International Journal of Application or Innovation in Engineering & Management... Web Site: www.ijaiem.org Email: , Volume 2, Issue 11, November 2013

advertisement

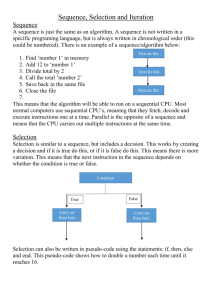

International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 11, November 2013 ISSN 2319 - 4847 Design and Development of Optimal Loop Water Distribution System Vinayak. V. Sadafule1, Rahul B. Hiremath2, S.B. Tuljapure3 1,2,3 Walchand Institute of Technology, Solapur Abstract With increasing population growth and industrial development, water flow rates and other hydraulic requirements associated with water distribution systems have been estimated to increase both national and local scale. Water shortage will cause inconvenience to people’s life and it will impact city function and industrial production. Hence to overcome this problem design and analysis of water distribution system is necessary to get optimal discharge. In this paper the optimization of water distribution network is discussed. An optimal model is developed which is based on the method of linear programming. In this model not only cost criteria of network but also energy consumption is to be considered. Computer program is developed in visual basic for looped water distribution network using Hardy-cross method to minimize the time required for analysis and to make tedious work to easier. Result shows that software results were more accurate, time saving than manual results. Keywords: Correction factor, Hardy-cross method, Hazen constant, Loop, Optimal, Visual basic, Water Distribution system. 1. Introduction In India demand for water is continuously increasing due to population growth, industrial development, and improvements of economic conditions. Water distribution systems generally consist of a number of sources of supply from which water is pumped to storage reservoirs to meet demands at consumer nodes through interconnected pipeline networks. In many water distribution systems, due to large amounts of energy are required to pump, transport and apply water, improved management of pumps leading to a reduction in energy usage and operational cost must therefore be regarded as a priority when more efficient network operation is sought.The municipal water industry is a very complicate task to keep municipal water distribution system in optimal operation. If we lack the rainfall for extended period of time, we will face problem of water shortage. On one hand it needs to produce safe drinkable water. On the other hand, it needs to provide excellent service to user. If you have a water shortage, it will cause inconvenience to people’s life and it will impact city function and industrial production. Design and analysis of pipe networks are important, not only because water is an important economical development parameter, but also because water is a deciding factor in the future of peace between states or between countries. 2. Literature Review The literature review is done, which exposed relevant research work carried out (till today) on various aspects of studies related to analysis of water distribution networks. A.Alperovits and U. Shamir presented first time a linear programming gradient method for optimizimg a water distribution network [1]. A. Kessler and U. Shamir used the linear programming gradient method in two stages: a LP problem is solved for a given flow distribution and a search is conducted in the space of flow variables [2]. A decomposition technique is suggested for optimal design of water supply networks. In this method the flow variables are solved in the first submodel for a fixed value of the head variables,using a minimum concave cost flow algorithm. The head variables are solved in the second submodel for a fixed value of the flow variable usng LP [3]. Ioan Sarbu developed an improved linear model which has the advantage of using not any cost criteria but also energy consumption. The model is based on the method of linear programming and allows the determination of an optimal distribution of commercial diameters for each pipe in the network and the length of the pipes which corresponds to these diameters [4]. U. Zessler and U. Shamir used Dynamic Programming for optimal operation of a water supply system[5]. A dynamic programming algorithm is utilized to establish the optimal number and size of pumping stations[6]. Emre Ertin, Anthony N.Dean, Mathew L.Moore and Kevin L.Priddy suggested Monte Carlo Version of the dynamic program for non-smooth discontinuous control regions [7]. Selami Demir, Kaan Yetilmezsoy and Neslihan Manav developed computer program in M S Excel to implement iterative, Hardy-Cross method for steady state and time-dependent analysis. The program was tested for an example water distribution system along with EPANET calculations. The modified Hardy-Cross method was proved to be an accurate tool for time-dependent simulation of water distribution networks [8]. Wheeler [9] developed a computer program that Volume 2, Issue 11, November 2013 Page 374 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 11, November 2013 ISSN 2319 - 4847 hydraulically simulates water distribution systems under steady-state conditions. The program employed standard HardyCross method. 3. Optimal Model Formulation Optimization of distribution network considers multicriterial objective function. Cost and Energy criteria may be used which considers network cost, pumping energy cost etc. Linear programming technique is applied to formulate the optimal model for distribution system Multicriterial Objective Function is K Minimize N C D Lij + ij ij =1 T C nt Ent ( 1 ) n = 1t = 1 The first objective of the optimal water distribution network is the least cost design of a water distribution network can be stated as follows. Network cost is obtained by adding the cost of each compound pipe. The objective cost function can be mathematically expressed as N Minimize C D ij L ij 2 ij =1 Where Cn – Unit cost associated with the pipe ij; Dij is the Diameter of pipe ij; Lij is the Length of pipe ij; N is the Number of pipes in the network. The second objective of the optimal water distribution network is to minimize the energy cost while satisfying the hydraulic requirements of the system. The objective cost function can be mathematically expressed as N Minimize T C nt Ent 3 n =1t=1 C nt = 9 .8 1 Q ij ( h i j + H ) 4 Where N represents the number of pumps ; T is the number of control Time Span ; Cnt is the unit energy cost of pump n at schedule time of t ; Ent is the energy consumption of pump n during the schedule time interval from t to t+1 with a pump control setting ; Qij is the pump discharge through pipe ij ; ƞ Efficiency of pump ; H is the Static Head ; h ij is the Head loss in the pipe ij. Computation of optimal design of distribution network must be performed in the following stages. 1. Establishment of optimal distribution for discharges through pipes Qij. 2. Computation of optimal pipes diameters Dij considering the optimized discharges. 4. Materials and Methods The Objective of this study is to develop software using VISUAL BASIC (VB) programming language based on the Hardy-Cross method of analysis of pipe network that can handle small and large distribution system to solve flow rates and head losses in pipes. 4.1 Flow rate problem employed To evaluate the software developed in this study, 2 loop [figure 1] pipe networks are adopted. Outflow at each node and assumed flow directions are drawn as illustrated in [figure 1]. Analysis of the pipe network is carried out manually and the results are compared with software solution. Figure 1: Two loop Network Volume 2, Issue 11, November 2013 Page 375 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 11, November 2013 ISSN 2319 - 4847 Table 1: Pipe Details Pipe Pipe Pipe Diameter Length Name ( mm ) (m ) AB 300 500 BC 200 300 DC 200 500 AD 300 300 BE 300 500 EF 200 300 CF 300 500 Table 2: Pipe Details Node A B C D E F Population 0 10000 20000 10000 20000 10000 4.2 Description of the software The simulation is controlled by user defined criteria. The user can define accuracy between correction factor (∆). The iterations are stopped when the correction factor (∆) difference for all loops is reduced to that user defined value. Screen 1: From this screen, user enters the Project Name, User Name and No. of pipes in loops. Select the Per capita water requirement (liter per capita daily) Screen 2: In this screen parent details of each node can be enter. It include 1. Node Population 2. Node Sources 3. After entering node population and node sources click on Find button 4. Then software calculates discharge at each node and assumed discharge through each pipe in lit/sec. Discharge = Population × Per capita × peak factor Peak factor is depending upon population. Screen 3: Loop Details Volume 2, Issue 11, November 2013 Page 376 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 11, November 2013 ISSN 2319 - 4847 In this screen enter loop details. It includes 1. Pipe name 2. Pipe length in meters and pipe diameters in meters. 3. Enter Hazan constant depends upon pipe materials. Here Hazan constant is considering as 100. Screen 4: Iterations 5. Results Table 3: Comparison of correction factor (∆) by manual and software Loop Name Iteration 1 loop ABCD loop BEFC Iteration 2 loop ABCD loop BEFC Iteration 3 loop ABCD loop BEFC Iteration 4 loop ABCD loop BEFC Iteration 5 loop ABCD loop BEFC Iteration 6 loop ABCD loop BEFC Iteration 7 loop ABCD loop BEFC Iteration 8 loop ABCD loop BEFC Iteration 9 loop ABCD loop BEFC Iteration 10 loop ABCD loop BEFC Volume 2, Issue 11, November 2013 Manual Result (∆) Software result (∆) -7.8819 0.2063 -7.52326871 0.20590218 0.527 0.2063 0.164419629 -3.77734428 -0.86836 0.2561 -0.82663587 0.07471806 0.05941 -0.43828 0.01818685 -0.41778154 -0.10245 0.02952 -0.054716 0.00900391 0.013928 -0.05254 0.00206491 -0.04792184 -0.01618 0.006988 -0.0109043 0.00104212 0.0010311 -0.0079348 0.00023744 -0.00551778 -0.0012523 -0.0042073 -0.00125606 0.00012011 -0.00084615 -0.001014 0.00002734 0.0006356 Page 377 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 11, November 2013 ISSN 2319 - 4847 Comment: Software results show correction factor accuracy at Iteration 9 whereas Manual results at Iteration 10. Software saves the time and gives more accurate values then manual method. 6. Conclusions 1. Optimization of water distribution network is a function of cost criteria of network and energy consumption for pumping which is depends upon the discharges and diameters of each. 2. Hardy-cross method is suitable for loop network to get optimal discharge value for optimum diameters of pipe. 3. Visual basic technique is economical and time saving for analysis of water distribution network compared with routine manual method. Acknowledgment The authors wish to thank Mr. Vijay Gaydhankar, Junior Engineer, Maharashtra Jeevan Pradhikarn, and Mr. Vishal Kulkarni for their consistent technical guidance and support throughout the project. References [1] A.Alperovits and U. Shamir, “Design of optimal water distribution systems”, Water Resource Res AGU 13(6):885900(1977). [2] A.Kessler and U. Shamir, “Analysis of linear programming gradient method for optimal design of water supply networks”, Water Resources Research, Vol. 25(7)(1989):1469-1480. [3] A.Kessler and U. Shamir (1991), “Decomposition technique for optimal design of water supply networks”, vol. 17. [4] Ioan Sarbu (2009), “Design of optimal water distribution systems”, International Journal of Energy, Issue 4,Vol.3. [5] U. Zessler and U. Shamir (1989)., “Optimal operation of water distribution systems”, Journal of Water Resources Planning and Management, Vol.115(6). [6] Q. W. Martin (1980), “Optimal design of water conveyance systems”, Journal of Hydraulics Division, ASCE, no. HY9. [7] Emre Ertin, Anthony N.Dean, Mathew L.Moore and Kevin L.Pridd (2010), “Dynamic Optimization for Optimal Control of Water Distribution Systems”. [8] Selami Demir, Kaan Yetilmezsoy and Neslihan Manav (2008), Development of a modified Hardy-Cross algorithm for time-dependent simulation of water distribution networks, Fresenius Environmental Bulletin [9] Wheeler, W. (1977), Hardy-cross distribution analysis. Water Sewage Works, 124,130–133 AUTHOR Dr. Rahul B. Hiremath received Master degree from BITS Pilani and Phd from IISC Banglore. Prof. S.B.Tuljapur received Master degree in Design Engineering. Now working as a Assistant Professor in Walchand Institute Of Technology, Solapur(India). Mr. Vinayak V. Sadafule pursuing Master degree in Design Engineering from Walchand Institute Of Technology , Solapur University (India). Volume 2, Issue 11, November 2013 Page 378