Research Journal of Applied Sciences, Engineering and Technology 3(5): 415-425,... ISSN: 2040-7467 © Maxwell Scientific Organization, 2011

advertisement

Research Journal of Applied Sciences, Engineering and Technology 3(5): 415-425, 2011

ISSN: 2040-7467

© Maxwell Scientific Organization, 2011

Received: March 12, 2011

Accepted: April 06, 2011

Published: May 25, 2011

Analysis of the Effect of Rotor-to-Casing Diameter Ratio on the Power Output

of a Vaned-Type Air Turbine-II

1

Bharat Raj Singh and 2Onkar Singh

Department of Mechanical Engineering, SMS Institute of Technology, Kashimpur Biruha,

Near Gosainganj, Lucknow-227125, Uttar Pradesh, India

2

Department of Mechanical Engineering, Harcourt Butler Technological Institute,

Nawabganj, Kanpur-208002, Uttar Pradesh, India

1

Abstract: This study describes new results of the performance evaluations of an air powered vane type rotary

novel air turbine/engine. The mathematical model with different parametric values such as; different rotor to

casing diameter (d/D) ratios at optimum vane angle of 45º and injection angle of 45º, have been considered and

analyzed. The optimum power output is obtained at some typical values of rotor/casing diameter ratios without

consumptions of excessive air. The study shows that the optimum power developed under such conditions

would be 4.3-5.5 kW (5.84-7.47 HP) at linear expansion (without excessive air consumption) when d/D ratios

are between 0.85 to 0.80 and casing diameter is kept 150 mm, injection pressure as 6 bar (90 psi) and speed of

rotation as 2500 rpm. This power output is enough to drive any motorbike or light vehicle.

Key words: Air turbine, compressed air, injection angle, motorbike, rotor/casing diameter ratios, zero pollution

In continuation to earlier analysis, this paper presents

new results on power output due to effect of rotor/casing

diameter ratios of the vaned-type turbine. The results of

earlier study show that the power output would be

optimum when injection angle is kept more than 30º. Thus

injection angle is kept 45º as constant throughout the

study. The effect of isobaric admission and adiabatic

expansion of high pressure air on different rotor/casing

diameter ratios have been considered and analyzed with

the help of the mathematical modeling shown in earlier

study. The results show that the optimum power would be

developed under linear expansion (without excessive air

consumptions) when d/D ratios are kept at 0.85 to 0.80

and casing diameter of 150 mm.

INTRODUCTION

Globally transport sector alone is consuming huge

quantity of hydrocarbon fuel (Hubbert, 1956), and

releasing about 77.8 percentage air pollutants in the

atmosphere (Aleklett and Campbell, 2003). Recent study

also indicates that in developing countries like India,

China, Taiwan etc., 80 percentage pollutants are

generated by the motorbikes. In order to reduce the air

pollution condition and eliminate 50-60% of the

pollutants exhausting, an air engine of small capacity is

proposed to be equipped on motorbikes. It was seen in the

author’s earlier study (Singh and Singh, 2010a) that the

compressed air driven prime movers are cost effective as

compared to fossil fuel driven engines and may become

the dominant technology in place of the electric, hydrogen

cell and other alternative fueled vehicles available in the

market (Fuglsang et al., 2004; Gorla and Reddy, 2005;

Honton, 2004; Knowlen et al., 1998; Rose et al., 2004;

Selig et al., 2004; Schreck and Robinson, 2004). Also the

pioneer work in the area of compressed air engine has

been carried out by Negre and Negre (2004) and SaintHilaire et al. (2005) and some of studies on performance

optimization of the low capacity of air turbines have also

been carried out in the author’s earlier publications (Singh

and Singh, 2010a, b, c).

HISTORY OF COMPRESSED AIR ENGINE

The compressed air as an energy is not a recent

technology. At the end of the 19th century the first

approximations to what could one day become a

compressed air driven vehicle already existed, through the

arrival of the first pneumatic locomotives. Yet even two

centuries before that Dennis Papin apparently came up

with the idea of using compressed air (Royal Society

London, 1687).

Corresponding Author: Bharat Raj Singh, Department of Mechanical Engineering, SMS Institute of Technology, Kashimpur

Biruha, Near Gosainganj, Lucknow-227125, Uttar Pradesh, India. Tel: +91-522-2238116/+91-9415025825

415

Res. J. Appl. Sci. Eng. Technol., 3(5): 415-425, 2011

The first recorded compressed-air vehicle in France

was built by the Frenchmen Andraud and Tessie of Motay

in 1838. A car ran on a test track at Chaillot on the 9th

July 1840, and worked well, but the idea was not pursued

further. In 1872 the Mekarski air engine was used for

street transit, consisting of a single-stage engine. It

represented an extremely important advance in terms of

pneumatic engines, due to its forward thinking use of

thermodynamics, ensuring that the air was heated, by

passing it through tanks of boiling water. Numerous

locomotives were manufactured and the first in Nantes in

1879. The H.K. Porter Company in Pittsburgh sold

hundreds of these locomotives to coal-mining companies

in the eastern U.S. With the hopeful days of air powered

street transit over, the compressed air locomotive became

a standard fixture in coal mines around the world because

it created no heat or spark and was therefore invaluable in

gassy mines where explosions were always a danger with

electric or gas engines.

Also in 1896, Porter supplied ten compressed air

motor cars for the Eckington System in Washington, D.C.

There was a tank on the front of the engine and it was

recharged at the station. Between 1890 and 1902 ten

compressed air trams circulated in Bern, Switzerland. In

1892, Robert Hardie introduced a new method of heating

that at the same time served to increase the range of the

engine. However, the first urban transport locomotive was

not introduced until 1898, by Hoadley and Knight, and

they introduced a two stage engine. Later on, in 1912 the

American’s method was improved by Europeans, adding

a further expansion stage to the engine (3 stages).

In 1926 Lee Barton Williams of Pittsburg USA

presented his invention: an automobile which he claims

run on air. The motor starts on gasoline, but after it has

reached a speed of ten miles an hour the gasoline supply

is shut off and the air starts to work. At the first test his

invention attained a speed of 62 miles an hour. In January

1932 what appears to be the first journalistic article ever

written about a car driven by compressed air was

published. In 1934, 21-year-old Johannes Wardenier

announced he developed the world’s first fuel-less

automobile. For weeks Dutch newspapers reported of an

incredible invention that would change the world for ever.

After the Second World War the term air engine was

never again used in textbooks referring to compressed air

or pneumatic locomotives and, whenever they were

mentioned the article would go on to state that these

engines were of little use or efficiency.

In the 1970’s Willard Truitt presented his invention

in McKees Rocks, USA. But because he did not have the

financial means to develop his compressed air car further

he gave the rights of his invention to NASA and the US

Army in 1982.

In 1979, Terry Miller decided that compressed air

was the perfect medium for storing energy. He developed

Air Car One, which he built for $ 1,500. Terry’s engines

showed that it was feasible to manufacture a car that

could run on compressed air. He patented his method in

1983 (US4370857).

In the 1980’s Carl Leissler developed a motor that

was able to function on air. The retired horticulturalist had

been working from his garage in Hollywood for over 15

years. He says that to use his motor in a car you might

have to use a small electric or gas energy source to help

drive the air compressor. ‘We might be able to get 2000

miles per gallon; air is a power in itself’ Leissler

comments. Until 1987 the German company Arnold Jung

Lokomotivenfabrik GmbH produced locomotives

functioning on compressed air to be used in mines. In the

1980’s they were still selling and renovating locomotives.

Currently the tram association in Bern Switzerland (BTG)

is developing a locomotive according to the original

plans.

At present (2008) various researchers and industries

are developing compressed air motors applicable to

transportation, apart from the many industries that

produce and commercialize compressed air motors for

industrial purposes.

Scope of compressed air engine: The per capita income

of a person in India, as a developing country, is very low

to meet livelihood requirements. On the basis of the recent

data 80% of the population of the country still lives in

rural and suburban areas where the means of transport is

either bicycle or motorbike. The continuous hikes of fossil

fuel prices at the rate of around 20-30% every year are

making the situation miserable. Extrapolation shows that

at this rate, by 2010-12, prices may be double as what

they were in 2005, and by 2030-40, may touch Rs. 1000

per L. A time will come when the common person will

not be able to purchase fuel to run motorcycles. This is

not only due to the high demand for vehicles or its

increasing numbers worldwide, but also due to the cost of

fossil fuel going high as 80% of the available fossil fuel

is presently being consumed in transport. Thus, it is

imperative to explore the possibility of alternatives to

fossil fuel to make the environment free from emission for

keeping the present and future generations healthy.

During last two decades, major work has been done

to tap the air freely available in the atmosphere and to

compress it for storage in cylinders for further use. Apart

from other uses of compressed air, this can also be used to

416

Res. J. Appl. Sci. Eng. Technol., 3(5): 415-425, 2011

run combustion engines with the mixture of gas and air

getting Wred after the compression stroke at top dead

centre. The use of compressed air will eliminate the need

of having a separate compression stroke. Compressed air

helps in the attainment of the expansion stroke after

ignition takes place. Thus, the efficiency of the internal

combustion engine is improved, and without running all

four stroke cycles, it runs on two stroke cycles. The air

engines developed so far are basically running on hybrid

systems (Negre and Negre, 2004; Saint-Hilaire, 2005)

such as compressed air and gases, and are not 100%

pollution free.

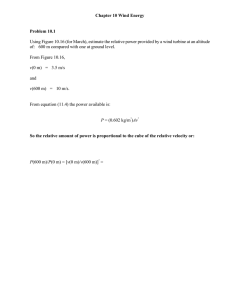

Concept of multi vanes air turbine model: This study

proposes a multi-vanes type air turbine as shown in Fig.

1. Such air turbine is considered to work on the reverse

working principle of vane type compressor. In this

arrangement total shaft work is cumulative effect of

isobaric admission of compressed air jet on vanes and the

adiabatic expansion of high pressure air.

A prototype of air turbine was developed in an earlier

study (Singh and Singh, 2008d). At initial stage a cylinder

for minimum capacity of storing compressed air for the

requirement of 30 min running and maximum pressure of

20 bar is used as a source of storage energy. The

compressed air storage cylinder is designed to produce

constant pressure for the minimum variation of torque at

low volumes of compressed air and attached with filter,

regulator and lubricator which regulate and maintain the

constant pressure. The clean air then admits into air

turbine through inlet passage/nozzle. Vanes of novel air

turbine are placed under spring loading to maintain their

regular contact with the casing wall to minimize leakage

which is proposed as improvement over the currently

available vane turbine. A study on high efficiency energy

conversion system for liquid nitrogen (Honton, 2004),

design and verification of airfoil and its tests, influence of

tip speed ratios for small wind turbine and parabolic heat

transfer and structural analysis were also carried out for

conceptualizing the energy conversion system and design

of the air turbine (Fuglsang et al., 2004, Gorla and

Reddy, 2005; Honton, 2004; Knowlen, 1998;

Rose et al., 2004, Selig et al., 2004; Schreck and

Robinson, 2004), A detailed method of energy conversion

processes, development concept of utilization of air

turbine and optimization of its shaft work were made and

presented in various symposium, seminars and

conferences of international levels (Singh and Singh,

2006a, b, 2007a, b, 2008a, b, c, d, e, f, 2009a, b, c, d).

The objective of the earlier study was to investigate

the performance of an air turbine by varying vane angles

Fig. 1: Air turbine-model

with a particular injection angle, i.e., at which angle air

should admit into the turbine between first two

consecutive vanes. The air turbine considered has

capability to yield output of 4.0 to 5.5 kW at 4-6 bar air

pressure and for speed of 2000-2500 rpm, which is

suitable for a motorcycle.

MATHEMATICAL MODELING

The high pressure jet of air at ambient temperature

drives the rotor in novel air turbine due to both isobaric

admission and adiabatic expansion. Such high pressure air

when enters through the inlet passage, pushes the vane for

producing rotational movement through this vane and

thereafter air so collected between two consecutive vanes

of the rotor is gradually expanded up to exit passage. This

isobaric admission and adiabatic expansion of high

pressure air contribute in producing the shaft work from

air turbine. Compressed air leaving the air turbine after

expansion is sent out from the exit passage. It is assumed

that the scavenging of the rotor is perfect and the work

involved in recompression of the residual air is absent as

seen from Figure 1. Similar type mathematical modeling

is considered in earlier publications by authors and it is

being reproduced here for maintaining continuity and

benefits to the readers (Singh and Singh, 2009e, f, g,

2010a, b, c, d, e, f).

From Fig. 2, it is seen that work output is due to

isobaric admission from E to 1, and adiabatic expansion

from 1 to 4 and reference points 2, 3 in the figure shows

417

Res. J. Appl. Sci. Eng. Technol., 3(5): 415-425, 2011

Fig. 2: Thermodynamic processes (Isobaric, adiabatic and

isochoric expansion)

the intermediate position of vanes. Thus, total work output

due to thermodynamic process may be written as:

Fig. 3: Variable length BG and IH and injection angle ø

[Area under (E145CE)] = [Area under (E1BOE)

+Area under (14AB1) - Area under (4AOD4)

+ Exit steady flow (45CD4)] or

Total work output = [Thermodynamic expansion work

(w1)] + [Exit steady flow work (w2)]

(1)

or

w = [(w1) + (w2)]

where

⎛ γ ⎞

⎟.

Wexp = n. N 60 . ⎜

⎝ γ − 1⎠

(

⎧

⎪ ⎛ p4 ⎞

⎟

p1 . v1 ⎨ 1 − ⎜

⎪ ⎝ p1 ⎠

⎩

The process of exit flow (4-5) takes place after the

expansion process (E- 4) as shown in Fig. 2 and air is

released to the atmosphere. In this process; till no over

expansion takes place pressure p4 can’t fall below

atmospheric pressure p5. Thus at constant volume when

pressure p4 drops to exit pressure p5 no physical work is

seen. Since turbine is functioning as positive

displacement machine and hence under steady fluid

flow at the exit of the turbine, the potential work is

absorbed by the rotor.

Thus, the total power output or work done per unit

time (Wtotal), for speed of rotation N rpm, will be

mentioned as (Singh, 2009):

γ −1

γ

)(

⎫

⎪

⎬

⎪

⎭

Wflow = n.( N 60).( p4 − p5 ) v4

Figure 1 shows that if vanes are at angular spacing of

2 degree, then total number of vanes will be n = (360/2).

The variation in volume during expansion from inlet to

exit (i.e., v1 to v4) can be derived by the variable extended

length of vane as shown in Fig. 3 at every point of

movement between two consecutive vanes.

From Fig. 3, it is seen that when two consecutive

vanes at OK and OL moves to position OH and OB, the

extended vane lengths varies from SK to IH and LM to

BG, thus the variable length BG at variable "i is assumed

as Xat’variable’" can be written from the geometry:

(2)

⎫

⎪

⎬ + n. N 60 . p 4 − p5 . v 4

⎪

⎭

(

γ −1

γ

and

⎛ γ ⎞

⎟ . p .v .

Wtotal = n. ( N / 60). ⎜

⎝ γ − 1⎠ 1 1

⎧

⎪ ⎛ p4 ⎞

⎟

⎨1 − ⎜

⎪ ⎝ p1 ⎠

⎩

)

)

418

Res. J. Appl. Sci. Eng. Technol., 3(5): 415-425, 2011

BG = X at ,var iable'α '

where,

⎡

⎧⎛ R − r ⎞

⎫⎤

⎟ .sin α ⎬ ⎥

= R.cos⎢ sin −1 ⎨ ⎜

⎩⎝ R ⎠

⎭⎦

⎣

+ ( R − r ).cos α − r

⎧( X

+ X 2 min ) ⎫

v1 = vmin = L. ⎨ 1 min

⎬.sin θ ,

4

⎩

⎭

(3)

⎧( X

+ X 2 max ) ⎫

v4 = vmax = L. ⎨ 1 max

⎬.sin θ ,

4

⎩

⎭

where, 2R = D is diameter of casing and 2r = d is

diameter of rotor, " is angle ∠ BOF, $ is angle ∠ BAF

and 2 is angle ∠ HOB or ∠ H’OF or ∠ KOL, between

two consecutive vanes and N is angle ∠ KOJ at which

injection pressure admits to the air turbine.

Variable volume of cuboids’ B-G-I-H-B can be

written as:

vcuboids

X 1 min =

⎡

⎫⎤

⎧⎛ R − r ⎞

⎟ .sin 180 − θ − φ ⎬ ⎥

R.cos⎢ sin −1 ⎨ ⎜

⎭⎦

⎩⎝ R ⎠

⎣

(

[

X 2 min =

⎡

⎧⎛ R − r ⎞

⎫⎤

R.cos⎢sin −1 ⎨⎜

⎟ .sin(180 − φ ) ⎬⎥

⎩⎝ R ⎠

⎭⎦

⎣

where, BG = X1i and IH = X2i variable length of vanes

when rotate into turbine as shown in Fig. 3. The lengths

(IG, HB and LK, SM), are considered linear whereas all

are chords of circles. This approximation is done in

mathematical model which has least effect on the overall

values.

The volume at inlet v1 or vmin will fall between angle

∠ LOF= "1min = (180-2-N) and angle ∠ KOF= "2min =

("1min + 2) = (180 - N) as seen in Fig. 3, when air is admits

into turbine at angle N.

The Volume at exit v4 or vmax will fall between angle

∠ BOF = "1max = " = 0 and angle ∠ HOF = "2max =

("1max + 2) = 2.

Applying values of v1 and v4 to Eq. (2), the total

power output available Wtotal can be written as:

Wtotal

(

)

γ −1

γ

) ]

+ ( R − r ).cos 180 − θ − φ − r

⎧ ( X + X 2i )( 2r + X 1i ) ⎫

= L. ⎨ 1i

⎬.sin θ (4)

4

⎩

⎭

⎧

⎛ γ ⎞ ⎪ ⎛ p4 ⎞

⎟

⎟ . ⎨1 − ⎜

= n. N 60 . ⎜

⎝ γ − 1⎠ ⎪ ⎝ p1 ⎠

⎩

(

)

[

+ ( R − r ).cos(180 − φ ) − r

]

X 1 max = ( D − d ) = 2( R − r )

and

X 2 max =

⎡

⎧⎛ R − r ⎞

⎫⎤

R.cos⎢sin −1 ⎨⎜

⎟ .sin θ ⎬⎥

⎩⎝ R ⎠

⎭⎦

⎣

+

⎫

⎪

⎬ p1

⎪

⎭

{( R − r ).cosθ } − r

Input parameters and assumptions: Various input

parameters are considered and listed in Table 1 for

investigation of effect of rotor/casing diameter ratio and

its optimization. It is assumed that rotor will have 8

numbers of vanes and hence angle between two

consecutive vanes would be 45º. It is also considered that

high pressure air (2-6 bar) will enter into two consecutive

rotor vanes at an injection angle 45º. Rotor to casing

diameter ratios for study was considered from 0.95, 0.90,

0.85 to 0.55 for different set of casing diameters 150 mm.

Exit air pressure is considered as atmospheric pressure

(1.0132 bar) and rotor length also assumed as 45 mm for

this study.

⎡ ⎧ ( X 1 min + X 2 min ).( 2r + X 1 min ) ⎫

⎤

⎢ L. ⎨

⎬.sin θ ⎥

4

⎢⎣ ⎩

⎥⎦

⎭

+ n. ( N 60). ( p4 − p5 ).

⎡ ⎧⎪ ( X 1 max + X 2 max ). ( 2r + X 1 max ) ⎫⎪

⎤ (5)

⎢ L. ⎨

⎬.sin θ ⎥

4

⎪⎭

⎢⎣ ⎪⎩

⎥⎦

419

Res. J. Appl. Sci. Eng. Technol., 3(5): 415-425, 2011

Table 1: Input parameters

Symbols

Parameters

Rotor to casing

0.95, 0.9, 0.85, 0.80, 0.75 , 0.70, 0.65, 0.60 and

(d/D) ratio

0.55 when casing diameters are kept D = 150 mm

p1

2 bar (.30 psi), 3 bar (.45psi), 4bar (.60psi),

5 bar (.75psi), 6bar (.90psi) - inlet pressures

= (v1 / v4)y. p1 assuming adiabatic expansion

p4

1 atm = 1.0132 bar

p5

N

2500 rpm

L

35mm length of rotor

(

1.4 for air

n

(360 / 2) Number of vanes

2

45º angle between 2-vanes, (i.e., rotor contains

correspondingly 8 number of vanes)

M

45º angle at which compressed air through nozzle

enters into rotor

RESULTS AND DISCUSSION

Using the mathematical model the effect of

rotor/casing diameter ratio and different injection

pressures 2-6 bar on the expansion power output, flow

work output and total power output from air turbine is

studied. Here the vane angle 2, injection angle N and

speed of rotation N of the air turbine are considered to be

constant for whole of the study. The results obtained have

been plotted in Fig. 4-8, for the rotor/casing diameter ratio

(d/D), varied as 0.95, 0.90, 0.85, 0.80, 0.75, 0.65, 0.60

and 0.55 at vane angle of 45º, injection angle of 45º, at

different injection pressures of 2, 3, 4, 5 and 6 bar (i.e.,

Fig. 4: Expansion power vs. Rotor /casing diameter (d/D) ratio when D = 150 mm

Fig. 5: Exit flow power vs. Rotor/casing diameter (d/D) ratio when D = 150 mm

420

Res. J. Appl. Sci. Eng. Technol., 3(5): 415-425, 2011

Fig. 6: Percentage contribution of expansion power vs. rotor / casing diameter (d/D) ratio when D = 150 mm

Fig. 7: Percentage contribution of exit flow power vs. rotor/casing diameter (d/D) ratio when D = 150 mm

Fig. 8: Total power output vs. rotor/casing diameter (d/D) ratio when D = 150 mm

421

Res. J. Appl. Sci. Eng. Technol., 3(5): 415-425, 2011

different injection pressure 2-6 bar is shown in Fig. 8.

Total power at 2-6 bar is seen increasing linearly from

rotor/casing diameter ratio 0.95 to 0.80 and gradually

further increases parabolically to highest when

rotor/casing diameter ratio reaches to 0.55. This shows the

behavior of higher air consumption. Thus for moderate air

consumption maximum value of shaft power output is

obtained as 4.29-5.50 kW at rotor/casing diameter ratio

0.85 to 0.80.

Thus it is observed that in the rotary vane type air

turbine total shaft power output is combined effect of the

component of expansion power and exit flow power. The

contribution of exit flow power due to steady flow in

respect to total power output varies from 4.60 to 7.84%

only for all injection pressure 2-6 bar at constant injection

angle 45º, constant vane angle 45º, at speed of rotation

2500 rpm. Thus it is obvious that the expansion power

output as well as total power output is found optimum as

4.29 and 5.50 kW, respectively for moderate air

consumption when rotor/casing diameter ratio lies

between 0.85 to 0.80 at casing diameter 200 mm and is a

deciding factor for desired shaft power output.

30, 45, 60, 75 and 90 psi), speed of rotation of 2500 rpm,

and casing diameter 150 mm.

Figure 4 shows the variation of expansion power at

different rotor/casing diameter ratios with respect to

different injection pressure. It is evident that the shaft

power due to expansion at 2 bar is lower at higher

rotor/casing diameter ratio of 0.95, thereafter gradually

increases linearly upto 0.85 to 0.80 and, largest when

rotor/casing diameter ratio is kept 0.55. For higher

injection pressure 4 to 6 bar, this is attributed to the large

work output per time unit in similar pattern. It is evident

that there exists maximum rotor/casing diameter for every

injection pressure which offers the linear expansion power

at moderate air consumption and beyond 0.75 to 0.55

rotor/casing (d/D) ratios, the value of maximum

expansion power is more but expansion is parabolic which

shows the higher air consumption for higher shaft output.

The higher injection pressures produces higher shaft

power in similar manner as compared to lower injection

pressures.

Figure 5 shows the variation of exit flow power at

different rotor/casing diameter ratios with respect to

different injection pressure. It is evident that the shaft

power due to exit flow work is lowest at 2 bar and

parabolically increases up to rotor/casing diameter ratio of

0.55. It is quite evident that the shaft power due to exit

flow work gradually increases with reducing value of

rotor/casing diameter ratio in view of the gap between the

rotor and casing as increases gradually. On these ground,

the exit flow power is nearly insignificant for rotor/casing

diameter ratio of 0.95 and would be absent when this ratio

value is unity.

Figure 6 shows the percentage contribution of

expansion power against total work output at different

rotor/casing diameter ratios with respect to different

injection pressure. It is evident that percentage

contribution of expansion power is low at (d/D) ratio =

0.95 and highest at (d/D) = 0.55 for all injection pressure

2-6 bar. At rotor/casing ratio 0.95 the contribution of

expansion power against total power is lowest and

gradually increases from 92.16 to 95.40% as rotor/casing

diameter ratio decreases from 0.95 to 0.55.

Figure 7 shows the percentage contribution of exit

flow power in total power output at different rotor/casing

diameter ratios with respect to different injection pressure.

It is evident that percentage contribution of exit flow

power is higher, when rotor/casing diameter ratio is 0.95

and gradually decreases from 7.84 to 4.60% as this

diameter ratio drops up to 0.55 when casing diameter is

kept 200 mm at all injection pressure from 2-6 bar.

Variation of total power output with respect to

different rotor/casing diameter ratios with respect to

CONCLUSION

The results obtained from above investigations based

on input parameters such as injection angle, vane angle

and speed of rotation are kept 45º, 45º and 2500 rpm,

respectively, following conclusions are drawn:

There exists an linear value of shaft power output at

rotor/casing diameter ratio (approx. 0.85 to 0.80) and

between 0.75 to 0.55, though the shaft output increases in

parabolic form that indicates higher air consumption for

the considered air turbine for all air injection pressures.

Thus the rotor/casing diameter ratio 0.80 offers the

optimum expansion power to 5.14 kW at injection air

pressures 6 bar for the moderate air consumption.

The exit flow power due to steady flow is seen to increase

parabolically for the rotor/casing diameter ratio varying

from 0.95 to 0.55 and is found maximum 0.12 to 0.43 at

6 bar injection pressure.

Total output power from the air turbine is seen to be

optimum for the higher injection air pressure and there

exists an optimum value of rotor/casing diameter ratio for

all injection pressure 2-6 bar at linear increase (moderate

air consumptions). The optimum power output is seen to

be 5.50 kW at 0.80 rotor/casing ratio for injection

pressure of 6 bar.

Thus the optimum shaft power output of a rotary

novel vane type air turbine having casing diameter 150

mm and other design parameters such as: rotor to casing

diameter (d/D) ratios between 0.85 to 0.80 and at

422

Res. J. Appl. Sci. Eng. Technol., 3(5): 415-425, 2011

optimum value of vane angle 45º (8 vanes) and pressure

injection angle 45º, offers 4.29-5.50 kW (5.84-7.47 HP)

power output. Here air consumption has also an important

role for optimizing the power output.

REFERENCES

Aleklett, K. and C.J. Campbell, 2003. The peak and

decline of world oil and gas production. Miner.

Energ. Raw Mater. Rep., 18(1): 5-20.

Fuglsang, P., C. Bak and M. Gunna, 2004. Design and

verification of the Ris0-B1 airfoil-family for wind

turbines. J. Solar Energ. Eng., 126: 1002-1008.

Gorla, R. and S. Reddy, 2005. Probabilistic heat transfer

and structural analysis of turbine blade. IJTJE, 22:

1-11.

Honton, E.J., 2004. Hydrogen Fuel Cell Car. Presented at

15th Annual US Conference and Hydrogen Expo,

April, USA.

Hubbert, M.K., 1956. Nuclear energy and the fossil fuels;

Amer. Petrol. Inst. Drilling and Production Practice,

Proc. Spring Meeting, San Antonio, Texas., 725(187).

Knowlen, C., A.P. Bruckner, A.T. Mattick and

A. Hertzberg, 1998. High efficiency energy

conversion systems for liquid nitrogen automobiles.

Society of Automotive Engineers, Inc., AIAA

98-1898.

Negre, G. and C. Negre, 2004. Compressed air - the most

sustainable energy carrier for community vehicles,

speech in front of assembly at kultur gathered for fuel

cells world, Tuesday 29th June ’2004.of a vaned type

air turbine. Int. J. Nat. Sci. Eng., 1(1-5): 28-35.

Rose, R. and J.V. William, 2004. Fuel Cell Vehicle

World Survey 2003, Breakthrough Technologies

Institute, February, Washington, D.C.

Royal Society London, 1687. The History of the

Compressed Air Vehicles. Retrieved from:

http://www.aircarfactories.com/air-cars/compressedair-history.html.

Saint, H.G., R. Saint Hilaire and Y. Saint Hilaire, 2005.

Quasiturbine zero pollution car using gasoline.

Festival at Le Lundi, Montreal Gazette, 26

September.

Schreck, S. and M. Robinson, 2004. Tip speed ratio

influences on rationally augmented boundary layer

topology and aerodynamic force generation. J. Solar

Energ. Engg., 126: 1025-1033.

Selig, M.S. and B.D. McGranahan, 2004. Wind tunnel

aerodynamics tests of six airfoils for use on small

wind turbines. J. Solar Energ. Engg., 126: 986-1000.

Singh, B.R. and O. Singh, 2006a, Necessity and Potential

for Bio-Diesel Use in India. International Conference

on Bio-Fuel Vision-2015, October’13th -15th, 2006

at Bikaner, India- Proceedings, pp: 71-89.

ACKNOWLEDGMENT

The Authors are indebted to express thanks to the

CEO, SMS Group of Institutions, Lucknow and

Mechanical Engineering Department, Harcourt Butler

Technological Institute, Kanpur for their support to

provide facilities of the library and laboratories.

NOMENCLATURE

d

D

L

n

N

p

p1, v1

:

:

:

:

:

:

:

p4, v4

:

p5

:

v

w

W

X1i

X2i

:

:

:

:

:

Diameter of rotor (2r) in meter

Diameter of outer (2R) cylinder in meter

Length of rotor having vanes in meter

No. of vanes = (360/2)

No. of revolution per minute

Pressure in bar

Pressure and volume respectively at which air

strike the Turbine,

Pressure and volume respectively at which

maximum expansion of air takes place,

Pressure at which turbine releases the air to

atmosphere.

Volume in cum

Theoretical work output in (J) Joules

Theoretical power output (W) Watts

Variable extended lengths of vane at point 1

Variable extended lengths of vane at point 2

Subscripts:

: Subscripts-indicates the positions of vanes in

1, 2...4, 5

casing

exp

: Expansion

min

: Minimum

max

: Maximum

Greek symbols:

"

: Angle BOF (Fig. 3)

"1

: Angle LOF (=180 - N) (Fig. 3)

"1

: Angle KOF (=180 - 2 - N) (Fig. 3)

$

: Angle BAF (Fig. 3)

(

: 1.4 for air

2

: Angle between 2-vanes (BOH) (Fig. 3)

N

: Angle at which compressed air enters into

rotor through nozzle

>d

: Eccentricity (R-r)

423

Res. J. Appl. Sci. Eng. Technol., 3(5): 415-425, 2011

Singh, B.R. and O. Singh, 2006b. Study of compressed air

as an alternative to fossil fuel for automobile engines.

International Conference on Challenges and

Strategies for Sustainable Energy and Environmentheld on 10-11th June'2006 at UPTU, Lucknow, UPProceedings, pp: 179-191.

Singh, B.R. and O. Singh, 2007a. Use of nonconventional energy for sustainability to fossil fuel.

National Conference on Recent Trend on Mechanical

Engineering, RAME-2007, held on 28-29th

March'2007 at Baba Sahab Dr. Bhim Rao Ambedkar

College of Agricultural Engineering and Technology,

Etawah-Proceedings, pp: 130-136.

Singh, B.R. and O. Singh, 2007b. Uses of wind power as

a non-conventional/renewable energy for

sustainability. National Conference on State of Art

Technology in Mechanical Engineering, STEM2007, held on October 29-31, 2007 at College of

Technology, G.B. Pant University, Pant Nagar, UPProceedings, pp: 503-515.

Singh, B.R. and O. Singh, 2008a. A concept for

development of a vaned type novel air turbine. 12th

International Symposium on Transport Phenomena

and Dynamics of Rotating Machinery - held on

February 17-22, 2008 at Pacific Center of ThermalFluids Engineering, Sheraton Mohana Surfrider Hotel

Honolulu, Hawaii - Paper No. ISROMAC-12-20046.

Singh, B.R. and O. Singh, 2008b. A Study on Sustainable

Energy Sources and its Conversion Systems towards

Development of an Efficient Zero Pollution Novel

Turbine to be used as Prime-mover to the Light

Vehicle. ASME International Mechanical

Engineering Congress and Exposition, held on

October 31-November 6, 2008 at Boston,

Massachusetts, USA, Paper No. IMECE-2008-66803.

Singh, B.R. and S. Onkar, 2008c. A study to optimize the

output of vaned type novel air turbine. 4th

International Conference on Energy Research and

Development, held on 17-19 November, 2008 at

State of Kuwait, Kuwait- Paper No. ICERD-4-1353.

Singh, B.R. and O. Singh, 2008d. Development of a

vaned type novel air turbine. Int. J. Mech. Eng., Sci.,

222(Part C): 1419-1426.

Singh, B.R. and O. Singh, 2008e. Energy storage system

to meet challenges of 21st century- an overview. All

India Seminar on Energy Management in Perceptive

of Indian Scenario-held on October 17-19, 2008 at

Institution of Engineer (India), State Centre,

Engineer's Bhawan, Lucknow-Proceedings

Chapter15, pp: 157-167.

Singh, B.R. and O. Singh, 2008f. Parametric evaluation of

vane angle on performance of novel air turbine. J.

Sci. Eng. Manage., 2: 7-18.

Singh, O., 2009. Reciprocating and Rotary Compressor,

Applied Thermodynamics, New Age International

(P) Ltd., Publishers, New Delhi, India, ISBN: 97881-224-2583-3, pp: 727-728.

Singh, B.R. and O. Singh, 2009a. Analytical study on a

vaned type novel air turbine for different conditions

of casing and rotor diameters. 2009 ASME

International Conference on Energy Sustainability held on July 17-23, 2009, at San Francisco,

California, USA, Paper No. ES-2009-90207.

Singh, B.R. and O. Singh, 2009b. Applications of

compressed air as an alternative energy to meet

challenges of 21st century- global warming.

International Conference on Engineering Congress

on Alternatives Energy Applications: Option or

Necessity? held on 3-5 November, 2009 at State of

Kuwait, Kuwait- Paper No. EC2009 Kuwait-1082.

Singh, B.R. and O. Singh, 2009c. Effect of rotor to casing

ratios with different rotor vanes on performance of

shaft output of a vane type novel air turbine. Int. J.

Nat. Sci. Eng., 1-3(21): 133-138.

Singh B.R. and O. Singh, 2009d. Numerical analysis of

pressure admission angle to vane angle ratios on

performance of a vaned type novel air turbine. Int. J.

Nat. Sci. Eng., 1(1-4): 20-27.

Singh, B.R. and O. Singh, 2009e. Optimization of power

output of a vaned type novel air turbine with respect

to different injection angles-under ideal adiabatic

expansion. Int. J. Mech. Eng., 2(2): 205-211.

Singh, B.R. and O. Singh, 2009f. Parametric evaluations

of injection angles and vane angles on performance

of a vaned type novel air turbine. Int. J. Math. Phys.

Eng. Sci., 3-4(38): 226-233.

Singh, B.R. and O. Singh, 2009g. Theoretical

investigations on different casing and rotor diameters

ratio to optimize shaft output of a vaned type air

turbine. Int. J. Nat. Sci. Eng., 2(2): 61-68.

Singh B.R. and O. Singh, 2010a. Analytical investigations

on different air injection angles to optimize power

output of a vaned type air turbine. Int. J. Power

Energ., 224(Part A): 305-310.

Singh, B.R. and O. Singh, 2010b. Effect of different vane

angles on rotor-casing diameter ratios to optimize the

shaft output of a vaned type novel air turbine. Int. J.

Eng. Sci. Technol., 2(3): 114-121.

424

Res. J. Appl. Sci. Eng. Technol., 3(5): 415-425, 2011

Singh, B.R. and Singh, 2010d. Study of influence of vane

angle on shaft output of a multi vane air turbine. J.

Renew. Sustain. Energ., American Institute of

Physics, New York, USA, 11747-4502.

Singh, B.R. and O. Singh, 2010c. Study of effect of

injection angles to rotor-casing diameter ratios on

performance of a vaned type novel air turbine. Int. J.

Eng. Sci. Technol., 2(4): 409-416.

425