THE PERMIT SYSTEM OF CREAM-BUYING STATE DAIRY COMMISSIONER’S BULLE TIN No. 4

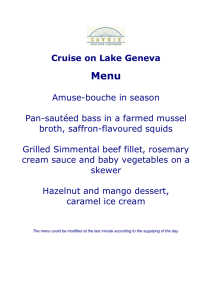

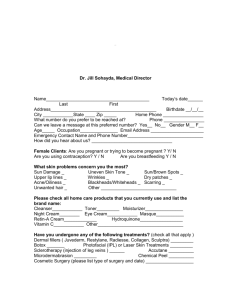

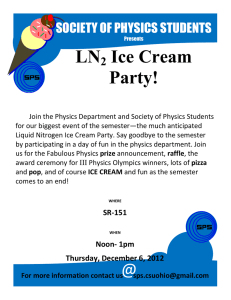

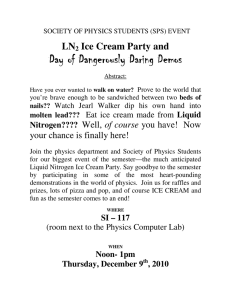

advertisement