Enclosure 4A - Project Summary Form (541) 737-3437

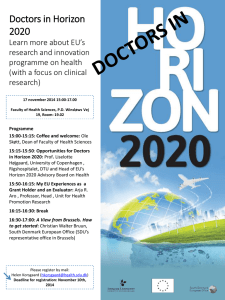

advertisement

Enclosure 4A - Project Summary Form NATIONAL FIRE PLAN COMMUNITY ASSISTANCE AND WILDLAND URBAN INTERFACE PROJECTS Application for Fuels Utilization and Marketing Projects Applicant Applicant/Organization: Oregon State University c/o Peggy S. Lowry, Director of Sponsored Programs Phone: FAX: Email: (541) 737-3437 (541) 737-3093 Sponsored.programs@orst.edu Address (Street or P. O. Box, City, State, Zip): Research Office, Oregon State University, 312 Kerr Administration Bldg, Corvallis, OR 97331-2140 Project Coordinators Project Coordinator (Name and Title): James W. Funck, Associate Professor; C.C. Brunner, Assoc. Prof.; J.B. Forrer, Faculty Res. Assoc. Organization/Jurisdiction: Department of Wood Science and Engineering, Oregon State Univ., Corvallis, OR 97331-5751 Phone: FAX: Email: (541) 737-4207 (541) 737-3385 Jim.Funck@orst.edu Project Information Project Title: The influence of processing parameters on lumber and cut-stock recovery from small-diameter timber Proposed Project Start Date: 9/30/2003 Proposed Project End Date: 12/31/2004 Federal Funding Request: $112,365 Total Project Funding: $134,146 Are you submitting multiple projects? If so, please explain and prioritize: No Brief Project Description: Past forest management practices in the western United States have resulted in significant acreages containing dense stands of small-diameter and underutilized (SDU) timber. When producing traditional lumber products, much of this material has insufficient value to offset harvesting costs, which limits economical stand management. While a variety of products have been suggested as potential uses for SDU material, the reality is that sawmills and cut-stock operations are the main industries in many of the areas containing SDU material. Therefore, to be used in sufficient quantities, techniques need to be developed to make the use of this material more economically viable for the lumber and cut-stock industries. SDU stem size and form provide logs with very small scale volumes and little opportunity to produce traditional dimension or shop lumber. Therefore, it must be shown that the true value of the logs is based on higher-value secondary products, such as cut-stock parts. This project will analyze various processing parameters and strategies to determine the optimum stem bucking, log breakdown, and board edging strategies to produce the optimum log value by maximizing cut-stock part and by-product recoveries. When combined with previous research, sawmills and cut-stock manufacturers will have a clearer picture of the feasibility of utilizing SDU material. If feasibility is shown, increased bidding for stand management operations will lead to improved forest health and fuel reduction. If not, subsidy levels required will be identified. Project Location (latitude/longitude if applicable): County: Congressional District: Oregon State University Benton Five If the applicant is an unincorporated area, define the geographic area being represented: Enclosure 4B (Page 1 of 3) - Project Narrative Description Applications for funding must include a narrative response that describes the proposal. Please do not submit responses longer than one page, single space, 12-pitch font. Describe project including, but not limited to: project location Address these project implementation items as anticipated outcomes applicable: measures and reporting interagency partners project relationship to community or natural landscape fire plans. project time frames and income specify types of activities and equipment used amount or extent of actions (acres, number of homes, etc) environmental, cultural and historical resource requirements Response: The goal of this project is to evaluate processing and end-product parameters to demonstrate the potential for increasing the value of small-diameter and underutilized (SDU) timber from over-stocked stands for use as a raw material source for the primary and secondary wood products manufacturing industry as a means to offset harvesting costs which limit economical stand management. The specific objectives are to: (1) digitally reconstruct full tree stems from full external shape and internal features digital representations of logs obtained in a previous study, (2) simulate the bucking of those stems into all possible length combinations, (3) process the bucked logs through SAW3D, a log breakdown model, to determine the resulting lumber value, (4) develop suggested bucking strategies, (5) use the SAW3D results to quantify the cut-stock yields from SDU trees for three different edging strategies ranging from edging to meet Shop-grade wane rules to edging only for the minimum length of a fingerjoint block, (6) perform an analysis that accounts for differences in the revenue or cost associated with cut-stock recovery, sawmill residue, roughmill residue, drying, trucking, and handling, and (7) present the analyses to lumber and cut-stock producers for use in investment decisions and land managers for use in planning. This project will build on data and analyses performed in an earlier project funded by the USDA (Punches, J., J.W. Funck, C.C. Brunner, S. Willits, R. Ross and T. Black. Evaluation of small-diameter timber for value-added manufacturing. USDA CSREES Fund for Rural America Program. 10/97 - 2/2002). In that project, the concept of providing new ways for viewing the value of small-diameter timber value was investigated with SAW3D by looking at cut-stock value rather than initial lumber value. The digital log representations will come from that project. However, that project did not fund the reconstruction of the whole stem or an analysis of the influence of edging decisions on the resulting cut-stock value. In that project, 48 Douglas-fir (Pseudotsuga menziesii) and ponderosa pine (Pinus ponderosa) trees were selected, measured, felled, bucked, live-sawn, and optically scanned. The resulting digital images were reconstructed into 127 logs. The technique allowed knowledge of internal features and external shapes to be used when sawing alternatives were investigated. Results from that study clearly illustrated the highly significant influence of stem form on both lumber and cut-stock parts recovery, thus pointing to the need for this proposed project. Therefore, each log will be digitally adjusted to match its corresponding sections, thus regenerating the original 48 stems. Once the stems are reconstructed, a program will be written to buck them into all possible combinations of feasible sizes. The resulting logs will contain the correct external shape and internal defect information. The digital logs will be run through SAW3D, a log breakdown model, which will predict traditional lumber yields and product grade values using the internal defect information. In addition, program CORY, a cut-stock optimization model, will be used to determine cut-stock parts recovery from the traditional lumber, as well as material produced under three different edging strategies. After analysis of the results of the various runs, specific recommendations will be made regarding appropriate bucking, breakdown, and edging strategies. When combined with previous research, sawmills and cut-stock manufacturers will have a clearer picture of the feasibility of utilizing SDU material. If feasibility is shown, increased bidding for stand management operations will lead to improved forest health and fuel reduction. If not, subsidy levels required will be identified. This information will be provided to the partners in the original project (USDA Forest Service, Rogue River National Forest, Applegate Ranger District) and presented at appropriate SDU and forest health conferences and workshops. Enclosure 4B (Page 2 of 3) - Project Evaluation Criteria Applications for funding must include narrative responses that address the following four criteria. Within each criterion, subcriteria are listed in descending order of importance. Limit your responses to the areas provided. 1. Increasing Local Capacity (35 Points) A. How would the proposal improve or lead to the improvement of the local economy in terms of jobs and sustainable economic activity? How many jobs are expected to be created or retained and for how long (please distinguish between essentially year-round and seasonal jobs)? How will this proposal link to other projects (or proposed projects) to create year-round jobs? B. Will biomass or forest fuels be utilized; if so, in what manner and how much? C. Which, if any, private businesses will participate? D. To what extent will this project be offered to serve as a model for other communities or businesses, or natural landscapes? Response: Producing traditional lumber products from SDU material produces insufficient value to offset harvesting costs, limiting the economic resources for stand management. LeVan-Green and Livingston (2001) have estimated that thinning costs alone range from $150 to $550 per acre. Many uses for SDU material have been proposed, but in reality saw-milling and cut-stock operations are the primary industries in areas with this material meaning new techniques must be developed to make its use more economically viable. However, researchers such as Barbour (1999) and Wagner et al., (2000) have shown that mill production decreases when processing small-diameter material. This study did not look at the true shape or internal defect characteristics of SDU material, but LeVan-Green and Livingston (2001) indicate that much of this material actually contains small knots and tight grain suggesting that this material might to be economically utilized by sawmills. However, recovery from SDU material is significantly affected by stem form, which has not been adequately studied. Cut stock is one of the highest valued products produced from Western softwood species, however because of cutting-width requirements and wane allowances, it is difficult for smalldiameter logs to produce shop grade lumber. Earlier research has shown small-diameter trees can produce significant amounts of cut-stock yields and that edging boards less severely produces greater amounts of cutstock also. This suggests that ignoring conventional grading rules and producing slightly edged flitches may increase cut-stock material yields. This study should demonstrate the feasibility of using SDU material to small-log sawmill and cut-stock operators throughout the western United States and result in increased bid prices for timber sales that leads to improved forest health and fuel reduction. 2. Reducing fire risk. (30 points) Describe how the proposal promotes reduction of risk in high hazard areas and communities or natural landscapes. Describe how the proposed project benefits resources on federal land or adjacent non-federal land, or how it protects the safety of communities. C. To what extent does the project implement or create a cooperative (1) fuels treatment plan or (2)community fire strategy (include evidence of the plan if it already exists)? D. Explain how the proposal (1) leads to, enhances or restores a local fire-adapted ecosystem, and/or (2) mitigates or leads to the mitigation of hazardous fuels conditions. A. B. Response: Many softwood forests in the Western United States have exceedingly high levels of hazardous fuel which create the danger of catastrophic fires. In the past year alone, hundreds of thousands of acres of ponderosa pine and Douglas-fir forests have been destroyed by such fires. The major cause for high fuel levels is the suppression of wild fires over the last century. This has gradually transformed many of our forests into timberlands densely stocked with small-diameter trees stunted by severe competition for water and nutrients. Such trees would normally be eradicated by low intensity fires before they grow enough in number and size to fuel large fires capable of destroying a forest’s large mature trees. Removing these smaller trees would solve this problem, but harvesting or thinning is expensive. Therefore, the major impediment to any effective fuels treatment plan is cost. If these trees can be shown to produce high-value products, harvesting costs could be recovered, or at least partially offset. At the same time, the raw material would provide employment in communities close to the resource and needed products to society. Quantifying these yields and presenting it in a useful format may persuade lumber and cut-stock producers to consider using this resource as a raw material for their operations. Enclosure 4B (Page 3 of 3) - Project Evaluation Criteria 3. Expanding Community Participation. (15 Points) A. To what extent have interested individuals, groups, and communities been provided an opportunity to become informed and involved in this proposal? B. Describe the extent of local support or opposition for the project, including any cost-sharing arrangements C. What are the environmental, social and educational benefits or concerns of the project? Response: This proposal is an outgrowth of the findings of a previous study concerning SDU material. That project was funded by the USDA (Punches, J., J.W. Funck, C.C. Brunner, S. Willits, R. Ross and T. Black. Evaluation of small-diameter timber for value-added manufacturing. USDA CSREES Fund for Rural America Program. 10/97 - 2/2002) and included a consortium of groups (OSU, USDA Forest Service PNW Station, USDA Forest Service FPL, USDA Forest Service Applegate Ranger District, and Applegate Community Development and Partnership). The State of Oregon will be supporting this project through the OSU College of Forestry and its cost-sharing by providing the services of two of the co-principal investigators (the other Co-PI is in a soft-money position funded solely by grants). All information obtained in this proposed project will be included with findings of the previous project and disseminated in the same fashion. Information found in this study will be of use to small-log sawmills and cut-stock operations throughout the western United States, which are the largest industries in the areas containing this type of SDU material. Also, as previously mentioned, if the use of SDU material is shown to be economically feasible, increased bidding will lead to improved forest health and fuel reduction. Even if harvesting and processing costs can not be completely recovered, the partial offset will be identified so that land managers will understand the subsidy requirements associated with stand management activities. 4. Increasing interagency and intergovernmental coordination. (20 Points) A. Explain the level of cooperation, coordination or strategic planning through a “Local Coordination Group” for wildland fire activities, or among federal, state, tribal, local government and community organizations in developing this proposal. List the cooperators (a detailed list of cooperators will be required for projects that are funded). B. Describe how this project implements a local intergovernmental strategy or plan, or creates such a plan. Describe the plan if it already exists. Response: It is clear that in the development of a strategy or plan, any stand management activities designed to reduce the fuel load and improve forest health will not be cost effective under current timber valuation practices. Stem size and form provide logs with very small scale volumes and little opportunity to produce traditional dimension or shop lumber. Therefore, it must be shown that the true value of the logs is based on highervalue secondary products, such as cut-stock parts. As an example, for one of the logs that was 16 feet (4.9m) long with a 5.7 inches (14.5 cm) large-end diameter, the value of the log as traditional lumber products and chips when optimized for exterior shape only was $2.88, the value when optimized for cut-stock parts from that lumber and chips was $5.35, while the value when optimized for cut-stock parts but leaving the flitches unedged and ungraded was $6.47. However, log valuation under this concept will require log sellers, buyers, and producers to accept a new paradigm, because current practices and procedures will need to be changed. Upon doing so, these concepts can be incorporated in planning activities. Enclosure 4C - Project Work Form Tasks Time Frame Responsible Party 1. Develop software to reconstruct logs into stems 9/1/2003 – 3/31/2004 Forrer and Funck 2. Develop software to buck stems into all possible combinations of log lengths 4/1/2004 – 6/30/2004 Forrer and Funck 3. Modify SAW3D to simulate different edging strategies 9/1/2003 – 6/30/2004 Forrer, Funck, and Brunner 4. Run all possible log combinations through SAW3D to produce log values based on traditional lumber products and by-products 7/1/2004 – 7/31/2004 Funck and Forrer 5. Run all SAW3D results through different edging strategies in preparation of CORY runs 7/1/2004 – 7/31/2004 Funck and Forrer 6. Run all SAW3D results through CORY to determine cut-stock parts values and by-products 8/1/2004 – 8/31/2004 Brunner and Forrer 7. Prepare final report 9/1/2004 – 12/31/2004 Funck, Brunner, and Forrer 8. Prepare articles for publication and disseminate findings 9/1/2004 – 12/31/2004 Funck, Brunner, and Forrer Enclosure 4D - Project Budget Cost Category Description Federal Agency Applicant Partner 1 Partner 2 Total Personnel $49,508 $11,281 $60,789 Subtotal $49,508 $11,281 $60,789 Fringe Benefits $20,552 $4,112 $24,664 Subtotal $20.552 $4,112 $24,664 Travel $3,000 Subtotal $3,000 $0 $3,000 Subtotal $0 $0 $0 Supplies $3,350 Subtotal $3,350 $0 $3,350 $0 $0 $0 Other Publications Indirect costs (41.5%) Subtotal $3,000 $32,955 $35,955 $6,388 $6,388 $3,000 $39,343 $42,343 Total Costs $112,365 $21,781 $134,146 $3,000 Equipment $3,350 Contractual Subtotal Project (Program) Income1 1 Program income is the gross revenue generated by a grant or cooperative agreement supported activity during the life of the grant. Program income can be made by recipients from fees charged for conference or workshop attendance, from rental fees earned from renting out real property or equipment acquired with grant or cooperative agreement funds, or from the sale of commodities or items developed under the grant or cooperative agreement. The use of Program Income during the project period may require prior approval by the granting agency.