International Journal of Application or Innovation in Engineering & Management... Web Site: www.ijaiem.org Email: , Volume 2, Issue 9, September 2013

advertisement

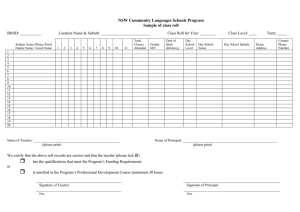

International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 9, September 2013 ISSN 2319 - 4847 ROLLOVER STABILITY ANALYSIS OF COMMERCIAL VEHICLE Venkata Ramesh Chaganti1 , Dr.A.Siva Kumar2, G.Hima Bindu3 and Dr.K.Vijaya Kumar Reddy4 1 M.Tech Student, Department of Mechanical Engineering, MLR Institute of Technology, Dundigal, Hyderabad-43, Andhra Pradesh, India. 2 Professor & HOD, Department of Mechanical Engineering. MLR Institute of Technology, Dundigal, Hyderabad-43, Andhra Pradesh, India. 3 Asst. Professor, Department of Mechanical Engineering. MLR Institute of Technology, Dundigal, Hyderabad-43, Andhra Pradesh, India. 4 Professor, Department of Mechanical Engineering. JNTUHCEH, Kukatpally, Hyderabad-500085 Andhra Pradesh, India. ABSTRACT Rollover stability of commercial vehicle is concerned with the study of various vehicle parameters in relation to lateral acceleration, yaw rate , roll dynamics and their influence on rollover stability. These parameters are examined to evaluate the severity of the rollover of commercial vehicles. In this work the mathematical models are used to simulate these models using SIMULINK software. The vehicle is firstly consider as simplified and then simulated as bicycle model with 2 DOF (lateral slip and yaw). Further a 3 DOF model (lateral slip, yaw and roll) is constructed and also simulated using Simulink. The results of these two models are compared with existing published work and showed good accuracy. Additionally a PID (Potential, Integration, Derivation) control system has incorporated in for the 2 and 3 DOF truck models to control yaw, slip and roll. Keywords: PID(Potential, Integration, Derivation),DOF(degrees of freedom),SIMULINK 1. INTRODUCTION: When The vehicles which are used for transportation of freights via roads across the world are called as commercial vehicles. Commercial vehicle undergoing modification in design, power train, suspension, etc. according to the human requirements. But one of the astonishing fact is there exists a proportionality between the number of vehicles manufactured and the number of vehicles involved with the fatal accidents. This is in the inadequate safety features equipped in the vehicle and the careless driving of the driver. According to the information by US National Highway Traffic Safety administration there are so many accidents caused due to the inferior roll stability of heavy vehicles compared with light vehicles made them more likely to roll over[1]. These technologies are playing significant role in controlling the vehicle under braking but no significant contribution is made against the vehicle rollover[2]. 2. OBJECTIVE: In this work an attempt is made to study the influence of yaw and lateral acceleration, on the rollover stability of heavy vehicle and create a mathematical model using MAT LAB/SIMLINK in order to predict and optimize the commercial vehicle stability. To incorporate a yaw control system to the models developed employing SIMULINK as described below Review the theory of vehicle dynamics and its application on commercial vehicles. Develop mathematical models for 2 and 3 degree of freedom system with PID and without PID which simulates lateral acceleration, yaw, and rollover of typical commercial vehicle. Use MATLAB/SIMULINK to simulate the mathematical equation and predict various responses 3. M ATHEMATICAL M ODELING: 3.1. Mathematical modeling of roll dynamics 3.1.1. Static vehicle model Roll model with tire and suspension compliance as shown in Figure 1 : The relation among loads on wheels , lateral force and roll angle could be achieved as K∅×∅∅+Ws(h c-h u)∅u+Ws×ay(h c-hu)+Fz×ay×h u=(Fz/2+Kt×∅u×T)(T-h u×∅u)-(Fz/2-Kt×∅u ×T) ; The relation among the lateral acceleration and angle of roll is given by Ws×ay×h r=K∅×∅s=Ws×h r×∅ ; At the point where tire lift-off the normal forces at that tire leads to zero Fz/2-Kt×∅UL×T=0 Volume 2, Issue 9, September 2013 Page 208 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 9, September 2013 ISSN 2319 - 4847 Roll model of a Single unit vehicle given in Figure 2 : The balance of roll moment about the roll centre of mass which is not supported by springs is specified as ay=([K∅-ms g h r(1+fj)]∅+Wi Ti (1+fj ))/(ms h r+(ms qi h ci+mui hui+muj huj )) in which ay is lateral acceleration; Fi are vertical tire loads; h is the height of cg; T is the track width; W is the weight of the vehicle; ∆y is the lateral motion of the cg relative to the track ; ∅ is the roll angle of the vehicle; kt = tire stiffness in ; T = half track width in; ∅L is the roll angle at the point where wheel lifts Figure 1 Vehicle while taking a steady turn Figure 2 Single unit vehicle coordinate system employed for analysis of stability of roll 3.1.2. Dynamic vehicle modeling The dynamic model structure as displayed in Figure3 has a number of inputs and outputs. A commercial vehicle with Three Degrees of Freedom (lateral velocity ‘v’, the yaw rate and roll angle ‘∅' ) moving forward on the flat road with a unvarying speed ‘U’ is taken in to account. The equations of motion used for modeling withofthe above stated is dynamic given model Figure 3 schematic input-output of condition the rollover m((v+Ur) . )+(amf-bmr ) (r+ms ) h r ∅.. = Fyf+Fyr (amf-bmr )(v. +Ur)+Izz r. +Ixz ∅.. = aFyf-bFyr +Mzf+Mzr Ixx ∅.. +D∅ ∅. +(K∅-ms gh r )∅+ms h r (v. +Ur)+Ixz r. = df Fyf+dr Fyr In which, a and b are the distance from the vehicle CG to the front and rear axles. m, ms, mf and mr are the complete mass, vehicle sprung mass, unsprung mass at the front and rear K∅, and D∅ are the tortional stiffness co-efficient and tortional damping co-efficient.Ixx, Izz and Ixz are the vehicle roll inertia, vehicle yaw inertia and product of vehicle rollyaw inertia. ∅,∅. and ∅.. are the vehicle sprung mass roll angle about the roll axis and its derivatives. hf is the sprung mass CG height above the roll axis. df=h cf-ha and dr=hcr-h a are the scrub derivatives of front and rear scrub. h a is the reference roll centre height and h c is the roll centre height at the axle. 3.2. Rollover simulations using Simulink software The vehicle modeling is generally done mathematically as it plays a significant role in analyzing the dynamics of the vehicle, such as visualizing the data, analyzing the data and computing numerically. Software of Various types are employed for modeling. In this paper I had chosen SIMULINK for modeling and analysis. It is a podium for designing the dynamic systems by model based, which is incorporated in MATLAB. Simulink is employed for mathematical modeling of the 2 and 3 DOF models a step steering input and a forward velocity which is constant thought out the modeling is given as inputs. The outputs of lateral velocity, yaw rate, roll angle verses time are plotted in graphs. Though the TWO DOF model is built and the results are conferred. The 3 DOF model is built in order to analyze the roll. Inputs taken are given Table1 Volume 2, Issue 9, September 2013 Page 209 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 9, September 2013 ISSN 2319 - 4847 Table 1 Inputs for Simulink Parameter m (kg) ms(kg) Izz (kg m2 ) Ixx (kg m2 ) Ixz (kg m2 ) a(m) b(m) c(m) Cαf (N/Radians) Cαr (N/Radians) Cαm (N/Radians) h s(m) hcf(m) hcr(m) h c(m) h r(m) k∅f (N-m/degrees) k∅r (N-m/degrees) k∅m (N-m/degrees) k∅ (N-m/degrees) D∅f (N-ms/degrees) D∅r (N-ms/degrees) D∅m (N-ms/degrees) D∅ (N-ms/degrees) g(m/s2 ) Tf(m) Tr(m) Tm(m) Iwf(kg-m2) Iwm(kg-m2) Iwr(kg-m2) Ksf(N/m) Ksr(N/m) Kt(N/m) rd(m) Description Total mass of the vehicle Sprung mass of the vehicle Inertia yaw moment of sprung mass Inertia roll moment of sprung mass Yaw roll product of inertia of sprung mass Distance from front axle to CG Distance from rear axle to CG Distance from middle axle to CG Cornering stiffness of the front axle. Cornering stifnees of the rear axle Cornering stiffness of the middle axle Height of CG above the ground Front roll centre height Rear roll centre height Roll centre height of the vehicle Roll axis height Cornering stiffness of the front axle Cornering stiffness of the rear axle Cornering stiffness of the middle axle Total vehicle roll stiffness Damping coefficient of Front axle Damping coefficient of Rear axle Damping coefficient of middle axle Damping coefficient of entire vehicle Acceleration due to gravity Track width of front axle Track width of rear axle Track width of middle axle Front wheel moment of inertia Middle wheel moment of inertia Rear wheel moment of inertia Spring stiffness of the front axle Spring stiffness of the rear axle Stiffness of the tyre Unloaded tyre radius Values 14193 12487 34917 24201 4200 1830 2.520 1.220 10157.81 13665.9 11321.31 0.83 0.53 0.53 0.578 1.15 1000 1500 1500 4000 260 200 200 660 9.81 2.040 1.850 1.850 2.040 1.850 1.850 3,78,666 10,83,004 10,00,000 0.524 3.2.1. Two DOF vehicle model in Simulink The initial step in the modeling process is the building of 2 DOF model (slip and yaw). A step steering input and a constant forward velocity are given as inputs to attain lateral acceleration and yaw rate as outputs as displayed in figure4 . The equations employed for the modeling are given be m(v. +Ur)+(amf-bmr) r. +ms h r ∅.. = Fyf+Fyr (amf-bmr )(v. +Ur)+Izz r. +Ixz ∅.. =aFyf-bFyr+Mzf+Mzr Figure 4 Two DOF model in Simulink Volume 2, Issue 9, September 2013 Figure 5 Three DOF model in Simulink Page 210 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 9, September 2013 ISSN 2319 - 4847 3.2.2.Three DOF vehicle model in Simulink The roll is taken in to account along with the lateral acceleration and yaw rate of the vehicle. Therefore the step steering input and a constant forward are the inputs to the model . The lateral acceleration, the yaw rate and the roll rate are the out puts from the model as displayed in Figure5. A step input is taken in this paper in order to see the effect of roll on the vehicle. The equations employed as m(v.+Ur)+(amf-bmr )r. ms h r ∅.. (amf-bmr )(v.+Ur)+Izz r.+Ixz ∅.. Ixx ∅..+D∅ ∅..+(K∅-ms ghr )∅+ms h r (v..+Ur)+Ixz r . = Fyf+Fyr =aFyf-bFyr+Mzf+Mzr =df Fyf+dr Fyr 3.2.3.Designing of a PID control system The PID (Proportional, Integration, controller is the simplest one, which can be implemented with ease. This control system is extensively applied to many practical applications control system characteristics. A typical PID (or linear PID controller) can be explained as: U=kp (e+T1 ∫e+TD e. ) . Where e, ∫e and e denotes the error, its error integration, and its error derivative, respectively. kp Denote the proportional gain, T1 is the integral time constant, TD is the derivative time constant and U is the output of the controller 3.3.1.Trial and Error Tuning The trial and error approach is extensively employed mainly in the process industries. A skilled engineer can normally tune a loop of control swiftly depending on plant knowledge and a bit of trail and error.Tune the ‘P’ term initially (kp ) to a sensible transient response keeping the values of ‘kt’ and ‘kd’ to zero.Vary the ‘I’ term (ki ) for suitable steady state error keeping ‘(kd )’ =0.The value of ‘D’ term (kd ) can be varied if needed to elevate the transient response. This trial and error method is adopted in this paper in order to reduce the lateral velocity and yaw rate for the 2 DOF model.The values of kp,ki and kd used for the 2 dof model of slip and yaw are taken as kp=0.80 ; kt=0.001; kd =0.0013.2. 3.3.2.Two DOF vehicle model in Simulink with PID PID control system (in green) in Figure 6 is incorporated to reduce the lateral velocity and yaw rate by measuring the generated yaw rate and performing the Proportional, Integration, derivation and subtracts the generated outputs from the initial generated yaw rate and lateral velocity to minimize them.. Thus in this paper an attempt is made to reduce the lateral velocity of the heavy vehicle based on Active Yaw Control (AYC) system by taking the yaw output as input which reduced the model complexity. Figure 6 Two DOF model with PID Figure 7 Three DOF model with PID 3.3.3. Three DOF vehicle model in Simulink with PID Two PID control systems are incorporated in 3 DOF in Figure7 to reduce the lateral velocity, yaw rate and roll rate of the vehicle. The first PID control system uses the yaw rate as an input to regulate or mitigate the lateral velocity and yaw rate. The second PID control system uses the roll rate as an input to reduce the roll rate itself.The method of controlling used in the PID control system is the Trail and error. Volume 2, Issue 9, September 2013 Page 211 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 9, September 2013 ISSN 2319 - 4847 4.RESULTS AND DISCUSSION: 4.1. Results and discussion of Two & Three DOF Model without PID: Figure:8 describes the Step input with step time 5 sec, initial value 0 degrees, and final value 5 degrees, and sample time of 1 sec is given. The analysis is done for the given forward speed of 13,5 m/s; The output of the 2 DOF model are achieved by simulating the model for 10 seconds. Figure:9 describes the lateral velocity of the 2 DOF model start to vary at 5 sec in 10 seconds simulation for the given 5 degrees steering input and reaches a steady state value of 17 m/s at 5.5 sec and follows till 10 sec. Figure 10 shows the yaw rate of the 2 DOF model start to vary in the same manner as the lateral velocity for the given step steer and reaches a steady state value 6.5 deg/sec at 5.5 sec and follows the same till the 10 sec. Figure :11 shows the roll angle of the 3 DOF model start to vary at 4.8 sec to the given step steer of 5 degrees and reaches a steady state value of 0.5 deg at 5.5sec and follows till 10 sec or till the end of simulation. Figure 8 The graph shows the step steering input Figure 10 Variation of Yaw rate with respect to time for step steering input Figure 9 Variation of lateral vel with respect to time for step steering input Figure 11 Variation of roll angle with respect to time for step steering input 4.2. Comparison of Two DOF model with PID and Two & three DOF model with PID From the Figure12 it is learnt that variation of lateral velocity of the 2 DOF model with and without PID control system for the given step steer . The lateral velocity without PID control system (blue line) rised from 0 at 5 sec to 17 m/s at 5.5 sec and remains unvaried till the end of simulation of 10 sec for the given steer. The lateral velocity of with PID control system (green line) rises a maximum of 11.7 m/s at 5.7 sec and remains unvaried till the end of simulation. In comparison with the conventional the lateral velocity of the 2 DOF model with PID is reduced to 35% for the same step steer. From the Figure13 it is observed that variation of yaw rate of the 2 DOF model with and without PID in the same manner as the lateral velocity. The yaw rate of the model without PID varies from 0 at 5 sec and reaches a steady state of 5 deg/sec at 5.5 sec and remains unvaried till the end of simulation of 10 sec. The yaw rate of the model with PID control system reaches a steady state of 1deg/ sec at 5.7 sec and remains unvaried till end of simulation. The Figure14 shows the variation of roll of the 3 DOF model with PID and without PID control system for the given step steer. The roll of the model without PID control system varied from ‘0’ at 5 sec and reached to ‘0.55’ deg/sec at 5.5 sec. The roll of the model with PID control system varied from ‘0’ at ‘5’ sec and reached to ‘0.1’ deg/sec at 5.5 sec and remained unvaried till the end of simulation. Volume 2, Issue 9, September 2013 Page 212 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 9, September 2013 ISSN 2319 - 4847 Therefore from the results shown in figures (12), (13), (14) it is evident that with the implementation of PID control systems to the three DOF model the lateral velocity is reduced to 35% , yaw rate is reduced to 75% and roll rate is reduced to 80%. Figure 12 Lateral velocity with time to a step input with control system feedback Figure 13 Yaw rate with time to a step input feedback of control system with Figure 14 Variation of the roll rate with time to a step input with feedback of control system in three DOF 5. CONCLUSIONS: The two DOF and three DOF models built using truck data in Simulink made understand the variation of the lateral velocity, yaw rate and roll of the truck for the given inputs of step steer and forward velocity. With the incorporation of the PID (potential, integration, derivation) the lateral velocity, yaw rate and roll of the truck model are reduced significantly in order to improve the dynamics of the truck. in this the yaw rate and roll are reduced to greater extent than the lateral velocity as the control system is build based on active yaw control technology . REFERENCES [1] Hussain. (2005). Modelling Commercial Vehicle Handling and Rolling Stability. Proceedings of the Institution of Mechanical Engineers, Part K: Journal of Multi-body Dynamics (Volume 219, Number 4 / 2005), 1-13. [2] Díaz,M.B. (2007). Active roll control using reinforcement learning for a single unit heavy vehicle. 12th IFToMM World Congress, (pp. 1-6). Besançon (France). [3] Hirokazu Okuyama, F. M. (2006). Stability Augumentation System For The Heavy Duty Commercial Vehicles Estimation Of The Gravity Position With Ar Method And Application For Antirollover.Japan: Toyota Central R&D Labs, Inc.,http://www-nrd.nhtsa.dot.gov/pdf/nrd-01/Esv/esv16/98S4O06.PDF. [4] (2013, Sep 01). Retrieved from PID controller tunning a short tutorial: http://saba.kntu.ac.ir/eecd/pcl/download/PIDtutorial.pdf . Volume 2, Issue 9, September 2013 Page 213