Separation of Colloidal Particles from Groundwater by Cross-Flow

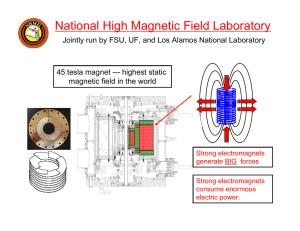

advertisement