ) = A−1 ( x ) B ( x ) Y (14) s =1 Obtain the moving least square fitting surface without interpolation conditions. Calculate the deviation of the key points. Obtain the moving least square fitting surface with interpolation conditions. According to the simulation results, the sets of scattered nodes are got. In order to analysis the material utilization, the dimensionless values should be independent variables, the buckling load values should be dependent variables. The detailed data is shown in Table 2. The MATLAB simulation tool was used to write the fitting procedures and paint the surface graph. The fitting 2761 (11) Res. J. Appl. Sci. Eng. Technol., 6(15): 2757-2763, 2013 Fig. 10: Surface of X partial derivative function Fig. 9: The fitting surface Table 2: The original data of surface fitting z z x y 20.414 0.9 0.1000 11.508 33.423 0.9 0.0500 18.631 37.782 0.9 0.0250 37.092 26.533 0.9 0.0125 84.627 15.568 0.8 0.2000 7.871 25.572 0.8 0.1000 12.644 51.306 0.8 0.0500 25.620 5.059 0.5 0.5000 54.605 8.230 0.5 0.2500 12.648 16.594 0.5 0.1250 52.306 0.8 0.0250 83.849 Table 3: The relative error of fitting surfaces The maximal error The minimal error 13% 0.6% x 0.7 0.7 0.7 0.7 0.6 0.6 0.6 0.5 1 y 0.3000 0.1500 0.0750 0.0375 0.4000 0.2000 0.1000 0.0625 0 0.6 0.0500 The average error 2.6% Fig. 11: Surface of Y partial derivative function surface was constructed by the interpolation nodes which are (12.648, 1, 0), which is shown in Fig. 9 and the formula of fitting is expressed as: 3 2 1 i 4 −i i 3−i i 2 −i i i i =i 0 =i 0=i 0 =i 0 f ( x, y ) = 4 ∑a x y + ∑b x y + ∑c x y + ∑ di xi y i −i + e where, a0 b0 c0 d0 e a1 a2 a3 a4 −8230 −73500 −55830 136760 123180 0 b1 b2 b3 −190660 30030 164170 = −39130 −107030 53670 c1 c2 d1 21120 16490 −3770 According to the fitting function, the relative errors among fitting surfaces and original data are shown in Table 3. The error fits for the accuracy requirement. MATERIAL UTILIZATION Maximizing material utilization in structure design is paramount important. Materials typically represent 75% and even more of the total costs in manufacture, so a poor design can significantly increase costs of structure over its life. The concept of material utilization is a common vocabulary in energy industry, materials science and etc., but relatively new in structure design. The definition is also different from different structure design. In this study, Material utilization is defined as the effective degree of material use in stiffened cylindrical shells structure. With the same material amount the higher the material utilization ratio, the stronger the carrying capacity of structure. So, the material utilization is the change rate of the function of structure parameters and target variable. In the fitting function, the independent variables are the shell and rib proportions of the total material. Therefore, the effective degree of material usage is the main factor that the independent variables affect the dependent variable. Partial derivative function for X and Y coordinate axis are got respectively. As shown in Fig. 10 and 11, the change of the parameter x is higher than the change of the parameter y. That is to say, in this case, the utilization of the shell is higher than the utilization of the rib. Material utilization will be the new criteria and method of structural design. Through the procedures, the 2762 Res. J. Appl. Sci. Eng. Technol., 6(15): 2757-2763, 2013 utilization of the shell and ribs in other cases can be got. How to measure material utilization and its usage in structures design are the key contents of the authors’ research in the future. CONCLUSION A simple procedure to create a family of stiffened cylindrical shells, which is the revolution of constant mass, has been shown. A lot of data points about buckling load and material shares of the shell and ribs are got form buckling analysis using ANSYS code. A conclusion can be drawn from the fitting function: in the case of uniform external pressure load stiffened cylindrical shells, the utilization of the shell are higher than the rib. Material utilization in structural system has special significance to design reasonable structures and ensure the safety of the overall structure. In the future study, the criteria of material utilization in structural design will be studied based on the results of this study. This research project is innovative in its approach of stiffened cylindrical shells design. It is expected that this approach will make immense contribution to the structural design. ACKNOWLEDGMENT The authors would like to express their gratitude and sincere appreciation to the anonymous reviewers for constructive suggestions to improve the quality and readability of this study. This study was conducted with supported of the Defense Pre-research Foundation of Shipbuilding Industry (No. 11J1.3.1). REFERENCES Chen, J., 2001. Stability Theory and Design of Steel Structures. Science Press, Beijing, China, pp: 11-20. Feng-Mei, Y., R. Shu-Yi and Z. Rong-Xi, 2011. Empirical comparison term structure of interest rates model based on polynomial spline function with penalty term. Syst. Eng. Theory Pract., 31(4): 735-739. Gao-Feng, S., Z. Ai-Feng and W. Zheng-Quan, 2010. Optimum design of cylindrical shells under external hydrostatic pressure. J. Ship Mech., 14(12): 1384-1392. Jarmai, K., J.A. Snyman and J. Farkas, 2006. Minimum cost design of a welded orthogonally stiffened cylindrical shell. Comput. Struct., 84: 787-797. Lang, B. and J. Yue, 2002. Optimum design of cylindrical shell on stability. J. Mech. Strength, 24(3): 463-465. Ni, H., Z. Li and H. Song, 2010. Moving least square curve and surface fitting with interpolation conditions. Proceeding of ICCASM International Conference on Computer Application and System Modeling. Taiyuan, pp: 300-304. Siryus, V., 2011. Minimization of the weight of ribbed cylindrical shells made of a viscoelastic composite. Mech. Comput. Mater., 46(6): 593-598. Xiao-Hong, S., Z. Gang and F. Zhao-Hua, 2005. A homogeneous high precise direct integration based on legendre polynomial series. Chinese J. Comput. Mech., 22(3): 335-338. Young-Shin, L., 2009. Review on the cylindrical shell research. J. Mech. Sci. Technol., 33: 1-26. Bagheri, M., A.A. Jafari and M. Sadeghifar, 2011. Multi-objective optimization of ring stiffened cylindrical shells using a genetic algorithm. J. Sound Vib., 330: 374-384. 2763