The Permit System of Cream-Buying. Persons and Testing Kansas.

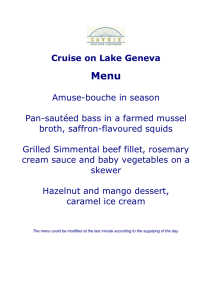

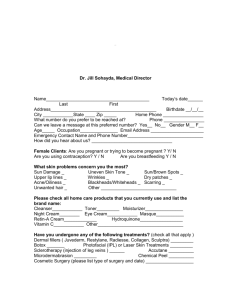

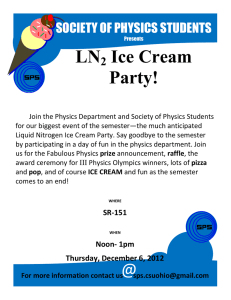

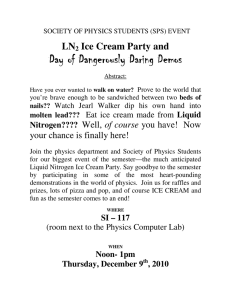

advertisement