Research Journal of Applied Sciences, Engineering and Technology 4(6): 670-674,... ISSN: 2040-7467 © Maxwell Scientific Organization, 2012

advertisement

Research Journal of Applied Sciences, Engineering and Technology 4(6): 670-674, 2012

ISSN: 2040-7467

© Maxwell Scientific Organization, 2012

Submitted: December 06, 2011

Accepted: December 26, 2011

Published: March 15, 2012

Application of Implicit Space Mapping in the Design of Hammerhead Filter in

Millimeter-Wave Band

Fuqun Zhong, Bo Zhang, Yong Fan, Minghua Zhao and Guan Gui

School of Electronic Engineering, University of Electronic Science and Technology of China,

Chengdu, 611731, China

Abstract: In this study, we present advances in microwave and millimeter-wave device modeling exploiting

the Space Mapping (SM) technology. New SM-based modeling techniques are used that are easy to implement

entirely in the Agilent ADS framework. The implicit space mapping algorithm is applied to the design of

hammerhead filter in millimeter-wave band. The validity of this method is confirmed by comparison with fullwave EM simulation result and measured data. Based on the proposed method, a filter was designed and

fabricated on a substrate with thickness of 0.254 mm and dielectric constant of 2.2. The experimental results

show good agreement with simulated results. It is proved that the accuracy can be achieved using the implicit

space mapping algorithm, and the design efficiency can be greatly improved.

Key words: Accuracy and high efficiency, hammerhead filter, implicit space mapping algorithm

INTRODUCTION

of reducing CPU demand. Implicit Space Mapping (SM)

technology (Bandler et al., 2004) addresses the issue of

reducing the time-consuming full-wave Electromagnetic

(EM) simulations of microwave structures with the help

of a fast physics-based model or surrogate for device

modeling and optimization. In the design of microstrip

hammerhead filter, coarse models are realized in Agilent

ADS. We use HFSS as the fine model evaluators. Agilent

ADS schematics organize the ADS optimization engine

and coarse and fine models to perform parameter

extraction and surrogate optimization.

In this study, we adopt the simplified space mapping

implementation in Agilent ADS, all the space mapping

steps are integrated into ADS schematic. The processing

of design for microstrip hammerhead filter was described.

Filters play an important role in the successful

operation of millimeter and submillimeter-wave mixers

and frequency multipliers (Xue et al., 2003; Marsh

et al., 2007; Porterfield, 2007; Maestrini and Ward, 2008;

Zhang et al., 2011; Zhong et al., 2011a,b). Many simple

filters can be designed with direct full-wave

electromagnetic (EM) simulation optimization. However,

occasionally it is necessary to achieve a larger bandwidth

of operation and a greater level of stopband rejection

which often involves the use of more complicated filter

geometries which would spend so much time doing the

direct EM optimization. The relative simplicity and

flexibility of the implicit space mapping algorithm make

it a particalarly attractive tool for design of these more

complex circuits.

The microstrip hammerhead filter has been an

attractive candidate for use in wide stop-band mixer and

frequency multiplier circuits since its introduction many

years ago (MaMaster et al., 1976). Compared with the

traditional low-and-high-impedance microstrip filter, the

microstrip hammerhead filter is characterized by lowinsertion loss, sharp rejection, shorter size and wider stopband. These superior characteristics can be used to

improve the performance of the mixer and multiplier in

microwave and millimeter-wave band. However, complex

structures, too much variables and absence of a simple

and quick method for design have hindered its widespread

use.

Electromagnetic (EM) simulation is accurate, but

CPU intensive; hence, using a full-wave EM simulators

such as Ansoft HFSS, or Agilent Momentum, in the hope

Implicit space mapping algorithm: The formulation of

the implicit space mapping algorithm is presented in

(Bandler et al., 2004; Cheng et al., 2009).

A fine model optimal solution can be expressed as:

x * = arg min U ( R f ( x ))

x

(1)

where, Rf (x) is fine-model response vector, U is typically

a minimax objective function with upper and lower

specifications (Zhu et al., 2007), x is fine-model design

parameters, and x* is the optimal design to be determined.

In order to solve Eq. (1), the following iterative

procedure is used by implicit space mapping:

x k +1 = arg min U ( Rc ( x , p k ))

x

(2)

Corresponding Author: Fuqun Zhong, School of Electronic Engineering, University of Electronic Science and Technology of

China, Chengdu, 611731, China

670

Res. J. Appl. Sci. Eng. Technol., 4(6): 670-674, 2012

where, Rc (x, p) is a response vector of the coarse model

with x and p being the design variables and preassigned

parameters, respectively, Rc (x, pk) is an implicit space

mapping surrogate model with preassigned parameters pk

obtained at iteration k using the parameter extraction

procedure.

p k = arg min R f ( x k ) − Rc ( x k , p)

(3)

p

In which we try to match the surrogate to the fine

model. The initial surrogate model is

Rc (x, p0), where p0 represents the initial preassigned

parameter values. In other words, the surrogate model is

the coarse model with updated values of the preassigned

parameters. From the above derivation of the formulation

of the implicit space mapping algorithm, we can find that

our goal is to obtain the fine model optimal design

without going to direct optimization of the fine model but

instead using the surrogate model; i.e., the coarse model

with updated values of the preassigned parameters.

Parameter extraction and design optimization are

performed solely on the surrogate model. A prediction of

the next fine model design is also obtained through the

surrogate.

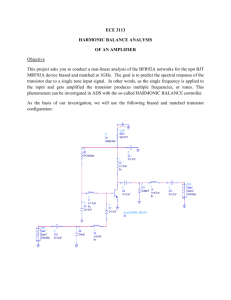

Fig. 1: The structure of microstrip hammerhead filter.

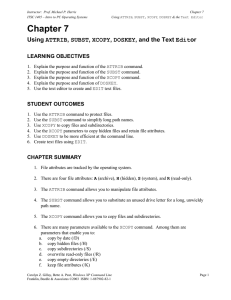

ADS schematic design framework: We implement

implicit space mapping optimization in the ADS

schematic framework in an interactive way to greatly

raise efficiency of microstrip hammerhead filter design.

The space mapping implemented in 5 steps is as fellows:

Step 1: Set up and optimize the coarse model in ADS

schematic

Step 2: Create the parameterized fine model in HFSS,

the structure dimension is same as the value

obtained in Step1

GOAL

Goal

OptimGoal6

Expr="sub_wide"

SimInstanceName="S P1"

Min=

Max=9

Weight=1000

RangeV ar[1]=

RangeMin[1]=

RangeMax[1]=

S-P ARAMETERS

MSub

S_Param

SP1

Start=0 GHz

Stop=9 GHz

Step=1 GHz

Meas

Eqn

MSUB

MSub1

H=1.27 mm

Er=2.2

Mur=1

Cond=5. 8E+7

Hu=3.73 mm

T=90 um

TanD=0. 0009

Var

Eqn

MeasEqn

Meas1

sub_wide=W1+2* W3+2*L2

banch_long=L2-L4

structure=L1-W3-L3

cent er_structure=L5-2*(L3+W3)

V AR

V AR1

GOAL

W1=1.65728 {o}

L4=0.8147 {o}

W2=0.603471 {o}

W3=1.13307 {o}

L3=1.85819 {o}

L1=4.09479 {o}

L5=10.8342 {o}

L2=2.51905 {o}

Rough=0 mil

W=0. 7 mm

L=1 mm

Min=1

Max=

Weight=1/0. 01

RangeVar[1]=

RangeMin[1]=

RangeMax[1]=

MCORN

Corn2

Subst="MSub1"

Subst="MSub1"

W=W3 mm

L=L3 mm

TL3

Subst="MS ub1"

W=W2 mm

L=L2 mm

MLIN

TL2

Subst="MSub1"

MSTEP

Step2

Subst="MS ub1"

W1=W1 mm

W2=0.7 mm

W=W1 mm

L=L1 mm

MLIN

TL9

S ubst="MSub1"

W=W3 mm

L=L3 mm

MLOC

TL26

Subst="MSub1"

W=W3 mm

L=L4mm

L=L4 mm

Subst="MSub1"

W=W3 mm

L=L3 mm

TL29

Subst="MSub1"

W=W2 mm

L=L2 mm

W=W1 mm

L=L5 mm

W1=W1 mm

W2=W2 mm

W3=W1 mm

W4=W2 mm

MLIN

TL11

Subst="MSub1"

W=W3mm

L=L3 mm

MCORN

Corn4

Subst="MSub1"

W=W3 mm

MCORN

Corn12

Subst="MSub1"

W=W3 mm

Fig. 2: The coarse model in ADS

671

MCORN

Corn9

Subst="MSub1"

Subst="MSub1"

W=W3 mm

L=L3 mm

W1=W1 mm

W2=W2 mm

W3=W1 mm

W4=W2 mm

MTE E_ADS

Tee2

Subst="MSub1"

W1=W3mm

W2=W3mm

W3=W2mm

SaveSolns=yes

SaveGoals=yes

SaveOptimVars=no

UpdateDataset=yes

MLIN

MCROSO

Cros2

S ubst="MSub1"

MLOC

TL31

Subst="MSub1"

W=W3 mm

L=L4 mm

UseAllGoal s=yes

SaveCurrentEF=no

SaveNominal=no

SaveAllIterations=no

UseAllOptV ars=yes

MLIN

TL27

MLIN

TL13

S ubst="MSub1"

MLOC

TL12

Subst="MSub1"

W=W3 mm

L=L4 mm

Optim

Optim1

OptimType=Random

MaxIters=10000

DesiredError=0.0

StatusLevel=4

FinalAnalysis="SP1"

NormalizeGoals=no

SetBestValues=yes

Seed=

W=W3mm

MLIN

TL28

MLOC

TL8

Subst="MSub1"

W=W3 mm

Goal

OptimGoal5

Expr="center_structure"

SimInstanceName="SP1"

Min=1

Max=

Weight=1/0.01

RangeVar[1]=

RangeMin[1]=

RangeMax[1]=

MTEE_ADS

Tee5

Subst="MSub1"

W1=W3 mm

W2=W3 mm

W3=W2 mm

MCORN

Corn10

S ubst="MSub1"

W=W3 mm

OPTIM

GOAL

Goal

OptimGoal4

E xpr="structure"

S imInstanceName="SP1"

Min=1

Max=

Weight=1/0.01

RangeVar[1]=

RangeMin[1]=

RangeMax[1]=

MCROSO

Cros1

Subst="MSub1"

MLIN

TL4

Subst="MS ub1"

W=W2 mm

L=L2 mm

MLOC

TL10

S ubst="MSub1"

W=W3 mm

L=L4 mm

MCORN

Corn3

Subst="MSub1"

W=W3 mm

Min=

Max=-25

Weight=1

RangeVar[ 1]="freq"

RangeMin[ 1]=7 GHz

RangeMax[1]=9 GHz

MLIN

L=L4 mm

MLIN

TL1

Subst="MSub1"

Min=

Max=-20

Weight=1/0.09

RangeVar[1]="freq"

RangeMin[1]=0 GHz

RangeMax[1]=3 GHz

MLIN

TL6

Subst="MS ub1"

W=W3 mm

L=L3 mm

MLOC

TL7

Subst="MSub1"

W=W3 mm

Term

Term1

Num=1

Z=50Ohm

Goal

OptimGoal3

Expr="banch_long"

SimInstanceName="SP1"

W=W3 mm

MLIN

TL5

GOAL

GOA L

Goal

OptimGoal 2

Expr="dB(S (2,1))"

SimInstanceName="SP 1"

MTEE_ADS

Tee1

Subst="MSub1"

W1=W3 mm

W2=W3 mm

W3=W2 mm

MCORN

Corn1

Subst="MS ub1"

W=W3 mm

GOAL

Goal

OptimGoal1

E xpr="dB(S(1,1))"

S imInstanceName="SP1"

L=L4 mm

MS TEP

Step12

Subst="MSub1"

W1=W1 mm

W2=0.7 mm

MLIN

TL34

Subst="MSub1"

W=W2 mm

L=L2 mm

MLIN

TL33

Subst="MSub1"

W=W3 mm

L=L3 mm

MLOC

TL25

Subst="MSub1"

W=W3 mm

MLOC

TL30

Subst="MSub1"

W=W3 mm

L=L4 mm

MTEE_A DS

Tee6

Subst="MSub1"

W1=W3 mm

W2=W3 mm

W3=W2 mm

MLIN

TL32

Subst="MSub1"

W=W3 mm

L=L3 mm

MCORN

Corn11

Subst="MSub1"

W=W3 mm

MLIN

TL24

Subst="MSub1"

W=0.7mm

L=1 mm

Term

Term2

Num=2

Z=50 Ohm

Res. J. Appl. Sci. Eng. Technol., 4(6): 670-674, 2012

S-PARAMETERS

MLOC

TL7

Subst="MSub1"

W=W3 mm

L=L4 mm

Term

Term1

Num=1

Z=50 Ohm

MLIN

TL1

Subst="MS ub1"

W=0.7 mm

L=1mm

MLIN

TL5

S ubst="MSub1"

W=W3 mm

L=L3 mm

MCORN

Corn2

Subst="MSub1"

W=W3 mm

MLIN

TL6

Subst="MSub1"

W=W3 mm

L=L3 mm

MCORN

Corn3

Subst="MSub1"

W=W3 mm

MLIN

TL9

Subst="MSub1"

W=W3 mm

L=L3 mm

MLOC

TL12

Subst="MSub1"

W=W3 mm

L=L4 mm

MTEE_ADS

Tee2

Subst="MSub1"

W1=W3 mm

W2=W3 mm

W3=W2 mm

MLIN

TL11

Subst="MSub1"

W=W3 mm

L=L3mm

Term

Term3

Num=3

Z=50 Ohm

VA R

VA R2

E1=2.0213 {o}

H1=0.539067{o}

MCORN

Corn9

S ubst="MSub1"

W=W3 mm

MLIN

TL28

Subst="MS ub1"

W=W3mm

L=L3 mm

MLIN

TL27

Subst="MSub1"

W=W3 mm

L=L3 mm

MLIN

TL29

Subst="MS ub1"

W=W2 mm

L=L2 mm

MLOC

TL25

Subst="MSub1"

W=W3 mm

L=L4 mm

MSTEP

S tep12

S ubst="MSub1"

W1=W1 mm

W2=0.7 mm

MCROSO

Cros2

S ubst="MSub1"

W1=W1 mm

W2=W2 mm

W3=W1 mm

W4=W2 mm

MLIN

TL34

Subst="MS ub1"

W=W2mm

L=L2 mm

MLOC

TL31

Subst="MSub1"

W=W3 mm

L=L4 mm

MCORN

Corn4

Subst="MSub1"

W=W3 mm

Var

Eqn

MTE E_ADS

Tee5

Subst="MSub1"

W1=W3 mm

W2=W3 mm

W3=W2 mm

MCORN

Corn10

Subst="MSub1"

W=W3 mm

MLIN

TL13

S ubst="MSub1"

W=W1 mm

L=L5 mm

MLIN

TL4

S ubst="MSub1"

W=W2 mm

L=L2 mm

MLOC

TL10

Subst="MSub1"

W=W3 mm

L=L4 mm

Goal

OptimGoal1

Expr="abs(db(S(2,1))-db(S(4,3)))"

SimInstanceName="SP 1"

Min=

Max=0

Weight=

RangeV ar[1]=

RangeMin[1]=

RangeMax[1]=

MLOC

TL26

S ubst="MSub1"

W=W3mm

L=L4 mm

MCROSO

Cros1

Subst="MSub1"

W1=W1 mm

W2=W2 mm

W3=W1 mm

W4=W2 mm

VAR

VAR1

W1=1.66 {-o}

L4=0.81 {-o}

W2=0.6 {-o}

W3=1.13 {-o}

L3=1.86 {-o}

L1=4.09 {-o}

L5=10.83 {-o}

L2=2.52 {-o}

Var

Eqn

GOAL

Optim

Optim1

OptimType=GradientSaveCurrentEF=no

MaxIters=100

DesiredError=0.0

S tatusLevel=4

FinalAnalysis="S P1"

NormalizeGoals=no

S etB estV alues=yes

S aveS olns=yes

S aveGoals=yes

S aveOptimVars=no

UpdateDataset=yes

S aveNominal=no

S aveA llIterations=no

UseAllOptV ars=yes

UseAllGoals=yes

MLOC

TL8

Subst="MSub1"

W=W3 mm

L=L4 mm

MLIN

TL3

S ubst="MSub1"

W=W2 mm

L=L2 mm

MLIN

TL2

Subst="MSub1"

W=W1 mm

L=L1 mm

MSTEP

S tep2

S ubst="MSub1"

W1=W1 mm

W2=0.7 mm

MSUB

MSub1

H=H1mm

E r=E1

Mur=1

Cond=5.8E+7

Hu=3.73 mm

T=90 um

TanD=0.0009

Rough=0 mil

MTEE_ADS

Tee1

Subst="MS ub1"

W1=W3 mm

W2=W3 mm

W3=W2 mm

MCORN

Corn1

S ubst="MS ub1"

W=W3 mm

OP TIM

MSub

S_Param

SP1

Start=0 GHz

Stop=9 GHz

Step=1 GHz

MCORN

Corn12

Subst="MS ub1"

W=W3 mm

MLIN

TL33

Subst="MS ub1"

W=W3 mm

L=L3 mm

MLIN

TL24

Subst="MSub1"

W=0.7 mm

L=1mm

Term

Term2

Num=2

Z=50 Ohm

MLOC

TL30

Subst="MSub1"

W=W3mm

L=L4 mm

MTEE_A DS

Tee6

S ubst="MSub1"

W1=W3 mm

W2=W3 mm

W3=W2 mm

MLIN

TL32

Subst="MSub1"

W=W3 mm

L=L3 mm

MCORN

Corn11

S ubst="MSub1"

W=W3 mm

Term

Term4

Num=4

Z=50 Ohm

S2P

SNP 1

File="C:\design_THz\wenzhang\cmrc_SM\cmrc_ori_scale_model_ori.s2p"

1

2

Re f

Fig. 3: Parameter extraction in ADS

Surrogate responses

Fine responses

Surrogate responses

Fine responses

20

0

0

-20

-20

| S21| in dB

| S21| indB

20

-40

-40

-60

-60

-80

-80

-100

-100

0

1

2

3

7

5

6

4

Frequence (GHz)

8

9

0

10

(a)

1

2

3

7

5

6

4

Frequence (GHz)

8

9

10

(b)

Fig. 4: (a) The response of our initial tuning model and fine model,. (b) The response of our tuning model and fine model after the

first iteration

of the fine model and coarse model is very

small; if

Step 3: Simulate the fine model and import the S

parameter into ADS. Check the stopping criteria

which are that the difference between responses

satisfied, stop. Otherwise, optimize ADS coarse

model to match fine model to perform parameter

extraction

Step 4: Reoptimize the calibrated coarse model design

parameters to predict the next fine model design

Step 5: Update the fine model design and go to Step3

0.254 mm, dielectric constant is er = 2.2, loss tangent is

0.0009, and the metallization is copper. The design

specifications are # S11#< - 15 dB for DC #w#15 GHz, and

# S21##- 25 dB for 35GHz #w# 45GHz.

Because the microstrip hammerhead filter works at

high frequency, we use the scale model with scale factor

of 5 to improve the accuracy of the coarse model in ADS.

In this design, the fine model is simulated in Ansoft

HFSS, the coarse model is constructed and optimized in

Agilent ADS (Fig. 2).

The initial guess is x(0) = [4.09, 2.52, 1.86, 0.81,

10.83, 1.66, 0.6, 1.13]T, the response of our initial tuning

model and fine model is shown in Fig. 4a. One of the

most important steps, parameter extraction, is

implemented entirely in ADS (Fig. 3). We compensate the

deviation between the tuning model and the fine model

Design of microstrip hammerhead filter: Microstrip

hammerhead filter with a rogers 5880 substrate is shown

in Fig. 1. Design parameters are x = [L1, L2, L3, L4, L5,

W1, W2, W3]T mm. Thickness of the substrate is H =

672

Res. J. Appl. Sci. Eng. Technol., 4(6): 670-674, 2012

model and the corresponding fine model are shown in

Fig. 5. Clearly, difference between responses of the fine

model and coarse model is very small. After structure

dimensions of the scale model are divided by the scale

factor of 5, we can get the final microstrip hammerhead

filter satisfying the design specifications, which will be

fabricated in section 5.

Surrogate responses

Fine responses

10

|S21| in dB

0

-10

-20

-30

Filter measurement: The hammerhead filter is fabricated

using current microelectronics technology without any

additional process, and the entire physical configuration

of filter circuit is shown in Fig. 6a, The dimensions of

microstrip hammerhead filter are as follows: L1 = 0.5

mm, L2 = 0.71 mm, L3 = 0.2 mm, L4 = 0.24 mm, L5

=1.53 mm, W1 = 0.18 mm, W2 = 0.1 mm, W3 = 0.1 mm.

The measured S-parameter is shown in Fig. 6b. The LPF

with two hammerhead cells in series has a 25 GHz

stopband from 25 to 50 GHz. This achieves above 100%

(-10 dB) relative bandwidth. As can be seen from Fig.

6b, the insertion loss from DC to 20 GHz is less than 1.1

dB, and the return loss is better than 18 dB in the

passband.

-40

-50

0

1

2

3

7

5

6

4

Frequence (GHz)

8

9

10

Fig. 5: The optimized tuning model and the corresponding fine

model responses.

CONCLUSION

In this study we reviewed the implicit space mapping

concept and adopt the simplified space mapping

implementation in Agilent ADS, all the space mapping

steps are integrated into one ADS schematic. A detailed

and easy-to-follow design optimization procedure was

provided and the Agilent ADS implementation of the

algorithm was described. Implicit SM algorithm greatly

improves the efficiency of the design of complex

structure. It will create favorable conditions for the

widespread use of microstrip hammerhead filter in field of

mixer and frequency multiplier.

(a)

|S21| in dB

0

-20

-40

-60

ACKNOWLEDGMENT

-80

0

10

20

40

Frequence (GHz)

50

This study is supported by the National Natural

Science Foundation of China under Grant No.61001030

and supported by The Fundamental Research Funds for

the Central Universities under Grant No. ZYGX2009J022

60

(b)

Fig. 6: (a) Photograph of hammerhead filter, (b) The

measurement result of hammerhead filter

REFERENCES

by calibrating the dielectric constant er and the height H

of the substrate as tuning parameters. We can see that the

specification is not satisfied after the first iteration, but the

parameter extraction using implicit SM yields a good

match between the coarse and fine models (Fig.4b). The

coarse model is then optimized in ADS with respect to the

design parameter. The new design parameters are

assigned to the fine model. The optimal values obtained

are x* = [2.52, 3.55, 1.01, 1.18, 7.64, 0.9, 0.5, 0.5]T mm

after three iterations. The responses of optimized tuning

Bandler, J.W., Q.S. Cheng, N.K. Nikolova and

M.A. Ismail, 2004. Implicit space mapping

optimization exploiting preassigned parameters.

IEEE Trans. Microwave Theory Tech., 52(1): 378385.

Cheng, Q.S., J.W. Bandler and J.E. Rayas-Sanchez, 2009.

Tuning-aided implicit space mapping. Int. J. RF

Microwave Computer-Aided Eng., 18(5).

Maestrini, A. and J.S. Ward, 2008. In-phase powercombined frequency triplers at 300 GHz. IEEE

Microwave Wireless Component. Lett., 18(3).

673

Res. J. Appl. Sci. Eng. Technol., 4(6): 670-674, 2012

MaMaster, L.L., M.V. Schneider and W.W. Snell, 1976.

Millimeter-wave receivers with subharmonic pump.

IEEE Trans. Microwave Theory Tech., MTT-24, 12:

948-952.

Marsh, S., B. Alderman, D. Matheson and P. de Maagt,

2007. Design of low-cost 183 GHz subharmonic

mixers for commercial applications. IEEE Circ.

Device Syst., 1(1).

Porterfield, D.W., 2007. High-efficiency terahertz

frequency triplers. Microwave Symposium,

IEEE/MTT-S International.

Xue, Q., K.M. Shum and C.H. Chan, 2003. Low

conversion-loss fourth subharmonic mixers

incorporating CMRC for millimeter-wave

applications. IEEE Trans. MTT, 51(5).

Zhang, B., Y. Fan, Z. Chen, X.F. Yang and F.Q. Zhong,

2011. An improved 110-130 GHz fix-tuned

subharmonic mixer with compact microstrip resonant

cell structure. J. Electromagnetic. Waves Appl., 25:

411-420.

Zhong, F., Z. Bo, F. Yong, Z. Minghua and Y. Xiaofan,

2011a. A broadband W-band subharmonic mixers

circuit based on planar schottky diodes. IEEE

International Conference on Opto-Electronics

Engineering and Information Science.

Zhong, F.Q., B. Zhang, Y. Fan, M.H. Zhao and

X.F. Yang, 2011b. 170 GHz high-efficiency

frequency doubler. IEEE International Symposium

on Microwave, Antenna, Propagation and EMC

Technologies for Wireless Communications.

Zhu, J., J.W. Bandler, N.K. Nikolova and S. Koziel,

2007. Antenna optimization through space mapping.

IEEE Trans. Antennas Propag, 55(3): 651-658.

674