Document 13274123

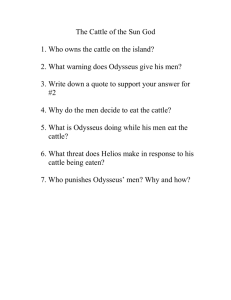

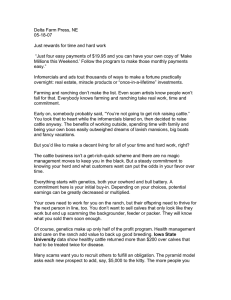

advertisement