EFFECTS OF PARABOLIC AND INVERTED PARABOLIC SALINITY GRADIENTS ON DOUBLE DIFFUSIVE MARANGONI

advertisement

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

ISSN 2319 - 4847

EFFECTS OF PARABOLIC AND INVERTED

PARABOLIC SALINITY GRADIENTS ON

DOUBLE DIFFUSIVE MARANGONI

CONVECTION IN A COMPOSITE LAYER

AN EXACT STUDY

1

R. Sumithra and 2B. Komala

1

Department of Mathematics, Government Science College, Bangalore – 560 001,

Karnataka, INDIA.

2

Department of Mathematics, BTLITM, Bangalore-560 099,

Karnataka, INDIA.

ABSTRACT

The Effects of Parabolic and Inverted parabolic Salinity gradients on the onset of Double Diffusive Marangoni Convection in

a two-layer system, comprising an incompressible two component fluid saturated porous layer over which lies a layer of the

same fluid in the microgravity condition, are investigated. The upper boundary of the fluid layer is free and the lower

boundary of the porous layer is rigid and both the boundaries are insulating to heat and mass. At the interface, the velocity,

shear stress, normal stress, heat, heat flux, mass and mass flux are assumed to be continuous conducive for Darcy-Brinkman

model. The resulting Eigen value problem is solved exactly. The Thermal Marangoni numbers for linear, parabolic and

inverted parabolic salinity profiles are obtained. The effects of different physical parameters on the onset of double diffusive

Marangoni convection are investigated for above profiles in detail.

Keywords: Double diffusive convection, Salinity gradients, Thermal Marangoni numbers, Darcy-Brinkman model

1. INTRODUCTION

In the generation of techno-savvy world, the chips made up of pure crystals are of great demand leading to the

enormous scope for the evolutions and explorations in the industry of crystal growth. There are many methods of

growing crystals and these can be classified on the basis of method of producing super saturation as Isothermal methods

(constant temperature method) ex., Hydrothermal growth and Non isothermal methods (temperature variation

method) In the case of Isothermal methods, any property of the crystal that is temperature dependent will be under

better control. Hydrothermal growth is a crystal growth from aqueous solution at high temperature and pressure. Even

under hydrothermal conditions most of the materials grown have very low solubilities in solvents. Thus to achieve

reasonable solubilities, large quantities of other materials are added which do not react with the material being grown.

These materials are called mineralizers. The apparatus consists of an autoclave consisting two layers. Nutrients in the

lower part (nutrient region) of the autoclave dissolve in the fluid (solvent + Mineralizers + crystal material), which is

kept to hotter than the upper part (growth region) of the autoclave. The temperature difference causes convection from

the nutrient region to the growth region and the upper fluid is supercooled which drives the crystallization. Since the

fluid has more than one diffusive component of different molecular diffusivities (heat, concentration of mineralizer) the

convection is multi diffusive and the materials in the nutrient chips can be regarded as a porous medium. This method

of growing crystals exactly simulates the double (if one mineralizer is added), triple (if two mineralizers are added) and

multi component (if more than two mineralizers are added) diffusive convection in a horizontal composite layer( a fluid

layer overlying a fluid saturated porous layer ). In the case of non isothermal methods of growing crystals that is, when

the temperature gradient is imposed on the system, the main advantage is that the diffusion path is usually shorter, so

reasonable rates are achieved without elaborate control or apparatus investment. In these situations, maintaining a

uniform temperature and salinity gradients is a limitation and occurrence of non-uniform temperature and salinity

gradients is a reality. The study of non uniform gradients is not given much attention and the non uniform salinity

gradients are rarely touched. Though some literature is available on the study of non uniform temperature gradients,

but the non uniform salinity gradients is at scarce. Recently Subbarama Pranesh et al (2012) have investigated the

effect of non uniform basic concentration gradient on the onset of double diffusive convection in a micropolar fluid

layer heated and saluted from below and cooled from above. The Eigen values are obtained using Galerkian method for

free-free, rigid-free, rigid-rigid velocity boundary combination with isothermal on spin-vanishing permeable

Volume 3, Issue 10, October 2014

Page 258

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

ISSN 2319 - 4847

boundaries. One linear and five non linear concentration profiles are considered and their comparative influence on

onset is discussed and results are depicted graphically. It is observed that the fluid layer with suspended particles heated

and saluted from below is more stable compared to the classical fluid layer without suspended particles. Here we make

an attempt to study the effects of two non uniform salinity gradients (parabolic and inverted parabolic profile) on the

onset of surface tension driven double diffusive convection in a horizontal composite layer by Exact method [6]. Here

we give some literature on the effects of non uniform temperature gradients on Marangoni convection in single

horizontal fluid and porous layers separately. Nanjundappa Rudraiah and Pradeep G Siddheshwar (2000) have

investigated the effect of non-uniform basic temperature gradients on the onset of Marangoni convection in a horizontal

layer of a Boussinesq fluid with suspended particles. It is observed that the fluid layer with suspended particles heated

from below is more stable compared to the classical fluid layer without suspended particles. The problem has possible

applications in microgravity situations [4]. Shivakumara et al (2002) have investigated the effect of different basic

temperature gradients on the onset of ferro convection driven by combined surface tension and buoyancy forces are

studied. The results indicate that the stability of Rayleigh-Bernard-Marangoni Ferro convection is significantly affected

by basic temperature gradients and the mechanism for suppressing or augmenting the same is discussed in detail. It is

shown that the results obtained under the limiting conditions compare well with the existing ones [1]. Melviana

Johnson Fu et al (2009) have studied the effect of six different non-uniform basic state temperature gradients on the

onsets of Marangoni convection in a horizontal micropolar fluid layer bounded below by a rigid plate and above by

non-deformable free surface subjected to a constant heat flux. They used Rayleigh Ritz technique to solve the resulting

Eigen value problem and discussed the influence of the various parameters on the onset of Marangoni convection [3].

Siti Suzillian Putri Mohamed Isa et al (2009) have investigated the effect of six different non-uniform basic

temperature gradients on the onset of Marangoni convection in a horizontal layer with a free-slip bottom heated from

below and cooled from above. They solved the resulting the Eigen value problem using single-term Galerkian

expansion procedure and have discussed the effect of the various parameters on the onset of Marangoni convection [5].

Coming to the single porous layers, Shivakumara et al (2012) have investigated the effect of different forms of basic

temperature gradients on the criterion for the onset of convection in a layer of an incompressible couple stress fluid

saturated porous medium is investigated. It is shown that the principle of exchange of stability is valid, and the Eigen

value problem is solved numerically using the Galerkian technique. The parabolic and inverted parabolic basic

temperature profiles have the same effect on the onset of convection [2]. Sumithra and Manjunath (2014) have

investigated the an exact study of Magneto-Marangoni-convection in a two layer system comprising an

incompressible electrically conducting fluid saturated porous layer over which lies a layer of the same fluid in the

presence of a vertical magnetic field in the microgravity condition. The lower rigid surface of the porous layer and the

upper free surface are considered to be insulating to temperature perturbations. At the upper free surface, the surface

tension effects depending on temperature are considered. At the interface, the normal and tangential components of

velocity, heat and heat flux are assumed to be continuous. The resulting Eigen value problem is solved exactly for both

parabolic and inverted parabolic temperature profiles and analytical expressions of the Thermal Marangoni Number

are obtained. Effects of variation of different physical parameters on the Thermal Marangoni Number for both profiles

are compared [7].

2. FORMULATION OF THE PROBLEM

We consider a horizontal two – component fluid saturated, isotropic, sparsely packed porous layer of thickness

dm underlying a two component fluid layer of thickness d , in the microgravity condition. The lower surface of the

porous layer is rigid and the upper surface of the fluid layer is free with the surface tension effects depending on both

temperature and concentration. Both the boundaries are kept at different constant temperatures and concentrations. A

Cartesian coordinate system is chosen with the origin at the interface between porous and fluid layers and the z – axis,

vertically upwards. The continuity, momentum, energy and concentration equations are,

q 0

(1)

q

0 q q P 2 q

t

T

q T 2T

t

C

q C s 2 C

t

For the porous layer,

m qm 0

Volume 3, Issue 10, October 2014

(2)

(3)

(4)

(5)

Page 259

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

ISSN 2319 - 4847

0 qm

2

(6)

m Pm m qm qm

t

K

T

A m qm m Tm m m2 Tm

(7)

t

C

m qm . Cm sm 2Cm

(8)

t

Where the symbols in the above equations have the following meaning q u , v, w is the velocity vector, t is the

time,

is the fluid viscosity, 0 is the fluid density, A

C

C

0

p m

p

is the ratio of heat capacities, C p is the

f

specific heat, K is the permeability of the porous medium, T is the temperature, is the thermal diffusivity of the

fluid, C is the concentration, s is the solute diffusivity of the fluid, is the porosity, and the subscripts m and

f refer to the porous medium and the fluid respectively. The basic steady state is assumed to be the quiescent and we

consider the solution of the form,

u , v, w, P, T , C 0, 0, 0, Pb z , Tb z , Cb z

(9)

in the fluid layer

and in the porous layer

(10)

um , vm , wm , Pm , Tm , Cm 0, 0, 0, Pmb zm , Tmb zm , Cmb ( zm )

where the subscript ‘b’ denotes the basic state. The temperature distributions Tb z , Tmb zm , are found to be

T T z in 0 z d

Tb z T0 u 0

(11)

d

T

T z

Tmb zm T0 l 0 m in 0 zm dm

(12)

dm

d T m dTl

is the interface temperature.

T0 m u

dm m d

The concentration distributions Cb z , Cmb z m , are found to be

Cb C0 Cu

h z in 0 z d

z

d

C

C C0

mb L

hm z m in 0 zm dm

zm

dm

Here

h( z ), hm ( zm )

salinity

gradients

in

fluid

and

(14)

porous

layers

respectively

the

basic

state.

such

dm

d

that

are

(13)

h z dz d and h z dz

m

0

m

m

d m .The

b denotes

subscript

At

the

0

interface h z hm zm and note that C0

d mCu m dCl

dm md

is concentration at the interface.

In order to investigate the stability of the basic solution, infinitesimal disturbances are introduced in the form,

q, P, T , C 0, Pb z , Tb z , Cb z q , P, , S

(15)

And

qm , Pm , Tm , Cm 0, Pmb zm , Tmb zm , Cmb z m qm , Pm , m , S m

(16)

where the primed quantities are the perturbed ones over their equilibrium counterparts. Now Equations (15) and (16)

are substituted into the Equations (1) to (8) and are linearized in the usual manner. Next, the pressure term is

eliminated from (2) and (6) by taking curl twice on these two equations and only the vertical component is retained.

Volume 3, Issue 10, October 2014

Page 260

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

ISSN 2319 - 4847

d2

The variables are then non-dimensionalized using d ,

,

, T0 Tu and C0 Cu as the units of length, time

d

d 2 m

velocity, temperature, and the concentration in the fluid layer and dm , m ,

, Tl T0 , Cl C0 as the

m dm

corresponding characteristic quantities in the porous layer. Note that the separate length scales are chosen for the two

layers so that each layer is of unit depth.

In this manner the detailed flow fields in both the fluid and porous layers can be clearly obtained for all the depth

ratios dˆ

dm

.

d

The dimensionless equations for the perturbed variables are given by,

1 2 w

4w

(17)

Pr t

w 2

(18)

t

S

w h( z ) 2 S

(19)

t

2 2m wm

ˆ 2 4m wm 2m wm

(20)

Prm t

A m wm m2 m

(21)

t

S

m wm hm ( zm ) m m2 Sm

(22)

t

For the fluid layer Pr

is the Prandtl number, s is the diffusivity ratio in the fluid layer. For the porous

m

K

layer, Prm

is the Prandtl number, 2 2 Da is the Darcy number, ˆ m is the viscosity

m

dm

ratio, m sm is the diffusivity ratio in the porous layer. We make the normal mode expansion and seek solutions for

m

the dependent variables in the fluid and porous layers according to

w W z

z f x , y e nt

S S z

(23)

And

wm Wm zm

z f x , y e nmt

(24)

m m m m m

S m S m zm

2

2

2

2

With 2 f a f 0 and 2 m f m am f m 0 , where a and am are the non-dimensional horizontal wave numbers,

n and nm are the frequencies. Since the dimensional horizontal wave numbers must be the same for the fluid and

a am

ˆ . Substituting Equations (23) and (24) into the Equations

porous layers, we must have

and hence am da

d dm

(17) to (22) and denoting the differential operator

and

by D and Dm respectively, an Eigen value

z

z m

problem consisting of the following ordinary differential equations, is obtained,

Volume 3, Issue 10, October 2014

Page 261

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

In 0

ISSN 2319 - 4847

z 1,

n 2

2

2

2

D a D a W 0

Pr

2

D a2 n W 0

(25)

(26)

D 2 a 2 n S W h( z ) 0 (27)

In

0 zm 1

2

n 2

ˆ 2 m 1 Dm2 am2 Wm 0

Dm am2

Prm

(28)

2

2

(29)

Dm am nm A m Wm 0

m Dm2 am2 nm Sm Wm hm ( zm ) 0

(30)

It is known that the principle of exchange of instabilities holds for Double Diffusive Marangoni convection in both fluid

and porous layers separately for certain choice of parameters. Therefore, we assume that the principle of exchange of

instabilities holds even for the composite layers. In other words, it is assumed that the onset of convection is in the

form of steady convection and accordingly, we take n nm 0 .

We get,

In

0 z 1

2 2

D a W (z) 0

D a ( z ) W ( z ) 0

D a S ( z) W ( z ) h z 0

ˆ 1 D a W

In 0 z 1 D a

D a (z ) W (z ) 0

D a S (z ) W ( z ) h z 0

2

2

2

2

2

m

m

2

m

2

m

m

(32)

2

m

2

m

(31)

m

2

m

m

2

2

m

m

2

m

(33)

m ( z m ) 0 (34)

(35)

2

m

m

m

m

m

m

m

(36)

Thus to solve the above ordinary differential equation we need 16 boundary conditions.

3. BOUNDARY CONDITIONS

The bottom boundary is assumed to be rigid and insulating to temperature and concentration so the boundary

conditions at

zm 0 are

wm 0,

wm

Tm

S m

0,

0,

0

zm

zm

zm

(37)

The upper boundary is assumed to be free, insulating to temperature and concentration so the appropriate boundary

2w

T

S

t 22T t 22 S ,

0,

0 where

conditions

at

z d are

2

z

T

C

z

z

t 0 T T S S is the surface tension, here T t

, S t

At the interface

T T T0

S C C0

w 0,

(i.e., at

ˆ

z 0, zm dm ), the normal component of velocity, tangential velocity, temperature, heat flux, mass and mass

flux are continuous and respectively yield (following Nield (1977)),

T

T

S

S

(38)

m m , S Sm ,

sm m

z

z m

z

z m

We note that two more velocity conditions are required at z 0. Since we have used the Darcy-Brinkman equations of

w wm ,

w wm

, T Tm ,

z zm

motion for the flow through the porous medium, the physically feasible boundary conditions on velocity are the

following, at the interface z 0 and zm dm

Volume 3, Issue 10, October 2014

Page 262

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

Pm 2 m

wm

w

P 2

z m

z

ISSN 2319 - 4847

(39)

which will reduce to

2 w

w

2 w

3 22 2

m m m 2 3 22 m 2 m

z z

K z m

zm zm

The other appropriate velocity boundary condition at the interface z 0, zm d m can be,

2 wm

2w

2

2 2 w m 2 22 m wm

z

zm

(40)

All the Sixteen boundary conditions (35) to (40) are non-dimensionalised and are subjected to Normal mode expansion

and are given by

D 2W (1) M a 2 (1) M s a 2 S (1) 0,

W (1) 0,

D (1) 0,

DS (1) 0

ˆ (0) W (1), TdDW

ˆˆ

ˆ ˆ 2 D 2 a 2 W (0) ˆ D 2 a 2 W (0)

TW

(0) DmWm (1), Td

m

m

m

m

ˆ ˆ 3 2 D3W (0) 3a 2 DW (0) D W 1

ˆ 2 Dm3Wm 1 3am2 DmWm 1

Td

m m

(0) Tˆ m (1),

wm 0 0,

ˆ (1),

D(0) Dm m (1), S (0) SS

m

Dm wm (0) 0,

DS (0) Dm S m (1),

Dm m (0) 0, Dm Sm (0) 0

(41)

t T0 Tu d

t C0 Cu d

is the thermal Marangoni number, M s

is the solute

T

v

S

v

Marangoni number, while Tˆ TL T0 / T0 TU , Sˆ CL C0 / C0 CU , and dˆ d m / d is the depth

ratio. We see that ˆ / dˆ / Tˆ and ˆ / dˆ / Sˆ because the steady state heat and mass fluxes are

Where

M

m

s

sm

s

continuous across the interface. The Equations (31) to (36) are to be solved with respect to the above boundary

conditions (41).

4. EXACT SOLUTION

The solutions of the Equations (31) and (34) are independent of z ,

can be solved and expressions for

S z , m zm , S m zm and thus

W and Wm can be obtained as,

W z C1Cosh az C2 zCosh az C3 Sinh(az ) C4 zSinh(az )

Wm z m C5Cosh am zm C6 Sinh am zm C7Cosh zm C8 Sinh zm

where

(42)

(43)

1

am2 , and the expressions for W ( z ) and Wm ( z ) are

2

ˆ am

W z C1 Cosh az A1 zCosh az A2 Sinh(az ) A3 zSinh(az )

(44)

Wm zm C1 A4Cosh am z m A5 Sinh am zm A6Cosh zm A7 Sinh zm

(45)

where

A1 , A2 , A3 , A4 , A5 , A6 , A7 are constants which are determined using corresponding velocity the boundary

conditions

(41)1 , (41)5 , (41)6 , (41)7 , (41)8 , (41)13 , (41)14 as

Volume 3, Issue 10, October 2014

Page 263

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

A1 A4 3 A5 4 ,

A4

A5

A2 A4 1 A5 2 ,

1 ˆ

10

T

9

8 9 10 7

A3 a A4 5 A5 6

aSinh(a) Cosh(a)

aSinh(a) Cosh(a)

9

Tˆ 7

8 9 10 7

,

ISSN 2319 - 4847

A6 A4 ,

9

Tˆ 7

A7

A5 am

's

And i are

1

1

1 3am2

ˆ 2 am Sinh(am ) Sinh( )

ˆ 2 am3 Sinh(am ) 3 Sinh( )

3 ˆ ˆ3 2

2a Td

2

1

1 3am2

ˆ 2 Cosh(am ) Cosh( ) am

ˆ 2 am2 Cosh(am ) 2Cosh( ) am

3 ˆ ˆ3 2

2a Td

3

1

ˆ ˆ , 1 a (Cosh(a ) Cosh( )) Tda

ˆˆ

am Sinh(am ) Sinh( ) Tda

1

4

m

m

2

ˆ

ˆ

ˆ

ˆ

Td

Td

1

ˆ ˆ2

2aTd

1

6

ˆ ˆ2

2aTd

5

ˆ 2am2 Cosh(am ) 2 am2 Cosh( )

2

am 2

2

ˆ 2am Sinh(am ) am Sinh( )

7 3Cosh(a ) 1Sinh(a) 5 Sinh(a ), 8 4Cosh(a) 2 Sinh(a) 6 Sinh(a )

9 Cosh am Cosh , 10 Sinh am

am

Sinh

The Temperature distributions are obtained from the Equations (32) and (35) by substituting expressions for

W and

Wm , are as below

1

Az

Az

[ Sinh (az )(2 z A1 z 2 3 ) Cosh (az )(2 A2 z 1 A3 z 2 )]}

4a

a

a

Az

m z m C1{ A10Cosh am zm A11Sinh am z m 4 m Sinh(am zm )

2 am

z C1{ A8Cosh az A9 Sinh az

A5 zm

A

A

Cosh(am zm ) 2 6 2 Cosh zm 2 7 2 Sinh z m }

2am

am

am

The constants

A8 , A9 , A10 , A11 are determined using temperature boundary conditions (41)3 , (41)9 , (41)10 ,

(41)15 and are obtained as below.

ˆ

A8 A10TCosh

am 4 , aA9 A10 am Sinh am 5

A10

Where

1 a 4 Sinh a 5Cosh a

ˆ

TaCosh

am Sinh a amCosh a Sinh am

,

A11

A

1 A5

27 2

am 2am am

i's are

Volume 3, Issue 10, October 2014

Page 264

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

1

ISSN 2319 - 4847

A

A

1

aCosh a 2 A1 3 Sinh a 2 2 A1 3

4a

a

a

A

A

1

aSinh a 2 A2 1 A3 Cosh a 2 A2 1 2 A3

4a

a

a

2

A4

A

A

A

Sinh am 5 Cosh am 2 6 2 Cosh 2 7 2 Sinh

2am

2am

am

am

3

A

A

A

A4

Sinh am amCosh am 5 Cosh am am Sinh am 2 6 2 Sinh 2 7 2 Cosh

2am

2am

am

am

4

1 A5

A ˆ

2 7 2 TSinh

am Tˆ2

am 2am am

5

1

A1 A5

A

2 7 2 Cosh am 3

2 A2

4a

a 2am am

4.1 Linear Salinity Profile

We consider linear salinity profile of the form h

z hm zm 1 ,

substituting this in eq.(33) and (36) the

expressions for S z and S m z m are obtained as

S z C1 A12Cosh az A13Sinh az

1

Az

Az

Sinh az 2z A1z2 3 Cosh az 2A2 z 1 A3 z2

4a

a

a

S m zm C1 A14Cosh am zm A15 Sinh am zm

1 A4 zm

Az

A

A

Sinh am zm 5 m Cosh am zm 2 6 2 Cosh z m 2 7 2 Sinh z m

pm 2am

2am

am

am

The constants

A12 , A13 , A14 , A15 are determined using salinity boundary conditions (41)4 , (41)11 , (41)12 , (41)16 and

are obtained as below.

Sinh am A5

A7

A12 Sˆ 6 10 Cosh am

2 2 7

am pm 2am am

9

Cosh am A5

A7

6 10

1 A5

A7

aA13 6 10 amSinh am

, A15

2 2 3, A14

2 2

pm 2am am

9

am pm 2am am

9

Where

i' s , for i = 6 to 10 are

6

1

4a

A3

A3

Sinh a 2 2 A1 a aCosh a 2 A1 a

A

A

Cosh a 2 A2 2 A3 1 aSinh a 2 A2 A3 1

a

a

Volume 3, Issue 10, October 2014

Page 265

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

ISSN 2319 - 4847

7

1 A4

A

A

A

Sinh am 5 Cosh am 2 6 2 Cosh 2 7 2 Sinh

pm 2am

2am

am

am

8

1

4a

A1 1

2 A2

a pm

A4

A

A

A

Sinh am 4 Cosh am 5 Cosh am 5 Sinh am

2

2am

2

2am

A6

A

Sinh 2 7 2 Cosh

2

am

am

2

ˆ

9 aSSinh

a Cosh am amCosh a Sinh am

10

ˆ

aSSinh

a Sinh am A5

A ˆ

2 7 2 SaSinh

a 7

am pm

2a m a m

Cosh a Cosh am A5

A

2 7 2 8Cosh a

pm

2am am

The Thermal Marangoni number for Linear Salinity Profile is obtained by the boundary condition

Mt

11 M s a 2 12

(41) 2 as

2

a 13

Where

11 C1 a 2Cosh a A1 2aSinh a a 2Cosh a A2 a 2 Sinh a A3 2aCosh a a 2 Sinh a

A3

A1

Sinh a 2 A1 a Cosh a 2 A2 a A3

1

A

A

13 C1{ A8Cosh a A9 Sinh a [ Sinh (a )(2 A1 3 ) Cosh (a )(2 A2 1 A3 )]}

4a

a

a

12 C1 A12Cosh a A13 Sinh a

1

4a

4.2 Parabolic Salinity Profile

We consider parabolic salinity profile of the form h

z 2z, hm zm 2zm , substituting this in eq.(33) and (36), the

expressions for S z and S m z m are obtained as

z 2 A1 z 3 A1 z A2 z A3 z 2

2

S z C1 A16Cosh az A17 Sinh az Sinh az

3 2

4a 2

4a 12a 4a 4a

z

A z 2 A z 2 A z 3 A z

Cosh az 2 1 2 2 3 3 3

4a

4a

12a 4a

4a

A4 zm2 A5zm

A5zm2 A4zm

2

Sm zm C1 A18Cosh amzm A19Sinh amzm Sinh amzm

2 Cosh amzm

2

pm

4am 4am

4am 4am

Az

2 A7

Cosh zm 2 6 m 2

am 2 a 2

m

The constants

Sinh z A7 z m 2 A6

m

2

2 am2

2 am2

2

A16 , A17 , A18 , A19 are determined using the salinity boundary conditions (41) 4 , (41)11 , (41)12 ,

(41)16 and are obtained as below.

Volume 3, Issue 10, October 2014

Page 266

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

ISSN 2319 - 4847

p

p

p

A16 Sˆ 7 Cosh am 7 Sinh am p3 , aA17 7 am Sinh am p5Cosh am p6 ,

am

p8

p8

p

A18 7 , am A19 p5

p8

's

Where pi , for i = 1 to 8 are

p1

p2

A3

2 1

2 3

4 a 4a

2

A

A

A

A

A

A

A

1 A1

1

Sinh a

13 22 32 aCosh a

1 13 22 32

2a 4a 4a 4a 2a

4a 12a 4a 4a 4a

A

A

A

A

A

A

A

A

1

1

Cosh a 2 12 2 3 33 aSinh a 2 12 2 3 33

2a

2a 4a 4a

4a

4a 12a 4a

4a

4a

p3

A

A5

2

A5

A

42

Sinh am 4 2 Cosh am

pm

4am 4am

4am 4am

A

2 A7

Cosh 2 6 2

am 2 a 2

m

p4

A4

2

A

52

am Cosh am

pm

4am 4 am

Sinh A7 2 A6

2

2 am2

2 am2

A4

A

52

Sinh am

2 am 4 am

A5

A

2 A6

A4

Cosh am

2 Cosh 2 7 2

am 2 a 2

2 am 4 am

m

A

2 A7

Sinh 2 6 2

am 2 a 2

m

p5

2

A5

A

42

am Sinh am

4am 4am

Sinh A7

2

2

2

am

Cosh A6

2

2

2

am

2 A4

2 A6

2

2

2

pm 4am

am

A6 ,

2

2 am2

p6 p4 p1

p ˆ

ˆ

p7 p2 p6Cosh a p5Cosh am Cosh a p3 SaSinh

a 5 SaSinh

a Sinh am

am

ˆ

p SaSinh

a Cosh a aCosh a Sinh a

8

m

m

The Thermal Marangoni number for Parabolic Salinity Profile is obtained by the boundary condition

Mt

11 M s a 2 12

(41) 2 as

2

a 13

Where

11 C1 a 2Cosh a A1 2aSinh a a 2Cosh a A2 a 2 Sinh a A3 2aCosh a a 2 Sinh a

12 C1 A16Cosh a A17 Sinh a

Volume 3, Issue 10, October 2014

Page 267

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

ISSN 2319 - 4847

2

A

A

A

A

A

A

A

A

1

1

Sinh a

1 13 22 32 Cosh a 2 12 2 3 33

4a 12a 4a

4a 12a 4a 4a 4a

4a 4a

1

A

A

13 C1{ A8Cosh a A9 Sinh a [ Sinh (a )(2 A1 3 ) Cosh (a )(2 A2 1 A3 )]}

4a

a

a

4.3 Inverted Parabolic Salinity Profile

We consider parabolic salinity profile of the form h

z 2 1 z , hm zm 2 1 zm , substituting this in eq.(33)

and (36) the expressions for S z and S m z m are obtained as

2 z A1 z 2 z 2 A1 z 3 A1 z A3 z A2 z A3 z 2

2

S z C1 A20Cosh az A21Sinh az Sinh az

4a

12a 4a 3

4a 2

2 A2 z A3 z 2 A2 z 2 A3 z 2 A3 z A1 z z A1 z 2

Cosh az

4a

12a 4a 3

4a 2

S m zm C1 A22Cosh am zm A23 Sinh am zm

A4 zm A4 zm2 A5 zm

A z

2

A z2 A z

2 Cosh am zm 5 m 5 m 4 2m

Sinh am zm

pm

4am 4am

4am 4am

2am

2am

A

Az

2 A7

Cosh zm 2 6 2 2 6 m 2

am am 2 a2

m

The constants

Sinh z A7 A7 zm 2 A6

m

2

2 am2 2 am2 2 a2

m

2

A20 , A21 , A22 , A23 are determined using salinity boundary conditions (41)4 , (41)11 , (41)12 , (41)16 and

are obtained as below.

I

A20 Sˆ A22Cosh am 5 Sinh am I3 , aA21 A22 am Sinh am I 5Cosh am I1 I 4

am

I

A22 6 ,

am A23 I5

I7

's

Where Ii , for

i 1to 7 are

I1

I2

A3 2 A2

A

2 1

12

2 3

4a 4a

4a 4a

2

A

A A A

A

A

2A

1 A1 A1

Sinh a 1 13 2 2 3 1 aCosh a

13 22

4a

4a

12a 4a 4a

4a 4a

4a

A

A

A

1

A 1 2 A 2 A

A A3

Cosh a 1 2 3 3 33 aSinh a 2

2 3 33

4a 12a 4a

4a

4a 12a 4a

4a

I3

A

2

A

Sinh am 4 52

pm

4am 4am

2 A7

Cosh

2 a2

m

Volume 3, Issue 10, October 2014

A5

A

42

Cosh am

4am 4am

Sinh 2 A6

2

2 a2

m

2

Page 268

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

I4

A

A

2

A

amCosh am 4 52 Sinh am 52

pm

4am 4am

4am

2 A6

Cosh

2 a2

m

ISSN 2319 - 4847

Cosh A6

2

2 am2

A6

2 am2

Sinh A7 Sinh 2 A7

2

2 a2

2 am2

m

2 A5

A4

A

2 A6

I5

2 2 7 2

am 2 a 2

pm 2am 4am

m

ˆ

I 6 I 2 I 4Cosh a I5Cosh am Cosh a I 3 SaSinh

a

2

I5 ˆ

SaSinh a Sinh am I1Cosh a

am

ˆ

I 7 SaSinh

a Cosh am amCosh a Sinh am

The Thermal Marangoni number for inverted Parabolic Salinity Profile is obtained by the boundary condition

Mt

11 M s a 2 12

(41) 2 as

2

a 13

Where

11 C1 a 2Cosh a A1 2aSinh a a 2Cosh a A2 a 2 Sinh a A3 2aCosh a a 2 Sinh a

A

A

A

2

1 A1

12 C1 A20Cosh a A21 Sinh a Sinh a

1 13 22

12 a 4 a

4a

4a

A

1

A A3 A3

Cosh a 2

33 2

12a 4a 4a

4a

1

A

A

13 C1{ A8Cosh a A9 Sinh a [ Sinh (a )(2 A1 3 ) Cosh (a )(2 A2 1 A3 )]}

4a

a

a

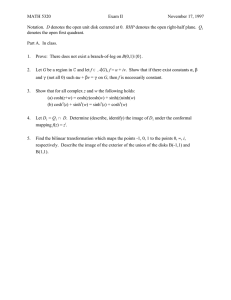

5. INTERPRETATIONS

The Thermal Marangoni numbers for the profiles, namely, linear, parabolic and inverted parabolic profiles for different

parameters are presented graphically as a function of depth ratio d̂ by fixing the other parameters. The effects of the

variations of the parameters like

Horizontal Wave number

number M s , Diffusivity ratio , and the Darcy number

a , Viscosity ratio ˆ

m

, Solute Marangoni

Da on the thermal Marangoni number is displayed in figures

2,3, 4,5 and 6 .

800

PARABOLIC PROFILE

600

LINEAR PROFILE

400

INVERTED

PARABOLIC PROFILE

200

0

0.0

0.2

0.4

0.6

0.8

1.0

Fig.1: The variation of thermal Marangoni number for Linear, Parabolic and Inverted parabolic profiles with respect to

the depth ratio. Figure1 shows the variation of thermal Marangoni numbers for different profiles with respect to the

Volume 3, Issue 10, October 2014

Page 269

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

depth ratio for fixed values of

ISSN 2319 - 4847

Da 10, Sˆ 1, Tˆ 1, 1, pm 1, a 5, M s 10, 5. Here the thermal

Marangoni numbers for the profiles differ only for smaller values of depth ratios. Graphically it is evident that the

parabolic salinity profile is the most stable one and the inverted salinity profile is the unstable one, so by choosing the

appropriate salinity profile one can control the onset of double diffusive Marangoni convection in a composite layer in

microgravity condition.

500

120

a=5

150

a=5

400

100

a=4

80

300

a=4

a=5

100

60

a=3

a=4

a =3

200

a=3

40

50

100

20

0

0

0

2

4

6

8

10

0

2

4

Fig. (a)

6

8

10

0

0

Fig (b)

2

4

6

8

10

Fig. (c)

a 3, 4,5 on the Thermal Marangoni numbers M t

Fig 2. The effects of horizontal wave number

The effects of ' a ' horizontal wave number on the Thermal Marangoni numbers in linear, parabolic and inverted

parabolic profiles are shown in Figures (a), (b) and (c) respectively for fixed values of

Da 10, Sˆ 1, Tˆ 1, 1, pm 1, M s 10, 5. The line curve is for a 3 , the big dotted curve is for

a 4 and the small dotted line curve is for a 5 . The curves for all the profiles are converging, indicating that for

larger values of depth ratios, the corresponding thermal Marangoni numbers coincide. The effect of horizontal wave

number is same for all the profiles, that is the increase in the value of the horizontal wavenumber a, the value of the

thermal Marangoni number increases, so the onset of double diffusive Marangoni convection is delayed and hence the

system is stabilized.

500

200

250

180

400

160

=3

140

=4

200

=5

120

=3

=5

=4

=3

300

200

=4

150

=5

100

100

80

100

50

60

0

2

4

6

8

10

0

0

Fig. (a)

2

4

6

Fig. (b)

8

10

0

0

2

ˆ

m

6

8

10

Fig. (c)

Fig.3. The effects of ˆ 3, 4,5 on the Thermal Marangoni number

The effects of the viscosity ratio

4

Mt

which is the ratio of the effective viscosity of the porous medium to the

fluid viscosity are displayed in Figures (a), (b) and (c) respectively for fixed values of Da 10, Sˆ 1, Tˆ 1,

1,

pm 1, a 5, M s 10. The line curve is for 3 , the big dotted curve is for 4 and the small dotted line

curve is for 5 . The curves for the parabolic profile are converging at both the ends, (fig. 3(b)) that is, the effect

of the viscosity ratio is only for the values of depth ratio 0.2 dˆ 10 , so the effect of the viscosity ratio is limited to

this range of depth ratio. In this range, for a fixed value of depth ratio, the increase in the value of viscosity

Volume 3, Issue 10, October 2014

Page 270

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

ratio ˆ

ISSN 2319 - 4847

m

increases the thermal Marangoni number. Whereas the effect of the viscosity ratio is opposite to that for

linear and inverted parabolic salinity profile. The curves for the linear and inverted parabolic profile are diverging and

the effect of the viscosity ratio is larger for larger values of the depth ratio. For a fixed value of depth ratio, the increase

in the value of viscosity ratio decreases the thermal Marangoni number and so destabilizes the system and hence the

onset of the double diffusive Marangoni convection is earlier.

200

200

Ms = 5

600

Ms = 10

500

150

150

Ms = 5

Ms = 15

Ms = 15

400

100

Ms = 10

100

Ms = 10

300

Ms =15

Ms = 5

200

50

50

100

0

0

2

4

6

8

10

0

2

4

Fig. (a)

6

8

10

0

0

Fig. (b)

Fig.4. The effects of

2

6

8

10

M s 5,10,15 on the Thermal Marangoni number M t

The effects of the Solute Marangoni number

M s are displayed in Fig. a ,b and c for the linear, parabolic and inverted

parabolic salinity profiles respectively for fixed values of Da 10, Sˆ 1, Tˆ 1, 1,

line curve is for

4

Fig. (c)

pm 1, a 5, 5. The

M s 5 , the big dotted curve is for M s 10 and the small dotted line curve is for M s 15 .The

curves for the parabolic profile are converging at both the ends, that is, the effect of the viscosity ratio is only for the

range of values of depth ratio

number

1 dˆ 9 .The increasing values of M s increases the value of the Thermal Marangoni

M t i.e., to stabilize the system, so that, onset of surface driven double diffusive convection is delayed.

Whereas the curves for the linear and inverted parabolic profile, are converging for larger values of depth ratio and

the increase in the solute Marangoni number has no much effect of the thermal Marangoni number for larger values

of the depth ratio. For a fixed value of depth ratio

d̂ , the increase in the values of of the solute Marangoni number

decreases the thermal Marangoni number, so the double diffusive Marangoni convection sets in earlier and hence

destabilizes the system.

=1

140

700

=0.5

120

=1

600

150

100

= 0.25

500

= 0.75

80

= 0.25

= 0.5

=1

400

100

300

= 0.5

60

40

200

20

50

100

0

2

4

6

8

10

Fig. (a)

Fig.5. The effects of

Volume 3, Issue 10, October 2014

0

2

4

6

Fig. (b)

8

10

0

0

2

4

6

8

10

Fig. (c)

0.5, 0.75,1 on the Thermal Marangoni number M t

Page 271

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

The effects of the diffusivity ratio

in fluid layer are displayed in Figures (a), (b) and (c) for linear, parabolic and

Da 10, Sˆ 1, Tˆ 1,

1, a 5, M s 10, 5. The line curve is for 0.5 , the big dotted curve is for 0.75 and the small

inverted

pm

ISSN 2319 - 4847

parabolic

salinity

profiles

respectively

for

fixed

values

of

dotted line curve is for

1 . The curves for the parabolic profile are converging at both the ends, that is, the effect of

the viscosity ratio is only for the values of depth ratio 1 dˆ 10 , whereas the curves for the linear and inverted

parabolic profile are converging. The increase in the values of increases the value of the Thermal Marangoni

number M t for the linear and inverted parabolic salinity profile, to stabilize the system, so the onset of surface driven

double diffusive convection is delayed, where as the same decreases the corresponding thermal Marangoni number for

the parabolic salinity profile.

250

500

Da = 10

Da =10

Da = 10

800

200

400

300

Da = 9

Da = 9

Da = 9

600

Da = 8

Da = 8

150

400

100

200

200

100

0

50

0

0.0

0.2

0.4

0.6

0.8

1.0

0

0.0

Fig. (a)

Fig.6. The effects of

inverted

parabolic

salinity

0.2

0.4

0.6

Fig.(b)

The effects of the Darcy number Da

Da = 8

2

profiles

0.8

1.0

0.0

0.2

0.4

0.6

0.8

1.0

Fig.(c)

Da 8,9,10 on the Thermal Marangoni number M t

K

, are displayed in Figures (a), (b) and (c) for linear, parabolic and

d m2

respectively

for

fixed

values

of

Sˆ 1, Tˆ 1, 1,

pm 1, a 5, M s 10, 5 The line curve is for Da 8 , the big dotted curve is for Da 9 and the small

dotted line curve is for Da 10 . The effect of The Darcy number is visible only for small values of depth ratios. The

effect of Darcy number is same for all the profiles. For a fixed value of depth ratio, increase in the value of Darcy

number increases the thermal Marangoni number for all the profiles, that is this stabilizes the system, so the onset of

surface driven double diffusive convection is delayed, this may be due to the presence of second diffusing component.

6. CONCLUSIONS

1. The parabolic salinity profile is the most stable one and the inverted salinity profile is the unstable one.

2. For various variations of the parameters, the effect of the parabolic salinity profile is opposite to those of linear and

inverted parabolic salinity profiles except for that of Darcy number.

3. The variation of Darcy number has same effect on the onset on the double diffusive Marangoni convection for all

the profiles.

4. The increase the values of horizontal wave number a , the viscosity ratio and solute Marangoni number and the

decrease in the values of diffusivity ratio in the fluid layer stabilizes the system for parabolic salinity profile,

where as the same destabilizes the system for the linear and inverted parabolic salinity profile.

Acknowledgements

I express my gratitude to Prof. N. Rudraiah and Prof. I.S. Shivakumara, UGC-CAS in Fluid mechanics, Bangalore

University, Bangalore, for their help during the formulation of the problem.

REFERENCES

[1] I.S. Shivakumara, N. Rudraiah and C.E. Nanjundappa “Effect of non-uniform basic temperature gradients on

Rayleigh-Bernad- Marangoni convection in ferrofluids” Journal of Magnetism and Magnetic Materials, 248,379395, 2002.

Volume 3, Issue 10, October 2014

Page 272

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 3, Issue 10, October 2014

ISSN 2319 - 4847

[2] I.S.Shivakumara, S.Sureshkumar and Devaraju N “Effect of non-uniform temperature gradients on the onset of

convection in a couple stress Fluid saturated porous medium” Journal 0f Applied Fluid Mechanics, Vol.5, No.1 ,

49-55, 2012.

[3] Melviana Johnson Fu, Norihan Md. Arifin, Mohd Noor Saad and Roslinda Mohd Nazar “Effects of Non-Uniform

Temperature gradient on Marangoni Convection in a Micropolar Fluid” European Journal Scientific Research,

ISSN 1450-216X Vol. 28, No. 4 , 612 -620,2009.

[4] Nanjundappa Rudraiah and Pradeep G. Siddheshwar “Effect of non-uniform basic temperature gradients on the

onset of Marangoni convection in a fluid with suspended particles” Aerospace science technology, 4,517-523,2000.

[5] Siti Suzillian Putri Mohamed Isa , Norihan Md. Arifin, Mohd Noor Saad and Roslinda Mohd Nazar “Effects of

Non-Uniform Temperature gradient on Marangoni Convection with Free Slip Condition” Americal Journal of

Scientific Research ISSN 1450-223X issue 1 , 37-44,2009.

[6] Subbarama Pranesh, Arun Kumar Narayanappa “Effect of Non-Uniform Basic Concentration Gradient on the

Onset of Double-Diffusve Convection in Micropolar Fluid”, Scientific Research an academic publisher,

Vol.3,No.5,May 2012.

[7] Sumithra R and Manjunath N ‘Effects of parabolic and inverted parabolic temperature profiles on magneto

Marangoni convection in a composite layer’, International Journal current research(IJCR), vol.06, Issue 03, pp

5435-5450, March 2014.

Volume 3, Issue 10, October 2014

Page 273