FINAL REPORT Separation of Colloidal Particles from Groundwater by Cross-

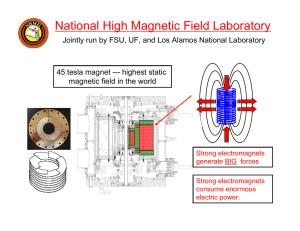

advertisement