Research Journal of Applied Sciences, Engineering and Technology 2(6): 504-507,... ISSN: 2040-7467 © M axwell Scientific Organization, 2010

advertisement

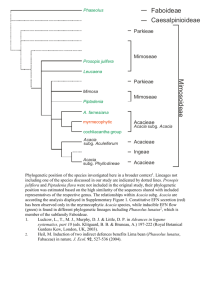

Research Journal of Applied Sciences, Engineering and Technology 2(6): 504-507, 2010 ISSN: 2040-7467 © M axwell Scientific Organization, 2010 Submitted Date: November 02, 2009 Accepted Date: December 07, 2009 Published Date: September 10, 2010 Evaluation of the Effective Baking Conditions for Grade 3 Nigerian Acacia Species Bonded Foundry Sand Cores 1 1 Nuhu A. Ademoh and 2 A.T . Abdullahi Department of Mechanical Engineering, Nigerian Defence Academy, P. M. B 2109, Kadu na, Nigeria 2 Department of Mechanical Engineering, Bayero University, Kano Abstract: The most effective economical baking conditions w ere determine d for foundry cores bonded with the grade 3 Nigerian acacia species exudates. Silica sand base cores bonded with the material were oven baked at temperatures ranging from 160 to 250ºC for varying pe riods oven cooled and then subjec ted to ten sile strength tests to ascertain the best baking co nditions for different alloy ca stings. The ex perimental core specimens were in accordance with foundry test standard, shaped like figure number eight. They were tested with standard universal strength machine equipped with attachment for gripping the cores and an instantaneous meter from which the test values w ere read. The result were compa red with estab lished standard foundry core property table which showed that the class V iron/steel cores are best made with 3% acacia bonded silica sand baked at 160ºC for 1 h. For magnesium cores, sand bonded with 4.5% acacia baked at 160ºC for 1-2 h was optimum. For class IV iron/steel cores 4.5% acacia bon ded sand baked at 180ºC for 1 hour was optimal. Sand bonded with 4 .5% grade 3 acacia baked at 200ºC for 1.0-2.0 h was optimum for copper, aluminium, classes II and III iron/steel cores. Sand bo nded w ith 8.0-13.0% grade 3 N igerian acacia sp ecies bake d at 200ºC for 1.5-2 h was found m ost effective for class I iron and steel cores. Key w ords: Acac ia grade 3, bak ing, cores, oven , temperature INTRODUCTION Acacia species is a natural resin that contains arabin; a semi-solidified sticky fluid that oozes from incision made on ba rk of acacia tree s (Fen nem a, 199 6). Nigeria produces four grades of acacia species exudates in commercial quantities some of which are exported for foreign exchange earnings. Grad es 1 and 2 acacia are preferred by major importer countries of USA and Europe that use it in food, beverage, pharmaceutical, confectionary, textile and printing industries (Rahim et al., 2007). This creates a research gap to find industrial uses for grades 3 and 4 acacia species like using it in other sectors like foundries that lack cheap sources of good binders. Ademoh and Abdullahi (2009) tried the grade 3 Nigerian acacia exudates as sole binder for sand mou ld and it was found suitable at 6-9% compositional content for non -ferrous and grey iron casting at co ntent. The use of acacia species in foundry core production include addition of 5% acacia spec ies exu dates gum to 10% sugar and protein in gelatinous a mix derived from amino acid for binding expendable cores for casting (Siak et al., 1994). Acacia gum com bined with sugar, urea formaldehyde resin and boric acid to bind cores (Eric, 1965). These processes inv olve u se of acids to enhance core performance. Other processes free of acids use corrosive organic, inorganic resins and chemicals, which are toxic to human and involve multiple process stages that imply additional costs for safety precautions. This coup led w ith defects like porosity, cavities and pinholes caused by evolved gases entrapment require that simpler, non-hazardous processes that generate less gas and defects are developed to assist small scale and less advanced foundries especially in the developing countries. The aim of this paper is to determine the most effective bakin g temperatu re and time for Nigerian acacia species grade 3 bonded cores. The objectives are to measu re tensile strength of cores bonded w ith acac ia grade 3 baked at 160, 180, 200, 220 and 250ºC for 1-3 h, test them for tensile strength; permeability and shatter index and compare result with the standard in Table 1 (Titov and Stepanov, 1982), to determine the optimal baking conditions for such sand cores. The significance is that foundries that use the material in oven baking process for core production would be properly guided on the most effective and eco nomica l operating conditions for best results. MATERIALS AND METHODS Silica sand sample with clay content of 0.3% was used to prod uce the core test specimens. The sand was oven dried at 110ºC to remove free water, weighed and transferred to a mechanical sieve and vibrated for about Corresponding Author: Dr. Nuhu A. Ademoh, Department of Mechanical Engineering, Nigerian Defence Academy, P.M. B 2109, Kaduna, Nigeria 504 Res. J. Appl. Sci. Eng. Technol., 2(6): 504-507, 2010 Table 1: Desired physical properties ranges of sand cores Alloys Permeability (No) Ten sile streng th (K N/m 2) Class I iron/steel cores 130-150 700-1000 Class II iron/steel cores 100 500-700 Class III iron/steel cores 100 350-600 Class IV iron/steel cores 70 200-300 Class V iron/steel cores 70 80-150 Copper bronzes cores 90 400-600 Copper brasses cores 60 500-700 Aluminium co res 80-100 400-700 Magn esium cores 80 300-500 30 min for grain size distribution (AFS , 1989). A quantity of sieved sand of BS standard grain size of 40-72 meshes was taken and used to produce specimens. The grade 3 Nigerian acacia species exudates was milled to grain size corresponding to BS sieve of 30 mesh for prop er particle mix and bond reaction. The sand and acacia exudates were thoroughly mixed in a roller mill for 10 min and moulded into core specimen in accordance with the research test schedule. The tensile strength specimen was in accordance with usual foun dry standard mo ulded in split core box to shape like figure number eight (Busby and Stancliffe, 1997). They were rammed with three compacting blows each weighing 6.5 Kg dropped from a 50 m m he ight. After oven baking specimens at 160, 180, 200, 220 and 250ºC for periods of 1-3 h, they were oven cooled and tested with standa rd universal strength equip ped with attachment to grip sp ecimen an d me ter that read tensile strength instantaneously (AFS, 1989). Permeability and shatter index specimens were cylindrical in shape, measured 50 mm diameter by 50 mm height and weighed 130 g after ramming with three compaction blows each of 6.5 Kg dropped from 50mm height with a standard sand ramm er. These are the most critical mechanical properties of cores that determ ine their performance in practice (Titov and S tepan ov, 19 82; D ietert, 196 6). For tensile test, a steadily increasing tensile force was applied on core specimen by universal strength machine until failure just occurred and the strength was read instantaneously. For the green permeability test, standard air pressure of 9.8x102 N/m 2 was passed through the specimen in the sample tube placed in meter and after 2000 cm 3 of air passed through it, perme ability was read (Dietert, 1966). Shatter specimen placed in container of the test machine was push ed up wards ov er strippin g post until it struck anvil, fell and shattered. Retained sand and over size were collected, measured and automatically used by machine to compute shatter index read instantaneously from the meter. Fig. 1: Green Permeability and shatter index (No) of foundry sand cores bonded with varying percentages grade 3 Nigerian acacia species DISCUSSION The results of green permeability and shatter index tests are as presented in Fig. 1. Permeability was observed to decrease from 201.0No at 3% acacia binder to 143.5No at 13% acacia binder content. The trend is explained by the fact that increase in binder led to increased compaction and decreased porosity for gas escape. The permeability was compared to the standard in Table 1 showed that the material is suitable at all compositions investigated for all classes of sand cores for different alloys. Shatter index decreased with increased binder because more binder imposed higher bonding and less collapsibility of sand cores. However the values are adeq uate for all classes of cores. Figure 2 presented the result for cores bon ded with grade 3 acacia ba ked at 160 ºC for 1-3 h. When com pared with foundry standard in T able 1, it show s that 16 0ºC is the optimum baking temperature for classes IV and V iron and steel cores, 1 h is the optimum ba king period for class V cores and 2.5-3.0 h for class IV iron and steel cores. For magnesium and class III iron and steel cores, sand bonded with 4.5% acacia baked for 1-2 h is the optimum. For bronze and aluminium cores optimum baking period at the same composition is 1.5-2.0 h. Cores bonded with 11.513% acacia baked at 160ºC for 1.5-2.0 h is most effective for brass, class II iron and steel castings. RESULTS Figure 1-6 presents the experimental results of research in graphical plots. Figure 1 presents the result of green perm eability test. Figure 2-6 present the results of the tensile strength specimen’s oven baked at 160, 180, 200, 220 and 250ºC for of 1-3 h, oven cooled and then tested as described above. Tensile strength is the most critical of the properties of cores and it measured their ability to withstand the rupture stresses imposed on them by thermal expansion during casting . Perm eability measured the ease of escape of gas from sand cores during casting, while shatter index measured the collapsibility of core after casting for easy fettling and cleanliness. 505 Res. J. Appl. Sci. Eng. Technol., 2(6): 504-507, 2010 Fig. 4: Tensile Strength (KN/m2) of sand cores bonded with varying percentages grade 3 Nigerian acacia species baked at 200ºC for varying periods in hours Fig. 2: Tensile Strength (KN/m2 ) of sand cores bonded with varying percentages grade 3 Nigerian acacia species baked at 160ºC for varying periods in hours Fig. 3: Tensile Strength (KN/m2) of sand cores bonded with varying percentages grade 3 Nigerian acacia species baked at 180ºC for varying periods in hours Fig. 5: Tensile Strength (KN/m2) of sand cores bonded with varying percentages grade 3 Nigerian acacia species baked at 220ºC for varying periods in hours The result for core specimens baked at 180ºC is presented in Fig. 3. Just as observed in Fig. 2 tensile strength of baked cores increased with increasing binder and baking period because the two baking temperatures of 160 and 180ºC are below the melting point of material above which it will begin to burn off and weaken strength. The grade 3 Nigerian acacia melts at 184-188ºC (Eric, 1965). The result in Fig. 3 when com pared with Table 1 show that 3.0% acacia bonded sand is optimum for class IV iron an d steel core w hen it is baked a t 180ºC for 1-3 h. 4.5% acacia bonded sand baked for 1-3 h at 180ºC is optimum for copper, aluminium and classes II and III iron and steel cores; while 9-13% acacia bonded cores baked at 1.5-3.0 h is optimum for class I iron and steel cores. Figure 4 presented tensile strength test result for cores specimens bonded with grade 3 acacia baked at 200ºC for 1-3 h. Cores strength increased with baking time for each acacia binder composition up to a baking time of 2.5 h from w here strength decreased with baking period because above the m elting point (184-188ºC) prolonged holdin g of the material caused so me acacia binder to burn off from cores resulting to weakening of strength. In comparison with Table 1, the result shows that sand bonded with 3 .0% acacia baked for 1 .0 hou r is suitable for class IV iron and steel cores; that with 4.5% acacia binder bak ed for 1.0-2.0 h is effective for copper, aluminium and classes II and III iron and steel cores while 8.0-13.0% acacia bonded sand baked for 1.5-2 .5 h is optimum for class I iron and steel casting co res. Figure 5 and 6 presented tensile strength test results for cores specimens bon ded with grade 3 acacia baked at 506 Res. J. Appl. Sci. Eng. Technol., 2(6): 504-507, 2010 different alloy castings at specified compositions, baking temperatures and time for best result. The effective baking condition determ ined in the stud y is vital as it prevents unnecessary waste of time, material and energy and lowers production cost. When com pared with the chem ically based core processes (Rahim et al., 2007; Siak et al., 1994), this work produced good sand cores with simpler materials and method. REFERENCES Ademoh, N.A. and A. Abdullahi, 2009. Determination of mechanical properties of m ould sand bonded with grade 3 Nigerian acacia species. Int. J. Appl. Eng. Res., 4(10): 1903-1910. American Foundry Men Society (AFS), 1989. Mould and Core test Handbook. 2nd Edn., Procedure, 113: 74-78. Busby, A.D. and M.R. Stancliffe, 1997. Lies, Damned Lies on Sand Testing. British Foundry Men, London. 90(2): 35-46. Dietert, H.W., 1966. Foundry Core Practice. 3 rd Edn., American Foundry M en’s Society, Des Plaines, Inc., pp: 2-154. Eric, P., 1965. USA Patent 3182030-Core binder composition com prising sugar, gum Arabic, urea formaldeh yde and b oric acid. 4 M ay. Fennema, O.R., 1996. Food Chemistry. 3rd Edn., Marcel Dekker Inc., New Y ork, pp: 60-82. Rahim, A.H., E.C. Ierland and H.P. Weikard, 2007. Competition in gum Arabic: G ame theoretic mod eling approach. afaf.rahim @wur.nl. Siak J.S., R.M. Schreck and K. Shah, 1994. USA Patent no: 5320157. Expendable core for casting processes. 14 Ju ne. Titov, N.D. and Y.U. Stepanov, 1982. Foundry Practice Translated by Iva nov. P.S. M ir Publishers, Moscow, pp: 49-101. Fig. 6: Tensile Strength (KN/m2) of sand cores bonded with varying percentages grade 3 Nigerian acacia species baked at 250ºC for varying periods in hours 220 and 250ºC for 1-3 h, respectively. In Fig. 5 there was marg inal increase in strength from baking period of 1-1.5 h follow ed by rapid decrease in co re bon d strength with increased baking duration. This trend was caused by over baking of cores at a temperature in excess of what was required. Acacia species exudates as a class 3 type of binder that melts and flows to form strong bonds w ith sand when cooled to low temperature would perform best at just above its melting range. Therefore, the 220ºC baking temperature appears excessive for optimum performance of material. The situation in Fig. 6 is even worse than that in Fig. 5 as tensile strength followed trend of slopping continuously from 1-3 h o f bakin g due to similar reason of over baking cores. Thus cores bonded with grade 3 acacia exudates are not to be baked at or above these two temperatures. CONCLUSION The grade 3 Nigerian acacia species exudates has been shown to be suitable for binding sand cores for 507