Research Journal of Applied Sciences, Engineering and Technology 4(2): 131-134,... ISSN: 2040-7467 © Maxwell Scientific Organization, 2012

advertisement

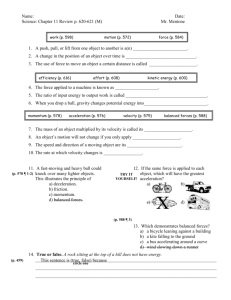

Research Journal of Applied Sciences, Engineering and Technology 4(2): 131-134, 2012 ISSN: 2040-7467 © Maxwell Scientific Organization, 2012 Submitted: September 23, 2011 Accepted: November 02 , 2011 Published: January 15, 2012 S-Curve Acceleration/Deceleration Algorithm Based on Reference Table Xia Yubin and Wang Wei School of Computer Science and Engineering, Beihang University, Beijing 100191, China Abstract: To satisfy the need of bond speed and precision, S-curve acceleration/deceleration based on reference table is used on LED bond-system. Compute the PVT data and store them in a table in advance. In actual processes the PVT data which meet the requirements can be calculated by the data in the table. The results show that the algorithm based on reference table can effectively reduce the computation time and satisfy our needs. Key words: Numerical control systems, reference table, S-curve Acc/Dcc INTRODUCTION Segment VII, including accelerated acceleration, constant acceleration, decelerated acceleration, constant velocity, accelerated deceleration, constant deceleration and decelerated deceleration. Li Xiaohui (Li et al ., 2007) simplified the processes by removing the segment constant acceleration and segment constant deceleration. Here the process is further simplified by removing the segment constant velocity as shown in Fig. 1. The symbols of Fig. 1 are defined as follows: The main function of LED high-speed bonding system is to bond golden wire to a chip. Ultrasonic wave is used to improve the bonding quantity. It demands that the system can bond at least 18000 wires per hour. Acceleration and deceleration control is the key to the high speed, high precision system. Designing a simple acceleration and deceleration algorithm that meets the demand is the emphasis for research. The algorithm of traditional methods such as linear and exponential acceleration/deceleration control techniques (Xuguang et al ., 2008) would like to bring about unnecessary shocks and are not suitable for high speed, high precision numerical systems. S-curve acceleration/deceleration adopted in some advanced CNC systems at present overcomes the weakness of linear and exponential acceleration/deceleration control methods. But this algorithm is relatively complicated and the procedure of computing is time-consuming. The papers (Li et al., 2007; Zhang et al., 2009; Hu et al., 2010) improve the s-curve acceleration/deceleration control method in the aspects of simplifying the sub-function, computing the acceleration region and deceleration region. However there are still cubic calculations in these algorithms. The procedure of computation is also time-consuming. Polynomial acceleration and deceleration control proposed in paper (Xu et al., 2009) guarantees the acceleration are continuous, but the computation becomes more complicated and time-consuming. Based on the solid facts discussed above, s-curve acceleration/deceleration based on reference table is proposed. The procedure of computation is easy and fast. C C Tk(k = 0, ...3): The time of transitional point Tk(k = 0, ...3): The duration of each segment Suppose that the time from zero to maximum acceleration is equal to that from the maximum acceleration to zero, acceleration/deceleration rate is J. To ensure that acceleration at the start of T0 is equal to acceleration at the end of T1, T0 should be equal to T1. For the same reason, T3 should be equal to T2. Given t1 = 2t0, t2 = 3t0, t3 = 4t0, then the formula of the acceleration, the velocity and the position are given below: S-CURVE ACCELERATION/DECELERATION AND ITS FURTHER SIMPLIFICATION The s-curve acceleration/deceleration process is usually divided into seven segments form Segment I to 0 t t0 Jt J (t t ) t t t 1 0 1 a (t ) J ( t t ) t t t 1 1 2 J (t 2t1) t2 t t3 (1) J 2 2 t J ( t t )2 1 2 v( t ) J ( t t )2 1 2 J ( t 2t1 )2 2 (2) 0 t t0 J 2 t1 4 J 2 t1 4 t0 t t1 t1 t t2 t2 t t3 Corresponding Author: Xia Yubin, School of Computer Science and Engineering, Beihang University, Beijing 100191 131 Res. J. Appl. Sci. Eng. Technol., 4(2): 131-134, 2012 s v T0 T1 t0 T2 t1 Table 1: Example of reference table T1 T2 T3 T4 V1 V2 V3 V4 P1 P2 P3 P4 T3 t2 t3 t t0 t1 t2 t3 t t0 t1 t2 t3 t J 2 0 t t0 2t J J v (t ) (t t1 )2 t12 t0 t t1 4 2 t1 t t3 v (2t1 t ) A s(t1 ) 0 t t0 J 3 t t t t1 8 1 0 J 3 t1 t1 t t2 8 Tn Vn Pn (4) To the position formula, there is conclusion: s (t1+)) = 2s(t1)-s(t1-)), and 0#)#t1.The conclusion can be proved as follow: Suppose that ª is a positive integer. If 0#)#t0, then t0#t1-)#t0 and t1#t1+)#t2. t1+) and t1-) is symmetry about the straight line t = t1. Fig. 1: Four segments s-curve acceleration/deceleration J 3 6t J (t t ) 3 J t 2t 1 6 4 1 s( t ) J (t t ) 3 J t 2t 1 1 6 4 J J (t 2t1) 3 t13 4 6 … … … Scope of sample points: As can been seen from Fig. 1, the velocity line is symmetrical about straight line t = t1. So the velocity at a time point in [t1, 2 t1] is equal to that at symmetry point in [0, t1]. For this reason, a new velocity formula can be described as (4): V a T5 V5 P5 J 3 J 3 J 3 t1 t1 t1 4 8 8 J J J (t1 t1 ) 3 t12 (t1 ) t13 6 4 8 J 3 J 2 J 2 t1 t1 ( ) 8 4 6 (3) (5) s(t1 ) t 2 t t3 (6) J J J (t1 t1 ) 3 t12 (t1 ) t13 6 4 8 (7) J 3 J 3 J 2 J 3 2( t1 ) t1 t1 ( ) 8 4 6 8 s(t1 ) As is shown from the formulae above, there are square and cube calculations in the process of computation and the formulae are complicated. So it will take much time to compute the velocity and position. It can be inferred from (5) (6) (7) that s (t1+)) = 2s(t1)-s(t1-)) . If t0#)#t1, then 0#t1-)#t0 and t2#t1+)#t3. t1+) and t1-) is symmetry about the straight line t = t1. S-curve acceleration/deceleration based on reference table: Square calculation, cube calculation and complicate formulae make the process of computation time-consuming. For this reason, S-curve acceleration/deceleration algorithm based on reference table is proposed. s(t1 ) J (t1 ) 3 6 (8) REFERENCE TABLE CONSTRUCTION J J (t1 2t1 ) 3 t13 6 4 J 3 J 2( t13 ) t1 8 6 s(t1 ) Firstly, set the parameters J and t1 specific values. Then, sample some time points. In the end, compute the velocity and position at the sampled time points and store the results in a three-dimensional array. Store time points in the first dimension of the array. Store velocity results in the second dimension of the array. Store the position results in the third dimension of the array. For conveniences, call the array reference table. A reference table example is shown in Table 1. (9) It can be inferred from (5), (8), (9) that s (t1+)) = 2s t1 1)-s (t1-)). Prove up. To sum up, there is relationship s(t1+)) = 2s (t1) s(t1-)) on the position line. For this reason, a new position formula can be described as follows: 132 Res. J. Appl. Sci. Eng. Technol., 4(2): 131-134, 2012 J 3 6 t J J J s( t ) ( t t1 )3 t12t t13 4 8 6 2 s( t1 ) s( 2t1 t ) (15), (16) can be deduced from (2), (3), (13) (14). 0 t t0 (10) t0 t t1 t1 t t3 It can be seen from the conclusion above that the function value of the velocity formula in the interval [0, 2t1] could be computed by the function value of velocity formula in the interval [0, t1]. So is the position formula. So just sample points in the interval [0, t1] and store them in the reference table. The last sample point should be at t = t1. New formulae deduction under three circumstances: C Move certain distance in 2t1: Suppose that the actual condition demands the machine moves Lb in 2t1. Given Lb = k*La. Under the circumstances set sb(t) as a new position formula and sb (t) = k*s(t). s(t) is the formula (3) above. It can be inferred sb (2t1) = k*La. Calculate the derivative of sb(t) and the corresponding velocity formula vb (t) can be deduced. The result is vb (t) = sb (t) k*v (t).v (t) is the formula (2) above. Then (11) (12) are the new velocity formula and position formula. C (11) snew k s(t ) (12) C Move La in certain time: Suppose that the actual condition demands the machine moves La in 2d1 and d1 = u*t1. (13) (14) are the velocity and position formulas which are similar to (2) (3): J 2 2 t J ( t d )2 1 2 v d (t ) J ( t d )2 1 2 J ( t 2d1 )2 2 d1 2 t d1 d1 t 3d1 J 3 6 t J ( t d )3 J d 2t 1 1 6 4 sd ( t ) J J 3 ( t d ) d 2t 1 1 6 4 J J ( t 2 d1 )3 d13 4 6 3d1 (13) 2 2 t 2d1 d 0 t 12 J 8 J 8 d13 d1 d13 d1 t 3d1 2 t d1 3d1 d sd ( m * d1 ) ( 1 )3 s( m * t1 ) u3 s( m * t1 ) t1 (16) vnew (t ) vd (t 0) u3 (17) snew (t ) sd (t ) u3 (18) Move certain distance in certain time: Suppose that the actual condition demands the machine moves Lb in 2d1 and Lb = k*La, d1 = u*t1. It can be inferred from the analyses in a) and b) that (19) (20) are the new velocity and position formulae: vnew (t ) k vd (t ) u3 (19) snew (t ) k sd (t ) u3 (20) Use reference table to compute a new PVT table: First the values of parameters d1 and Lb should be obtained. The values of t1 and La can be calculated from reference table. Then the values of k and u can be calculated by the formulae k = Lb/La, u = d1/t1. From the analyses in 2.1 and 2.2, every point Ti, Vi and Pi can be computed by referring to reference table and doing some simple calculations. Store the data Ti, Vi and Pi in a new array. At last let Ti = Ti/u, Vi = Vi*k/u, Pi = Pi*k. To reduce time further, the result of k/u could be calculated in advance and store it in a variable (given that the variable is named w, w = k/u). Then Vi = Vi*k/u can be described as Vi = Vi*w. The data in the new array guarantees the machine moves Lb in 2d1. d 0 t 12 J 2 d1 4 J 2 d1 4 (15) As can be seen from (15) (16), if the sample points of (2) (3) are t = m*t1 (m*t1 is in the interval [0, 2t1]) and the sample points of (13) (14) are t = m*d1 (m*d1 is in the interval [0, 2d1]), then the velocity computed by (13) is u2 times of the velocity computed by (2) and the position computed by (14) is u3 times of the position computed by (3). In order to change the movement position in 2d1, multiply (13) (14) by 1/u3, respectively, which is proved in a). (17) (18) are the new velocity and position formulae. How to use reference table: The data in reference table is calculated at specific parameters J and t1. Given that the position calculated from the reference table at t = 2t1 is La. That is to say the machine moves La in 2t1. However the request may change at actual conditions. vnew k v (t ) d 2 v d ( m * d1 ) ( 1 )2 v ( m * t1 ) = u C (m*t1) t1 (14) 2 Advantage of the algorithm: The most significant advantage of s-curve acceleration/deceleration based on reference table is that it reduces much time taken by 2 t 2 d1 133 Res. J. Appl. Sci. Eng. Technol., 4(2): 131-134, 2012 Table 2: Rreference table for test 0 10 20 0 500 2000 0 1 13 30 4500 45 40 8000 106 50 12500 208 Table 3: Values of d1 and Lb in experiments Group 1 Group 2 Group 3 Group 4 Group 5 Group 6 d1 = t1/2 d1 = t1/2 d1 = t1 d1 = 2t1 d1 = 4t1 d 1 = t1 Lb= La Lb = La Lb = 2La Lb = 3La/2 Lb = 3La/2 Lb = 3La/4 60 17000 356 0.42 56 56 61 56 0.41 110 110 98 56 100 25000 1250 0.44 0.43 98 90 24500 1001 0.45 Use formula 97 80 23000 763 0.46 Use reference table 98 70 20500 545 0.40 0.39 65 1 2 3 4 5 6 Fig. 3: Time reduction rate 1 2 3 4 5 formulae. Then time reduction rate is defined as (tf-tt)/tf. The time reduction rate of the experiments is shown in Fig. 3. 6 Fig. 2: Results of experiments calculating every point Ti, Vi and Pi. There is only simple subtraction, multiplication in the process of computation. Square calculation, cube calculation and complicated formulae which make the process of computation timeconsuming are avoided. The algorithm also could meet the needs of actual conditions. CONCLUSION S-curve acceleration/deceleration based on reference table guarantees the movement of machine is smooth. Meanwhile the algorithm reduces the time taken by calculating PVT data. The implement of the algorithm is simple. It meets the demands of LED high-speed bonding system. The comparison of using reference table and using formula on efficiency: To test the algorithm, set J = 10000000, t1 = 100 ms. Then reference table as is shown in Table 2 can be obtained from (1) (2) (3). Values in the first column of the table are arbitrary. These values would not be used in the process of calculation. Units of measurement in reference table are as follows: REFERENCES Hu, L., S.L. Lin, J.M. Xu and H. Dong, 2010. A new speed control algorithm for s-curve acceleration deceleration. Modular Machine Tool Automatic Manufacturing Technique, 1: 22-26. Li, X., Y. Wu and H. Leng, 2007. Research on a new Scurve acceleration and deceleration control method. Modular Machine Tool Automatic Manufacturing Technique, 10: 50-53. Xuguang, S., X. Bugong, X. Wei and L. Boren, 2008. Design and Implementation of S-shape Acceleration/Deceleration Algorithm based on Rounding Error Compensation Tactic. Zhang, B., W. Gao, L. Shen and Q. Yan, 2009. The study of new s-curve accelaration/decelaration arithmetic. Machine Tool Hydraulics, 10: 27-29. Time: ms, velocity: count/s, position: count In order to make a comparison comprehensively, six experiments in which parameters d1 and Lb are deferent are made. Values of parameters in the experiments are shown in Table 3. The results of the experiments are shown in Fig. 2. Unit of time in Fig. 2 is millisecond. As can be seen from Fig. 2, the time taken by computing PVT data by means of reference table is much shorter than that by means of formula. Donate tt as the time taken by computing PVT data by means of reference table and tf as that by means of 134