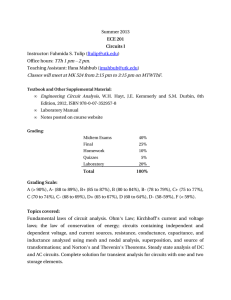

ADVANCE YOUR MANUFACTURING CAREER

advertisement

ADVANCE YOUR M A N U FA C T U R I N G C A R E E R Two new Industrial Technology certificates for those working in manufacturing. Learn the latest technologies including PLCs, Networking, Touch Screens and Robotics when you attend class one day per week. TWO CERTIFICATES TO ADVANCE YOUR CAREER LTC is now offering two new Industrial Technology certificates to help you advance in a manufacturing environment. These 9-month certificates build on your knowledge of electricity, industrial controls and basic computer usage to give you the latest automation knowledge and skills. Industrial Technician Basic-Industry Automation Certificate #19-620-3 Specifically designed for those already working in a manufacturing environment who wish to gain new skills and pursue employment in the maintenance field. We build on your general industry knowledge of electro-mechanical systems to give you the latest in electrical and mechanical skills. SCHEDULE September 2, 2015 – May, 18 2016 Wednesdays • 8 am – 4:30 pm No classes 12/23, 12/30 and 3/23 Fluid Power 1 OTHER BENEFITS • Apply 15 credits to an ElectroMechanical associate degree • Defer tuition with small down payment until you’re reimbursed by your employer Prepares the learner to identify hydraulic and pneumatic component symbols; adjust a pressure relief valve; analyze the operation of a pilot operated relief valve; analyze Pascal’s law; evaluate flow, velocity, work and power in industrial hydraulic and pneumatic circuits; analyze meter-in, meter-out, and bypass flow control circuits; identify basic hydraulic and pneumatic control valves; and assemble hydraulic circuits. Basic Tools and Measurement Prepares the learner to use hand tools, precision measuring instruments, and torque tools. Industrial Controls Introduction Prepares the learner to follow safety procedures; maintain a safe and healthy work environment; construct electrical circuits; measure electrical quantities using a VOM and/or DVM; analyze measured values using electrical circuit laws; construct typical industrial control circuits; and analyze typical industrial control circuits. DC Fundamentals Prepares the student to convert values to scientific and engineering notations; calculate math quantities; describe basic atomic theory; identify basic electrical terms; use established symbols standards; describe DC voltage characteristics and current sources and electrical resistance; measure and analyze electrical quantities in series and parallel circuits; and desolder/ solder single lead components. Fluid Power 2 TO APPLY • Apply online at gotoltc.edu or contact Jami Kapral at 920.693.1159 for assistance. Enhances the learner’s ability to read schematics containing fluid power component symbols; assemble systems using schematics; analyze system’s operation using a schematic; evaluate the general characteristics and terms of fluids under pressure, fluid conditioning, conductors, reservoirs, accumulators, pressure control; and troubleshoot malfunctioning pressurized systems. Industrial Controls and Motors Prepares the learner to select control devices by function and operation; illustrate electrical circuits using symbols, diagrams, and abbreviations; explain the operation of magnetic solenoids and apply motor control techniques and introduces the student to three-phase power motor circuits for industrial applications. AC Fundamentals Prepares the student to analyze electrical circuits using AC math, analyze AC waveforms, measure and analyze AC power, analyze capacitors and inductors in DC and AC circuits, analyze AC circuits containing reactance and calculate resonance, apply the elements and properties of basic measuring circuits, and describe transformer characteristics. These certificates are offered as part of our new WorkForce1 training schedule which offers consecutive courses in a one-day-a-week schedule. WORKFORCE 1 ONE DAY A WEEK TO ADVANCE YOUR CAREER 1 DAY A WEEK EXPERIENCED INSTRUCTORS HIGH-TECH LABS & CLASSROOMS Industrial Technician-Industry Automation Certificate #19-620-2 This certificate is specifically designed for those already working in a maintenance environment, or who are experienced in production work and who need to gain skill in the foundations of automation. This certificate is perfect for industrial apprentices or Journeyworkers who would like to learn robotic automation while working full time. SCHEDULE September 2, 2015 – May, 18 2016 Wednesdays • 8 am – 4:30 pm No classes 12/23, 12/30 and 3/23 OTHER BENEFITS • Apply 13 credits to an ElectroMechanical associate degree • Defer tuition with small down payment until you’re reimbursed by your employer Programmable Controllers - Allen Bradley Prepares the student to understand basic PLC structure and terminology; learn to create and troubleshoot basic PLC programs using the RSLOGIX 500 software and the RSLINX communication software; become familiar with communicating with programming SLC-500 and Micrologix PLCs. This course is highly computer based. Programmable Controllers Allen Bradley Advanced Prepares the student to develop applications utilizing subroutine instructions, analog modules; gain a basic understanding of creating and troubleshooting programs using the ControlLogix, RSLOGIX5000 software. This course is highly computer based. Robotics Introduction Introduces the student to robotic axes, movement control, navigating the teach pendant, robotic frames, basic programming commands such as conditional branching, wait and call instructions. Industrial Networks Prepares the learner to configure, install and troubleshoot device-level, control-level and enterprise-level industrial communication networks. This course is highly computer based. TO APPLY • Apply online at gotoltc.edu or contact Jami Kapral at 920.693.1159 for assistance. Robotics Advanced Introduces students to advanced robot programming commands to include use of Fanuc vision on the Fanuc Robots. Touch Screen Applications Prepares the student to create, edit, and troubleshoot screens, objects and I/O related to the RSView32, FactoryTalkME and Wonderware software applications. Students will create, edit and communicate with Allen-Bradley PLC programs for real-time control utilizing the touchscreen applications. This course is highly computer based. DOES YOUR EMPLOYER OFFER AN EMPLOYEE TUITION REIMBURSEMENT PLAN? Ask how you can defer your LTC tuition with a small down payment until you’re reimbursed by your employer. LAKESHORE TECHNICAL COLLEGE gotoltc.edu/PublicSafetyTrainingCenter 1.888.GO TO LTC 1290 North Avenue • Cleveland WI NCA-Accredited ncahlc.org THIS PROGRAM MADE POSSIBLE THROUGH A WISCONSIN FORWAR GRANT