AGRICULTURAL ECONOMICS RESEARCH UNIT

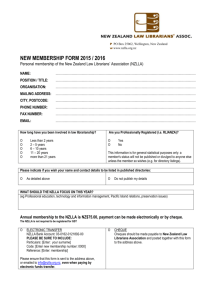

advertisement