Document 13274223

advertisement

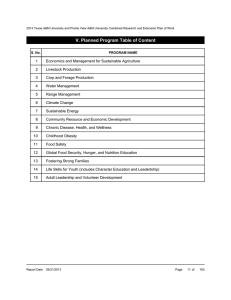

C O N T E N T S Cowherds and Reproduction Survey of Kansas Cow-Calf Producers .................................... Incidence o f Short Estrous Cycles After Weaning in Beef Cows. ....................... 1 6 E f f e c t s from Using Ralgro S e q u e n t i a l l y on Sexual Development o f B u l l s and on Growth and Carcass C h a r a c t e r i s t i c s o f Steers and B u l l s . E f f e c t o f Growth Rate from B i r t h Through ................................. T h i r t y Months on Performance of H e i f e r s . . . . . . . . . . . . . . 8 11 P e l v i c Area, C a l v i n g Ease and Rebreeding i n F i r s t C a l f H e i f e r s Delayed Winter Supplemental Feeding and Year-round Mineral Supplementation o f Beef Cows on Native Range . . 17 Effects o f Ralgro and DES Implants During the S u c k l i n g P e r i o d on Later Reproductive P e r f o r m a n c e o f Beef H e i f e r s E v a l u a t i n g t h e Breeding P o t e n t i a l o f ............................... Y e a r l i n g Bulls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 22 Forages and Pastures Minerals in Esophageal Samples f r o m Steers on N a t i v e Bluestem Pastures. . . . . . . . . . . . . . . . . . . .25 M i l o Stover, Forage Sorghum, P r a i r i e Hay, Soybean Meal and Urea Compared f o r Growing H e i f e r s . ................................... Annual Forages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Using Wheat S t r a w i n Beef Cow Rations Y i e l d and Quality o f S i x Summer 28 32 35 Feedlot Studies P r o t e i n L e v e l s With and Without Monensin f o r F i n i s h i n g Steers . . . . . . . . . . . . . . . . . . . . . . . 39 P r e d i c t i n g Feedlot Performance Using Mathematical Models 44 ............................... .................................. P r o t e i n Adjustments During Temperature S t r e s s 48 High Moisture Corn f o r F i n i s h i n g Steers 51 Conventional versus Accelerated Beef Production f o r T r a d i t i o n a l and La t e r - m a t u r i n g C a t t l e Types Performance, Carcass, and M e a t T r a i t s of D i f f e r e n t C a t t l e Types . 55 58 Meats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 Processing R e t a i l Beef Cuts f r o m Boxed Beef N u t r i t i o n a l Effects on Beef P a l a t a b i l i t y . Mechanical Blade Tenderization o f Meat. Rumen Physiology Rumen B a c t e r i a l Endotoxins and T h e i r Possible Role i n t h e Sudden-death Syndrome E f f e c t s o f Rumensin or L a s a l o c i d on Rumen Fermentation i n V i t r o ...................... B i o l o g i c a l Variability and Chances o f Error The variability among individual animals in an experiment leads t o problems i n i n t e r p r e t i n g Although t h e c a t t l e on treatment X may have had a larger average d a i l y g a i n than those on treatment Y , v a r i a b i l i t y w i t h i n t r e a t m e n t s may mean t h a t t h e d i f f e r e n c e w a s n o t t h e r e s u l t o f the t r e a t m e n t alone. S t a t i s t i c a l a n a l y s i s l e t s researchers c a l c u l a t e t h e p r o b a b i l i t y t h a t such d i f f e r e n c e s were f r o m chance r a t h e r than treatment. the r e s u l t s . In some of the articles t h a t f o l l o w , you will see t h e notation "P<.05." That means t h e p r o b a b i l i t y o f t h e d i f f e r e n c e r e s u l t i n g from chance i s l e s s than 5%. I f t w o averages a r e said t o be " s i g n i f i c a n t l y different," the p r o b a b i l i t y i s l e s s than a 5% t h a t the d i f f e r e n c e i s f r o m chance- -the p r o b a b i l i t y exceeds 95% t h a t t h e d i f f e r e n c e r e s u l t s f r o m t h e treatment. I n other cases you may see a mean g i v e n as 2.50 + 0.10. The 2.50 i s t h e m e a n ; 0.10 is the "standard e r r o r . " Two- thirds of the I n d i v i d u a l v a l u e s w i l l f a l l w i t h i n one standard error from the mean. I n this case between 2.40 and 2.60 (2.50 - 0.10 and 2.50 + 0.10). Many animals p e r treatment, r e p l i c a t i n g t r e a t m e n t s several times, and using u n i f o r m animals increases the p r o b a b i l i t y t h a t observed d i f f e r e n c e s r e s u l t f r o m t r e a t m e n t s , n o t chance. I n n e a r l y a l l t h e research reported here, statistical analyses are included t o I n c r e a s e t h e confidence you can p l a c e i n t h e r e s u l t s . 71 73 28 1 Milo Stover, Forage Sorghum, Prairie Hay, Soybean Meal and Urea Compared for Growing Heifers Keith Bolsen, Jim Oltjen and Harvey Ilg Summary Milo stover silage, prairie hay or forage sorghum silage was fed in rations containing 10, 12 or 14% protein from soybean meal (SBM) or 12% protein from urea; 100 heifers were fed in the 78-day growing trial (November 11, 1977 to February 2, 1978). Heifers fed forage sorghum silage, prairie hay or forage sorghum silage + prairie hay had similar rate and efficiency of gains; those fed milo stover silage made slowest and least efficient gains. Rations containing prairie hay were consumed in the greatest amounts. Feeding rations with 12 or 14% protein from SBM gave better performance than rations with 10% protein from SBM. Heifers fed urea gained slower and less efficiently than those fed SBM. Gain from a ration containing equal parts of milo stover silage and forage sorghum silage exceeded predicted gain by 7.8%, and efficiency was 13.9% better than predicted. Introduction Milo stover and forage sorghum silages were compared in five previous heifer growing trials at this station (Prog. Rpt. 210, 230, 262, 291 and 320, Kansas Agr. Expt. Sta.). Results show: (1) growing calves fed milo stover silage should gain about 1.0 lb. per day and require 10 to 14 lbs. of dry m a t t e r p e r l b . o f g a i n , (2) milo stover silage has a feeding value of 65% of that of forage sorghum silage, (3) milo stover silage fed in combination with forage sorghum silage is better feed than milo stover alone for growing calves, (4) supplying supplemental protein in milo stover silage rations is a large cost because stover usually contains so little protein, and (5) at least 12% protein rations are needed for maximum rate and efficiency of gain. This trial was to verify previous results from feeding milo stover and forage sorghum silages, to evaluate prairie hay and to compare three levels of supplemental protein from soybean meal and one from urea. 29 Experimental Procedure Shown below are the forage and protein rations compared in a 78-day growing trial (November 11, 1977 to February 2, 1978). Forages Protein, % of the ration from (SBM) Milo stover silage (MSS) Prairie hay (PH) Forage sorghum silage (FSS) ½ MSS + ½ FSS ½ PH + ½ FSS 10, 10, 10, 10, 10, 12 12 12 12 12 and and and and and 14 14 14 14 14 Protein, % of the ration from urea 12 12 12 12 12 The 100 heifer calves averaged 430 lbs. when allotted by breed and weight into 20 pens of five each. Breeds included Angus, Hereford, Angus x Hereford and Hereford x Simmental. Four pens were assigned to each of the 5 forage treatments. All rations were 73% of the appropriate forage and 27% rolled milo plus protein supplement on a dry matter basis and formulated to be equal in minerals, vitamins and additives. All were mixed and fed to appetite twice daily. All calves were fed 2 lbs. of rolled milo and alfalfa hay free-choice for 5 days before initial weighing and all were fed the same amount of experimental ration for 2 days before final weighing. All feed and water were withheld 16 hours before weights were taken. Forage sorghum was a high-grain variety harvested in the dough-stage at 70 to 72% moisture. Milo stover was from dryland milo that had been harvested about 30 days before stover was harvested. The stover was about 70% moisture when the grain was harvested. The forage sorghum and milo stover silages were s t o r e d i n c o n c r e t e s i l o s ( 1 0 f t . x 5 0 f t . ) . The native prairie hay was swathed and field-dried before being baled into rectangular bales about 75 to 80 lbs. each, and later processed in a tub grinder before being fed. Results Dry matter (%), crude protein (%, DM basis) and crude fiber (%, DM basis), r e s p e c t i v e l y , f o r t h e t h r e e f o r a g e s w e r e : 28.0, 8.0, 31.0 for milo stover silage; 88.0, 5.5, 32.6 for prairie hay; and 28.5, 8.9, 26.3 for forage sorghum silage. There were no interactions between forage and protein. Performances of heifers fed each of the five forages (averaged across protein treatments) are shown in Table 10.1; performances of heifers fed each of the four protein treatments (averaged across forages), in Table 10.2. Heifers fed forage sorghum silage, prairie hay or FSS + PH had similar rates of gain. Feed intake was higher (P‹.05) for prairie hay and PH + FSS than for forage sorghum silage. Milo stover silage supported the slowest (P‹.05) and least efficient (P‹.05) gains. 30 The 12 and 14% protein rations from SBM supported the fastest and most efficient gains (P<.05)(Table 10.2). Calves fed the 10% protein ration from SBM gained faster and more efficiency (P‹.05) than calves fed the 12% protein ration from urea. In general, performance of faster gaining calves (those fed forage sorghum silage, prairie hay or FSS + PH) tended to be improved more with additional SBM protein than that of calves gaining slower (those fed milo stover silage). From these results feed costs and feed cost per lb. of gain can be calculated for each combination of forage and protein. When the price of SBM is high compared with that of urea and grain, the economic advantage of feeding 12 or 14% protein rations from SBM, of course, would be less than when SBM prices are low. We used gains and feed efficiencies from the milo stover silage and forage sorghum silage rations to calculate predicted gain and efficiency for the 50% MSS + 50% FSS ration (Table 10.3). Observed gain exceeded predicted gain 0.08 lb. per day or 7.8%, and observed feed efficiency exceeded predicted efficiency 1.86 lbs. of feed per lb. of gain or 13.9%. The value of milo stover silage in growing rations for calves, therefore, is improved by feeding it with forage sorghum silage. Table 10.1. Performances of heifers fed the five forages. Item FSS 1 MSS 1 Forage PH 1 20 429 20 427 20 429 1.25 a .79c 1.22 a 13.03 b 11.84 c 10.59 a 16.18 c No. of calves Initial wt., lbs. Avg. daily gain, lbs. Avg. daily feed, lbs. 2 Feed/lb. of gain, lbs. 2 MSS + FSS PH + FSS 20 429 20 429 l . l 0b 1.32 a 15.03 a 12.43 b 14.26 a 12.40 b 11.52 b 11.58 b 1 FSS = forage sorghum silage; MSS = milo stover silage; PH = prairie hay. 2 100% dry matter basis. a,b,c Means in (P‹.05). the same row with different superscripts differ significantly 31 Table 10.2. Performances of heifers fed the four protein treatments. Item Protein treatment: source and level SBM Urea 10% 12% 14% 12% No. of calves Initial wt., lbs. 25 429 Avg. daily gain, lbs. l.l0 Avg. daily feed, lbs. 1 13.39 13.55 13.45 12.90 12.83 b 11.33 a 10.67 a 15.00c Feed/lb. of gain, 1bs. 1 a,b,c l 100% dry matter basis. Means in the same row (P‹.05). Table 10.3. b with 25 428 25 427 1.22 a 1.28 different superscripts 25 429 a .94 differ significantly Observed and predicted rates and efficiencies of gain by heifers fed milo stover silage, milo stover silage + forage sorghum silage, or forage sorghum silage. Item No. of calves Avg. daily gain, lbs. Observed Predicted 1 Improvement, lb. Improvement, % Feed/lb. of gain, lbs. Observed Predicted Improvement, 1bs.l Improvement, % 1 Observed minus predicted. MSS 20 Forage FSS + MSS 20 FSS 20 .79 --- 1.10 1.02 +.08 +7.8 1.25 --- 16.18 --- 11.52 13.38 -1.86 +13.9 10.59 --- c 35 Yield and Quality of Six Summer Annual Forages Mopoi Nuwanyakpa, Gerry L. Posler, Keith K. Bolsen, and Harvey Ilg Summary In 1977, all summer annual forages studied produced excellent yields. Based on leafiness and regrowth ability, sudangrasses and pearl millet appeared to be best for early vegetative and boot cutting management. The sorghumsudan hybrids had suitable yields and quality at all harvest stages. The hybrid forage sorghum appeared best suited for soft-dough-stage harvest although yields of pearl millet and sorghum-Sudan hybrids were also excellent. Introduction Many summer annual crops can provide excellent forage during the hot, dry summers in Kansas when other pasture grasses have declined in production and quality. Summer annuals, including sudangrasses, hybrid sudangrasses, sorghum-sudangrass hybrids, sorgos, hybrid forage sorghums, and pearl millets, may be used for pasture, hay, silage, and greenchopping. Differences in their anatomy and growth characteristics reward producers who carefully select the proper crop to match their livestock needs. Materials and Methods In 1977 at Manhattan and Hutchinson, we evaluated forage yield and quality of six forages, harvested at early vegetative, boot, and soft-dough stages of growth. Forages tested were 'Piper' sudangrass, Northrup King 'Trudan 6' hybrid sudangrass, Dekalb 'Sudax SX-11', and Ring Around 'Super Chow Maker 235' sorghum-sudangrass hybrids, Dekalb 'FS 25a' hybrid forage sorghum, and Northrup King 'Millex 23' hybrid pearl millet. The hybrid forage sorghum was planted in 30-inch rows; all others, in 6-inch rows. Plots were 5 x 20 feet for the narrow spacing and 10 x 20 feet for the wide spacing. The center 3 feet or 2 rows were harvested for yield, leaving a 6-inch stubble. Harvests were by stage of growth, not calendar date. At Hutchinson, forages were cut 3 times at the early vegetative stage, 2 times at the boot stage, and 1 time at the dough stage. One additional early vegetative cutting was obtained at Manhattan. Samples were taken from the flail-chopped material for dry matter and quality analyses. 36 Experimental Results As shown in Tables 12.1 and 12.2, mean forage yields were similar at Hutchinson and Manhattan for the early vegetative stage, greater at Hutchinson for the boot stage, and greater at Manhattan for the soft-dough stage. The forages sometimes responded differently at the two locations. The most difference was noted for Millex at the soft dough stage; it yielded much better at Manhattan. C u t t i n g s w e r e a t d i f f e r e n t c a l e n d a r d a t e s , a n d r a i n f a l l p a t t e r n s d i f f e r e d b e t w e e n l o c a t i o n s , but such differences are expected and would be expected in other years. Crude protein content and in vitro digestible dry matter (IVDDM) declined with advancing maturity. Crude protein was always lower at Hutchinson, particularly at the soft dough stage, probably partly because of near-record August rainfall, unusually high yields, and moderate nitrogen fertilization. Piper sudangrass and Trudan hybrid sudangrass performed best for early vegetative and boot harvests. The FS 25A hybrid forage sorghum, as expected, performed poorly under early vegetative management, and its yield was quite low at the boot stage at Manhattan. At Hutchinson, it yielded well despite being cut only once, while the others were cut twice. Yields of the two sorghum-sudan hybrids and pearl millet varied most at the various stages and locations. Additional years of data are needed to better estimate the forages' true yielding abilities. Summer annual forages vary in growth characteristics. 37 Table 12.1. Forage yields and quality of six summer annual forages cut at three stages of growth, Manhattan. Forage Forage yield (ton/acre) Dry matter 60% H2 0 Crude protein % IVDDM % Early vegetative stage Piper Trudan-6 S.C. Maker 235 Sudax SX-11 Millex 23 FS 25A Mean 5.0 4.9 5.1 5.4 6.1 2.9 4.9 14.3 14.0 14.7 15.5 17.5 8.4 14.1 19.2 17.8 19.2 20.1 21.5 19.7 19.6 67.3 67.6 66.1 65.1 67.4 65.6 66.5 14.3 15.6 14.5 12.6 16.6 12.5 14.4 63.1 61.8 62.6 61.0 63.9 58.6 62.6 Boot stage Piper Trudan 6 S.C. Maker 235 Sudax SX-11 Millex 23 FS 25A Mean 6.5 6.3 8.2 6.9 7.4 5.0 6.7 18.7 18.0 23.4 19.6 21.2 10.3 19.2 Soft dough stage Piper Trudan 6 S.C. Maker 235 Sudax SX-11 Millex 23 FS 25A Mean LSD.05 7.6 8.4 16.6 9.1 13.4 12.2 11.2 21.7 24.0 47.3 26.0 38.2 34.8 32.0 10.2 8.9 8.3 9.9 10.2 8.7 9.4 49.8 51.5 50.9 50.3 52.8 53.1 51.4 2.3 4.8 1.2 2.5 a IVDDM = In vitro digestible dry matter. a 38 Table 12.2. Forage yields and qualities of six summer annual forages cut at three stages of growth, Hutchinson. Forage Forage yield (ton/acre) 60% H2 0 Dry matter Crude protein % IVDDM % Early vegetative stage Piper Trudan 6 S.C. Maker 235 Sudax SX-11 Millex 23 FS 25A Mean 5.1 5.7 5.8 5.8 4.4 3.9 5.1 14.5 16.4 16.7 16.7 12.6 11.4 14.7 13.8 14.3 13.8 14.9 14.8 17.3 14.8 66.2 67.2 67.4 66.6 70.8 64.6 67.1 9.1 8.5 8.3 10.3 11.1 7.8 9.2 59.8 62.9 62.3 61.0 65.8 58.3 61.7 Boot stage Piper Trudan 6 S.C. Maker 235 Sudax SX-11 Millex 23 FS 25A Mean 22.2 23.6 28.7 35.3 20.0 28.4 26.4 7.8 8.3 10.0 12.4 7.0 9.9 9.2 Soft dough stage Piper Trudan 6 S. C. Maker 235 Sudax SX-11 Millex 23 FS 25A Mean LSD .05 5.4 8.1 15.7 11.0 8.4 12.0 10.1 15.5 23.1 44.7 31.0 23.9 34.2 28.3 6.6 6.0 3.3 5.7 3.9 4.0 4.9 50.9 51.3 53.9 56.3 55.3 58.6 54.4 1.6 3.7 1.7 2.4 a IVDDM= I n v i t r o d i g e s t i b l e d r y m a t t e r . a ACKNOWLEDGMENTS T h e D e p a r t m e n t of A n i m a l S c i e n c e s a n d I n d u s t r y s i n c e r e l y t h a n k s t h e f o l l o w i n g i n d i v i d u a l s a n d companies for s u p p o r t t h r o u g h r e s e a r c h g r a n t s , p r o d u c t s , or s e r v i c e s . T h e i r h e l p h a s a d d e d much t o o u r r e s e a r c h e f f o r t . Abbott Laboratories Chicago, C. Savannah, Missouri K. Al l e n , W o o d l a n d F a r m s Illinois A m e r i c a n C y a n a m i d Company P r i n c e t o n , New Jersey C a d c o Company D e s Moines. C e l a n e s e C h e m i c a l Company Corpus C h r i s t i . Bi ll y C l a r k . B a r n a r d , Kansas Clark Herefords Texas El k h a r t , K a n s a s F l o y d Coen Cry-O-Vac Iowa Division, W. R . Grace Duncan, S o u t h C a r o l ina D u g d a l e P a c k i n g Company St. Joseph, Missouri Dow C h e m i c a l Company Midl a n d , M i c h i g a n E l a n c o P r o d u c t s Company D i v i s i o n of E l i L i l l y Indianapolis, I n d i a n a F o u r t h N a t i o n a l Bank Wichita, Hess a n d C l a r k Company Ashland, Ohio Kansas New Jersey Nutley, Roman L. H r u s k a U.S. Research C e n t e r Meat Animal IMC C h e m i c a l G r o u p I n c . I n t e r n a t i o n a l S t o c k Food. I n c. Clay Center, Nebraska Terre Haute, Indiana . Waverly New York D e s Moines, Iowa Lilll y R e s e a r c h L a b o r a t o r i e s D i v i s i o n of E l i L i l l y Greenfield, Indiana Livestock & M e a t Industry C o u n c i l , I n c . (LMIC) Manhattan, Kansas Manhattan L i v e s t o c k Exchange Manhattan, Kansas M e r c k & Company. Rahway, Kemin I n d u s t r i e s , Inc. Inc. New J e r s e y Ross I n d u s t r i e s Inc. Midland, G. D. S e a r l e Company E l b u r n , Illinois T h e i s P a c k i n g Company Great B e n d , K a n s a s Thompson- Hayward C h e m i c a l Co. Virginia Kansas C i t y , Kansas Ill1 i n o i s Union C a r b i d e Chicago. T h e UpJohn Company Kal a m a z o o , M i c h i g a n U n i v e r s i t y o f Nebraska Lincoln, Nebraska USS A g r i - C h e m i c a l s Atlanta, Georgia Company a n d b r a n d n a m e s a r e u s e d o n l y f o r e a s i e r c o m m u n i c a t i o n . imply no p r e f e r e n c e or endorsement. They