Hydrides and Dihydrogen as Ligands: Hydrogenation Catalysis

Hydrides and Dihydrogen as Ligands: Hydrogenation

Catalysis

Synthesis of Organometallic Complex Hydrides

• Reaction of MCO with OH , H , or CH

2

CHR

2

– M(CO) n

+ OH = M(CO) n-1

(COOH) = HM(CO) n-1

+ CO

2

–

M(CO) n

+ H = M(CO) n-1

(C(=O)H) - = HM(CO) n-1

+ CO

– M(CO) n

CH

2

CHR

2

= HM(CO) n-1

- + CH

• Protonation of MCO anion*

2

=CR

2

+ CO

– M(CO) n

+ H + = M(CO) n

H

• Hydrogenation of MCO dimer**:

– M

2

(CO)

2n

+ H

2

= M(CO)

• Oxidative addition of H n

H

2

to (typically) d 8 metal

– M(PR

3

)

3

X + H

2

= M(CO) n

X(H)

2

*

Oxidative addition of a proton. If a dianion, the resultant MCO hydride will be anionic and may react as a hydride transfer reagent.

** The resultant neutral hydride may have acidic characteristics (i.e., the hydrogen may be removed by a base (reductive deprotonation)

Properties of the M-H functionality

• Stereochemically active

• M-H distance range (3d transition metals): 1.5 -1.7 Ǻ

• M-H stretch: 2100 – 1600 cm -1

• M-H hydride resonance: typically upfield, -1 to -20 ppm, but little correlation with electron density

• M-H Bond Dissociation Energy: 60 -100 kcal/mol (Contrast M-C BDE of ca. 26-30 kcal/mol

• Homolytic cleavage can initiate radical chain reactions

• Acid/Base character: Varies. HCo(CO)

HFe(CO)

.

4

– is weak; Cp

2

W(H)

2

4

is strong acid, pK a

<1;

forms Lewis Base/Acid adduct with

AlMe

3

• Proton loss is slow as in carbon-based acids.

Acidity of MCO Hydrides

HM(CO) n

+ OH H

2

O + M(CO) n

-

HCo(CO)

4

HCo(CO)

3

PPh

3

HMn(CO)

5

HRe(CO)

5

H

2

Fe(CO)

4

CpCr(CO)

3

H

CpMo(CO)

3

H

CpW(CO)

3

H

K a

~2

1 × 10 -7

8 × 10 -8 very weak

3 × 10 -5 ; 1 × 10 -14

10 -13.3

10 -13.9

10 -16.1

The M-H Bond Functionality: Reactivity

H

M

No change in M oxidation state; reverse is β-elimination

M• + H•

Oxidation state of M reduced by 1; can yield H

2 or initiate radical rxns

MH

M + H +

Formal reduction of M oxidation state by 2; electron

Withdrawing ligands stabilize

M + + H -

M oxidation state is unchanged; electron donating ligands stabilize

Hydride Transfer Reactivity

HM(CO) n

+ RX XM(CO) n

+ RH

Rate = k

2

[HM ][RX]

Organometallics , 1984 , 3 , 646

Suppose one protonates the anionic metal hydride of HW(CO)

5

-

. Is it possible that the resultant H

2

would remain bound to the metal?

Heinekey, JACS, 2005, 850-851;

Heinekey, JACS, 2006, 2615-2620

The

2 -Dihydrogen as Ligand Story

Kubas, JACS , 1984 , 10 , 451.

The η 2 -H

2

Complexes

- Typically d 6 , Oh structures of Cr 0 , Mo 0 , W 0 , Fe II , Ru II , Ir III .

Kubas, LANL

- Bonding: Delicate Balance Required for Stability

H

M

H

H

M

H

M

H

H

Morris, U. Toronto

- donor * acceptor M

2+

(H

-

)

2

- Examples of

2

-H

2

complexes

++

R

3

P

O

C

H H

C

O

W 0

PR

3

C

O

Kubas

P

P

H H

Fe II

C

N

H

Morris

P

P

Ph

3

P

H H

Ir III

N

C

+

Crabtree, Yale

H

PPh

3

Crabtree

Every Molecule Has a Story: The 2 -H

2

Complexes

R

3

P

O

C

H H

C

O

W

PR

3

C

O

R

3

P

O

C

H

W

H

C

O

PR

3

C

O

- stability towards H

2

dissociation

- oxidative addition to dihydride

Kubas, LANL

P

P

H H

Fe

C

N

H

P

P

+ H + - H +

H

P P

Fe

P P

C

N

H

- strong acid

- CNH ligand

+

Morris, U. Toronto

+ +

R

3

P

N

H H

Ir

H

PR

3

C

+

R

3

P

N

H H

Ir

H

PR

3

C

+

- resonance forms

- H/D exchange

Crabtree, Yale

H

2

Ir III

Vaska’s Complex and Its Oxidative Addition Reactions

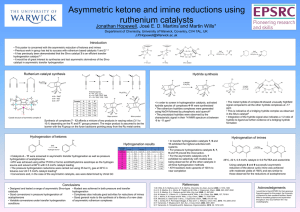

Catalysis

© 2009 W.H. Freeman

Catalyst Development

Catalyst Development

Inorganic Chemistry Chapter 1: Figure 26.16

Schematic representation of physisorption and chemisorption of Hydrogen

on a nickel metal surface

Schematic representation of

Diverse sites exposed on a

Metal surface — a) different

Exposed planes, edges; b) steps,

And kinks from irregularities

© 2009 W.H. Freeman

Hydrogenation of alkenes on supported metal

Involves H

2

dissociation and migration of H-atoms

to an adsorbed ethene molecule. (Paul Sabatier, 1890)

Mechanism: All isotopomers are seen, therefore highly

Reversible prior to loss of the ethane.

Volcano diagrams relate stability of products on

Surface: Temp. for a set rate of release vs. the

Enthalpy. Intermediate values of ΔH f

, with the rate being a combination of the rate of adsorption and the rate of desorption gives best catalyst.

Just right

Surface adducts

Very strong

Surface adducts

Very weak

Surface adducts

The Goldilocks Effect

© 2009 W.H. Freeman

A Prominent Example of Heterogeneous http://www.greener-

Hydrogenation Catalysis: Ammonia Synthesis

CH

4

+ H

2

O 3 H

2

+ CO

CO + H

2

O H

2

+ CO

2

CO/H

2

500 x 106 tons/year; Known as “population detonator” http://www.greenerindustry.org.uk/pages/ammonia/6AmmoniaPMHab er.htm

http://www.greenerindustry.org.uk/pages/ammonia/6AmmoniaPMHab er.htm

Conditions

According to the equation, the equilibrium mixture will contain more ammonia:

• When the temperature is lower (the reaction is exothermic in the ammonia direction)

• When pressure is higher (4 moles of reactant gas make 2 moles of product gas)

In practice, the equilibrium is run under conditions of moderate temperatures and pressure.

Low temperatures affect the equilibrium favorably, but the reaction would be too slow. Very high pressures, though favoring product creation, increase the costs of plant construction, and present a greater risk to plant workers.

With the conditions used, a yield of approximately 20 - 30 % is achieved from each pass over the catalyst. http://www.greenerindustry.org.uk/pages/ammonia/6AmmoniaPMHab er.htm

Some homogeneous catalytic processes

(Adapted from J. Halpern, Inorg. Chim. Acta 1981, 50 , 11)

Hydrogenation of Alkenes: Wilkinson’s catalyst and

(one of several versions of) the mechanism

Hydrosilation of Terminal Alkenes

Mechanism :

H

2 activation prior to olefin addition

Mechanism :

Olefins add first to cationic catalyst

Wilkinson ’ s Catalyst: Mechanism for Olefin Hydrogenation

Pre-catalyst

With the Rh(I) cationic precursor:

Olefin adds prior to H

2

oxidative addition.*

* This mechanistic route followed by asymmetric Hydrogenation process

Halpern, Science , 1982

Halpern

( Science , 1982 , p. 401)

Halpern

( Science , 1982 , p. 401)

from Collman, Stanford

Wacker process: Oxidation of olefins

Inorganic Chemistry Chapter 1: Figure 26.2

Olefin Isomerization

© 2009 W.H. Freeman

from Collman, Stanford