Document 13272763

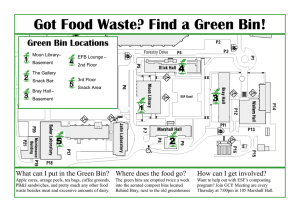

advertisement